Reichsbahn repair shop Salbke

The Reichsbahn repair shop Salbke was a repair shop of the Deutsche Reichsbahn in the Magdeburg district of Salbke . Parts of the facility are under monument protection .

The site is located at Alt Salbke 11-13 east of the Magdeburg – Leipzig railway line .

history

Foundation in the German Empire

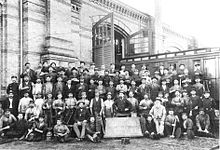

The factory was established as the Royal Main Railway Workshop Salbke from 1892 in the area of the then still independent village of Salbke. It was intended to relieve the main workshop , which was founded further north in Buckau in 1887 . The Prussian railway administration had acquired 33 hectares of land previously used as arable land east of the Magdeburg-Leipzig railway line and west of what was then Dorfstrasse. Construction began in 1893. The plant was spacious and modern and began operations on October 1, 1895. The inauguration ceremony took place on February 1, 1896 in the Turmpark. Initially, 100 workers and civil servants were employed who had been transferred to Salbke from the main workshops in Magdeburg-Buckau, Stendal, Wittenberge and Potsdam. The planning was done by Behrendt from the railway administration and Gerhard Schürmann . In 1898/1899 the factory was expanded for the first time due to the constantly increasing number of vehicles to be serviced. The plant employed 400 people. The electrical power required for the plant was initially generated in the boiler system itself, using 220 volts direct current . The battery was so powerful that it stopped generating electricity in the morning and afternoon for the first few years. The system was also used to illuminate the Magdeburg Südost and Magdeburg-Buckau train stations . However, after connection to the municipal power grid, own generation was stopped.

The plant's volunteer fire department was founded on March 15, 1904. The fire station of the fire brigade, which was only to a small extent equipped, was a shed in the area of the later medical center. An initially existing hand piston pump intended to be operated by eight people was replaced in 1920 by a motorized syringe . A vehicle was also purchased.

In 1910 a switch workshop was built in the southern part of the factory premises. The interior furnishings came from the main Buckau workshop, and 40 employees were also transferred from there to Salbke. In 1912, 800 people were already working here. Several villas were built at the southern end of the factory premises. Extensions were made in 1913 and 1932 to 1935.

In connection with the plant, the Salbker water tower and the Freundsweg settlement were built to the east of the site . The former Turmpark restaurant near the main entrance was used as a canteen at times. The Lüttgen-Salbke settlement further to the west was also initially designed as a railway housing estate . Another technical monument belonging to the plant was a hand-operated frame work that was erected around 1900 and housed in a brick-timbered building .

Before the First World War , the plant already had more than 1,000 employees. In addition to freight cars and special freight cars, passenger cars were also serviced. From 1904 apprentices were also trained. From initially 6 apprentices, the number increased to 30 by 1918. Due to the war, armaments-related tasks were also taken on during the First World War. So wagons were set up for military transports. A sewing plan was set up and the production of light cartridges started. To support the Buckau workshop, locomotive tenders were also processed during the war. Much of the work was done by women who took the place of men drafted for military service.

Operation during the Weimar Republic

In the course of the demobilization of the army after the First World War, the number of employees in the plant increased significantly. While 1118 workers were still employed in 1918, the number had risen to 1884 by January 1920. At the same time, however, production fell significantly. Of 513 wagons repaired every week in 1918, only 383 wagons were achieved in January 1920. On Monday, January 26, 1920, the plant was surprisingly temporarily closed along with twelve other railway workshops in Germany that were considered particularly uneconomical . The aim was to improve profitability, among other things by introducing piece work. The workers of the plant gathered on Monday morning in the Stiller pub in Fermersleben . Another meeting took place on the morning of January 30th in the Buckau Admiralspalast. After a heated debate, however, the old workforce ultimately almost completely agreed to resume work, accepting the changed working conditions. The plant was then put back into operation on Tuesday, February 3, 1920, with the workforce reduced by around 600 people.

In 1924, the equipment of the switch workshop with the superstructure warehouse was handed over to the RAW Brandenburg-West. In terms of content, the work increasingly focused on the repair of freight wagons and, in particular, two-axle, covered wagons. While repairs were initially carried out when necessary, over time regular maintenance came to the fore. The number of apprentices had risen to 70, who were trained by a master craftsman and six instructors on the upper floor of the building, which was later used as a training workshop. The training was carried out numerically beyond the plant's own needs.

With the dissolution of the Reichsbahndirektion Magdeburg and the closure of the repair shop in Buckau, there were fears that the plant in Salbke would also be closed. Lord Mayor Ernst Reuter wrote to General Director Julius Dorpmüller in 1931, demanding that the work be continued. The work was actually continued. On July 27, 1931, there was a major fire in the plant's wood workshop. The fire brigade was alerted at 6:20 p.m. In addition to the plant fire brigade, all Magdeburg fire brigades were alerted. The workshop, which also included a sawmill, was housed in a 100 meter long and 30 meter wide shed and largely burned down. A spread to other buildings could be prevented. The extinguishing work was facilitated by the rain that set in during the operation. The main street Alt-Salbke had to be closed. The extinguishing operation was ended at around 9 p.m.

A fatal work accident occurred in October 1931 when a worker was hit by a machine while crossing a track and later died as a result of a fractured skull.

The plant had its own men's choir, which also gave public concerts.

Period of National Socialism and World War II

In the time of National Socialism were also in the repair shop Salbke operation appeals introduced. From 1935 the construction of a central forge and a central turning shop began, which were completed in 1938. Spare parts required for the repair of cars were also produced here. After the beginning of the Second World War , many women were again used in place of the men drafted for military service. The working time was 10 hours a day. Then came the use of forced laborers and prisoners of war. A labor camp was set up at today's address Alt Salbke 117 . Italians and French were housed in this camp, which is located between the private railway route , what is now friendship route and Unterhorstweg . Further accommodations for German compulsory workers and foreign workers existed at Lothringer Strasse 1-7 , today's Ferdinand-Schrey-Strasse .

To operate the welding technology , a high-pressure acetylene plant was built in 1942, which could produce 40 m³ of acetylene gas per hour . The gas was distributed in the plant by means of a works ring line and a pressure of 0.9 bar. In 1952 another system with the same output was built.

From 1937 the Deutsche Reichsbahn planned to set up one of three new central forges in the Salbker factory by 1942. A forge hall measuring 117.5 by 24 m was therefore created. In addition, the central turning shop was housed in a low hall open to the side. New buildings for die construction and the material cutting workshop were built south of the forge shop . Behind it was the central forge's iron warehouse. The spring forge was located on tracks 23/25 of the wagon straightening hall. Initially, the central forge mainly manufactured spare parts for steam locomotives.

The apprenticeship training was further expanded and then comprised 100 training positions. For this purpose, the other areas of the building, which had previously been used as an iron store, were converted into a training facility. In addition to training workshops for metal and woodworking, a washroom was also set up. Apprenticeships were locksmith, carpenter and wheelwright . Theoretical training took place in a factory school, which was located in a building on the Salbker water tower. In 1937 the apprentices built the Zögling glider as part of their training .

In 1944, the plant's rail network comprised a total of 55 tracks with a total length of 35 kilometers.

During the Second World War, there was a major air raid on the plant on the evening of January 21, 1944, causing considerable damage to the plant and the surrounding residential areas. The company premises were destroyed up to 80%. The fabric store and the bathing establishment east of the plant were completely destroyed. The car straightening hall, joinery, saddlery, boiler house, central forge, training workshop and the administration building were damaged. Only minor damage was caused to the switch construction. The assembly hall was badly hit by several high explosive bombs. The north wall had been destroyed and the floor, paved with hardwood blocks and filled with tar, had caught fire over a large area and the roof had collapsed. The main material depot was destroyed by a chain bomb , which at the same time destroyed a pressurized water pipe running under the Alt Salbke street. The associated interruption of the water supply also led to the failure of the hydrants , which meant that the fire brigades could not extinguish the large fire that had developed. The situation in the boiler house was particularly dramatic. Boilers I and II were in operation when the boiler feed water failed. In order to prevent an explosion or the burnout of the boiler, the boiler attendant Paul Kelle, at the risk of his life , removed the embers and coals from the four fireplaces during the bombing. The coal bunkers at the plant were also hit by incendiary bombs and were on fire . The 80 t coal bunkers each were emptied by workers the next day to prevent a further bunker fire or a coal dust explosion. The pipe networks for acetylene gas, industrial gas, compressed air, steam and water were 90% damaged by the bombs.

Partial reconstruction took place during the war. In the course of 1944, the north wall of the car straightening hall was rebuilt by the construction company Jacob Petrie with 90 workers. After clearing up parts of the hall, work was resumed. At the beginning of 1945, tracks 4 to 11 of the 45 tracks could also be used again. The gaps in the roof were makeshiftly covered with corrugated iron . In January 1945 a train with furnishings reached the RAW Salbke as evacuated factories and offices were approaching the eastern front. The refugees were settled in Magdeburg. The constant air raids on places and facilities in the region led to an almost daily use of the company fire brigade towards the end of the Second World War. The plant fire brigade was even called to work in the Hanover / Braunschweig area .

On April 14, 1945, Wehrmacht commandos blew up ammunition trains between Buckau and Fermersleben at 1 p.m. Sea mines were also blown up. The detonations shook the area for several hours. The explosions also resulted in renewed destruction of the Reichsbahn repair shop. The north wall and the roof of the carriage assembly hall were again damaged. Other data date the explosions to April 17 or 18, 1945. In the period from April 12, US troops occupied Salbke. Initially, any activity in the Reichsbahn repair shop was prohibited.

Post-war and GDR times

On April 18, the clean-up was approved to begin. On April 23, 1945, old union members formed an action committee. The resumption of work took place on May 10, 1945, after a few weeks in addition to the removal of the rubble, the repair of freight wagons was already being carried out again. In the course of clearing the rubble, three million voluntary assembly hours were done. However, there were problems, especially in the early days, as many employees temporarily worked in agriculture or tried to obtain food in other ways.

The Reichsbahn repair shop then maintained regular contact with companies in the agricultural sector. For example, the machine rental station of the municipality of Langenweddingen received technical support against the delivery of natural produce, especially potatoes. To improve the food supply in the factory kitchen, pigs were also kept in the RAW.

Another problem arose from the fact that the employees living out of town often came to work late due to the poorly functioning public transport. In the Reichsbahn repair shop, a separate train was put together from a shunting locomotive and four freight cars. Later four damaged passenger cars were procured and repaired. The tool train was used as planned and drove from Eggersdorf via Magdeburg Südost station to the Reichsbahn repair shop . The train, which was also used to transport goods and firewood, was discontinued in 1953 after the functionality of the local transport was sufficient, also thanks to bus lines.

reconstruction

First of all, the repair hall, the roof structure of which had collapsed, was restored. In the area of the destroyed bathing establishment, the metalworking shop was built, which worked there from October 1948 and was completed in 1951. By 1951, in addition to the car straightening hall, the ancillary workshops and the central forge had been rebuilt. A total of 364 damaged machines were repaired. The training workshop was provisionally restored as early as 1947. The reconstruction of the material store and administration building began in 1947. The cost of this reconstruction was estimated at 3.385 million DM. Overall, the original structure of the plant and the building fabric were preserved. At the same time, the war damage was repaired in the Freundsweg settlement. In order to make apartments available to bombed-out employees, the plant was involved in housing construction and also made furniture. A Schumacher and tailor's workshop were also run from a social perspective. In 1945 there were 190 company-owned apartments. Dormitories were built between 1950 and 1953 in Ferdinand-Schrey-Strasse, south of the plant, and later converted into apartments. A residential building was built in Lüttgen-Salbker-Weg in 1950 and a twelve-family house in Alt Salbke in 1953. Albert Bethge was elected as the first works council chairman after the Second World War . In the 1960s, the plant in Raiffeisenstrasse ran its own television repair workshop.

Between 1946 and 1953, a workshop for the reconditioning of machine tools was set up in the switch construction company, which also repaired machines from other plants. Including machines from the former German eastern regions, such as the RAW Schneidemühl . The lack of typical standard parts such as hexagonal screws, rivets, buffer screws and flat clamp screws was problematic for carrying out the car repairs . With the help of a forging roll procured from Kirchmöser , the various required parts were built from old wheel tires and axle shafts in a complex process. This in-house production could then be abandoned from 1956/57.

For April 6, 1950, the 50,000. Freight wagons restored at the factory since the end of the war reported.

Plant fire brigade

The situation of the plant fire brigade after the end of the war was also difficult. The fire brigade's vehicle was stolen by former foreign workers and used to return home. The whereabouts of the fire engine is unknown. Nevertheless, the fire brigade was rebuilt immediately after the end of the war. A youth fire fighting group was formed from the ranks of the apprentices, which had a portable pump and a trailer. In 1949 the fire brigade was rebuilt. In 1951, a former Mercedes prison car that had been converted into a fire truck was purchased. Further new acquisitions were made in 1958, 1964, 1972 and 1976. Larger fires on the factory premises occurred in the roof area above track 28 of the assembly hall and in the oxygen system. In addition, there were frequent missions in freight wagons that caught fire during welding work. However, the operations were not only limited to the immediate plant area, but also to fires at other Deutsche Reichsbahn locations. Operations took place in Langenweddingen , Demker , Zielitz , Schönebeck (Elbe) and Oebisfelde . Major missions in Magdeburg involved fires in the Minol tank farm and in the Rothensee impregnation plant .

Cultural and social activities

In 1950 the company sports association Lok Südost was founded, which was GDR indoor handball champion in 1962/63. In 1959, the plant opened a children's holiday camp in Neukamp near Putbus on Rügen . First, four sleeping barracks as well as kitchen and medical barracks were built on a leased meadow on the banks of the Greifswald Bodden . The property was later acquired and the facility expanded with the erection of massive buildings, whereby the required building materials, including the gravel, had to be brought in from Magdeburg. In the 1980s, 120 children could be looked after per round. The first children's camps took place in Möser and Magdeburgerforth from 1950 to 1953 and in Waldheim from 1954 to 1956 . In 1957, 1958 a company holiday home in Schleusingen-Neuendorf in Thuringia was leased. From 1968 two bungalows in Kamminke on the Baltic Sea were made available as holiday accommodation. In 1970 and 1972 four more bungalows followed in Pretzien . In 1954, a friendship contract was concluded with railway workers from the railway repair shop in Duisburg-Wedau , which also included the admission of ten West German children to company holiday camps and five apprentices in the RAW holiday home for apprentices.

A kindergarten was set up in the Turmpark in 1947/48 and a day nursery in 1956. From 1953 there was a library with initially 1000 books, the stock of which was expanded over time and where readings and record evenings were also held. In 1949 an operating group of the Society for German-Soviet Friendship was founded in the plant. Incidentally, at that time there was also a CDU operating group in addition to the SED .

Various cultural activities took place in the plant. In addition to its function as a dining room, the Ernst-Thälmann-Saal was also used as a culture and theater hall. There was a folk dance group under the direction of Hans Fritsche . A photo circle existed from the mid-1950s. In 1963 a choir consisting of 29 members was founded. The cabaret Die Paprikaner was active from 1967 to around 1990. In addition, a circle of textile design and a brass band consisted of 13 colleagues, who succeeded a shawm band that existed in the 1950s and 1960s .

In 1950, the actors in the DEFA film, Mayor Anna Eva Rimski , Klaus Becker and Edith Hancke, visited the factory after they had already visited Buckau-Wolf.

A medical center was set up in the small administration building. It was manned around the clock by four nurses and paramedics. On May 15, 1954, a basic organization of the German Red Cross of the GDR was founded in the plant, which provided aid in the event of accidents but also at mass events. The disaster control , which has been in operation since the 1950s, as well as the later civil protection was also supported . In 1975 the medical center was expanded and a dental practice was added. In 1991 this facility was then closed.

Vocational and school education

On May 1, 1952, the company's new vocational school started work, taking over the entire vocational training of the Magdeburg State Railroad Office. Up to 800 apprentices were trained at the vocational school. With a special permit obtained from the Soviet city command on February 28, 1946, the full apprenticeship training of the RAW had been resumed considerably earlier after the end of the Second World War. First, the training center, which was partially destroyed and burned out on the upper floor, was made weatherproof. Destroyed machines and workbenches were repaired and refurbished. Voluntary reconstruction work was also done on weekends. In 1948 80 apprentices were employed again, by 1951 the number rose to 224, of which around 50 were girls. Later the number fell again significantly and fluctuated around 100 apprentices. An apprentice at this time was the later GDR diplomat Arthur Höltge , who completed an apprenticeship as a machine fitter.

With the start of the new school year, polytechnic lessons for students from the Salbker School were carried out in the factory from September 1, 1958 . Up to 450 students were trained on one day every two weeks. Later, a joint polytechnical training center was set up with the Fahlberg-List chemical plant further south , which opened on August 24, 1984. In 1989 these classes were discontinued. In 1959 the company academy opened, which was active in adult training at the plant.

In 1952, the plant became the home repair shop for all two-axle covered freight wagons of the Reichsbahn and took over the corresponding wagons from the Potsdam , Brandenburg-Ost and Blankenburg plants. A total of 33,000 cars were then part of the inventory. The cars were serviced every two years. A twelve to eighteen month maintenance cycle was aimed for. In addition, older wagons were modernized. At times the suspension springs of mine cars for the lignite industry were also reconditioned.

Uprising of June 17, 1953

During the popular uprising of June 17, 1953 , the RAW Salbke was also on strike. Striking workers from the SKL further north came to the RAW and urged the workforce to also go on strike . Parts of the workforce followed the call and left the company around noon. After the uprising was put down, work was normal again on June 18, 1953. As a result, as in other industrial enterprises in the GDR, a unit of combat groups was formed at the plant. It consisted of 20 people and was armed in 1954.

Before that, there had already been considerable unrest in the company in December 1952. With the decision of the GDR government of December 4, 1952, the Christmas bonus paid up to then had been replaced by an end-of-year bonus. The premium was dependent on the performance, but in particular on the fulfillment of the annual plan. The change was often associated with financial disadvantages and met with considerable criticism from employees. The apprentices were particularly hard hit, who could only be prevented from going out of work by a massive deployment of full-time FDJ functionaries. In the SKL, a little further north, there were already major strikes at this point.

From February 1954, the company newspaper Der Güterwagen, published by the SED 's working party organization, was published every 14 days . which finally appeared until 1992. 1954 became the 100,000. Freight wagons processed in the factory.

Consumer goods production

During the GDR era , various consumer goods were made from waste materials that were not needed. This is how handles for razors, hammers, hall wardrobes, wooden fences and parts for agriculture such as plowshares were created. Garden furniture, cutlery and chisels were also made later. As with a manufactured wringing machine, however, the required quality could not be guaranteed for these ultimately non-industry products. For a longer period of time, parts for forest heating systems were manufactured. The necessary materials were supplied by the SKL, a little further north . Until 1990, cardan shafts were also manufactured for the Trabant . Chandeliers and hall wardrobes made as ironwork were also among the long-term products produced by the plant, although production ultimately remained economically ineffective. Between 1983 and 1989 the training workshop also produced hand lever shears and, in other departments, wooden construction sets, flower boxes, wallpaper panels, tomato sticks, angle panels, shelves for car trailers and decorative strips. After 1989, however, all of these productions were discontinued.

In 1957 the 45-hour week was introduced in the Reichsbahn repair shop.

In the period 1958-59 a was oxygen - cold gas plant built. Oxygen supplied by TEGA Leipzig in liquid form was converted into gaseous form there. The gas generated in this way was distributed in the plant via a ring line and used for the welding technology in the various operating areas. The oxygen had previously been delivered in steel cylinders. In 1978 the system was replaced by a pressure gasifier system from Chemieanlagenbau Dresden with two tanks of 10 m³ each. Another exchange then took place in 1994 with the installation of a 20 m³ tank including an evaporator from Linde.

In 1959/60 a sponsorship agreement was signed with the LPG von Vehlitz . The Reichsbahn repair shop helped build stables and handle the harvests. The plant's brass band also performed in Vehlitz. The LPG delivered natural produce. In the 1980s there was also a sponsorship agreement with the LPG Niederndodeleben .

Some of the plant's larger machines, such as the forge hammers, were operated with superheated steam, which was not, however, available in sufficient quantities. In 1965, with the purchase of four reciprocating compressors, a compressed air network was set up as an alternative , which was used with an operating pressure of eight bar to operate forging hammers that had previously been operated with steam. Previously, compressed air was only used for checking brakes and control valves, as well as for drilling, riveting and rubbing in freight car reconditioning. A charging station for e-carts was built in 1969.

In 1969 the Reichsbahnausbesserungswerk became the lead plant of the newly formed product association of the goods wagon works of the Deutsche Reichsbahn. From the 1970s, there was a branch office of the plant at Oschersleben station , where so-called damaged wagons were collected and sent to the RAW.

In 1975 the plant received the traveling flag of the Council of Ministers of the GDR and the Federal Executive of the FDGB.

The acetylene gas system was renewed in 1976. It remained in operation until 1991 and was then replaced by a container from Linde.

In September 1976 a master workshop for rationalization equipment construction was formed, the most diverse devices for the rationalization of the operational work processes. Previously, two locksmiths had been working with similar tasks from 1963 under the guidance of the Office for Innovation . Initially 6 people were employed in the master shop. The number rose to 40 workers by 1983. At the end of 1990 the mastery was then dissolved.

The 40- and 42-hour week were introduced in 1977. In 1979 the wage structure was changed, in which a performance-based wage was introduced in addition to a basic wage.

The sudden onset of winter in 1978/79 led to considerable failures in operation as the energy supply collapsed. It then took several days to get the frozen pipes back to work. On September 17, 1980 Otto Arndt , Minister for Transport of the GDR, visited the plant.

From 1983 to 1986 a new company restaurant with a modern dining room was built. In 1984 a polytechnic center was set up together with Fahlberg-List , in which the polytechnic lessons for the Salbker and Westerhüser high schools were carried out. The establishment of a traditional cabinet took place on October 2, 1984. However, this was deliberately destroyed after 1989. The number of employees increased to up to 2,000 people. The reconstructed and partially automated buffer workshop was handed over in July 1988 in the presence of the president of the repair shop, Dieter Reissig . Trial operation ran until the end of 1988; regular production began in 1989. In 1988 the reconstruction of the wheelset workshop was also completed. In other areas too, efforts were made to modernize production through the use of EDP systems. A rust removal hall was also built with a length of 137 m and a width of 24 m, which was handed over in 1991.

Development after 1989

After the political change in 1989 , the company and the workforce were reduced further. As early as February 1, 1990, Group G 1 had been dissolved, which had previously worked for the GDR national defense. The political changes also led to the fact that the plant management took over the publication of the company newspaper in 1990, which until then had been published as the SED newspaper. The paper was discontinued in 1992. In 1990 the 40-hour week was finally introduced.

The apprenticeship training for carpenters, which had been discontinued in the past, was resumed for some time in 1990, initially with four and later with ten apprentices. The industrial and wood mechanic apprenticeships were also newly introduced and the training facility was renewed. In the 1990 apprenticeship year, the RAW employed 144 apprentices.

The first free staff council elections took place in September 1990. Modernization measures continued to be carried out. The topping-out ceremony for a new functional building was celebrated on October 18, 1990. The plant fire brigade specialized in accidents involving dangerous goods and received an emergency vehicle dangerous goods in January 1994. At the beginning of 1992, 1262 people were still working in the plant, compared with 800 in 1993 and 630 in 1994. In 1994, RAW was incorporated into Deutsche Bahn AG and assigned to the Magdeburg regional division of the plants division. In the end, there were only 150 employees left. The number of apprentices also fell accordingly. At the end of 1998 the plant was closed. It has since been unused and is in ruins.

Some of the buildings damaged by vandalism are in a ruinous state. Most of the former tracks were dismantled and no longer exist. The former culture hall has collapsed and the ruins of the hall have been cleared.

On March 15, 2012, the majority of Magdeburg's city council decided to initiate a development plan procedure to enable the construction of a solar park on the RAW site. It is feared that a large part of the listed building stock will be demolished in connection with the erection of the solar modules.

In early 2013, the site hit the headlines several times. Witnesses told the police that on January 27, 2013 they observed a man with a scared child on the premises. On the night of January 27-28, 2013, there was a large-scale operation of the police to look for the child. However, the mission was unsuccessful. No child was missing either. A similar situation arose after a further testimony of two witnesses on February 7, 2013. According to this, a man threatened a six to eight year old girl with a weapon. This renewed large-scale search, in which a helicopter with a thermal imaging camera and a dog squadron were also used, was unsuccessful. Again, there was no report of a missing child. On February 16, 2013, a 24-year-old man fell from a height of 22 meters from the plant's chimney onto a canopy, despite the safety line he was carrying with him, when an iron broke from the brickwork while climbing out of the chimney. He suffered a fractured skull base and several broken legs and was rescued by the fire department. The man tried to find a geocache hidden up on the chimney while geocaching . Several caches hidden on the site were archived after the accident.

Buildings

Car repair shop

The largest structure is the eleven-aisle car repair shop. This very large hall was planned from 1893 and then built in several construction phases in 1894/95, 1899 and 1911. In the final state, the hall has a size of 165 by 242 meters and thus an area of almost 40,000 m². Its area had thus quadrupled in relation to the original building. The roof is supported by supports that are 15 meters apart. The hall was designed by Behrendt; Maeltzer was responsible for the execution. A first phase of construction was carried out in 1894/95. The hall initially reached dimensions of 91.15 in width by 138.7 meters in depth. Already in 1899 there was an extension to the west. While maintaining the same width, the depth was increased by 59.6 to 81.6 meters. In 1911/12 an extension to the north was carried out, with which the hall reached its present dimensions. To commemorate this, the Borchard lime tree was planted in 1912 .

45 railway tracks led through the gates on the south side of the hall. The hall gable on the east side, made of yellow brick, consists of eleven gables designed in the same way. The gables are separated from one another by pillars that protrude above the height of the facade. At the top of each gable there is a structure reminiscent of a chimney. The facade is horizontally structured by bands made of red brick. There are console friezes and a stepped frieze on the slopes of the gables . The hall is covered by gable roofs , with lantern sheds providing daylight lighting. The railway tracks typical for the hall have meanwhile been dismantled.

Also in 1911, a two-story, elongated building was built on the northwest side of the hall, which was used for washing and polishing. The hall was badly damaged in the Second World War, but was rebuilt. Another elongated extension was added to the southwest of the hall in 1964. Ship 11 in the hall was rebuilt in 1970 so that the 14.5 m long G-wagons could pass through. The hall supports had to be moved to the outside.

Wrought

The tire, spring and hammer forge was already in the planning stage from 1892. This building was also planned by Behrendt and executed by Mältzer. The yellow, single-nave brick hall was extended to the west in 1899 and 1911 to a length of 108 meters. There were 4 quadruple forged fires in the middle and 23 double forged fires on the long sides. Rectangular chimneys towered over the forges, but only some of them have been preserved. Below the building there is a six-meter-deep foundation cellar with five oscillating foundations that was required for the forging hammers. The roof structure is wrought iron and has a gable roof. A lantern shed system was also used here for the lighting. Light also fell through the tall side windows. The facade of the building, which was later provided with extensions on the north and south sides, is decorated with battlements and console friezes. In addition, the structure is made up of narrow red bands.

The listed interior included universal scissors from the Berlin company Henry Pels & Co. AG from around 1910/20 and a steam hammer built around 1920 from the J. Banning company in Hamm . A 90 m long crane bridge with a 24 m span and a load capacity of 5 t was subsequently installed in the hall.

The forging furnaces at the plant were operated with town gas , which was supplied by the Magdeburg gas supply. In 1960/61, the forging furnaces were switched to heating oil HTB, as gas imports were to be saved. Only the normalization furnace was still operated with town gas due to its complicated control technology. In 1978 they returned to firing with town gas. The operational gas control station was renewed in 1980. In 1993 they switched to natural gas . The individual forge furnaces were connected to an underground exhaust gas duct that led the exhaust gases to the twelve-meter-high chimney. There was a system for waste heat recovery with which hot water should be generated. However, this system never worked.

At the end of the 1970s, the forge was rationalized. The Zentralschmiede was a supplier of new construction and spare parts for facilities of the Reichsbahn and industry. This is how the cardan shafts for the Trabant car produced in the GDR were created in the central forge. With 240 employees, the forge produced 6,000 tons of forged parts per year. After the political turnaround in 1989 , non-rail orders in particular ceased to exist at short notice. The order backlog sank, so that from 1991 the company also took part in tenders from the Federal Railroad. In 1996, however, the contract forging was stopped.

Boiler and machine plant

The boiler and machine system was built in 1894/95 and was needed for the car repair shop a little further north. It was expanded as early as 1899. There were then three superheated steam boilers that generated steam at a temperature of 400 degrees Celsius. The snake- tube boilers that were initially used were later exchanged for coal -fired Steinmüller and Büttner boilers, as boiler scale accumulated . The north gable of the building is characterized by two yellow gable panels and bears the year 1899 . The facade is structured by red ribbons made of brick as well as tooth-cut and roll-layer friezes. The 43 meter high steam chimney with its rich ornamentation is striking. Its shaft has a rectangular shape at the bottom, then merges into a polygon to ultimately continue as a cylinder. The design is reminiscent of sacred architecture. The color of the chimney, kept in the style of historicism , is characterized by red and yellow bricks. Another renewal of the boiler system took place from 1927 to 1932 with the acquisition of two Borsig boilers. The kilns fired with raw lignite generated eight tons of steam per hour at a temperature of 280 degrees Celsius. An induced draft from Bösdorfer Maschinenfabrik Leipzig with an output of 60,000 m³ / h was installed in the chimney because the draft was too low. Three pressure hammers , a drop hammer and a counter blow hammer as well as heaters were operated with the steam generated in this way. Another steam boiler with an output of six tons of steam per hour was installed in 1953/54 because the amount of steam available was insufficient. From 1990 to 1994 steam generation was converted to heating oil . Two thirds of the space for the heating steam dynamos was used as a compressor room and one third as a washing and changing room.

Large parts reconditioning

In the south-eastern area of the factory premises, the switch construction institute was built in 1908/09 according to plans by building officer Gerhard Schürmann, which was later used to recondition large parts. The gables of the two-aisled hall are oriented in an east-west direction. The east gable of the red brick hall faces the main street Alt Salbke. The hall is 61.56 meters long, with an eaves height of 8.4 meters. The height of the roof ridges is 11.5 or 14.64 meters. The hall is designed with eleven axes on the long sides. Bright plastered surfaces, brick friezes and pilaster strips structure the facades. The design cites medieval elements of the regional brick architecture. The roof trusses are designed as a riveted iron structure. The hall is covered by two gable roofs with skylights . On the east side facing the street, a flat 46-meter-long and 5.4-meter-deep extension is located in front of the hall, which served as a warehouse and contained the foreman’s rooms. The tools and toilets were also located there.

War memorial and Borchard-Linde

There is a war memorial near the main entrance , which commemorates the fallen of the First World War. It bears the inscription: Our comrades who died in World War 1914–1918 . The Borchard linden tree planted in 1912 is right at the entrance .

Personalities

The painter August Bratfisch was employed in the Salbke Reichsbahn repair shop from around 1919 until his retirement in 1948. Wilhelm Neumann , later a member of the People's Chamber, was the works representative from 1920 to 1933. The later SPD politician Christian Hanebuth did an apprenticeship as a locksmith at RAW from 1928. In the 1950s, handball player and later coach Klaus Miesner worked as an intern at the plant. The later GDR diplomat Arthur Höltge completed an apprenticeship as a machine fitter in the factory. The future Low German writer Marta Rothe worked in the headquarters of the plant.

The blacksmith Albert Heidecker , who was active as a painter and blacksmith , the caricaturist and graphic artist Oskar Schwalm and the painter Helmut Wolf were stated to be particularly involved in an artistic sense .

Heads and directors of the plant were:

- Mälzer, from 1893 (head of the construction department)

- Schittke, from 1895 (first head of the main workshop)

- Oppermann (Head of the Workshop Office)

- Blindow

- Werner

- Musks

- König (first workshop manager of the repair shop)

- Stinner

- Lehmann

- Poppe

- Gisewski, 1935

- Kneidl

- Winkelmann

- Sauermann

- Kotzott, 1945

- Fritz Adomeit, 1946

- Willi Schneider, 1947–1950

- Rudolf Gelzer, 1950–1954

- Harry Schrader, 1954-1960

- Oskar Hake, 1960–1963

- Harry Kohl, 1964–1980

- Rolf Moser, 1980–1983

- Dieter Müller, 1983–1984

- Rolf Moser, 1984-1992

- Ottfried Zillessen, 1993

- Rolf Moser, from 1994

literature

- Sabine Ullrich: Industrial architecture in Magdeburg, mechanical engineering industry. State capital Magdeburg 1999, p. 51 f. and 76 ff.

- Sabine Ullrich in Magdeburg - architecture and urban planning. Verlag Janos Stekovics Halle (Saale) 2001, ISBN 3-929330-33-4 , p. 288 f.

- Ed .: Deutsche Bahn AG, 100 years of Magdeburg repair shop 1895–1995. Magdeburg 1995.

- List of monuments Saxony-Anhalt, Volume 14, State capital Magdeburg. State Office for Monument Preservation and Archeology Saxony-Anhalt, Michael Imhof Verlag, Petersberg 2009, ISBN 978-3-86568-531-5 , p. 50 f.

Web links

Individual evidence

- ↑ On the closure of the Salbke railway workshop In: Volksstimme . January 31, 1920.

- ^ Closure of the Salbke railway workshop In: Volksstimme . January 27, 1920.

- ↑ On the closure of the Salbke railway workshop In: Volksstimme . January 31, 1920.

- ^ The reopening of the Salbke railway workshop In: Volksstimme . February 3, 1920.

- ^ Magdeburg's demands on the Reichsbahn. In: Volksstimme . July 10, 1931.

- ↑ Big fire in the Salbke railway workshop In: Volksstimme . July 29, 1931.

- ^ Fatal accident at work In: Volksstimme . October 28, 1931.

- ^ " Platzkonzert im Südost" In: Volksstimme. September 9, 1931.

- ^ Peter-Ernst Schmidt: Foreign, forced, concentration camp, prisoner of war and work education camps during the Nazi era in Magdeburg. March 2007.

- ^ Matthias Puhle (Ed.): "Then the sky turned blood red ...", The Destruction of Magdeburg on January 16, 1945. Magdeburger Museen, Magdeburg 1995, ISBN 3-930030-12-8 , p. 130.

- ↑ a b Deutsche Bahn AG (Ed.): 100 years of Magdeburg repair shop 1895–1995. Magdeburg 1995, p. 44.

- ^ Deutsche Bahn AG (ed.): 100 years of Magdeburg repair shop 1895–1995. Magdeburg 1995, p. 11.

- ^ The 50,000th freight car In: Neues Deutschland . April 6, 1950, p. 1.

- ^ Friendship treaty with Duisburg railroad workers. In: New Germany. May 25, 1954, p. 2.

- ↑ In the sign of friendship. In: New Germany. November 12, 1949, p. 1.

- ↑ Hubert Hartert: "Mayor Anna" speaks to activists. In: New Germany. April 13, 1950, p. 3.

- ^ Wilfried Lübeck: June 17, 1953 in Magdeburg. "If the friends hadn't been there, there would have been a defeat." In: Hermann-Josef Rupieper, Daniel Bohse, Inga Grebe (ed.): ... and the most important thing is unity. June 17th in the districts of Halle and Magdeburg. Lit Verlag Münster / Hamburg / London 2003, ISBN 3-8258-6775-7 , p. 108.

- ↑ Companies set up a polytechnic center. In: New Germany. September 22, 1984, p. 14.

- ↑ Robert Richter: Large contingent of the police looking for an armed man and a girl. In: Magdeburger Volksstimme . February 9, 2013.

- ↑ Geocacher still in mortal danger. In: Magdeburger Volksstimme . February 18, 2013.

- ^ Deutsche Bahn AG (ed.): 100 years of Magdeburg repair shop 1895–1995. Magdeburg 1995, p. 62.

Coordinates: 52 ° 4 ′ 53.9 " N , 11 ° 39 ′ 49.8" E