screw

Self-tapping wood screw with cross recess Slotted

screw with metric partial thread

Drywall screw for metal substructures with cross recess and drill point

Two slotted screws with metric full thread

left: corroded round head with hexagon socket

in the middle left: hexagon head, stainless steel

right: an aluminum screw in gold and a titanium screw in blue, both with a conical head and Torx drive

A screw is a cylindrical or slightly conical (conical) body, in the surface of which a thread (a spiral groove) is cut or rolled. In the case of shaft screws (screws with partial thread), only part of the shaft is provided with a thread.

At one of its ends is i. d. Usually a screw head is attached. The force is transmitted to the component to be fastened via the “chin” of the screw head (the lower ring surface). The so-called drive is located at one end of the screw . The drive has a special contour that creates the form fit for the appropriate tool, usually a screwdriver or a wrench with which the screw can be screwed in and out.

Screws headless be as set screw or hanger bolt , respectively. Threads without a drive are called threaded rods , threaded pins or threaded bolts.

Screws differ among other things in their thread and their application.

- Metal or machine screws: The shaft and contour of the thread are cylindrical, i.e. H. they have a constant diameter. You need a suitable mating thread to screw in, for example in a nut or a threaded hole .

-

Self-tapping / self-tapping screws

- Wood screws and chipboard screws have a coarse pointed thread that tapers to a point or ends in a drill head. Modern wood and chipboard screws, like some plastic screws and drywall screws for screwing into plaster, have a deeply cut pointed thread with a large pitch. Screws that are intended to be screwed into pre-drilled holes are also offered without a tip.

- Self-tapping screws as well as drywall screws for screwing into drywall profiles have a fine pointed thread that also tapers to a point or ends in a drill head. They form their mating thread in sheet metal themselves. Even screws with a pointed end can pierce thin sheet metal automatically.

- Self-tapping screws for metal have a slightly conical thread attachment, often with a slightly triangular cross-section. They press their own mating thread when screwing into holes in soft metals such as cast aluminum.

- Self-tapping screws have grooves over part of its length and may have their mating thread when screwing in the metal itself machined cut.

A connection made with a screw can usually be released again.

history

In the first century BC In the Mediterranean area, screw presses made of wood were known for pressing oil and wine fruits. These presses provide early information on the conversion of a rotary movement between screw and nut into a longitudinal movement between the two and the oldest indication of the force amplification ( wedge effect between the threads) by means of screw (and nut).

The first metal screws were occasionally made in Roman antiquity , such as the needle holders on several onion button fibulae from the 4th century , which were not only made of valuable metals, but also technically particularly complex as splendid badges of rank awarded by the Roman emperors . Metal screws were also manufactured in Europe at the beginning of the 15th century, but because of their high price they were also not generally accepted. It was not until industrialization in the 18th century that the inexpensive and mass production and widespread use of screws made possible. Below is a timeline of the modern achievements:

- 1770: The English toolmaker Jesse Ramsden (1735–1800) builds the first satisfactory lathe .

- 1797: The British engineer Henry Maudslay (1771–1831) patented a thread cutting machine.

- 1798: The American David Wilkinson has a similar machine patented in the USA .

- from 1800: manufacture and use of hand screwdrivers .

- 1908: The Canadian Peter Lymburner Robertson (1879–1951) introduces the “ Robertson screw ” with a square socket , which becomes the standard in the United States of America .

- 1930s: The American Henry F. Phillips purchases the Phillips screw patent from JP Thompson (patented 1933) for a cross-head screw head.

- During the Second World War , threads were standardized internationally so that uniform parts could be manufactured and used in all Allied countries .

Screw head shapes

The head shape is differentiated according to the following criteria:

- Edge: round, polygonal (mostly hexagonal, more rarely square) or corrugated (very rarely: knurled head) - see Figures 1 to 4

- Top, edge and bottom in the cut

- Upper side: flat, flat-rounded, spherical (maximum hemispherical), conical - see Figures 5 to 7

- Edge: mostly cylindrical , more rarely slightly conical - see Figures 8 and 9

- Underside: mostly flat, often conical (countersunk head) - see Figures 10 and 11

- Head height

- External dimension (diameter)

As a rule, several of these shape criteria are to be used for a specific screw head. For example, the head of a raised countersunk head screw (Figure 12) usually has a flat-spherical top and a conical bottom.

There are also cases with several forms of only one criterion. The screw head in Figure 13 has two edge shapes: In the lower part it is cylindrical, in the upper part it is hexagonal.

In the top of the head there is i. d. Usually (except for hexagon bolts and the like) a recess for the rotary drive (see below), which further increases the number of its manifestations.

- Edge of the screw head

- Top of the screw head

- Underside of the screw head

Screw head drives

The most common profiles on the screw head for the approach of a screwdriver or wrench are:

- Slotted head

- Outside hexagon

- Outside square

- Inside hexagon ( Allen )

- Inside six-round ( Torx ); with Torx Plus Security with five instead of six tips

- Internal spline ( XZN )

- Inside square ( Robertson , common in North America and in ventilation construction)

- Cross recess ( Phillips and Pozidriv )

length

The length specification for screws generally refers to the part of the screw that can no longer be seen after it has been completely screwed in. This is the length of the thread plus the possibly threadless part of the shaft and the possibly conical transition to the screw head. For screws with a countersunk head, the length is measured from the outer edge of the head, i.e. the point with the largest diameter. The required length results from the intended screw-in depth in the base material or the height of a standard nut plus the thickness of the components to be fastened.

The length of a screw is usually given in millimeters.

Material of the screws

Screws are mostly made of steel. Other materials are titanium , aluminum , brass, plastics and historically wood.

Steel screws are usually given a corrosion protection coating today. In particularly corrosive environments, brass , stainless steel or, if the load is low, plastic screws are used.

The following materials are generally considered:

- Steel, from simple structural steel to stainless steel

- Alloys such as brass and other non-ferrous metal alloys

- Non-ferrous metals such as copper , titanium , aluminum (e.g. in connection with magnesium components)

- plastic

- Composite material (fiber composite materials)

- Wood , today only for decorative purposes

Corrosion protection

Low-corrosion or rust-free screws are made of stainless steel , nickel alloys , copper alloys ( brass ), plastics, occasionally aluminum, titanium or, more recently, of carbon fiber reinforced plastic ("carbon"). Simple steel screws, on the other hand, require a protective coating if they are not used under corrosion-free or low-corrosion conditions. Possible methods of surface treatment are:

- Browning ( blackened screws ), a thin, firmly adhering dark brown to black oxide layer (iron oxide - Fe 3 O 4 ) is created by immersion in a heated, strongly alkaline salt solution. Standard for this: DIN 50938. The corrosion protection achieved is weak, it is more for visual reasons.

- Phosphating , a phosphate layer is chemically or electrochemically generated on the surface. Weak corrosion protection, mainly when there are requirements for adhesion, e.g. B. used by plaster (z. B. drywall screws drywall) or in the automotive industry for engine screws that are anyway not exposed to corrosion such. B. Connecting rod and cylinder head bolts. The good adjustability of the coefficients of friction and the high load capacity of the phosphate layer are advantageously used. Standard for this: EN 12476

- Piece galvanizing : Piece galvanizing screws ("tZn") according to the EN ISO 10684 standard are produced in sizes M8 to M64. They have an average minimum zinc layer thickness of 50 micrometers and are usually used in steel and metal construction. Galvanized screws are protected against corrosion for decades, even when used outdoors.

- Galvanic galvanization : Galvanized screws ("GalZn") in accordance with EN ISO 4042 and EN ISO 2081 are very widespread. B. available in hardware stores. Their commercially available zinc layer thickness is 5 micrometers. For this reason, galvanized screws are only suitable for temporary outdoor use.

- Chromating according to EN ISO 4520, EN ISO 4042). Common are u. a. yellow and black chromated fasteners, both of which contain hexavalent chromium , the use of which is in decline due to the health hazard. Blue passivated screws are a possible alternative .

- Passivate

- Tinning to produce a good soft solder surface (electrical industry)

- Cadmium (discontinued for environmental reasons) (standard on this: EN ISO 2082)

- Zinc flake coating : free of hexavalent chromium (Cr-VI) with high corrosion resistance, no hydrogen embrittlement (standard for this: EN ISO 10683, VDA 235-104)

- Zinc-nickel coating: Cr-VI-free, adjustable coefficient of friction, temperature resistant up to 300 ° C, maximum corrosion protection (> 1000 h according to EN ISO 9227), approved in the automotive industry (see EN ISO 4042, VDA 235-104)

- Sherardizing : Diffusion galvanizing process little known in Europe, corrosion resistance is comparable to that of hot-dip galvanizing, good adhesion.

- Only nickel-plated or brass-plated screws do not offer increased protection against corrosion.

Investigations have shown that corrosion protection layers containing hexavalent chromium - e.g. B. chromated and galvanized layers - can be carcinogenic. In accordance with the EU end-of-life vehicle regulation 2000/53 / EC, all new vehicles from July 1, 2007 must be free of hexavalent chromium (Cr-VI). For this reason, more and more coatings are being converted to zinc flake coatings, for example . In addition to the automotive sector, z. This also affects the electronics industry, for example, which must also switch to Cr-VI-free processes (see RoHS directive).

The corrosion resistance of coatings is often tested using the salt spray test. In this short-term test, coated parts (e.g. screws) are exposed to constant salt spray in a test chamber for a defined number of hours. When evaluating the results of salt spray tests, it should be borne in mind that these rarely match behavior in natural environments.

Further surface treatments, which are used for decoration or better electrical contact in addition to corrosion protection, are silver plating, copper plating, brass coating, chrome plating, nickel plating and gold plating.

Manufacturing

Today there are two main manufacturing processes for the production of head screws:

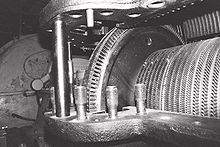

- The cold extrusion process on a multi-stage press for large quantities and diameters up to currently a maximum of M 36 . The starting material is delivered as wire wound on spools and unwound and straightened in the upstream systems . Modern cold extrusion presses work in several stages, i.e. H. in one stroke several steps are successively carried out, for example, blank shear , preforms hexagonal head finished dip , deburring and the threaded part reduce . In the following process, the thread is produced without cutting using a thread rolling machine by rolling the thread groove into the surface of the screw shank (see adjacent figure). The press and rolling machine usually form a unit, the so-called "boltmaker". Depending on the diameter and length of the screws, such systems can achieve production rates of more than 300 pieces per minute.

- The hot pressing process forging on a forging press for small to medium quantities and diameters up to M 200. The starting material is round material in bar form. After cutting to length, the blanks are wholly or partially heated to forging temperature - depending on the material up to 1250 ° C - and preformed in a press. Completion is by machining usually by CNC - Turning made and threading. After forging the raw shape, screws with a higher strength in the thread are produced without cutting on a thread rolling machine.

Smaller numbers of screws and nuts are usually turned from bar stock on lathes . The thread can be cut or rolled. In the case of small diameters, the internal threads are produced with the help of taps and the external threads with cutting dies. These two tools with several cutting edges that cut at the same time are also used for the production of smaller thread diameters by hand. A thread turning chisel is used for large diameters or special threads .

Assembly (tightening process)

There are screws with a diameter of less than half a millimeter for clockworks and also head-high, leg-thick connecting elements on large machines and buildings.

Screw connections can be loosened ; they facilitate the recycling of devices, machines and systems. They make repairs, modifications and dismantling of disused devices easier to separate the components according to type so that they can be reused if necessary. However, this is opposed by the fact that device manufacturers are more and more deliberately making the solvability and thus, for example, repairs more difficult in order to reserve this for workshops. For example, unusual screw heads are selected for which no common connection tool exists.

The screw heads have a connection geometry (slot, hexagon, etc.) for contact with an assembly tool (screwdriver, wrench) with which the tightening torque is transmitted. A torque wrench is used to generate a specific value of the tightening torque . The optimal value is particularly necessary for expansion screw connections . The screws for fastening a steel car rim are also tightened to a certain torque using a torque wrench. The wheel bolts are not expansion bolts , but the surroundings of the rim holes yield elastically, so that self-locking screw connections are created in the same way as with expansion bolts. An additional safeguard against loosening is provided by the frictional forces between the screw and the rim, which are increased due to the conical shape of the contact surface.

Various assembly methods are used in industry:

- torque-controlled tightening, e.g. B. with an electric torque wrench

- torque-angle-controlled tightening, e.g. B. with torque wrench

- Yield limit-controlled tightening, e.g. B. with torque wrench

- hydraulic preloading

The screw should be tightened in such a way that the operating force to be transmitted (e.g. the drive or braking torque of a wheel screw connection) can be safely transmitted via the friction in the connection. If this is not the case and the screw is exposed to transverse forces, there is a risk of unscrewing or the screw breaking.

The VDI guideline VDI 2230-1 "Systematic calculation of highly stressed screw connections - cylindrical single screw connections" deals with the calculation and design of screw connections.

Metallic threaded connections without a specified tightening torque should be protected in a corrosive environment with grease, assembly paste, screw locking agent or sealant in order to make it easier to loosen the connection later. If the tightening torque is specified by the manufacturer, screwing in the screw, which is facilitated by the lubrication, can lead to overstretching of the thread. Here the manufacturer's instructions should be followed or, if necessary, a special, non-lubricating assembly paste should be used. Applying oil, grease or soap to the thread of wood screws makes it easier to screw them in and can prevent the screw from shearing off when overloaded. Screw connections on pipes or containers for pure oxygen must not be greased, as the oxygen can cause the grease to self-ignite.

Ideally, the main elements of a screw connection are made of materials with the same coefficient of thermal expansion in order to avoid alternating mechanical loads due to temperature fluctuations.

For lightweight connections requiring little space, rivets are used instead of screws .

In the case of very large screws, tightening with a torque wrench is no longer possible, so that thermal processes are used, for example. The heated screw is inserted into the through hole of the components to be connected and the nut is screwed on until it comes to rest. When it cools down, the screw contracts, creating the required preload force.

Hand operated screws

- Knurled screws, such as Adjusting screws on machines

- Wing nuts (and wing nuts)

- T-shaped toggle screws .. The toggles can also be designed as a folding handle in confined spaces.

- Screws with ergonomic metal, plastic or wooden handles, for example on screw clamps

- Spindle or upper spindle with handwheel or hand knob, for example on shut- off valves

- Stage drill or theater drills are robust screw with a molded handle by which it can be screwed into the stage floor or scenes quickly. They resemble a powerfully executed nail drill .

Screw locks

Wood screws

Modern processes enable the production of threads that have a significantly larger diameter than the shaft. This reduces the required screw-in torque. For further reduction, the screws of some manufacturers are given short milling ribs at the transition between thread and shaft , which reduce the friction on the shaft by fraying the wood. Please note that the outermost thread diameter is always specified as the diameter of the screws. The shaft can therefore be much slimmer than the specified screw diameter. This is a disadvantage when the shaft is subjected to bending or shearing stress. The latter is especially the case when steel components are attached to wooden elements that are loaded by tensile forces parallel to the wooden surface. For this type of load, screws are available whose shaft is reinforced below the head.

There is a risk of the wood splitting, especially when screwing in screws near the edge of wooden components. The tendency to split is reduced by:

- Pre-drilling - before countersinking the screw, a hole is drilled, approximately the same diameter as the screw shaft. The hole need not reach the full length of the screw.

- Fraying of the wood when screwing in the screw

- Drill head at the tip of the screw

- counter-rotating thread or embossed rings at the tip of the screw

- Milling ribs in the middle of the shaft of the screw

- Milled ribs or milled pockets under the head of countersunk screws

Modern wood screws can usually be screwed into coniferous wood without pre-drilling. A hole should first be drilled near the edge and generally with hardwoods in order to avoid the screw head shearing off due to the increased resistance when screwing in. When using modern wood construction screws, pre-drilling with the following diameters is recommended:

| Outer thread diameter |

Softwood | Hardwood |

|---|---|---|

| 4th | 2.5 | 3 |

| 4.5 | 2.5 | 3.5 |

| 5 | 3 | 3.5 |

| 6th | 4th | 4th |

| 7th | 4th | 5 |

| 8th | 5 | 6th |

| 10 | 6th | 7th |

| 12 | 7th | 8th |

| 14th | 8th | 9 |

Traditionally, when rolling in the thread of wood screws, the result was a thread diameter that roughly corresponded to the diameter of the remaining shaft. To reduce the force required for screwing in, it may be necessary in the case of longer screws to drill a hole in the length and with the diameter of the shaft in addition to or instead of the hole for receiving the thread.

Special designs

- Plank screw, terrace screw (hardwood screw)

- Floor board screws have a particularly narrow head. The head is screwed into sufficiently thick floorboards until it disappears under the wooden surface. The elastic fibers of coniferous wood close together again over the head, so that it can hardly be seen later. In thinner boards and less elastic types of wood, the screw should be tightened by hand over the last millimeters so that the screw head is flush with the wood surface. Even then, he is often hardly to be seen. If the surface is to be sanded off after laying, the screw heads should be countersunk by one or two millimeters accordingly.

- Terrace screws are usually made of stainless steel in order to be able to withstand the weather and the acids contained in some resistant types of wood.

- Hardwood screws also have a smaller head and are often made of stainless steel. Due to the hardness of the wood, the narrow head is sufficient to generate the intended contact pressure. Often the heads are slightly rounded or convex and can have a decorative effect if they are screwed in evenly deep. The transition to the wood is very even if a countersunk hole is made for the screw head with a Forstner bit.

- In addition to the partial thread, plank and terrace screws with fixing thread have a second, shorter thread directly below the head. The short upper thread prevents the plank from moving along the shaft after a possible shrinkage of the wood and causing creaking noises.

Screws with a fixing thread create less pressure between the floor board and the substructure than screws with a normal partial thread. This does not represent a disadvantage with horizontally laid timber, since it is hardly loaded in the horizontal direction. In the event that a strong pressure between the components is desired, screws are also available whose fixing thread has a lower pitch than the main thread. - Adjusting screw (spacer screw, facade screw)

- Some sharp-edged rings are stamped into these screws below the head, which have a sawtooth profile in the longitudinal section. As a result, the rings dig into the wood like barbs. There is usually a smooth screw shaft between the rings and the actual thread. If thin battens, boards, panels or wood-based panels are attached to an uneven substructure with this screw, the screw can be turned back by a few threads after the initial complete screwing in to allow for compensation of the unevenness. The material on top of it is lifted off the ground by the desired amount by the toothed rings.

- Please note the reduced load-bearing capacity of the screws in this application. The clothing material to be fastened may have to be supported separately.

Metal screws

Marking, strength classes

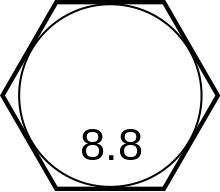

The hexagon and socket head screws from M5 are marked on the screw head, on which the manufacturer's abbreviation and the property class are indicated, with screws made of stainless steel also A2 or A4.

With the full name, all relevant data is given, an example is:

- ISO 4014 - M10 × 60 - 8.8 - A2E

Based on the ISO standard ISO 4014 ( metric ISO thread or standard thread), the designation indicates that it is a hexagon screw with a shank and a nominal diameter of 10 mm, as well as a length of 60 mm and the strength class 8.8 explained below . The screw has a galvanic coating with the coating metal zinc (A), layer thickness 5 μm (2) with a bright gloss level , no color (E); designated according to EN ISO 4042.

- ISO 8765 - M20 × 2 × 60 - 8.8

The pitch 2.0 mm has been added to the identification of this hexagon screw . This is not a standard thread (pitch 2.5 mm), but a fine thread . Additional parameters such as flank and core diameters, stress and core cross-sections, and helix angles can be determined using DIN 13.

The tensile strength R m and the yield point R e can be calculated from the strength class of steel screws . As an example the strength class 8.8:

- R m is calculated by multiplying the first number by 100: 8 N / mm 2 × 100 = 800 N / mm 2 minimum tensile strength,

- R e by multiplying both numbers together and multiplying the result by ten again: (8 × 8) N / mm 2 = 64 N / mm 2 , 64 N / mm 2 × 10 = 640 N / mm 2 minimum yield strength. In this case, at 80% of the tensile strength (this is where the constriction of the screw begins and the maximum transferable force is greatest) the yield point (from here onwards irreversible deformations occur); and the deformation changes from the elastic to the plastic range. If the screw is loaded beyond that, the material is permanently deformed and the screw is permanently extended. A screw stressed in this way has become unusable and must be disposed of.

According to the standard for mechanical and physical properties (EN ISO 898-1), the strength classes 4.6, 5.6, 5.8, 6.8, 8.8, 10.9 and 12.9 are common.

For screw types with reduced load capacity (weak head screws) due to their geometry, a "0" has been placed in front of the strength class since 2009, e.g. B. "08.8" or "010.9". Affected are u. a. Cylinder screws with hexagon socket and low head, flat head screws and countersunk screws.

| Strength class |

Tensile strength R m in N / mm 2 |

Yield strength R e in N / mm 2 |

annotation |

|---|---|---|---|

| 4.6 | 400 | 240 | |

| 5.6 | 500 | 300 | |

| 5.8 | 500 | 400 | |

| 6.8 | 600 | 480 | |

| 8.8 | 800 | 640 | Screws in these strength classes (mainly 10.9) are also available for "high-strength, systematically pre-tensioned screw connections for metal construction" (coll. HV screws) according to EN 14399. |

| 10.9 | 1000 | 900 | |

| 12.9 | 1200 | 1080 |

Class 8.8 is very often used in industry. Classes 4.6, 5.6 and 5.8 are mainly used for bulk goods and low-stress connections. Exceptions are flange connections in pipeline construction, here classes 4.6 and 5.6 are often prescribed due to their high elongation at break (e.g. Pressure Equipment Directive 97/23 / EU or AD 2000-Merkblatt W7: 2008-05). 10.9 and 12.9 are mainly used for calculated and defined prestressed screw connections.

In hardware stores, on the other hand, strength class 4.6 is often offered.

For screws made of stainless steel , the quality and strength class is indicated on the screw head. These are e.g. B. A (for austenitic steel), 1 to 5 (grade) and 50 (soft), 70 (work-hardened) or 80 (high-strength), for example A2-70 or A5-80. Further mechanical properties of stainless screws are described in ISO 3506-1.

Grades A2 in general and A4 for increased corrosion stress are mainly used. These qualities are still called colloquially today with the factory designations “V2A” and “V4A” coined by Krupp . In special cases, screws made from materials with the material numbers 1.4439 or 1.4462 are also used, for example in the offshore area. “Non-rusting” (actually: low-corrosion) screws have a silvery matt sheen and are often (if austenitic) not ferromagnetic .

Mechanics of a screw connection

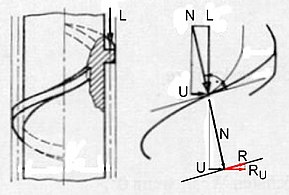

The flanks of the screw thread and the nut thread form a positive connection that acts perpendicular to the flanks . In the direction of the flanks, both parts can be moved against one another or rotated about their common central axis. If the parts are “attracted” to each other, a force is created that acts in the normal direction between the mutually facing flank surfaces ( N , see figure on the right) and, as a result of the friction between the two, a force against the rotation. The normal force N is determined by the longitudinal force L and the circumferential force U generated. In the state of equilibrium after tightening, the role of the necessary circumferential force U is taken over by the (rest) friction (force R ) between the flanks pressed against each other with the normal force N. The component R u of R is always greater than U with the usual thread pitch (shown in an exaggerated steepness in the figure opposite) , and the existing frictional connection against loosening is sufficient. There is self-locking .

The longitudinal force L is calculated as follows:

With

-

- Longitudinal force or pre-tensioning force of the screw

-

- Efficiency of the screw connection, e.g. B. 0.6

-

- length of the wrench

-

- Thread

-

- hand strength

The tightening torque , which is often prescribed for screw connections, is

The longitudinal force L remains stored in the screw connection as an elastic force (preload force) due to a small elastic deformation of the screw shaft and the workpieces involved. The screw shaft is stretched and the workpieces are compressed . The screw connection acts like a tensioned hard spring , which creates the frictional connection. This can be lost through creeping (slow plastic deformation of the materials, especially with plastic). By vibrations may lead to the automatic loosening come, which is why in such cases usually a screw locking ( form-locking against rotation) is necessary.

Only the particularly soft expansion screw connection (with metal screw), which is used, for example, between cylinder head and engine block in combustion engines and does not require additional (form-fitting) screw locking, is a sufficiently long-term secure connection based on the force-fit principle . The shaft of such a screw is extra long to act as a soft spring and make creep ineffective.

The force introduced into the screw shaft via the annular surface under the head and the counterforce introduced via the thread generate tensile stresses in it . Because of the frictional resistance to twisting in the thread, torsional stresses are also generated in the shaft . Shear stress can arise when two parts screwed together move transversely, bending stress when the area under the head (and / or the nut) is not perpendicular to the shaft. The thread represents a notch in the surface, which reduces the load capacity of the shaft in terms of tension, shear and torsion compared to a smooth bolt. In mechanical engineering, VDI guideline 2230 from 2003 provides basic information on dimensioning.

The power transmission on the thread flanks is not evenly distributed over the entire length of the thread in contact:

screw and nut are elastically deformed in opposite directions in normal screw connections. The nut is compressed, the screw shaft is stretched. As a result, both parts take on different thread pitches at low loads, which means that the first gears transmit most of the power (the first gear about a third). As the load increases, the highly loaded thread turns begin to plasticize and the less loaded thread turns take on a higher proportion of the force acting on the screw. At low screw-in depths, the load is evenly distributed over the threads before the thread fails. At high screw-in depths, the screw fails in front of the thread, even before the load has been evenly distributed over the thread turns. Particularly notch-resistant material is used for particularly stressed screw connections and a more even load distribution in the elastic area is achieved by the slightly lower pitch of the screw in the screw-in area.

Special designs

Security screws

To make it difficult for unwanted access, screws with unusual drives are used on the head:

- Hexagon socket TR, hexagon socket with central mandrel

- Pentalobe Screw , by the company Apple from the iPhone 4 and from 2010 successively in MacBooks used

- Torq set , profile with offset cross, widely used in aerospace engineering

- Torx -TR (Tamper Resistant = tamper-proof, Torx with central spike)

- Torx Plus Security, Torx with a central mandrel and five instead of six tips

- Tri-Wing , widely used in aerospace engineering

Since independent manufacturers bring corresponding screwdrivers onto the market after some time, there is always reason to introduce a new, unusual shape.

Screw heads with slots, the left surface of which is inclined, can only be screwed in, but not loosened (example: one-way slot).

Headless screws

there with the designations set screws , studs , screws and threaded bolts . They can have a two-part or a continuous thread. Grub screws and set screws are used, for example, to attach door handles . Threaded bolts and studs are used to connect the cylinder head to the engine block in piston engines .

Device screws

are screws for fastening inserts in electrical installation boxes ("device boxes"), e.g. B. In-wall sockets. They are similar to common wood screws, but often have a slightly finer thread (about 7 threads per cm instead of 5.5). Common device screws have a diameter of 3.2 mm and are available in lengths of up to 40 mm. They are often made of relatively soft metal so that they can easily be shortened with side cutters.

Thread forming screws

Thread-stamping screws

According to DIN 7500, like thread formers, they automatically form a thread in a bore or a blind hole without producing a chip. They are mostly suitable for use in plastically deformable materials up to Brinell hardness 135 HB or tensile strength of Rm = 450 N / mm². An increased and linearly increasing torque is required for screwing in . Screws for use in hard materials are usually tempered on the surface and are therefore more expensive than metric standard screws . Overall, costs can be saved since the thread does not have to be cut separately and there is no need to protect against vibration. In many materials, a formed thread is more durable than a cut thread because it adapts to the screw and, if necessary, work hardening occurs. To make it easier to start the screw, self-tapping screws often have a conical tip, some have a slightly triangular ( trilobular ) profile to reduce friction.

Thread cutting screws

have grooves similar to a tap and can be used in soft materials such as aluminum.

Sheet metal screws

and screws for plastic also form a thread. Screws for soft plastics have a similar rough thread pitch as wood screws. Threads for sheet metal and for hard plastics usually have a pitch that is between that of wood and metal screws. In contrast to wood screws, however, they often do not have a pronounced tip and are rarely made with a countersunk head.

Self-drilling screws

are equipped with two cutting edges at their tips, which are suitable for cutting a hole in workpieces in which the subsequent thread is anchored automatically. Like self-tapping screws, self-drilling screws have a coarse thread because they are mainly suitable for use in thin or soft materials. Sufficient chip evacuation during drilling is not possible in thicker material. In tough materials, threads can only be cut with specialized tools.

Self-drilling screws speed up the work as there is no need to drill a hole beforehand. When joining several workpieces made of tough material, make sure that the length of the drill head is at least equal to the total thickness of the materials to be joined. Otherwise, the threads will grip before the hole is finished, which would force the workpieces apart.

If there is an increased risk of corrosion , screws made of stainless steel should be used. Stainless steel is less easy to harden . Therefore these screws are only suitable for use with aluminum materials.

Screw standards (selection)

Metal screws usually have a metric ISO thread ; The Whitworth thread is still widespread in English-speaking countries .

There are detailed standards for certain screw shapes and head shapes:

- Hexagon head

- Hexagon screw with shank ISO 4014 (old: DIN 931)

- Hexagon screw with thread up to head ISO 4017 (old: DIN 933)

- Hexagon screw with shaft, fine thread 8 × 1 to 100 × 4, ISO 8765 (old: DIN 960)

- Hexagon screw with fine thread 8 × 1 to 100 × 4 to head, ISO 8676 (old: DIN 961)

- Hexagon fitting screw for steel structures (hole clearance of 0.3 mm maximum) DIN 7968

- Hexagon screw for steel structures DIN 7990

- Allen-HV-screw for steel structures ( h ochfeste V Getting Connected ) EN 14399 (old: DIN 6914)

- Hexagon wood screw DIN 571 (Vienna screw)

- Hexagon tapping screw ISO 1479 (old: DIN 7976)

- Square head

- Cylinder head

- Cylinder screw with hexagon socket ISO 4762 (old: DIN 912)

- Cylinder screw with hexagon socket, low head, with key guide DIN 6912

- Cylinder screw with hexagon socket, low head DIN 7984

- Cylinder screw with slot ISO 1207 (old: DIN 84 )

- Cylinder tapping screw with slot ISO 1481 (old: DIN 7971)

- Cylinder screw with hexagon socket with metric fine thread EN ISO 12474

- Cylinder screws with hexalobular socket ISO 14579

- Hexalobular socket head cap screws, low head ISO 14580

- Countersunk head

- Countersunk screw with hexagon socket ISO 10642 (old: DIN 7991)

- Countersunk screw with slot ISO 2009 (old: DIN 963)

- Countersunk wood screw with slot DIN 97

- Countersunk tapping screw with slot ISO 1482 (old: DIN 7972)

- Countersunk screw with cross recess ISO 7046 (old: DIN 965)

- Countersunk wood screw with cross recess DIN 7997

- Countersunk tapping screw with cross recess ISO 7050 (old: DIN 7982)

- Countersunk screw with nose DIN 604 (can only be loosened from the side of the nut)

- Countersunk head screws ISO 14581

- Countersunk head screws with hexalobular socket, high head ISO 14582

- Countersunk tapping screws with hexalobular socket ISO 14586

- Raised countersunk head

- Raised countersunk head screw with slot ISO 2010 (old: DIN 964)

- Raised countersunk wood screw with slot DIN 95

- Raised countersunk tapping screw with slot ISO 1483 (old: DIN 7973)

- Raised countersunk head screw with cross recess ISO 7047 (old: DIN 966)

- Raised countersunk wood screw with cross recess DIN 7995

- Raised countersunk tapping screw with cross recess ISO 7051 (old: DIN 7983)

- Raised countersunk head screws with hexalobular socket ISO 14584

- Raised countersunk head tapping screws with hexalobular socket ISO 14587

- Round head

- Button-head wood screw with slot DIN 96

- Round-head wood screw with cross recess DIN 7996

- Pan head (wider, lower and rounder than cylinder head)

- Pan head tapping screw with cross recess ISO 7049 (old: DIN 7981)

- Hammer head

- Truss head (for decorative and security purposes; can only be loosened from the side of the nut)

- (Usually "round-head screw with square neck DIN 603 coach bolt called" or "Torbandschraube")

-

Grub screws (known colloquially in Germany as grub screw and in Austria as worm screw )

- Grub screw with hexagon socket and conical point ISO 4026 (old: DIN 913)

- Grub screw with hexagon socket and point ISO 4027 (old: DIN 914)

- Grub screw with hexagon socket and pin ISO 4028 (old: DIN 915)

- Grub screw with hexagon socket and cup point ISO 4029 (old: DIN 916)

- Grub screw with slot and tapered point DIN 551

- Grub screw with slot and point DIN 553

- Grub screw with slot and tenon ISO 7435 (old: DIN 417 )

- Grub screw with slot and cup point DIN 438

- Other screws

- Eye bolts DIN 444

- Wing screws DIN 316

- Knurled screws high form DIN 464

- Knurled screws low form DIN 653

- Eye bolts DIN 580

- Locking screw with hexagon socket, tapered thread DIN 906

- Locking screw with external hexagon, tapered thread DIN 909

- Screw plug with collar and hexagon socket, cylindrical thread DIN 908

- Locking screw with collar and external hexagon, heavy-duty design, cylindrical thread DIN 910

- Locking screw with collar and external hexagon, light version, cylindrical thread DIN 7604

- Thread cutting screw DIN 7513

- Stud bolts, screw-in end ~ 2 d DIN 835

- Stud bolts, screw-in end ~ 1 d DIN 938

- Studs, screw-in end ~ 1.25 d DIN 939

- Stud bolts, screw-in end ~ 2.5 d DIN 940

There are still numerous special screws for special purposes for which standard screws cannot be used. They usually differ in their head or thread shape (e.g. ligature or drilling screw with tapping screw thread DIN 7504).

Depending on the head shape, you need the appropriate wrench or screwdriver to turn the screw. A torque wrench should or must be used for many connections .

To prevent a nut from digging into the material when tightening, it should always be used with a washer . With normal-strength screws of strength class 4.6 ( raw screws according to DIN 7990), a washer on the screw head is not necessary. For high-strength screws according to DIN 6914, a washer is also required on the screw head if these are either used as a fitting screw or are preloaded as planned .

See also

- Motion screw

- Bolt (fastening)

- Dowels

- Museum Würth (collection of screws and threads)

- Standard part

- Hanger bolt

- Captive screw

literature

- Gustav Niemann , Hans Winter, Bernd-Robert Höhn: Machine elements - Volume 1: Design and calculation of connections, bearings, shafts . 4th edition. Springer, Munich 2005, ISBN 978-3-540-25125-5 .

- Karl-Heinz Decker, Karlheinz Kabus: Function, design and calculation . Including table volume, 2 volumes. 16th edition. Hanser, Munich 2007, ISBN 978-3-446-40897-5 .

- Hermann Roloff, Wilhelm Matek, Dieter Muhs, Herbert Wittel, Manfred Becker, Dieter Jannasch: machine elements, standardization, calculation, design . Textbook, book of tables, 2 volumes with CD-ROM. 14th edition. Vieweg, Wiesbaden 2000, ISBN 3-528-84028-5 .

- Karl-Heinrich Grote, Jörg Feldhusen : DUBBEL, paperback for mechanical engineering . 23rd edition. Springer, Berlin / Heidelberg 2011, ISBN 978-3-642-17306-6 , pp. G34 ff .

Web links

- Worksheet hot-dip galvanizing F. 5 - Hot-dip galvanized fasteners according to DIN EN ISO 10684 in worksheet hot-dip galvanizing F. 5

- Screw primer - technical reference work about fasteners

- Well-founded 3D animation to illustrate the processes within a screw connection

- Bolt standards - bolts and their drawings

- Data on standards, materials, strengths

- Animations on how thread-forming screws and screwing curves work

- Images of various recesses on screw heads for contact with a screwdriver

- History of the screw

- Screw production from "Die Sendung mit der Maus"

- Collection of exercises on screw connections - Collection of exercises on screw connections at the Anhalt University of Applied Sciences

Individual evidence

- ↑ Barbara Deppert-Lippitz, Reinhold Würth (ed.): The screw between power and splendor: the thread in antiquity . Thorbecke, Sigmaringen 1995, ISBN 3-7995-3628-0 , p. 88–89 (exhibition catalog).

- ↑ ASSY® - The screw for the woodworking and building trade 2016/2017, page 3, In: Wuerth.de; accessed in July 2019

- ↑ ASSY® - The screw for the woodworking and building trade 2016/2017, page 10, In: Wuerth.de; accessed in July 2019

- ↑ ASSY® - The screw for the woodworking and building trade 2016/2017, page 15, In: Wuerth.de; accessed in July 2019

- ↑ DIN EN ISO 14713-1 - Zinc coatings - Guidelines and recommendations for protecting iron and steel structures from corrosion - Part 1: General design principles and corrosion resistance (ISO 14713-1: 2009); German version EN ISO 14713-1: 2009, page 25.

- ↑ Stephan Voigt, M.Eng: 4 screw connections. (PDF) In: www.hs-anhalt.de. SS 23 , accessed on March 22, 2019 .

- ↑ ASSY® - The screw for the woodworking and building trade 2016/2017, page 15, In: Wuerth.de; accessed in July 2019

- ↑ SPAX International GmbH & Co KG: Fixing thread | Everything about screws & Co. February 7, 2017, accessed January 8, 2020 .

- ↑ Application technology__Weak head screws

- ↑ Hans H. Ott: Machine construction , lecture postscript, ETH Zurich, AMIV-Verlag 1978, Volume IIIa, p. 17.

- ↑ Axial load distribution in the thread of a screw connection , p. 8/9.

- ↑ Martin Lork, Andreas Hanke: Load distribution on thread turns of screws under elastic and plastic material behavior. In: https://www.ing-hanke.de/ . Retrieved April 9, 2020 .

- ^ Anonymous Anonymous: Alle Deutsche Schiffsdieselmotoren, at BoD - Books on Demand 2010, 148 pages, page 103

- ↑ Brochure " Trilobular Furchsystem " from Bossard AG.

- ↑ Description of self-drilling screws in the catalog of Adolf Würth GmbH & Co. KG, p. 251 ff.

- ^ Ulrich Krüger: Stahlbau, Part 1 , p. 57, Verlag John Wiley & Sons, February 19, 2008