Potash Works Union of Salzmünde

| Potash Works Union of Salzmünde | |||

|---|---|---|---|

| General information about the mine | |||

| other names | Salzmünde shaft | ||

| Mining technology | At the beginning painted chamber construction with offset; later roof chamber construction with offset | ||

| Information about the mining company | |||

| Operating company | Salzmünde Union | ||

| Employees | up to 250 | ||

| Start of operation | 1906 | ||

| End of operation | 1924 | ||

| Successor use | Reserve mine | ||

| Funded raw materials | |||

| Degradation of | Carnallitite and small amounts of hard salt | ||

| Geographical location | |||

| Coordinates | 51 ° 30 '6 " N , 11 ° 47' 45" E | ||

|

|||

| Location | Zappendorf | ||

| local community | Salzatal | ||

| country | State of Saxony-Anhalt | ||

| Country | Germany | ||

| District | Halle's potash district | ||

The mine of the Salzmünde Potash Works Union is located on the southwestern edge of the Zappendorf village in the Saale district . Various potash salts were mined in the mine from 1908 to 1924 . The mine since 1925 level of 868 m sole durchschlägig the southern of their pit box of potash Teutschenthal (formerly potash Kruger Hall AG ) and this in turn with the east adjoining pit box Angersdorf earlier ( potash union Saale and Halle Kaliwerke A.- G. ) connected. After the potash production in the Salzmünde shaft was stopped on July 1, 1924, z. B. the shaft tube as an escape and weather shaft for the Krügershall / Teutschenthal mine field for decades .

Search and exploration work

instigation

The beginnings of the mining of potash salts for the production of fertilizer for agriculture and other chemical products stood in Staßfurt . In 1839, the Staßfurt Saline began to sink a deep borehole , which was to serve as a borehole for the extraction of a richer brine for boiling. The well was stopped after twelve years of drilling in 1851 at a depth of 581 m in rock salt . But the “bitter-tasting” brine taken from this borehole contained, to the general disappointment, a large amount of undesirable additions (including potassium chloride ). One had the choice either to abandon the borehole or to use it as a pilot hole for a shaft through which the required pure rock salt for brine enrichment could be extracted separately. It was subsequently decided to sink two shafts lying close together (Teufbeginn shaft “von der Heydt” on December 4, 1851; Teufbeginn shaft “von Manteuffel” on February 9, 1852). The mining of rock salt began in 1857. At the end of 1858, a cross passage cut through the potash store, but had to be closed due to an inflow of lye . It was not until March 1860 that this exploration work could be successfully continued.

The now proven by various chemists industrial separation of the information contained in these potassium salts potassium , its effectiveness for plant growth already Justus von Liebig realized in 1840, and the process technology development of a building on potash fertilizer production by Adolph Frank in 1861 formed the starting point of a nearly euphoric search and exploration of further potassium salt deposits.

Starting from the so-called Staßfurter Berggeschrey , a lively search and exploration activity began in the Halle - Salzmünde - Teutschenthal area.

Bores and mutations

Based on the knowledge of the various brine springs in the near and far as well as the Zechstein outcrops through boreholes and copper shale shafts, Anton Raky's International Drilling Company in Erkelenz was pretty sure that it would also come across the coveted potash deposits here in the Teutschenthal - Salzmünder area .

With the wells Teutschenthal I (potash salt from 634.7–690.0 m), Langenbogen I (potash salt from 721.4–765.9 m), Langenbogen II (rock salt from 589.0 m), Langenbogen III ( Rock salt from 572.9 m) and Bennstedt I (potash salt from 950.5–1007.5 m) were found potash and rock salt. The drilling company then put suspicions on the finds in the Teutschenthal I and Langenbogen I and II boreholes and applied for the right to mine the rock salt and the breaking salts. Assumptions were made on the finds in the Langenbogen III and Bennstedt I boreholes , but the fields were not stretched, so that if the suspicions were submitted again in good time, the remaining parts of the entire field that had not yet been awarded were protected against third parties. In this way, the international drilling company had an area of interest of 10 Prussian normal fields . By assignment agreement of March 27, 1905, the bankers Friedrich H. Krüger from Halberstadt and Siegfried Weinstock from Halle / S acquired the rights to the speculations put in by the international drilling company and to the entire area of interest. This right became the subject of the Kaliwerk Krügershall Aktiengesellschaft , which was founded on March 29, 1905 .

It was not until almost a year later, on January 15, 1906, that the Salzmünde trade union was founded on the basis of 5 Prussian normal fields, ceded by the 10 potash fields of the Krügershall A.-G. potash works.

Drilling in the Salzmünde area

Several deep boreholes were also drilled in the vicinity of the later Salzmünde mine. The Salzmünde I, IV and V wells were sunk to rock salt purely for mutation purposes. The Langenbogen deep well opened up a 46.8 m thick potash deposit from a depth of 719.1 m.

The deep borehole Salzmünde II drilled from 71 m to 356 m of red sandstone with gypsum deposits from 356 m to 421 m of colored clay with gypsum deposits, then, after a 3 m thick roe stone bank from 424 m to 605 m of colored clay with plaster and sandstone banks , from 605 m to 629.50 m of blue anhydrite , followed by a 5.50 m thick hard salt deposit with a potassium chloride content of up to 50.5% under a layer of 7.20 m thick salt clay, including 642.20 m to 705.0 m of rock salt, which at 660 m was interspersed with a narrow layer of salt clay.

The geological and hydrogeological reservoir conditions

The Salzmünde mine is located in the area of the Salzmünder Saddle , a relatively narrow, dome-shaped salt vault . Another dome is the Salzke broad saddle adjoining it in the south , which is accompanied in the south and north by the so-called Salzke depressions (strong depressions in the saline deposits). This Salzke broad saddle crossed a connecting route from the Salzmünde mine field to the Krügershall mine field south of it (the current mine field of the Teutschenthal backfill mine). The salt domes mentioned were created as a result of the injection of salt into the area of the Hornburg Deep Fault . This disturbance and the saddles and domes connected with it separate the larger western Mansfeld Mulde from a smaller special trough to the east, the Bennstedt - Nietlebener Mulde. As a result of this regional geological position, there are relatively complicated tectonic conditions in the area of the Salzmünde mine .

The Salzke broad saddle strikes in a south-southwest-north-northeast direction. At its periphery , further large folds of the saline structures were detected by underground and surface drilling . Increasing tectonic influences can only be expected in a south-easterly direction. Here the transition to the essentially undisturbed deposit of the Teutschenthal mine takes place on the northwest flank of the Teutschenthaler saddle. The lively small tectonics encountered here within the salinar was expressed in slight folds and tears.

In the area of the Salzmünde shaft , the most recent deposits are those of the Quaternary ( ground moraines , interglacial gravel, loess and alluvial soil formations). The next older layers up to the Lower Muschelkalk have been removed again in the course of the earth's history , so that only the lying layers of the Upper Buntsandstein and, following them, the middle and Lower Buntsandstein are represented. Apart from local disturbances and the associated fluctuations in thickness in the saline, the salt sequence corresponds to the Staßfurt normal profile. The rock salt of the Leine series of the Zechstein was particularly badly deformed . Usually it is only present in a reduced thickness and is folded like a spur into the main anhydrite and interlocked with it.

The Salinarfolge "Hauptanhydrit-Gray salt clay-Deckanhydrit" characterized by numerous fractures from. In the main anhydrite of the Leine series (Zechstein 3), these fissures reach thicknesses of up to a few centimeters and in the gray salt clay even up to 40 cm. These fissures are healed with deposits of rock salt, sylvine or carnallite . Noteworthy are the smaller oil leakage points in the main anhydrite, which indicate an increased bitumen flow in this horizon. The potash deposit is up to 40 m thick and consists almost exclusively of a strongly mylonitized kieseritic carnallite halite and only showed a stronger tone in the hanging wall. The typical kieseritic transition layers are missing towards the lying area. Likewise, the so-called lead benches (as described below in the deposits of the Teutschenthal mine field ) are only rarely formed. A characteristic feature of the carnallitite of the Salzke saddle is the lack of tachydrite, a magnesium-calcium chloride . Also in the northern part of the Salzmünder Saddle tachhydrite hardly occurred. It was mainly to be found in the southern field, in which increasingly stratified tachhydrite - as a transition to the Teutschenthaler mine field - occurred. From a stratigraphic point of view, the greatest tachhydrite flow occurred below the last four meters bordering the Gray Salt Clay; immediately below the gray salt clay the potash store was free of tachhydrite (occurrence of anhydrite crystals). Average analyzes of around 400 boreholes in the Teutschenthal mine field revealed a magnesium chloride (MgCl 2 ) excess of 0.75% and a CaSO 4 x 2H 2 0 of 1.07%. Both values are an expression of the tachhydrite content of the salinar.

In the eastern field of the Salzmünder Saddle, up to two meters thick nests of layered, sealing lacquer-red hard salt have been approached on various occasions . Other peculiarities within the Salzmünder Kalilager - especially in the southern field - are larger Sylvinnesters , bishopric-leading fissures and Staßfurtite nodules (also known under the name Boracite , chemically Mg 3 B 7 O 13 Cl).

The hydrogeology in the area of the Salzmünde shaft was unproblematic. The water-bearing layers of the Cenozoic era are bound on the one hand to the valleys (Salzke) filled with weathered debris, and on the other to the hollow shapes created by the leaching of soluble rocks on the earth's surface (e.g. the leaching depression of the Röt above the Salzke broad saddle). The distribution and productivity of these layers are low because of the low rainfall and the small catchment areas . Main aquifers are the mighty and well permeable sandstone banks of the Middle Buntsandstein. The Rogenstein benches in the Lower Buntsandstein are water-bearing.

The financial and business situation

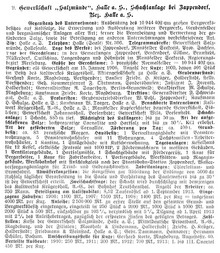

The prerogatives of 5 Prussian normal fields in the districts Salzmünde and Langenbogen (territorial once: Mansfeld Seekreis the province of Saxony ), were from the former Oberbergamt Hall on rock salt and salts beibrechende awarded . The Salzmünde trade union was founded on January 15, 1906, by branching off a number of fields from the right of the Krügershall potash works as a Prussian trade union. The original name of the Salzmünde union was Ernst Albertshall union , which was then changed to Salzmünde . Further details on the company and its close ties to the neighboring " Kaliwerk Krügershall AG " are shown in the information from 1914 on the right.

Number of Kuxe 1 : The usual 1000 Kuxe when the "Ernst Albertshall Union" was founded in Gotha was divided equally between the bankers Siegfried Weinstock from Halle aS and Friedrich Heinrich Krüger from Halberstadt. As a result of a change in the statutes, the company's name is changed to “Union of Salzmünde” and the administrative headquarters are moved to Halle aS. Chairman: Banker Weinstock, Deputy: Banker Krüger (both co-owners / branch managers of Mitteldeutsche Privatbank AG).

As a result of the trade union meeting on February 21, 1906, the trade shares were reassigned as follows: 374 Kuxe to banker Weinstock, 375 Kuxe to banker Krüger and 251 Kuxe to the neighboring Krügershall A.-G .; Decision of an additional fine of 4 million Mark = 4000, -M / Kuxe. On October 10, 1907, the Krügershall potash plant acquired another 100 Kuxe and now owns 351 Kuxe.

Pit Board : Director: Ferdinand Schweisgut Halle aS; Chairman: Banker Weinstock; Deputy Chairwoman: Banker Krüger, Judicial Counselor Joseph Frorath zu Halberstadt, City Councilor Franz Ohrtmann zu Halberstadt On November 18, 1907 these 5 board members each owned 20 Kuxe = 100 Kuxe. June 24, 1906 to August 22, 1907: successively granting of mine ownership to the 5 individual mine fields and finally all 5 fields to be merged as " Salzmünde " (according to the negotiations and certification before the royal notary Albert Herzfeld) .

1912: the Burbach union acquires the majority of the shares in Krügershall A.-G. Mr. Gerhard Korte from Magdeburg becomes the chairman of the supervisory board.

1912: Acquires Krügershall A.-G. another 50 Kuxe of the union Salzmünde and now has 401 Kuxe.

1912: Gerhard Korte becomes chairman of the mining board of the Salzmünde union.

1922: Acquires Krügershall A.-G. another 100 Kuxe, so that her property in the Salzmünde union is now 501 Kuxe. October 2, 1923: The trade union assembly decides to further increase the Kuxe from the original 1,000 to 5,000, the majority of which is now owned by the Krügershall A.-G. found.

Two-shaft question: On May 15, 1925, the connecting route to the Krügershall potash plant in the south, which was started in October 1912, broke through. The Salzmünde shaft is kept ready for use as an escape shaft and at the same time serves as an extending weather shaft for the Krügershall mine field.

Potash syndicate: In March 1909, a provisional contract was signed under which the union was entitled to deliver goods worth 100,000 marks to the syndicate in May and June 1909 . According to the notarized contract of December 13, 1909, the union had joined the syndicate with the Krügershall quota for 1909 retrospectively from November 1, 1909 and with the Ludwigshall quota for the new syndicate period; the definitive admission took place on December 21, 1909. Further quotas changed annually with a decreasing tendency. B. 1921 with 5.5515 thousandths to only 4.6258 thousandths from October 1932.

Daytime systems: The daytime systems had: A standard-gauge siding to the former "Zappendorf State Railway Station", the electrical center with 500, 350 and 70 HP steam output. Furthermore, workshops, water supply systems, administration buildings with apartments, main hoisting machine and secondary hoisting machine in addition to massive buildings, main pit ventilator with underground weather channel with a capacity of max. 4,500 m³ output / min, a wrought-iron headframe with shaft building and plateau. A massive boiler house for 14 boilers plus superheaters , 2 chimneys (55 m and 85 m high).

House and property: Around 85 Prussian acres , an administration building with apartments, 7 civil servants 'houses with a total of 26 apartments, 4 six-family workers' houses, a single house, a canteen, a stable with a coach house and a farm building.

The takeover of the former "Salzmünde Trade Union": At an extraordinary trade union meeting on December 12, 1928, the trade unions of the Salzmünde trade union decided to liquidate the trade union and sell the entire assets to Burbach-Kaliwerke A.-G. In exchange, this stock corporation offered the trades per Kux a nominal 280 Reichsmark - Krügershall shares with a subscription right to new shares at a ratio of 1: 3. The exchange offer came into effect on January 15, 1929. The Salzmünde mine was then a so-called "reserve plant", also referred to as "standby work". From July 1, 1924, potash mining operations were suspended. The number of shares in the plant was exhausted by the new group .

Pit field and shaft construction

The mining area of potash - mine covers about 1,000 m in the southwest-northeast and 400 m in the northwest-southeast direction.

Height of hanging lawn bench : + 93.30 m above sea level ; Levels attached to the shaft / filling points : 1st level (weather level): - 736.70 m above sea level, 2nd level (main level): −774.70 m above sea level.

Saline opened up in the shaft: up to 569.3 m depth of rock salt (Naj); up to 705.0 m depth anhydrite, up to 751.0 m depth carnallite; Rock salt up to 782.5 m depth (Naä).

Construction of the Salzmünde shaft began on September 18, 1906 near Zappendorf. At the beginning of January 1907 a depth of about 75 m was reached, on January 25, 1908 a depth of 415 m was reached. The shaft stood in the anhydrous mountains after the last water had closed at 320 m. In June 1908 the salinar was reached at 660 m depth. After reaching a depth of 750 m the Abteufarbeiten were temporarily adjusted by means of a transverse shock home base from the potash to. This project was abandoned shortly afterwards and the sinking of the shaft was resumed. First of all, the further sequence of layers is examined through a vertical bore. Here, from 816 m to 866 m of compact anhydrite, from 866 m to 879 m salt clay and from 879 m to 909.15 m a potash deposit with high-percentage and extremely uniform carnallite was drilled. The potash store was then approached on a main production bed set at a depth of 868 m. At a depth of 830 m, a weather crosscut was set which, at a distance of 58 m, was also used to approach the potash store (30 m thick). The shaft is sunk to the final depth of 888 m. It was intended to open up the hard salt deposit drilled near Müllerdorf by means of a cross passage from the shaft (the deep drilling Salzmünde II there drilled a 5.50 m thick hard salt deposit with a chlorine potassium content of up to 50, in the depth range from 636.70 m to 642.20 m. 5%).

The shaft has a diameter of 7.50 m down to the depth of 3 m, and from there a diameter of 5.25 m. It stands in masonry up to a depth of 19 m, from there up to 344 m in German tubbings . In the area from 302 m to 325 m, a wall was left behind the segments. The further area from 344 m to 879 m is lined with 2-stone masonry; the rest of the area up to the final depth of 888 m is again in German segments (wall thickness 30 mm). In the depths from 155 m to 180 m as well as from 300 m to 325 m, additional tubbings were installed in front of the masonry to seal off water from the eaves. The main excavation level is at a depth of 868 m.

Removal and installation, dismantling and relocation processes

The Salzmünde potash works produced carnallite and small amounts of hard salt from 1908 to 1925 .

The 732 m level is in the area of the Leine rock salt (Na3). It is only about 110 m long and has no further connection to the rest of the mine field.

The 830 m level was the former weather level; the 868 m level was the former main hoisting level.

Potash was only extracted in the SW-NE trending area of the Salzmünder Saddle. The dip here is between 10 and 30 degrees. The potash seam in this narrow salt dome was almost completely mined from the lying to the hanging wall .

The training and device took place in the following levels : On the II.- (−765 m above sea level), III.- (-758 m above sea level), IV.- (-752 m above sea level), V.- (−744 m above sea level) ) VI.- ridge sole (-737 m above sea level) in the area of the north flank and on the II.- (-763 m above sea level), III.- (-756 m above sea level) and IV.-ridge sole in the area of the south flank of the Salzmünder Saddle.

On the 868 m level (main delivery level), level −774 m above sea level: On the first underground level (−790 m above sea level) and the second underground level (−800 m above sea level) in the area of the southern flank of the Salzmünder saddle.

On the north flank, the mines extended from the main floor to the fifth ridge floor; on the southern flank from the main conveyor bottom to the IV ridge bottom. No excavations were made in the area of the substructure floors.

The connecting route to the Teutschenthal mine field begins on the Salzmünder side at Devil level −770.8 m above sea level and ends on the Teutschenthal side at the foot of a blind shaft at Devil level −774.8 m. A dam gate was built into this connecting route, but its functionality was lost over the years.

The existing pit void volume of the Salzmünder pit field was calculated on the basis of the available funding figures and shows the following balance:

Total cavity : 780,000 m³, including fixtures and fittings 80,000 m³, offset cavities 550,000 m³ and ultimately open pit cavities of 230,000 m³. These figures were calculated in 1975. Today (2012) lower values can be assumed due to the natural convergence of the mine workings as well as inflowing dripping water and introduced saline solutions (about 90,000 - 100,000 m³) (the author of this article estimates it at a maximum of 80,000 m³).

Fur, etc. (1975) came to the conclusion in their geomechanical assessment that, based on the experience of other potash works that have mined under similar conditions, the mining system used here can be regarded as relatively stable despite the narrow pier widths and only causes minor subsidence on the surface. Due to the collapse of the potash deposit, the mine field has only a small extent in the crosscutting direction. On the north flank it is a maximum of 120 m and on the south flank 150 m. As a result, the overburden is largely supported by the mining edges, so that the overburden pressure acting on the mining piers is reduced. Storage conditions and mining methods made it possible to introduce a dense offset, which increases the load-bearing capacity of the excavation pillars through side pressure and can also take on a support function against the hanging wall and lying.

Despite the existing significant differences, the authors made an assessment of the stability according to the dimensioning guidelines of the VEB Kaliwerk Teutschenthal that were valid in GDR times. Then they calculated the following safety factors without taking into account the introduced misalignment:

North flank: n = 0.8 to 1.2. South flank: n = 1.0 to 1.6. Safety factors of approx. N = 5.0 would be required.

If you reduce the dismantling height included in this calculation to the free height remaining above the offset, the following safety factors result:

North flank: n = 2.0. South flank: n = 2.4. Safety factors of approx. N = 3.0 would be required. Thus, according to these calculations, it was assumed that the pit area was underdimensioned. However, the small extent of the mine field and the associated supporting effect of the construction field edges make the mine field appear so stable that rockfalls or collapsing piers of orders of magnitude are not to be feared. The rock pressure phenomena (convergences) observed in the route systems are to be regarded as normal for the depths of these mine workings.

The factory processing of the extracted salts

The Salzmünde potash plant was technically self-sufficient. It had a potassium, bromine, Epsom salt and sulfate factory. The potassium chloride factory had a daily capacity of 5,000 quintals of crude salt. The table on the left shows the potash sales of the Salzmünde potash factory from 1913 to 1925. The discharge of the final liquors into the Saale near Zappendorf below the Pfütztal was approved by the responsible district committee on February 7, 1908. The objection raised by Adler-Kaliwerke and the City of Magdeburg was rejected by the Ministry as irrelevant. According to the concession, which was thus definitely granted, the factory wastewater of up to 8,000 dz daily processing could be fed into the Saale up to a wastewater hardness of 30 o dH. The Salzmünde trade union was allowed to use the Krügershall line to discharge the final lye.

The closure of the Salzmünde potash plant

At the beginning of the 20th century, drilling activities in Germany to search for potash salt and hard coal experienced a real boom . In order to prevent the proliferation of new potash works (as well as coal mines) and thus overproduction, the Prussian state parliament decided at the request of MP Karl von Gamp-Massaunen u. a. the " Law, regarding the amendment of the General Mining Act of June 24, 1865/1892, of July 5, 1905 (GB, p. 265) ", so called Lex Gamp .

It initially led to a temporary ban on speculation of potash salts and hard coal for two years . This meant that only the state could acquire mining property. The latter was able to transfer it to third parties in the form of a time-limited real extraction right .

The Lex Gamp was the beginning of further state interventions to avoid the formation of monopoly up to the regulation of prices and the overproduction caused by the excessive increase of potash mines. The latter was also served by the so-called decommissioning ordinance of October 22, 1921.

In § 83a of this regulation it is stated:

“A change in the conditions that are decisive for the assessment will not affect the continued existence and the amount of participation in those plants until December 31, 1953, which will be voluntarily shut down up to this point in time. An irrevocable declaration to this effect must be submitted to the potash inspection office by April 1, 1923 (extended to December 31, 1926). Taking into account the economic circumstances, in particular the salt reserves, this determines the point in time by which the shutdown must be carried out; an extension of this period beyond April 1, 1924 is not permitted. A shutdown within the meaning of this paragraph requires that any extraction of usable minerals from the shutdown shaft ceases. Exceptions can only be granted by the Reich Minister of Economics after hearing the Reichskalirat and the potash inspection office. "

Production at the Salzmünde potash plant was discontinued in 1924. A large part of the workforce was taken over by the Krügershall plant in Teutschenthal. The Epsom salt factory was dismantled and rebuilt in the Teutschenthal potash plant. The administrative headquarters of the Salzmünder Gesellschaft is relocated from Halle to Teutschenthal. The Teutschenthal potash plant and other potash plants of the Burbach Group take on the production quota.

State of the mine in 2006

At the beginning of the 1980s it was possible to dispense with the Salzmünde shaft as an escape and extending weather shaft. In October 1981, VEB Schachtbau Nordhausen installed a concrete plug below the tubbing column (lower edge of the plug at 354.5 m depth, i.e. at the upper limit of the sandstone-slate zone; upper edge of the plug at 345.5 m depth a clay packing with a thickness of 6.5 m and over this a fill of gravel with a thickness of 1.5 m). Above this, the tubbings were drilled to allow the groundwater from the middle red sandstone to enter the shaft. A measurement of the water level in the shaft tube on November 19, 1981 found it at a depth of 242.4 m. This grafting of the Salzmünde shaft tube does not represent the final shaft custody. This is implemented in the overall complex of custody of the three interconnected mine fields and their day shafts.

In 1983 the Erfurt Mining Authority approved the operating plan for the safekeeping of the mine building by filling the empty pit cavities with calcium and magnesium chloride solutions. The introduction begins on January 30, 1984 via a downpipe in the Teutschenthal shaft. The free exit of the brine from the pipeline at the beginning of the weather flattening to Salzmünde ensured that the solutions flowed via the earlier escape and weather route into the significantly deeper pit field of the Salzmünde mine.

Because in the long term - after the current GTS backfill mine in Teutschenthal has closed - due to the natural convergence of the mine, the introduced saline solutions could transfer into the Teutschenthal mine field and release pollutants from the backfill material introduced there, the installation of dam structures in the connecting route to the Teutschenthal mine field is planned. This then eliminates any risk that contaminated solutions can get into the hydrosphere via weak points in the barrier of the Salzmünde mine field.

Knoll et al. (2006) came to the conclusion that the Salzmünde mine field can to a large extent be regarded as safe due to the discharge of liquids that are inert towards the host rock . "Certain risk factors result from the fact that the long-term safety status cannot be quantitatively proven due to ignorance of the exact dimensions of the mining pillars and the specific dimensions of the geological barrier elements and from the fact that the connection pit between the GF TEU and SAL, which penetrates the tectonic element salt bank depression , is also due to The lack of geological and geomechanical parameters cannot be calculated in terms of its deformation behavior and its influences on the more complicated geological barrier there. For these reasons, the requirement for long-term safe separation from the GF TEU must be maintained. It is also considered necessary to re-analyze the situation of the GF SAL as part of a second update of the long-term safety certificate and, in the course of this analysis, to specifically quantify the specific tightness requirements that must be placed on the barrier structures between the GF TEU and SAL. At this point in time, further results of the R&D work on dam structures in carnallitite are available and the fluids actually present in the GF TEU as a result of the application of the thick matter backfilling method at the end of the operating time can be estimated more thoroughly. "

Bibliography

- Johannes Kluge: Mining historical documents and photos. Private collection.

- Peter Knoll, RB Wermuth, Matthias Finder: Development of a concept for the implementation of security measures for the final safekeeping of the Teutschenthal mine of GTS GmbH & Co. KG, 1st update of the concept from February 24, 2000. Teutschenthal January 31, 2006.

- Julius Mossner (ed.): Handbook of the potash mines, salt pans and deep drilling companies. Finanz-Verlag, Berlin 1936.

- Pelzel, Bauer, Götze: Analysis of mining damage in the Salzmünde mine. VEB potash and rock salt plant "Saale", 1975.

- W. Reichenbach: Long-term proof of safety in the Teutschenthal pit, update of the Angersdorf pit, geological section. IA of GFE Consult GmbH, Gutenberg, December 2005.

- Ferdinand Schweisgut: Twenty years of Krügershall Salzmünde. Teutschenthal 1925.

Individual evidence

- ↑ International drilling company . In: Meyers Großes Konversations-Lexikon . 6th edition. Volume 9, Bibliographisches Institut, Leipzig / Vienna 1907, p. 889 .

- ↑ Jens Heckl ( arrangement ): The Prussian mountain, smelter and salt works administration 1763-1865. The holdings of the Oberbergamt Halle in the state archive of Saxony-Anhalt. In: Publications of the State Archives Administration of Saxony-Anhalt . Sources on the history of Saxony-Anhalt (= row A ). tape 17 . Magdeburg 2001, ISBN 3-930856-00-X ( sachsen-anhalt.de - 4 volumes).

- ↑ On the development of mining law in the western part of the Prussian state. Rheinkamp-Repelen, accessed on July 28, 2013 .

- ^ Adolf Arndt (ed.): General mining law for the Prussian states . 5th, verb. u. probably edition. Leipzig 1907, p. 284 .

- ↑ Real extraction right. Retrieved July 28, 2013 (Google Books search).

- ↑ Ordinance on the amendment of the regulations for the implementation of the law on the regulation of the potash industry of July 18, 1919. Reichs-Gesetzbl, p. 663.

- ^ Reichskalirat. In: Yearbook of Public Law of the Present. Retrieved July 28, 2013 (Google Books search).

literature

- Collective of authors: Grube Teutschenthal, 100 years of potash and backfill mining . Ed .: GTS Grube Teutschenthal Security GmbH & Co. KG. 2005.

- Ernst Loock: Disused shafts - a problem for the potash industry . In: Freiberg research books (= A 136 series ). Akademie-Verlag, Berlin 1960.

- J. Löffler: The potash and rock salt deposits of the Zechstein in the GDR . In: Freiberg research books (= C 97 / III ). Part III: Saxony-Anhalt . Akademie-Verlag, Berlin 1962.

Web links

- Volker Wennrich: The late Weichselglacial and Holocene climate and environmental history of the Mansfelder Land / Saxony-Anhalt, derived from lake sediments of the former Salty Lake. (PDF 8.4 MB) University of Leipzig, December 19, 2005, accessed on July 28, 2013 (dissertation).

- Teutschenthal mine. GTS Grube Teutschenthal Sicherheits GmbH & Co. KG, accessed on July 28, 2013 .

- Union and drilling company. (PDF 2.4 MB) pp. 187–198 , accessed on July 28, 2013 .

- Hans-Heinz Emons: The Potash Industry - History of a German Industry? Retrieved July 28, 2013 .

- Ordinance on the transfer of responsibilities in old mining (AltBergEüVO). December 19, 2007, accessed July 28, 2013 .