Incineration

Waste incineration (also waste incineration , thermal waste treatment or recycling , in Switzerland waste incineration or waste recycling ) is the incineration of the atmospherically combustible parts of waste for the purpose of reducing the volume of the waste using the energy it contains , accompanied by the compaction of the remaining amount for further recycling or recycling. Landfill .

To improve the economic and technical yield, the different types of waste ( construction waste , waste wood , glass , small scrap , paper and cardboard , packaging ( yellow sack )) can be separated from each other when they are made available for collection. After delivery, conditioning , i.e. a mixing of the deliveries to compensate for the calorific value, is carried out. Electrical devices or electronic scrap and vehicles as well as clothing and shoes are also treated separately.

Regional differences

In Germany, the systems are partly distributed according to the population density. However, some of the industrial waste and municipal waste must be transported over long distances. An overview map with basic data for most of the plants can be found at the Interest Group for Thermal Waste Treatment Plants in Germany. V.

Waste incineration plants ( MVA ; in Switzerland waste incineration plants , KVA ) are used for waste incineration . Since, with a few exceptions, the energy contained in the waste is also used to generate electricity and / or heating (steam or district heating), MVAs are also called waste-to-energy plants (MKW) , waste-to-energy plants (MHW) or waste-to-energy plants (MHKW) - depending on whether they only electrical energy (power plant), only heat (-heizwerk) or both (- heizkraftwerk ) produce.

meaning

The proportion of waste that is incinerated in waste incineration plants varies widely around the world. While the water content of the waste in Germany is relatively low due to the almost area-wide organic waste collection (max. 30% by mass, 25% by mass is usual), the water content, for example in Asia, is sometimes significantly higher. In total, around 255 million tons of waste are incinerated in around 2,200 plants worldwide every year.

In industrialized countries the proportion of incineration is significantly higher than in developing countries, particularly because of the legal framework. In Germany, landfilling of non-pretreated waste has been prohibited since June 1, 2005 ( TA Siedlungsabfall ). Household waste may only be disposed of in the form of ash or slag after it has been incinerated . In Switzerland, 100 percent of all household waste is thermally treated. Waste incineration usually precedes landfill, since landfill space is scarce in densely populated countries and the landfill of incineration residues requires significantly less space and volume.

The degradation processes of the organic content and pollutants can significantly pollute the groundwater, soil and ambient air in a landfill. Thermally treated residues with a residual proportion of less than 3% carbon, however, can usually be disposed of without any problems. The EU Directive 1999/31 / EC limits the proportion of biodegradable components for landfills to 3%, which is why the pretreatment of municipal waste is required in the member states.

The amount of waste incinerated in Germany has quadrupled since 2000. In 2011 19.7 million tons were thermally recycled, an increase of 13% compared to the previous year. Two thirds of this was used to generate energy, 6.8 million tons in biomass power plants and 6.3 million tons in substitute fuel power plants. Otherwise, 2 million tons were accounted for by other power plants, 1.2 million tons by thermal power plants and 3.4 million tons by production facilities.

construction

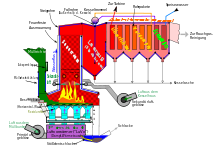

A conventional waste incineration plant consists of

- Garbage facility:

- Weighbridge , for determining the weight of the waste by means of incoming and outgoing weighing

- Garbage unloading hall , in which the garbage from the dumping points reaches the garbage bunker via slides or, if necessary, passes through a bulky garbage shredder beforehand

- Garbage bunker , which is used for intermediate storage and homogenization of the garbage

- Grab crane , via which the garbage is put into the feed hopper of the furnace

- Incineration plant in the narrower sense with steam generator:

- Furnace in which the garbage burns (see below for types)

- Purifier , into which the slag falls and is transported to the slag bunker

- Steam generator in whichsteam is generatedusing the hot flue gases , whichdrivesthe turbine andgenerates electricityvia a generator , or which is used as district heating for heating households or as process heat for industrial production processes

-

Flue gas cleaning system

- Denitrification , based on the principle of selective catalytic reduction ( SCR ) or selective non-catalytic reduction ( SNCR ).

- Filter system that separates dust as a surface filter and / or electrostatic precipitator

- chemical, adsorptive and / or catalytic cleaning to separate pollutants (especially HCl , SO 2 , heavy metals , dioxins / furans etc .; usually as wet gas scrubbing , dry or quasi-dry absorption with the addition of lime compounds and / or activated carbon ). If the SCR process is used as the denitrification stage, the existing catalyst can break down not only nitrogen oxides but also carbon monoxide and / or dioxins / furans.

- Chimney through which the cleaned flue gases are released into the outside air.

- Fly ash and wastewater treatment plant (FLUWA / ABA)

- various ancillary and auxiliary systems

Types of waste incineration plants

Waste incineration plants are available in different sizes and designs for different purposes. Small systems are located in hospitals in order to be able to dispose of bacterially contaminated waste on site. There are also systems for special purposes such as sewage sludge incineration . Another possibility is to use waste as a secondary fuel in plants that were not built for waste disposal, e.g. B. in rotary kilns in the cement industry. By far the largest share is treated in large-scale systems, with the energy released usually being used in the form of district heating or to generate electricity. The incineration method is usually incineration on oven grates, sometimes also using fluidized bed combustion after the waste has been processed beforehand. Pyrolysis and gasification systems or the thermoselect process have so far only played a subordinate role.

Conditioning

The delivered garbage from different loads and sources is first deposited in a mixing plant or directly in the garbage bunker of the incineration plant, which helps to condition the garbage for an improved consistency of the calorific value . In addition, substitute fuels such as non-recyclable plastic films or shredded wooden parts from bulky waste are added to the residual waste delivered .

Grate firing

With grate firing , no processing of the residual waste delivered is required. For loading, conveyor belts (from the mixing plant) or cranes (from the bunker) are used to transport the waste into the feed hopper. The refuse is fed into the furnace chamber in a metered manner via the loading device, which consists of a sluice and the feed table. There it ends up on the grate, which conveys the abandoned waste during the incineration phases.

Roller grates, forward or backward sliding grates, and less frequently also traveling grates are used (see also grate types ). In the first zone, the garbage is dried, followed by evaporation of the water at temperatures above 100 ° C. In the next zone in the temperature range of 250-900 ° C is performed a degasification of the waste. When the flash point of the degassing products is reached, combustion begins, which takes place at a sub-stoichiometric (incomplete) temperature of 800–1150 ° C. The remaining burnout occurs on the last grate zone.

The primary air supplied from below the grate and the secondary air supplied above have a significant influence on the combustion and the formation of the reaction products. The primary air initiates incomplete combustion on the grate. The amount of air is dosed in such a way that good burnout is achieved with low nitrogen oxide formation. The afterburning of the radicals (carbon monoxide, hydrocarbons) takes place in the afterburning zone by supplying the secondary air. The combustion air volume flows can be regulated zone by zone and according to the flue gas analysis (CO, NO x , excess air ). At the end of the grate, the combustion residues fall into a water bath (deslagging agent), from which they are removed by means of a ram or chain scraper , and are transported via conveyor belts to the slag preparation.

The temperature in the combustion chamber can be more than 1000 ° C, depending on the system. According to the 17th BImschV, the flue gases must have a temperature of at least 850 ° C for at least two seconds after the last combustion air supply. Lower temperatures are permitted in the combustion chamber if compliance with the emission limit values can be demonstrated. In order to prevent the release of dioxins and other undesirable toxic compounds, the smoke gases are "post-burned" again so that any dioxins that may have formed break down.

The entire lower section of the first pass of the steam boiler is lined to limit the heat transfer. A high post-combustion temperature is thus ensured and the pipe walls are protected from corrosion at high temperatures. Due to the reduced heat transfer, the flue gas has a high temperature for a longer period of time, which means that more complex hydrocarbons such as dioxins and furans decompose .

The flue gas transfers the heat to the heating surfaces of the steam boiler. However, when the residual particles cool down in the downstream exhaust gas cleaning system, new pollutants - including dioxins - can arise, which is why a complex filter technology is required.

Auxiliary burners (gas or oil burners) are only ignited in rare cases when starting up or when the waste heat values are poor in order to keep the temperature in the boiler high enough.

Pyrolysis systems

The process steps from drying to degassing are technically also referred to as pyrolysis or degassing. The individual stages can be carried out superimposed in a combustion chamber or one after the other in several reactors. Conventional systems usually only have one combustion chamber in which the five individual steps run in parallel. In addition, there are pyrolysis and gasification plants in which there is no residual burnout and which, strictly speaking, are not waste incineration plants because the gases produced are fed to other technical processes. However, there are only a few plants in the world that use the pyrolysis process on an industrial scale.

Fluidized bed combustion

The fluidized bed combustion is the usual method for the incineration of sewage sludge , the increasingly for substitute fuels is used. Unclassified fuels such as household and commercial waste must, however, be pre-sorted and shredded before incineration, as the fuels are fed in pneumatically (the piece size is limited to approx. 250 mm, sometimes larger depending on the design). Metals and stones damage the conveying and discharge systems and must be largely removed from the fuel.

Both stationary and circulating fluidized beds are used for the combustion of residues. After heating the furnace with oil or gas burners, the pre-treated waste or pre-dried sewage sludge is fed from a height of a few meters from the side onto the stationary fluidized bed, using throwing feeders or screw conveyors. In the principle of the circulating fluidized bed, delivery lines are used in which the fuel fed in from above is carried away by the prevailing air flow in so-called blow shoes and transported into the combustion chamber. In the case of fluidized bed combustion, a nozzle bed is built into the bottom of the furnace (i.e. a plate that is equipped with many air nozzles. In RDF systems, it is often designed as an open nozzle bottom in order to be able to discharge coarse ash particles or metals). Combustion air is fed through these nozzles and sand is added. The fuel, ash and sand are kept suspended in the furnace. The thorough mixing of fuel and air have the effect that a very uniform optimal combustion at low temperatures in the fluidized bed set, and a striation (z. B. unburned air) to can be effectively avoided, which in addition to a reduction of carbon monoxide according to pulls. The combustion parameters can be optimized by partially recirculating exhaust gas. The combustion temperatures in the combustion chamber are between 800 ° C and 900 ° C. Due to the even temperature distribution, relatively few nitrogen oxides are produced . The ash is discharged depending on the weight via the furnace hood upwards or through shafts downwards.

Hazardous waste incineration plants (rotary kiln)

Rotary kilns are used for the incineration of hazardous waste that requires high temperatures . With this technique, the garbage is placed in the upper end of a sloping and slowly rotating pipe. The length of such a rotary kiln for waste incineration is up to 12 m, the diameter is between four and five meters. This pipe is lined with refractory bricks in order to be able to maintain a high temperature of 1000–1300 ° C, because a minimum temperature of 1100 ° C has to be observed when incinerating waste that requires special monitoring and contains organohalogen substances. The lining protects the outer steel jacket from corrosion and an impermissibly high temperature. The rotary kiln has the advantage that waste of very different consistencies and lumps can be burned. This is how solids are fed, in addition to sludge and barrels up to 200 liters. The rotary kilns are ideally heated with high calorific solvent waste of at least 20,000 kJ / kg.

calorific value

When incinerating municipal waste that has not been pre-treated, a lower calorific value of 9–11 MJ / kg can be assumed in Germany . Taking into account all balance limits and efficiencies of the partial processes in a classic waste incineration plant (main components: waste task; main thermal process consisting of solid fuel burnout on a grate and steam generation in a water-tube boiler ; waste gas and waste water purification ; electrical energy conversion from superheated steam ), approx. 1.3 MJ or about 0.36 kWh of electrical energy per kg of wet waste. Although recyclable ingredients (e.g. single-origin plastics , paper, glass) and the limit are withdrawn from the municipal waste in accordance with the provisions of the Recycling and Waste Act (§ 4 Paragraph 1 KrW- / AbfG and § 6 KrW- / AbfG) for energy recovery from waste materials was set at 11 MJ per kg (Section 6 (2) KrW- / AbfG), independent incineration is possible without additional firing. Another possibility is to use a “mechanical-biological pre-treatment” (MBV) in order to separate, for example, low-calorific, moist organic waste and feed it to composting . Even inert substances are separated in this way. The lower calorific value of the residual waste, which is increased in this way, enables energy recovery. In this context, the thermal treatment of residual and waste materials is a technically sensible addition to an integrated waste management system for municipal waste.

The energy obtained from the incineration of waste can be used to generate electricity or in thermal form (for example through district heating ). It is extremely difficult to relate the energy balance of the manufacture of a product to the energy balance of its recycling in the case of municipal waste that is not single-type and is very heterogeneous due to multiple balance limits. Due to the second law of thermodynamics , the entire energy contained in the garbage can never be converted into usable energy. In addition, with every energy conversion there are also losses, for example in the form of heat losses from the boiler and combustion ducts, which in reality are never completely adiabatic . In addition, a waste incineration plant needs some of the energy it generates for its own use. This means that waste incineration can only recover part of the energy that was contained in the raw materials of the starting products and required for their production.

Ecological aspects

Exhaust gases

Since it is not known when the garbage is incinerated which ingredients are burned in which quantities at a certain point in time (e.g. PVC , batteries and electronic components, paints etc.), the composition of the flue gas and the ash varies. In addition to carbon dioxide and water, combustion also produces carbon monoxide , sulfur oxides , nitrogen oxides , but also hydrochloric acid (hydrochloric acid) and hydrofluoric acid (hydrofluoric acid) as well as mercury and dusts containing heavy metals . Highly toxic substances such as polychlorinated dibenzodioxins and dibenzofurans are also produced in very low concentrations . In the past, waste incineration was considered responsible for the spread of the latter substances in the environment, but the Federal Environment Ministry announced in a press release in 2005 that this statement was no longer up-to-date ( "In 1990, a third of all dioxin emissions came from waste incineration plants, it was in Year 2000 less than 1% ” ). However, this point of view has been criticized because the exhaust gas measurements at waste incineration plants allegedly make a systematic error: Dioxin is hydrophobic, and since the exhaust gases contain a lot of water vapor, the dioxin molecules push themselves against the dust particles emitted. However, only the dioxin concentration in the air is measured. This was countered by the fact that the pollutants were measured by regularly discharging smoke gas samples together with all particles and then determining the substances they contain. The exact number and variety of the pollutants arising from waste incineration and released by it is not known. There are only limit values for 40 known airborne pollutants. The danger lies in the fact that many different substances are present when waste is incinerated. Due to the large number of substances, the danger of individual compounds that only occur in trace levels can hardly be determined.

Ashes, slag and dust

The solid residues from a waste incineration plant, approx. 30% of the amount of waste incinerated, include ashes and slag from waste incineration as well as waste from flue gas cleaning and waste water cleaning and filter dust . A number of solid end products are created during the combustion process, exhaust gas cleaning and steam generation, of which slag makes up the largest proportion. In 2002, approx. 3.4 million tons of slag were produced in the German waste incineration plants, of which 2.9 million tons were left over after processing the slag. The slag is dumped, used to fill closed mines or recycled as building material for dams and roads . In addition, boiler and filter dust is generated, which is also deposited in landfills or in closed mines. In addition, scrap iron and non-ferrous metals are sorted out and gypsum is extracted.

In Austria, the maximum treatment capacity of the large waste incineration plants for incinerating municipal waste and the high calorific fraction was around 1.6 million t / year until the end of 2004. In 2003, around 190,000 t / year of coarse ash (slag) and 88,000 t / year of fly ash were produced from the incineration of municipal waste (excluding facilities for incinerating hazardous waste). These quantities should increase to around 314,000 t / year of coarse ash (slag) and around 170,000 t / year of fly ash by 2010.

In Austria, due to the large number of pollutants, a large amount of slag and filter dust is deposited above or below ground.

In Germany, filter dust and the dried residues from chemical flue gas cleaning are almost exclusively stored in salt mines. The incineration slag with the concentrated pollutants is partially dumped, but more often used as filler material in salt domes and in road construction. The waste incineration slag used in road construction is subjected to an eluate test in which some pollutants are examined.

In Switzerland, the slag is stored underground. Compensated slag from waste incineration plants is also used as a sealing layer for the closure and recultivation of landfill surfaces. Filter dust, sludge and ash are exported to Germany, where they are stored, for example, in the Herfa-Neurode and Zielitz underground landfills .

Resource conservation

In the sense of the Kyoto Protocol , techniques are to be used to conserve resources that conserve raw materials or recycle them sensibly through material flow management . After the potential for waste avoidance and material recycling has been exhausted, thermal recycling of appropriately sorted municipal waste can be used as a substitute fuel for fossil raw materials, for example in the cement industry or steel production, where the shredder light fraction from automobile recycling replaces hard coal coke as a reducing agent. However, this requires appropriate flue gas cleaning systems .

In connection with the dumping of untreated waste in landfills, which is still common in many countries, the topic of landfill mining is discussed. This should enable the later recycling of nowadays non-recyclable waste with future technologies.

Legal basis and limits

European Union

According to the European Union's Waste Framework Directive, the energy efficiency of a waste incineration plant decides whether the process used there is to be regarded as energy recovery or as a disposal process. According to their so-called waste hierarchy, recycling takes precedence over disposal with corresponding consequences for the approval of a facility, a process or the shipment of waste.

Germany

The Federal Immission Control Act (BImSchG) and the ordinances issued according to it apply to waste incineration plants . Thereafter, their construction and operation regularly require such a permit. In 1990 the ordinance on incineration plants for waste and similar combustible substances (in short: 17th BImSchV) came into force in comparison to the corresponding regulations of the TA Luft for a tightening of the permissible emission values. In its current form as a regulation on the incineration and co-incineration of waste , it contains special requirements for the design of the furnace and specifies limit values for permissible emissions. The emissions must be continuously monitored and the measurement results transmitted online to the responsible authorities. In addition, the system operator has to publish the measurement results annually.

Since the entry into force of the so-called European Incineration Directive, the same emission limit values have partly applied to waste incineration plants and co-incineration plants (e.g. power plants, cement plants). The 17th BImSchV had to be revised accordingly. Nonetheless, the legal equal treatment and also the basic advantages and disadvantages of the use of waste in co-incineration plants are controversially discussed by proponents and opponents, whereby, among other things, life cycle assessments are also used.

Built waste incineration plants in German-speaking countries

Germany

According to the legal requirements of the KrWG , only waste for disposal that cannot be recycled or treated in any other environmentally friendly way may be incinerated in the residual waste. This includes residual household waste and commercial waste that still accumulates despite the separate collection and collection.

The first waste incineration plant in Germany was built on Hamburg's Bullerdeich in 1893 . Trial operations began in 1894, and regular operations began in 1896. The first Munich plant was built around the turn of the century, the first in Berlin in 1921. However, the Schöneberg waste incineration plant could not fulfill the hopes placed in it, which is why waste incineration was only established in Berlin after the Second World War.

By 1998, 53 waste incineration plants had been built in Germany. The number rose to 61 by 2003. At that time it was planned to build another 15 plants, mainly in East Germany (then a total of 76). The Federal Environment Agency publishes a list on its website (as of April 2016). It names 68 German waste incineration plants that mostly incinerate municipal waste.

Since June 1, 2005, untreated residual waste may no longer be deposited in landfills. For a while the prices for the disposal of mixed and residual waste rose sharply. Therefore, many systems were built for the private sector. These plants mainly incinerate mixed commercial waste (see also substitute fuel power plant ). The disposal prices later fell again; it became apparent that there is overcapacity in the waste incineration plant. A prognos study from 2009, carried out on behalf of NABU , saw dangers for material recycling from this overcapacity. “Today, two million tons more waste is imported into Germany than it is exported. This amount corresponds to the capacity of four large waste incinerators or a freight train loaded with garbage with a length of 1000 kilometers. "

Switzerland

There are 30 waste incineration plants in Switzerland . Since 2000, municipal waste has no longer been allowed to be landfilled in Switzerland, but has to be incinerated. “5.5 million tons are produced in Switzerland every year - 174 kilograms every second. That amounts to 709 kilograms per person and year. Half of it is recycled. "

In the Italian-speaking canton of Ticino , there was no system for a long time, which is why the waste was either taken to other cantons or temporarily dumped. In Giubiasco a new plant was built and put into operation in 2009.

Austria

There are currently four large waste incineration plants in the capital Vienna : Flötzersteig waste incineration plant (1964), Spittelau waste incineration plant (1971), Pfaffenau waste incineration plant (2008) and, with the Simmeringer Haide plant (formerly part of the Simmering waste disposal company , 1980), a sewage sludge and hazardous waste incineration plant. The plants operated by Fernwärme Wien GmbH produce around 116 GWh of electrical energy annually, around 1,220 GWh of district heating, with 550,000 t of household waste, 180,000 t of sewage sludge and 90,000 t of hazardous waste being incinerated. This produces 190,000 t of ash, slag, scrap and filter cake. Further plants are located in Arnoldstein (2004), Dürnrohr (2004), Lenzing (1998), Linz (2011), Niklasdorf (2004), Wels (1973, new building 1995) and Zistersdorf (2009).

In Austria, too, further plants are being planned or built due to the ban on landfill for untreated residual waste that came into force on January 1, 2009.

South-Tirol

The only waste incineration plant in South Tyrol is located in Bolzano . In July 2013, a new, larger waste incineration plant went into operation that generates energy and district heating for up to 20,000 households.

Alternatives to waste incineration

The easiest and best alternative to waste incineration is to leave as little residual waste as possible. This is done by reducing the amount of waste ( waste avoidance ) and through the separate collection of the waste that still occurs so that it can be recycled.

When recycling z. B. new products can be created in recycling of pure waste materials . Since the purity of types, especially in the case of plastics from municipal waste, is only given in rare cases, either “ downcycling ” to products with lower material requirements or material recycling takes place after processing has been carried out. In a sustainable circular economy , non-recyclable waste should therefore be avoided as early as possible during production.

Since waste in Germany could only be dumped untreated until May 31, 2005 , plants for waste treatment were built. There are several other methods of waste treatment, such as cold waste treatment technologies , that have been approved by the federal government as equivalent treatment facilities instead of incineration.

Others

The London Convention (1972), OSPAR and the Bamako Convention contain bans on waste incineration on the high seas and in coastal waters.

See also

literature

- Carmelita Lindemann: Incineration or recycling: garbage as a problem at the turn of the 19th to the 20th century . In: Technikgeschichte, 59th Vol. (1992), H. 2, pp. 91-107.

Web links

- Best available techniques for waste incineration plants (BVT information sheet) ( Memento from July 17, 2013 in the Internet Archive ) Publication by the EU Commission and German partial translation by the Federal Environment Agency, 2005/2006

- Guideline VDI 3460 Part 1 Emission Reduction - Thermal Waste Treatment (PDF; 104 kB), published by: Air pollution control committee in VDI and DIN, 2012

- Information portal on waste assessment (IPA) d. LANUV u. a. Waste authorities: Waste profile "1901 waste incineration" , status 2013

Individual evidence

- ↑ Overview map with basic data for most of the plants in Germany .

- ↑ Markus Gleis: Thermal waste treatment . In: Peter Kurth , Anno Oexle, Martin Faulstich (Hrsg.): Practical handbook of recycling and raw materials management . Springer Vieweg, Wiesbaden 2018, ISBN 978-3-658-17044-8 , p. 621 .

- ↑ Johnke, Bernt: Emissions from Waste Incinieration . Environmental Panel on Climate Change.

- ↑ preliminary data from the Federal Statistical Office, quoted in according to UmweltMagazin March 2013.

- ↑ 17th Federal Immission Control Ordinance (17th BImSchV) ( Memento from February 16, 2007 in the Internet Archive )

- ↑ Klaus Sattler: Environmental Protection Disposal Technology . Vogel-Buchverlag, Würzburg 1982.

- ↑ Greenpeace Austria (2001): Waste Incineration and Health (long version) ( Memento from December 22, 2014 in the Internet Archive ) (PDF; 616 kB).

- ↑ BMU (2005): Waste incineration - a source of danger? Farewell to the dioxin spinner ( Memento from March 4, 2012 in the Internet Archive ) (PDF; 59 kB).

- ↑ Zwahr, Heiner (2005): MV-Schlacke - More than just an unpopular building material?

- ↑ Umweltbundesamt Österreich (2005): Waste avoidance and recycling: ash, slag and dust in Austria (PDF; 1.8 MB), Vienna.

- ↑ K + S sells waste disposal subsidiary in Switzerland. In: osthessen-news.de. January 17, 2020, accessed January 17, 2020 .

- ↑ Garbage becomes gold. In: NZZ. January 23, 2011, accessed August 12, 2018 .

- ↑ on the waste hierarchy see Article 4, on subordinate disposal Article 12 of Directive 2008/98 / EC of the European Parliament and of the Council of 19 November 2008 on waste ; to distinguish between process R 1 (main use as fuel / energy generation) according to Annex II and disposal process D 10 or 11 (Annex I), see footnote 8 with the calculation formula for energy efficiency and differentiation depending on the operating license; For the partly differently defined distinction regarding waste for recovery or waste for disposal in the case of notification and approval of waste shipment, see Basel Convention

- ↑ no. 8.1. of Appendix 1 to the 4th BImSchV , more rarely after no. 1.2.

- ^ Franz Joseph Dreyhaupt (editor): VDI-Lexikon Umwelttechnik. VDI-Verlag Düsseldorf, 1994, ISBN 3-18-400891-6 , p. 1077.

- ↑ Text of the 17th BImSchV , emission limit values in § 8 , for waste co-incineration plants § 9 with Annex 3 . For monitoring section 3.

- ↑ § 23 17th BimSchV

- ↑ Directive 2000/76 / EC of the European Parliament and of the Council of December 4, 2000 on the incineration of waste, was valid until January 6, 2014

- ↑ BGBl. 2003 I p. 1633

- ↑ [1] , Umweltbundesamt.de

- ↑ www.dradio.de .

- ^ Waste incineration ( Memento from November 21, 2011 in the Internet Archive ) published March 3, 2009. PDF, 68 pages. Quote from p. 2

- ↑ VBSA: Waste recovery , accessed on April 14, 2015.

- ↑ The big recycling report , NZZ 2009.

- ↑ Autonomous Province of Bolzano South Tyrol: Garbage recycling plant in Bolzano in operation: the most modern of its kind .

- ↑ imo.org , Annex I No. 10 .