Tunnel (mining)

A tunnel - in the Saxon region ( Erzgebirge ) a tunnel - is a mine that is driven horizontally or slightly rising into a mountain from the surface of the earth . Tunnels are used in mining as access to less days , the loss of deposits or mining purposes . When a mine for civil engineering goes, the studs are gradually losing importance.

Basics

Tunnels are created in the mining industry in order to perform different tasks. They are similar in structure to the underground routes , but in contrast to these they have a daytime opening. The miner describes tunnels and routes as tunnel- shaped structures. Unlike tunnels , however, tunnels only have one day opening. A tunnel is usually created in mountainous terrain at the lowest possible point in the valley. When exploring deposits, tunnels are initially the only mine workings of the respective mine. A mine consisting of tunnels is called a tunnel mine or a tunnel mine. A tunnel mine can consist of one or more tunnels. Larger pits usually have several tunnels. The most important tunnel in the mine is referred to as the main tunnel in these mines, the miner then calls the other tunnels auxiliary tunnels. In front of the tunnel entrance there was a hut made of boards, the tunnel chew . It was placed so that it coincided lengthways with the hour of the tunnel and covered the tunnel entrance. In the vicinity of the tunnel was the tunnel dump, on which the miners poured the debris .

Construction of a tunnel

Basic concepts

The opening of the day is the tunnel mouth hole , it is usually secured by a vault walling made of stones if the adjacent rock is used. The end of the tunnel or a mine , where work is done on the rock is, Stollort, place or mine face called. This is where the expression “work on site” comes from. The tunnel consists of the ridge (ceiling), the joints (sides) and the tunnel sole , in which, if necessary, there is a recess for the pit water , the so-called Rösche or Saige. The slope of the tunnel (bottom slope) depends on the purpose of the tunnel. If very muddy water has to run off, a greater gradient is required than for tunnels that are only used to convey the route.

Dimensions of the tunnel

The size of the tunnel depends on the task at hand. Agricola figures the height of a tunnel at 1 1 ⁄ 4 laughs and the width at 3 3 ⁄ 4 feet . In some mountain areas, however, these dimensions were not even close to being achieved. The tunnels there were only 0.8 meters high and 0.5 meters wide. In the past, the height of major tunnels was between 1.5 and 2.5 meters. The width of single-lane tunnels was between 0.9 and 2.2 meters. The width of the tunnel must be chosen so that the vehicles used in the tunnel had sufficient space. With two-lane conveyor tunnels, the width was up to 3.5 meters. The length of the studs varied widely. The shortest tunnels were mining tunnels, they were only a few meters long. But also some mine tunnels were only 50 to 80 meters long. The longest tunnels were the hereditary tunnels, they were often several kilometers long.

Securing the tunnel

The tunnel expansion serves to protect against collapse of the tunnel. A tunnel extension can be carried out using various methods. While in strength no expansion is required rock, must in soft rock or squeezing a expansion are introduced Mountains. Door frames , brick-lined vaults and arched arch profiles made from railroad tracks are often used in mining . In newer pits these consist of iron profiles or steel or concrete. This expansion of the tunnel, the carpentry, is called "gripping the tunnel". If the individual components ( stamps and caps ) did not fit together properly during the carpentry work , a small wedge-shaped piece of wood, the tunnel louse, was inserted into the gap. If a tunnel had collapsed, it had to be opened up and cleaned again; this was called lifting the tunnel.

Ventilation

In order for people to be able to stay in a tunnel, it must be ventilated with appropriate means . The miner uses different means and procedures for this. The tunnel is often ventilated by means of natural drafts . Where a natural draft is not sufficient, the weather must be guided into the mine building using technical aids. The fresh weather is normally fed into the tunnels through the tunnel mouth hole. In the mine they are distributed through weather doors . They are distributed further via overheating, in order then to be weathered out of the mine building again as weathering over daytime overheating and light holes . If a tunnel had to be provided with a light hole or a shaft for better ventilation , this was called "loosening the tunnel". Places in the tunnel that were not reached by the weather train were supplied with fresh weather by means of weather wheels . If necessary, additional weather tunnels were built . Under certain weather conditions, the weather also flows in via the light holes and out of the tunnel mouth hole. If there are several light holes, only the light hole closest to the site remains open. The other light holes must be closed to prevent short-circuits in the weather .

Tunnel operator

The operator of a tunnel was called a Stöllner, the operator of an Erbstollner was called an Erbstollner or Erbstollner. The tunnel was usually four Stollenhäuern occupied during a shift. If a Stöllner failed to operate a tunnel with the prescribed number of miners , a new mother could apply to the Bergmeister to clear the tunnel. For the mountain official supervision of the tunnels was one for each district Mountain juror used as Stoll juror. A mark , a step, was carved into the outer limits of the tunnel . When a Stöllner did not want to limit editing his cleats, a neighboring Stöllner was the mining authorities request that the studs verstuft was. After the tunnel had been stepped up by the mining authority, the second Stöllner was able to drive his tunnel further into the field. Investigating how much a tunnel brings in is called weighing the tunnel. If a tunnel site had to be driven forward very quickly, the other Stöllner workers within a union were obliged to provide this Stöllner tunnel aid (tunnel aid) and thereby support it.

business

The operation of a tunnel is linked to the shape of the terrain in which the tunnel is located. A tunnel can be created for various purposes. It can serve to drain the pit water from the deposit, but also for weather management. In civil engineering, it serves to reduce the depth of the water uplift. This was particularly important in early mining, as machines and the energy that powered them were very expensive. A tunnel can be used to collect impact water and forward it to the hydraulic machines. The production can also take place via special tunnels. Mining is also initiated from the tunnels. Depending on the task and purpose, the tunnels are prepared accordingly and labeled accordingly. The form of underground construction using tunnels is known as tunnel construction . If the planned excavation is carried out below the bottom of the tunnel, the miner speaks of underground mining . In this form of mining, the material to be conveyed and the pit water must be lifted , just like in civil engineering .

Types of tunnels

overview

In mining , all horizontal (“ söhligen ”) or almost horizontal connections between the surface of the earth and the deposit are called tunnels. The spelling “Stollen” is common in almost all German-speaking mountain areas , while “Stolln” is often still written in the Saxon areas. Recent research has shown that in Prussian mountain areas ( Duchy of Magdeburg , Bergamt Wettin , Kgl. Preuß. Oberbergamt Halle ) the spelling "Stolln" was common until around 1861/62, introduced by specialists originally from the Ore Mountains. "Stollen" has been written since 1863.

Tunnels are basically divided into mining tunnels and operating tunnels. Digging tunnels, also known as search tunnels, are only used to find the deposit. Operating tunnels are used to operate the mine. Depending on the function for the mine operation, tunnels are divided into genetic tunnels, water solution tunnels, weather tunnels and conveyor tunnels. Tunnels that attack the deposit in the upper depths are referred to as upper tunnels, and the mining tunnels are also counted among these tunnels. Pit tunnels are used to loosen the deposit at any depth. In the Hungarian and Transylvanian salt mines, so-called circumferential tunnels were often built around the shaft to keep the water away from the shaft. A tunnel driven laterally from the main tunnel to a neighboring pit, which is intended to convey fresh weather to the pit or to drain the pit water, is what the miner calls tunnel wings or wing locations .

Erbstollen

Hereditary tunnels are used for drainage and were of particular importance for the tunnel mines. Hereditary tunnels were known as "privileged tunnels". The importance of these tunnels for mining was already emphasized in the Chursächsische Stolln Ordinance from 1749. The main task of the Erbstollen is to loosen the water for as many mines as possible . Since they were used to dissolve water in various mine areas, they were also called district tunnels . The number of dismantled mines varies considerably depending on the tunnel. In addition to the task of draining water, the hereditary tunnels also had the task of weather management for the connected mine buildings . But there were also hereditary tunnels that only had the task of draining the mines located above. Scheduled dismantling was not carried out with hereditary tunnels. The term “Erbstollen” originated from the fact that in a mining area the deepest tunnel usually not only carried away the water from the mine belonging to it, but it also “inherited” the waste water from higher-lying mines.

Customary mining law describes this situation as follows:

"He who brings wind and takes water when it is right, he drives out the colonel with his aedic."

In order to be able to perform these tasks, the tunnel had to be excavated accordingly. To avoid so-called bad weather , a tunnel had to be sufficiently spacious, but the cross-section of the tunnel was not allowed to exceed certain sizes outside the open field. If a Stöllner wanted to expand the tunnel beyond these limits set in the mountain regulations of the respective mountain district , he had to apply for a permit from the mining authority. Since hereditary tunnels were driven for several pit fields , they had to be driven directly in a straight line. They were not allowed to be opened with explosives . Hereditary tunnels always had to have a slight incline from the tunnel mouth hole to the end of the tunnel. The most important thing that an Erbstollen had to bring in was the inheritance. This was a prerequisite for being recognized as an hereditary tunnel. The tunnel had to meet the inherited depth of 7 puddles (approx. 14 meters) and lie a span below the shaft exit of the associated colliery. If a tunnel met these conditions, the Stollner could apply for the tunnel to be granted hereditary rights . Due to the inheritance law, the owner of this inheritance tunnel had the right to levy a fee, the so-called "tunnel tax", from all mines whose water he diverted. The fairness of the tunnels also included the right to claim part of the deposits found underground with the cut of the tunnels . Another privilege of the hereditary tunnels was that, as a rule , they are not quartered unless they are driven into a corridor.

As soon as you wanted to work under the bottom of the tunnel, you needed a new, deeper tunnel. Otherwise hand pumps , horse power or a dewatering system had to be used for drainage. For a water art , a water wheel was installed to drive the pumps. Where the facility was installed underground, so-called "impact water" had to be brought in from a higher level. For this purpose, older, abandoned tunnels were used or new tunnels were built, which only served to transport water. However, if a Stollner was ready to drive a new, deeper tunnel, he could disinherit the old hereditary tunnel after the new tunnel was completed. He had to drive the new tunnel seven puddles below the water slope of the old tunnel. As a result, he achieved a depth gain , which was referred to as inheritance. The right to inheritance was then withdrawn from the old gallery. Hereditary tunnels sometimes reached considerable lengths. The longest hereditary tunnel in the Ruhr area , the Schlebuscher Erbstollen , had a length of 13 km as early as the middle of the 19th century . The Rothschönberger Stolln , which was started in 1844 and reached a length of 50.9 km, was also considered an hereditary gallery during its construction. Since July 1, 1869, no new studs have been awarded.

Water solution tunnel

A water solution studs , also water solution tunnel is applied for dewatering in extensive mine workings. That is why tunnels were often only built for the purpose of drainage. This is particularly important if parts of the deposit located higher up should be mined without dewatering . For water-dissolving tunnels, the principle applies that a tunnel that was once a water-dissolving tunnel will remain so forever. This principle also applies to water solution tunnels that have fallen dry. Often, water solution tunnels are also used to generate energy using hydropower. Water solution tunnels can reach considerable lengths, for example the key tunnel in the Mansfeld mining area is over 31 kilometers long.

With all the adjoining tunnels, the Rothschönberg tunnel in Saxony is to be around 51 km long. If the water solution tunnel was not able to discharge all of the pit water, so-called auxiliary tunnels were driven as secondary tunnels to relieve the main tunnel. These auxiliary tunnels had separate mouth holes. Some water solution tunnels were built with such large cross-sections that the materials could be transported by ship via them.

In the case of water solution tunnels, it can also happen that the pit water , depending on the amount of water, not only fills the florets, but also most of the tunnels. In this case, the term rose is applied to the entire tunnel. Water solution tunnels are not built for a short service life, but are often in use for many decades, sometimes even centuries, depending on the size of the tunnel system. That is why they are lined with a lining made of weatherproof stone material (clinker brick, natural stone). Tunnels excavated in the stable mountains are usually not provided with a brickwork, here only the bottom and the water lake are bricked. At certain intervals, larger holes are dug out of the bottom of the tunnel as sump or mud boxes. The sand and other solid water can settle in these sludge boxes. The sludge boxes are cleaned manually at certain intervals. In contrast to the Erbstollen, the Wasserlösungsstollen does not have an Erbstollen fairness.

The cross-section of a water solution tunnel is determined by the amount of water produced and any secondary tasks that may be required. Depending on the amount of water that accumulates, water solution tunnels have a cross-section between 7 and 10 m². The production of water solution tunnels took several years due to their length. The construction of the tunnels was associated with very high costs. The costs of driving and maintaining the water solution tunnel were usually shared by the mine owners connected to the tunnel. Special ordinances were issued for the maintenance of the water solution tunnels, which those involved had to strictly adhere to. There were also combinations of water solution tunnels and shafts. Large steam engines stood on the shafts with which the pit water was lifted.

Weather tunnel

Weather tunnels have the task of the mine workings to bewettern . They were mainly used in lignite and hard coal mining. Such tunnels were also used for ventilation in ore mines. The special local conditions were a prerequisite for the use of weather tunnels. They are laid out as short as possible and without bends so that the air could pass through without great resistance. To take advantage of the chimney effect, they are raised with a sharp rise towards the exit. Weather tunnels only play a subordinate role, as the use of weather shafts is mostly more advantageous.

Conveyor tunnel

In larger mines, separate conveyor tunnels are used to remove the usable minerals and the mountains. These studs are aligned so that they are as short as possible so that the funding can be made more effective and inexpensive. The tunnel mouth hole is often placed in such a way that it is close to a discharge road. The inclination of conveyor tunnels does not require a special gradient and is either rising or falling depending on the location of the mining tunnels and the starting point of the tunnel. If possible, conveyor tunnels are provided with a gradient in the conveying direction. In the case of conveyor tunnels with a moderate gradient, the conveyor vessels are equipped with brakes so that they can also be braked when conveying manually. Special braking mountains are driven up on very steep slopes . Depending on the size of the mine, several conveyor tunnels are often used. If the conveyor tunnel has an incline in the direction of the tunnel mouth hole, reel systems are used to pull the conveyor vessels .

Further use of the tunnels

During the Second World War , the entrance areas of abandoned mining tunnels were converted into air raid shelter, the so-called air raid shelter . Since there was still a risk of mine gas in these tunnels despite the renovation, firedamp-proof telephones were used for communication. Old disused water solution tunnels are still used today to drain off the accumulating water. They serve as mountain drainage in the affected areas during extreme water events. As relics of the old mining, they still have to be secured, cleaned and technically maintained.

Well-known mining tunnels

- 19-Lachter-tunnel , water solution tunnel of the Upper Harz mining industry

- Bärenberger adit , silver and copper mining near Plettenberg / Sauerland

- Bodelschwingh tunnel , Ibbenbüren, unfinished

- Ernst-August-Stollen , water solution gallery of the Upper Harz mining industry

- Felicitas tunnel , Bad Fredeburg, Hochsauerlandkreis, slate mining

- Fulbert tunnel , water tunnel on the Laacher See

- Marx-Semler-Stolln , Bad Schlema

- Meyersche Stollen , water collection system, Aarau, Switzerland

- Reinhold Forster Erbstollen , show mine, Siegen-Eiserfeld

- Rothschönberger Stolln , water gallery, ore mining Freiberg Revier, Saxony

- Key tunnel, water solution tunnel in the Mansfeld district

- Steinbecker Stollen , Ibbenbüren

- Deep Georg tunnel , water solution tunnel in the Upper Harz

- Deep tunnel (Wasseralfingen) , show mine

Sample gallery

Upper mouth hole of the Reinsberger Rösche

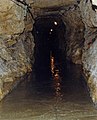

Old tunnel in Siegerland

Pipe tunnel in a dam

Philipstollen in the Sauerland

Tunnel of the Juliane Sophia mine near Schulenberg in the Harz Mountains .

Individual evidence

- ^ A b c Moritz Ferdinand Gaetzschmann: Collection of mining expressions . Craz & Gerlach Publishing House, Freiberg 1859.

- ↑ a b c d e f g B. W. Boki, Gregor Panschin: Bergbaukunde . Kulturfond der DDR (Ed.), Verlag Technik Berlin, Berlin 1952, pp. 32–35, 275.

- ^ A b c d e f g Walter Gantenberg, Rolf Köhling, Wilhelm Spieker: Coal and steel determined their lives. Mining in the south of Wattenscheid. 1st edition. Klartext-Verlag, Essen 2000, ISBN 3-88474-281-7 , pp. 22-23.

- ↑ a b c d e f g h i j Förderverein Rammelsberger Bergbaumuseum (Ed.): Stollen des Rammelsberg . Self-published by the Förderverein, Druck Papierflieger Verlag, Clausthal-Zellerfeld 2007, pp. 7–32.

- ↑ Oscar Hoppe: The mines, processing institutions and smelters, as well as the technical-scientific institutions, welfare institutions pp. in the Upper and Lower Harz . Grosse'sche Buchhandlung, Clausthal 1883, pp. 75, 153–155.

- ↑ a b c d Kurt Pfläging: Stein's journey through the coal mining industry on the Ruhr. 1st edition. Geiger Verlag, Horb am Neckar 1999, ISBN 3-89570-529-2 , pp. 20-22.

- ↑ a b c Alfred Nehls: All wealth lay in the earth . The history of mining in the Oberbergischer Kreis, Verlag Gronenberg, Gummersbach 1993, ISBN 3-88265-180-6 , pp. 22, 30–33.

- ↑ a b c d e Heinrich Veith: German mountain dictionary with documents . Published by Wilhelm Gottlieb Korn, Breslau 1871.

- ↑ a b c d Johann Christoph Stößel (Hrsg.): Mining dictionary. Chemnitz 1778.

- ^ Carl Johann Bernhard Karsten, Heinrich von Dechen (Ed.): Archives for Mineralogy, Geognosy, Mining and Metallurgy . Eleventh volume, printed and published by G. Reimer, Berlin 1838, p. 33.

- ^ A b Walter Bischoff , Heinz Bramann, Westfälische Berggewerkschaftskasse Bochum: The small mining dictionary. 7th edition. Glückauf Verlag, Essen 1988, ISBN 3-7739-0501-7 .

- ^ A b Johann Huebner: Newspaper and Conversations Lexicon . Fourth part: S – Z. 31st edition. Johann Friedrich Gleditsch, Leipzig 1828, pp. 427-428.

- ^ A b Tilo Cramm, Joachim Huske: Miners' language in the Ruhr area . 5th, revised and redesigned edition, Regio-Verlag, Werne 2002, ISBN 3-929158-14-0 .

- ↑ a b c d e f g h i j k l m Georg Haupt: The tunnel systems. Guide for miners and tunnel builders. Published by Julius Springer, Berlin 1884, pp. 3, 5–16.

- ^ Gustav Köhler: Textbook of mining science. 2nd Edition. Published by Wilhelm Engelmann, Leipzig 1887.

- ↑ a b c d e Association for mining interests in the Oberbergamtsiertel Dortmund (ed.): The development of the Lower Rhine-Westphalian hard coal mining in the second half of the 19th century . Part III: galleries - shafts. Springer-Verlag, Berlin / Heidelberg 1903, pp. 9-11.

- ↑ a b c d Gustav Adolf Wüstenfeld: Schlebuscher mining district in weather . Gustav Adolf Wüstenfeld-Verlag, Wetter-Wengern 1983, ISBN 3-922014-05-4 , pp. 25, 28–31.

- ^ A b c d Carl Friedrich Richter: Latest mountain and hut lexicon . Second volume, Kleefeldsche Buchhandlung, Leipzig 1805.

- ^ Jacob Grimm, Wilhelm Grimm: German Dictionary . First volume: A – beer whey. Verlag von S. Hirzel, Leipzig 1854, pp. 667–668.

- ↑ a b c d e f Ferdinand Stamm: Small school of mining. Comprehensive guide to rock and geology, to the search for sites of mining rock and to the teaching of mining and mining. Verlag von Karl Andre, Prague 1853, pp. 154–157.

- ^ Günter Heinrich von Berg: Handbuch des Teutschen Policeyrechts . Publishing house of the Hahn brothers, Hanover 1809.

- ↑ Gottfried Erich Rosenthal: Technological dictionary or alphabetical explanation of all useful mechanical arts, manufactories, factories and craftsmen . Seventh part from O to Torfschoppen S – Z, by Erich Nicolai, Berlin / Stettin 1794, p. 459.

- ^ Heinrich Lottner / Albert Serlo (ed.): Guide to mining science . First volume, published by Julius Springer, Berlin 1869.

- ↑ a b c Kurt Pfläging: The cradle of Ruhr coal mining. 4th edition. Glückauf Verlag, Essen 1987, ISBN 3-7739-0490-8 , p. 64.

- ↑ Joachim Huske: The coal mine in the Ruhr area. 3. Edition. Self-published by the German Mining Museum, Bochum 2006, ISBN 3-937203-24-9 .

- ↑ a b c d e f g Günter Maier: Water-bearing tunnels - a main component of the renovation of old mines. In: 12th Mining Forum . Conference proceedings, Leipzig 2013.

- ↑ a b c d e Kaspar Sternberg: Outlines of the history of mining and the mining legislation of the Kingdom of Bohemia . Second volume, print and paper by Gottlieb Haase Söhne, Prague 1838, pp. 281–283.

- ↑ Karl Heinz Bader, Karl Röttger, Manfred Prante: 250 years of coal mining in the Brandenburg region. A contribution to the history of mining, the mining administration and the city of Bochum. Study publisher Dr. N. Brockmeyer, Bochum 1987, ISBN 3-88339-590-0 , p. 37.

- ^ Hermann Brassert: Mountain orders of the Prussian lands . FC Eisen's Königliche Hof-Buch- und Kunsthandlung, Cologne 1858, p. 72.

- ^ Joseph Tausch: The mining law of the Austrian Empire. Second, revised and increased edition, published by JG Ritter von Mösle's sel. Widow, Vienna 1834.

- ^ A b Geognostic-mining association for Tyrol and Vorarlberg (ed.): Outline of mining knowledge with a description of the usable mineral products of Tyrol and Vorarlberg . Printed with Wagner's writings, Innsbruck 1839, pp. 50–51.

- ^ A b Carl Friedrich Richter: Latest mountain and hut lexicon . First volume, Kleefeldsche Buchhandlung, Leipzig 1805.

- ↑ Swen Rinmann: General mining dictionary . Zweyter Theil, Fr. Chr. W. Vogel, Leipzig 1808.

- ^ Wilfried Liessmann: Historical mining in the Harz. 3. Edition. Springer Verlag, Berlin / Heidelberg 2010, ISBN 978-3-540-31327-4 .

- ↑ Marcus Dehler: Water management in historical mining . ( online ), accessed on October 17, 2012 (PDF; 1.3 MB).

- ↑ Joachim Huske: The coal mine in the Ruhr area. 3. Edition. Self-published by the German Mining Museum, Bochum 2006, ISBN 3-937203-24-9 .

- ↑ Information about the tunnel at the Freiberg geographic and environmental portal. Retrieved October 17, 2012.

- ↑ F. Heise, F. Herbst: Textbook of mining science with special consideration of hard coal mining. First volume, published by Julius Springer, Berlin 1908.

- ↑ Mining monuments in the Ore Mountains / Krusnohory mining region, German / Czech, Karlovy Vary district, Czech Republic 2014, Rothschönberger Stolln p. 106

- ↑ Bochum bunker. Communication , accessed October 17, 2012.

See also

Web links

- Information on hereditary tunnels in the Ruhr area. Retrieved October 17, 2012

Remarks

- ↑ The Daily sculpting is known in mining a mine opening that reaches down over the seam of less days ascended was. Overwashes are used for weather management and driving . (Source: Tilo Cramm, Joachim Huske: Miners' language in the Ruhr area. )

- ↑ The term Ädich , also written Aedich , comes from the Saxon Annaberger Bergrecht and means Aquaeduct. What is meant here is the water slope of the lower tunnel, with which he drives out the upper one. (Source: Kurt Pfläging: The cradle of Ruhr coal mining. )