Oil production

As oil production is prospecting ( prospecting ) and opening up ( exploration ) of oil deposits and the promotion of oil from oil reservoirs ( recovery ), respectively.

Central terms

Deposits and minability

General

The targeted search for oil and gas deposits is known as prospecting . The focus of the search is primarily on deposits that are economically viable to mine . Such deposits are in the oil and raw material geology for delimiting non-viable deposits as reservoirs or oil fields designated ( "oilfield" alternatively referred to the area on the surface over a reservoir or more closely spaced deposits in which a larger number of Oil production is concentrated). With regard to the geology of the reservoirs and the viscosity of the oil and thus ultimately the effort required for oil productionConventional deposits are differentiated from unconventional deposits (see also → Oil production ).

Conventional storage facilities

Conventional deposits are located in relatively highly porous and permeable reservoir rocks and contain relatively thin oil. They can be managed comparatively inexpensively with conventional conveyor technology. The largest or most productive oil fields on earth are grouped together under the name of Giant Fields . The largest 500 oil fields, i.e. H. 1% of all known oil fields, supplied 60% of all oil produced in 2005, with the largest 20 supplying around 25% of all oil.

Unconventional storage facilities

Unconventional deposits are located in rather low-porosity and impermeable rocks or contain rather tough, bitumen-like oil, so that extraction can only take place with increased technical and energetic expenditure.

Whether or not oil production from a deposit is worthwhile or not always depends on the market price (see below) and the state of exploration and production technology. The extraction of many well-known unconventional deposits ( oil sands , heavy oil , "shale oil") only became economically viable in the first decade of the 21st century and experienced a real boom in North America. The fall in oil prices in the wake of the global economic crisis in the following decade, however, slowed down the expansion of unconventional production somewhat.

Recovery rate, delivery rate and maximum funding

The so-called yield rate refers to an oilfield real taken or removable share of the total in the deposit existing petroleum (the latter oil in place called). Thanks to better technology and methods, it was possible to increase this from 22% in 1980 to the best values of around 60% today. The most important variable for assessing the productivity of an oil field is the production rate , which indicates the production rate per time . The oil production maximumis the maximum production rate that an oil field can achieve in the course of its management. As a rule, the delivery rate rises very quickly until the delivery maximum is reached and then it falls again relatively slowly and more or less continuously. Both the recovery rate and the production rate are extremely dependent on the type of deposit. In conventional reservoirs, it is possible that the oil is driven through the reservoir rock to the borehole and to the surface at a very high rate solely by the local pressure (controllable by pipelines and built-in valves). Despite special, complex extraction methods, unconventional deposits have rather low extraction rates.

In offshore production , the very cost-intensive management of oil fields at sea, the highest possible production rate is more important than on land, where running costs are lower. Mature onshore fields (as they exist in oil production in Germany ) usually have a broad production maximum and a long production decrease phase, whereas offshore-stressed oil producing countries such as Norway have very narrow production maximums and short production decrease phases.

Demand, consumption and price

Cartels of the oil producers try to control the supply on the oil market and thus the price with their individual production rates . Together with the demand for oil by all oil consumers, this results in the oil price traditionally traded in dollars on the world market , which has been negotiated on commodity exchanges since 1869 and is also subject to speculative influences. The prices and availability of end products such as fuels and petrochemical products are also influenced by the costs incurred in oil refining as well as political factors such as B. dependent on mineral oil tax .

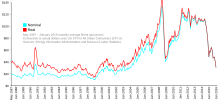

Static reach

Due to increasing demand and the corresponding increase in price as well as technical progress, the amount that is officially designated as globally recoverable oil reserves has increased more or less continuously since the beginning of the industrial age . This dynamic is particularly clear in the relationship between reserves and annual consumption, the so-called static range of oil. According to the latest figures from the BP group, the static range fluctuated between 40 and 50 years for about 25 years (1985-2010), despite the steadily increasing consumption, which is why one speaks of “ petroleum constant ” in this context . In the meantime, however, it has risen to over 50 years.

"Upstream" and "Downstream"

Activities in the oil and gas industry are divided into upstream and downstream . Downstream takes place closer to the consumer (e.g. refining crude oil into petrochemical products, distribution, marketing, etc.), while exploration and production take place upstream .

Phases of oil production

The extraction of crude oil from a conventional deposit takes place in several phases.

Prospecting

The first phase consists of tracking down oil deposits , known as prospecting . It is a combined task for geology and applied geophysics .

In the early days of oil production, people had to rely on signs on the earth's surface that indicated the presence of oil. For example, small amounts of crude oil are constantly escaping from shallow deposits. One example of this is the St. Quirins spring near Bad Wiessee am Tegernsee , which has been known since the 15th century but has now dried up , from which crude oil leaked for centuries and was primarily used as a medicinal product . The occurrence of bitumen is also an indication of hydrocarbon deposits.

The search for deep-lying oil deposits was previously carried out through a detailed analysis of the geological conditions of a region ( geological mapping ). As a result, test bores were then drilled at selected locations . Important information about pore size and shape in the rocks can be obtained with field gradient NMR methods.

Over time, elaborate test methods have been developed that enable a representation of the soil stratification. The most widespread method today is reflection seismics . In doing so, vibrations are generated on the earth's surface by large vibrator masses (less often by detonation), the signals of which are reflected on the different layers of soil are received and recorded via geophones . Layer profiles can be calculated from the transit times and characteristics of the reflected signals .

Today in Europe the vibroseis procedure is used in around two thirds of all cases . Groups of usually three to five special vehicles that transmit vibrations of a defined frequency into the ground via a type of vibrating plate are used to travel a measuring section . Geophones are arranged in groups along this profile to receive the reflected signals. The systematic driving of an area with crossing measuring sections allows the calculation of a three-dimensional model of the soil stratification.

Development of oil deposits

If the oil deposit is close to the earth's surface (so-called oil sands ), the oil can be extracted in open-cast mining (example: the Athabasca oil sands in Alberta , Canada). At the beginning of crude oil use was in some places in the pit operation produced, for example in Wietze, west of Celle (Lower Saxony). Crude oil is extracted from deeper reservoirs through probes that are drilled to the reservoir. Deposits in the marine area are from oil rigsdeveloped and exploited, which enable drilling and extraction in the middle of the sea. The drilling platforms used for development will later be partially replaced by production platforms . Hollow bits are used for drilling so that the cuttings produced can be transported out of the borehole. The drilling tool consists of steel tubes that can be screwed together to form an increasingly longer pipe string, the drill string. At the lower end is the actual drilling tool, the so-called drill bitwith the drill collar attached above. The drill bit usually has three toothed tapered rollers which are arranged at an angle to one another. Such chisels are used for drilling soft and moderately hard rock. Other designs have no moving parts, but are set with diamonds , cutting ceramics or carbide for drilling harder rocks .

To change the drill bit, the entire rod must be pulled out of the drill hole that has already been drilled. The service life of a drill bit can only be a few hours in extreme situations. Another not uncommon situation is the breakage of the drill bit. In this case, an attempt is first made to grasp the broken chisel with a gripping tool inserted into the bore. If this does not succeed, a new hole must be drilled a few meters above the broken tool to bypass the damaged area.

Most of the time, the entire drill string and thus also the drill bit is rotated by a device above ground ( rotary drilling method ), at about 100 revolutions per minute in a clockwise direction . In earlier drilling rigs, the drill string was rotated using a turntable, while new rigs mostly have a top drive on the rig's pulley system.

The drill bit has a larger diameter than the pipe string, so that a cavity is created around the pipe (so-called annulus), which is lined with a steel pipe to prevent it from collapsing ("casing").

In order to convey the cuttings out and to dissipate the frictional heat generated during drilling , a drilling fluid is pressed through the drill pipe, which emerges at the drill bit and is pushed up again in the annular space together with the cuttings. The drilling fluid must have a high specific weight and a high viscosity so that it can be pressed in through the hollow drill rod and pressed out again through the annular space and so that the cuttings are carried along. It consists of water, which includes dissolved polymers and suspended barite- Contains flour. Sometimes the drilling fluid is also used to drive a motor directly above the drill bit so that only the drill bit is rotated and not the entire drill string.

So that the individual tubes of the drill string can be handled, a derrick is erected above the borehole, in which the device for rotating the drill string by means of a motor is also located.

If the circumstances so require, it is also possible to drill in wide arcs so that a deposit can also be developed from the side (see directional drilling ) , for example in the case of deposits under populated, difficult terrain that is to be protected or used for military purposes.

If a borehole is "successful", the borehole is cased , usually double-walled. The pipes are firmly cemented to the rock . The pipe wall is perforated at the lower end of the borehole in order to create a connection to the reservoir. This provides a production probe through which crude oil can be produced in various ways (see below). First, production tests are carried out to determine the productivity of the deposit. In quite a few cases, after initially high productivity, a rapid dilution becomes apparent, so that a well has to be abandoned after a few weeks or months.

The borehole must be cleared at regular intervals in order to maintain, improve or restore the production capacity . For example, deposits are removed, the feed pump renewed, the perforation cleaned or a pipe section replaced.

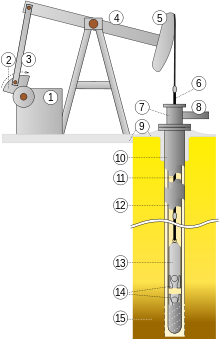

advancement

1. Drive motor

2. Counterweight

3. Connecting rod

4. Balancer

5. Horsehead

6. Piston rod

7. Seal as part of the eruption cross

8. Pipeline

9. Concrete backfilling of the borehole

10. Outer borehole casing

11. Pump rods

12. Inner borehole casing

13 Deep pump

14. Pump valves

15. Oil-bearing rock layer

In the course of the exploitation of the reservoir, the proportion of water in the material to be conveyed increases; later, as a rule, more water than oil is extracted, whereby extraction is considered to be profitable even with a water content of significantly more than 90%. Depending on the size of an oil well, it may take decades for production rates to decrease, but on average it is around 40 years. The discovery is followed by development; for this purpose, the oil field, which is usually under high pressure, is tapped via several production probes.

Primary funding

Primary production is the production phase in which the pressure in the reservoir is high enough, without artificial measures, to extract crude oil from it, be it by pressing out with the help of a naturally existing overpressure (reservoir pressure ) or by pumping.

At greater depths, the crude oil is under the pressure of the overburdening layers of earth and possibly the associated natural gas and is pressed out of the borehole after drilling, as it is lighter than water and the surrounding rock. When the reservoir is first drilled, the pressurized oil must therefore be prevented from escaping with the aid of a blowout preventer , which is located at the upper end of the drill string. At the beginning you can use the Artesian Well principlelarge quantities of especially light oil are extracted (primary or eruptive extraction). However, after a production of 10–15%, the pressure alone is no longer sufficient to transport the oil to the earth's surface. If the reservoir pressure decreases , the oil has to be extracted with technical aids - mostly deep pumps .

The image of most oil fields is dominated by rod pumps - also known as "horse head pumps" because of their appearance. The actual pump mechanism - a piston and a pipe closure with a check valve each - is located in a separate pipe string in the borehole near the oil-bearing layer. The piston is set in a continuous up and down movement by means of a screwable rod from a pump bracket located on the earth's surface via two parallel steel cables. The cycle is usually 2½ to 12 strokes per minute. However, rod pumps can only be used economically for depths up to a little more than 2500 meters, otherwise the weight of the column of liquid to be lifted would be too high.

Instead of a pump piston, an eccentric screw pump can also be installed in the borehole, which is operated on the surface of the earth via a screwable rod with a drive head. In the case of bores with a curved course, the eccentric screw pump can also be driven by an electric motor attached directly to the pump.

A hydraulic drive is ideal for bores with a curved course. The actual pump mechanism - like a piston with non-return valves in the rod-type deep pump - is actuated by means of a hydraulic cylinder located directly above the piston, which is connected to a hydraulic pump connected to the earth's surface via its own pipeline. The oil extracted serves as the operating medium for the entire pump system.

Gas lifts (see mammoth pumps ) are often used to extract oil from deeper deposits . The accompanying gas that comes to the surface during oil production is separated, dried and pressed into the cavity between the production line and the casing. The gas flows from the annular space into the delivery line via valves. Due to the effect of the rising gas bubbles, the oil-water mixture is carried upwards in the delivery line - similar to a mineral water bottle, in which the carbon dioxide causes the liquid to foam over.

Depending on the formation and pressure of the reservoir, the primary production can achieve a deoiling of 5% ( heavy oil ) to 50%. In Germany, an average of 18% of the oil can be primarily extracted.

Secondary funding

If the reservoir pressure drops in the course of oil production, it can be increased by (re) injecting water or natural gas into the reservoir. This is done through so-called Einpressonden (ger .: injection wells ) drilled for either new drilling into the deposit or existing, older holes are used. This funding phase is called secondary funding. By pressing in water, 30–40%, according to other sources up to 60% of the total available oil (“ oil in place") Are funded. The remaining, increasingly viscous and dense oil makes it difficult to continue the constant production. In Germany, the use of secondary processes can increase the oil removal rate to an average of 32%. The remainder cannot be removed from the solids of the storage rock using the conveying methods described.

The permeability of the storage rock can be increased by injecting acids, which dissolves components of the storage rock, especially carbonates .

Tertiary education

Through special measures, additional crude oil can be extracted from deposits in addition to primary and secondary production.

These measures include:

- Thermal process : Forcing in hot water or superheated steam ( steam flooding) or burning part of the crude oil in the deposit

- Injection of N 2 ( nitrogen ) (nitrogen flooding)

- Injection of CO 2 ( carbon dioxide ), which increases the reservoir pressure and dissolves in the oil, thereby reducing its viscosity (CO 2 flooding)

- Injection of light petrol or liquid gas, which also reduce the viscosity of the oil

- Injection of aqueous solutions of substances that increase viscosity (organic polymers ), whereby the oil is better detached from the solids (polymer flooding)

- Injection of aqueous solutions of surface-active substances ( surfactants ), which accumulate at the oil / solid and oil / water interfaces, thus detaching the oil from the solid and finely dividing it in the water, emulsifying it (surfactant flooding)

- Injection of selected microorganisms, mostly together with nutrients. The microorganisms produce metabolic products in the deposit ( in situ ), which have already been mentioned in this list as auxiliary substances that increase the oil yield: carbon dioxide, solvents (ethanol, 2-propanol, n-butanol, 2,3-butanediol, acetone), surfactants , Polymers, including organic acids (formic acid, acetic acid, lactic acid, succinic acid) that increase the permeability of carbonate storage rocks by dissolving carbonates . These measures are called Microbial Enhanced Oil Recovery (English for microbially increased oil yield), abbreviated MEOR.

The tertiary processes are sometimes also combined. However, a considerable amount of the remainder of the crude oil has not yet been able to be extracted from the deposit by any method. In Germany the de-oiling of a deposit is mostly below 50%, in individual cases up to 60%. With the deposits in the North Sea with its low-density oil, over 70% of the total oil can be extracted (oil in place) .

Offshore promotion

Oil production from deposits located under water ("offshore extraction") presents particular difficulties. In order to develop the deposit , drilling platforms that stand on the bottom of the water or that float above must be set up, from which drilling can be carried out and production can take place later. Directional drilling is advantageous here because it allows a larger area to be developed from a drilling platform. After the drilling work has been completed, a pure production platform can also be used. Example: Thistle Alpha .

Background of deep sea drilling

The amount of oil that can be extracted from conventional oil wells on land and in shallow water is limited. It can be increased by technical means (for example by pumping steam up to 340 degrees Celsius into the ground in order to liquefy viscous crude oils), which is worthwhile if the oil prices are sufficiently high. Since the beginning of the 1980s, the amount of newly discovered oil deposits has been declining in contrast to the continuously increasing consumption, which is why many experts expect a decline in oil production ( global oil production maximum ) within the next few years. Since the large, easily accessible and exploitable oil deposits were found and developed first and many states, e.g. B. OPECrestrict access to their oil reserves, it is therefore becoming increasingly difficult and costly for international oil companies that do not operate on national territory to develop new reserves.

Together with rising oil prices, these factors make it interesting for international, non-governmental oil companies to extract crude oil from great depths of water ( deep wells ) at a comparatively high level of effort and technical risks , and to extract unconventional oil sources that are highly controversial due to the serious ecological consequences of their use (e.g. the Athabasca oil sands ).

In addition, the occurrence of the global maximum oil production (peak oil) would presumably result in sharply rising prices for oil. The greater technical difficulties, together with the high costs for safety measures, also lead to significantly higher risks, because accidents at such great depth are fundamentally very difficult to control due to a lack of experience and extreme conditions. The effort and risks increase disproportionately in relation to the amount conveyed. For example , the estimated size of the oil field that the Deepwater Horizon platform was supposed to develop, which wrecked in April 2010 and thus caused the largest oil spill to date in the USA, only roughly corresponds to the global demand of one day.

Offshore production near ecologically sensitive coastal regions is the subject of heated political discussions in the USA. In addition to the objective of environmental protection, the government and industries heavily dependent on oil also have an interest in reducing their growing dependence on the OPEC states . In order to reach a consensus for the climate protection law , US President Obama granted eight billion US dollars for the construction of a nuclear power plant in February 2010 and in March 2010 announced the approval of previously suspended oil drilling off the coasts. The amount of additional oil produced in offshore wells off the coast in the next few years would be 0.2 million barrels per day (mbpd) are just enough to offset the growth in US consumption, which totaled 16 mbpd, but not the ongoing decline in domestic conventional oil production, which has to be offset by increasing imports.

60 billion barrels of oil are believed to be off the coast of Brazil. The Brazilian oil production company Petrobras already extracts 25 percent from all sources worldwide that are deeper than 500 meters below sea level. Brazilian production is to be increased to 2.3 million barrels a day by 2020, mainly from deep-sea sources.

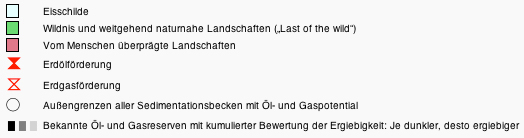

Location of oil and gas deposits on earth

History of oil production and future oil production

story

In Europe, at the end of the 15th century, crude oil was being extracted from the northern Vosges near the Palatinate , at Pechelbronn ( Pechelbronn layers ), initially primarily for medical purposes (e.g. ointment ) and for use as a lubricant . In 1734 the Pechelbronn oil was the subject of a doctoral thesis , in 1813 the world's first drilling rig was erected in the forest between Pechelbronn and Kutzenhausen , on two wooden posts (replica today an excursion destination), about 100 years before industrial oil production in the USA . From 1917 it was here toodug underground for petroleum lentils in mine tunnels.

The first underground mining oil production took place in 1854 in Bóbrka near Krosno ( Poland ); There are only three places around the world where crude oil is mined at greater depths: In Pechelbronn (Alsace) the total length of the corresponding tunnels is around 460 kilometers.

Large-scale exploitation of the oil deposits began in the 19th century. It was already known that when drilling for water and salt, oil occasionally seeped into the boreholes. The first wells were carried out in 1844 by the Russian engineer FN Semjonow with a percussion drilling system in the Bibi-Eibat oil field near Baku , which is still in use today . The report on this world's first industrial oil well remained in the bureaucracy of the tsarist empire for several years and only reached the tsar's court in a report dated July 14, 1848 .

The drilling for oil that Edwin L. Drake carried out on August 27, 1859 at Oil Creek in Titusville , Pennsylvania , became world famous . Drake was drilling on behalf of the American industrialist George H. Bissell and came across the first major oil deposit at a depth of just 21 meters.

In Saudi Arabia , the "black gold" was first discovered near the city of Dammam on March 4, 1938, after a series of unsuccessful explorations by the US company Standard Oil of California .

For oil production in Germany , more precisely in West Germany , the year 1950 represented a turning point in oil production after the war. The Emsland was discovered as an oil region and in 1951 contributed significantly to German oil production. The GDR, on the other hand, had less luck with prospecting.

future

In order to continue to produce oil, new oil wells must be discovered. The argument for a further increase in oil production is the rising oil price, which offers the opportunity to explore areas that have not been intensively investigated (e.g. Siberia) and to exploit unconventional, so far not economically viable deposits. These include oil sands , especially the large deposits in Alberta in Canada, oil shale , deep-sea drilling , Siberia or Alaska exploration, bitumen and other deposits.

While in the 1970s private western oil companies still controlled almost half of the world's oil production, this proportion fell to less than 15% in 2008. Some experts do not believe that there is a lack of oil, that there is a crisis in the access to advanced technology of the oil multinationals and, conversely, that the technically innovative multinationals are reluctant to get involved in the state-controlled oil-producing countries in view of the lack of investment security.

New discoveries of large oil and gas fields are according to Mann et al. (2007) are to be expected especially in the area of the passive continental margins and rift systems, especially in deep water basins. Also in the vicinity of existing “elephants”, such as the fields with more than 500 million barrels(more than about 80 million cubic meters, since 1 oil barrel = 159 liters), further discoveries are to be expected, which are significant by today's standards, but only make up about an eighth of the findings of the 1960s in their annual volume . More significant gas fields than oil fields are expected in the future. The infrastructure for the offshore production of crude oil is increasingly being concentrated on large floating platforms suitable for the oceans, at or on which the solid, gas and water separation, the intermediate storage and the loading of the crude oil on tankers take place from widely distributed boreholes. The use of such capital-intensive large-scale technology is economical from an oil price of $ 80 per barrel.

Between 2003 and 2011 there was a significant increase in personnel in the oil and gas industry, which instead of the forecast 200,000 has more than 440,000 employees. Predictions of decline have proven inaccurate.

Ecological consequences of oil production

The development of oil wells is not only associated with economic gains. Even with conventional deposits, development and extraction cause detrimental interventions in the ecosystem, especially in the case of offshore plants. In addition, the flaring of associated petroleum gas (around 140 billion cubic meters annually), which is still common under certain circumstances, damages the environment through the emission of cancer-causing soot particles, carbon dioxide, sulfur dioxide and nitrogen oxides.

Fires in oil wells, for example as a result of sabotage as in the Second Gulf War or as a result of accidents, also cause considerable environmental damage. Leaks in the pipelines of the oil and gas fields in Western Siberia have contaminated the soil and entire river systems for decades, with considerable negative effects on the reindeer industry and the health of the indigenous Mansen people who live there . In 2006, the oil spill from pipelines in the Prudhoe Bay oil field in Alaska caused a stir. In the Niger Delta , where the Shell group holds 40% stake in the NigerianIn addition to leakages (and fires) caused by wear, there are also those caused by politically motivated attacks and oil theft.

Furthermore, the strong increase in production from unconventional deposits since 2000 has led to a general increase in environmental pollution. A special circumstance here is that sparsely populated regions are often affected, in which no oil was previously produced and which were otherwise not characterized by industry. Such a region is then not only affected by the general increase in the number of drilling sites and the associated pollutant emissions, but also by the construction of new roads and the resulting fragmentation of previously connected habitats (see also Potential environmental damage and dangers from fracking). But the expansion of conventional subsidies can also endanger largely untouched ecosystems. A current (2016) example of such a development is the Ishpingo-Tambococha-Tiputini (ITT) oil field, which is located in the Yasuní National Park in the so-called Oriente Foreland Basin in eastern Ecuador.

In addition, environmental organizations such as B. Greenpeace that the prospect of much longer oil reserves could significantly reduce the motivation of those responsible in business and politics to quickly implement an energy transition (towards renewable energies and away from coal, oil, gas and nuclear power). This harbors the risk that carbon dioxide emissions could be reduced to a much lesser extent than stipulated in the Kyoto Protocol , or that emissions might even increase. Serious consequences for the world climate would then be inevitable.

Environmental damage as a result of military operations

Crude oil is a vital resource for the war effort, as it is a universal raw material and, not least, is used for the production of vehicle and aircraft fuels. As a result, oil wells, tankers, pipelines, and refineries are preferred targets. Large amounts of crude oil can be burned or released into the environment unburned. During the Second Gulf War , when the Iraqis withdrew from Kuwait in 1991, 700 of the 900 Kuwaiti oil wells were set on fire, burning up to three million barrels of crude oil a day. In addition, large amounts of crude oil escaped from the conveyor systems. The New York Times rated the fires as one of the "most serious air pollution disasters" on earth.

Environmental damage from deep sea drilling

The risks of deep-sea drilling are hardly controllable , especially in the event of a blowout , as various oil disasters show.

In 1979, after an accident, the Mexican PEMEX oil well Ixtoc I off Campeche leaked uncontrolled oil into the Gulf of Mexico for over nine months. Until the oil spill in the Persian Gulf in 1991, the accident was considered the largest oil spill . However, Ixtoc I was not a deep-sea well. The drilling platform was in shallow water.

In 2001, the Petrobras 36 oil platform , the world's largest platform of its kind at the time , sank off Brazil . The oil slick released by the accident was driven out into the open sea.

The oil spill in the Gulf of Mexico , triggered by the explosion and sinking of the Deepwater Horizon oil rig on April 22, 2010, released more oil than previous tanker disasters . The often cited assessment as the largest environmental disaster in the USA is doubtful, the effects of the Dust Bowl , for example, were much more serious. The ecological consequences for the marine ecosystems and the coastal regions from the Mississippi Delta to Florida are serious, but limited in time.

Radioactive waste

In the context of production, compared to the amount of oil produced, small amounts (0.1%) of natural radioactive materials ( NORM - Naturally Occurring radioactive material) are produced. The main problem here is the long-lived radium -226 (1600 years half-life), which is deposited in the form of radium sulfate and radium carbonate on the walls of the conveyor equipment. The activity of the waste is 0.1 or 15,000 Becquerel (Bq)very low per gram. In countries with larger amounts of oil or gas produced, significantly more waste is generated than in Germany, but in no country does an independent, continuous and seamless recording and monitoring of residues from oil and gas production exist. The industry deals with the material differently: In Kazakhstan , according to reports by the WDR, large areas of land are contaminated by this waste, in Great Britain the radioactive residues are discharged into the North Sea.

literature

- Friedrich P. Springer: From Agricola's “pomps” in mining, “which pulls the water through the wind”, to the rod-type deep pumps in oil production . In: petroleum, natural gas, coal . Year 123, issue 10/2007, p. 380.

Web links

- Annual review "Petroleum and natural gas in the Federal Republic of Germany" , each published in the journal Erdöl Erdgas Kohlen (list with article download links from 2002 on the LBEG website )

- Black gold, black plague , series on the effects of global oil production ( Deutschlandfunk 2010)

Individual evidence

- ^ Keyword field or oil field in the Schlumberger Oilfield Glossary .

- ↑ Mikael Höök, Robert Hirsch, Kjell Aleklett: Giant oil field decline rates and their influence on world oil production. Energy Policy . Vol. 37, No. 6, 2009, pp. 2262–2272, doi : 10.1016 / j.enpol.2009.02.020 (alternative download of the peer-reviewed, non-proofread manuscript: PDF 716 kB).

- ↑ bp.com: Statistical Review of World Energy 2013. Historical Data Workbook ( Excel sheet 1.5 MB).

- ↑ Fear of the Second Half, Die Zeit, No. 17, 2006

- ↑ Spiegel interview: “Part of the profit is undeserved”, Der Spiegel (24/2006), (English) .

- ↑ It's going to be incredibly expensive. Interview with Klaus Bitzer ( ASPO ) in the Frankenpost from May 26, 2010

- ↑ Der Höllentrip , article by Philip Bethge, Alexander Jung, Nils Klawitter and Renate Nimtz-Köster, Der Spiegel / Spiegel Online from May 12, 2010.

- ↑ BP cannot stop oil flow after all. Zeit Online from May 28, 2010.

- ↑ ZDF ( online ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. ).

- ↑ Matthias Brake: The price for the hunger for oil , telepolis from May 4, 2010.

- ↑ Frankfurter Rundschau, June 1, 2010, p. 16

- ^ A b Badische Zeitung: Memories of a time when oil was drilled in Alsace - Alsace - Badische Zeitung . ( badische-zeitung.de [accessed on April 8, 2018]).

- ↑ Maugeri, Leonardo (2004) Oil - False Alarm (PDF file; 292 kB). in: Science.

- ↑ a b [1] As Oil Giants Lose Influence, Supply Drops By JAD MOUAWAD. IN NYT . August 18, 2008.

- ↑ P. Mann, M. Horn, I. Cross. Archived copy ( memento of the original dated February 26, 2009 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. Emerging Trends from 69 Giant Oil and Gas Fields Discovered from 2000–2006 , April 2, 2007, Annual Meeting of the American Association of Petroleum Geologists.

- ↑ a b Christian Schubert in FAZ.net from November 23, 2011, Oil platform off Angola - A technical monster for 9 billion dollars, Total has inaugurated the largest floating oil platform in the world off the coast of Angola. .

- ^ The Non-Green Jobs Boom Forget 'clean energy.' Oil and gas are boosting US employment. WS Journal, November 26, 2011.

- ↑ Peggy Schulz, Verena Leckebusch, Jürgen Messner, Harald Andruleit: Use instead of flaring associated petroleum gas - opportunities and challenges for development and greenhouse gas reduction. Federal Institute for Geosciences and Natural Resources (BGR), Hanover 2013 ( PDF 3.25 MB).

- ↑ Susanne Donner: Natural gas - blown in the wind. In: Spiegel Online , September 22, 2012, accessed January 7, 2017.

- ↑ Background text on oil and gas production in Western Siberia. Website of the Society for Threatened Peoples, June 30, 2005, accessed on March 5, 2017.

- ↑ The "forgotten oil spill" in the Niger Delta. ( Memento from June 15, 2010 in the Internet Archive ) tagesschau.de, June 12, 2010.

- ↑ Ecuador begins oil production in Yasuní National Park. Zeit Online, September 8, 2016, accessed January 8, 2017.

- ↑ For the geology of the region see z. BP Baby, M. Rivadeneira, R. Barragán, F. Christophoul: Thick-skinned tectonics in the Oriente foreland basin of Ecuador. In: M. Nemčok, A. Mora, JW Cosgrove (eds.): Thick-Skin-Dominated Orogens: From Initial Inversion to Full Accretion. Geological Society, London, Special Publications. Vol. 377., 2013, pp. 59-76, doi: 10.1144 / SP377.1 (alternative full text access : ResearchGate ).

- ↑ Dieter Lohmann, Nadja Podbregar: In focus: Natural resources. Looking for raw materials. Springer, Berlin, Heidelberg 2012, pp. 88–89.

- ↑ Environmental disaster Gulf War. WG Friedensforschung (unchanged contribution from telepolis.de from September 16, 2002).

- ↑ quoted in Burning Oil Sources. ( Memento of the original from May 10, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. WhyWar.at

- ↑ Crude oil - danger to the environment, climate, people - the dirty trace of black gold. Information from Greenpeace, accessed January 13, 2014.

- ^ Antonia Juhasz: The Tyranny of Oil: The World's Most Powerful Industry - and What We Must Do to Stop It. , Harper Collins 2008.

- ^ Peter Maass: Oil. The bloody business. , Droemer-Verlag, Munich 2010.

- ^ Thomas Seifert, Klaus Werner: Black Book Oil. A story of greed, war, power and money. Ullstein, 2008.

- ↑ International Atomic Energy Agency (IAEA): Radiation Protection and the Management of Radioactive Waste in the Oil and Gas Industry. Safety Reports Series. No. 34, 2004, online , p. 50 ff.

- ↑ Radiant waste from oil and gas . In: tagesschau.de . December 7, 2009. Archived from the original on December 8, 2009. Retrieved on February 6, 2010.

- ↑ Unknown hazard - radioactive waste from the oil and gas industry . In: Deutschlandfunk . February 5, 2010. Retrieved February 6, 2010.