Compact cassette

| Storage medium Compact cassette

|

|

|

|

| General | |

|---|---|

| Type | Magnetic tape |

| capacity | up to 90 minutes per side |

| size | 10.16 cm × 6.35 cm × 1.27 cm (BHD) |

| origin | |

| developer | Philips |

| idea | 1963 |

| Launch | 1963 |

| successor | Digital compact cassette |

The compact cassette ( Compact Cassette , CC ), music cassette ( Musicassette , MC ) or audio cassette (German mostly just cassette , English also short cassette or tape ) is a sound carrier for electromagnetic , analogue recording and reproduction of sound signals . It contains a tape that is enclosed in a plastic case for ease of use and protection. The playback and recording of cassettes is done with a cassette recorder . In the period from the early 1970s until the late 1990s, the compact cassette was one of the most widely used audio - media in addition to the record and later the Compact Disc . The originally rather mediocre sound quality has been brought to a level over the years through improvements to the tape material and technical innovations such as the Dolby noise suppression systems that also met high standards.

The cassette and the associated recorder were designed as a system for mobile music use by a team of developers led by the engineer and inventor Lou Ottens at the Dutch company Philips . Development work began in 1960, and in August 1963 the cassette and device were presented as a pocket recorder . The cassette initially competed with other types of tape cassettes from various competitors and prevailed, the compact and robust sound carrier enjoyed great popularity for decades. Today, due to the triumph of digital audio technology , especially the MP3 format, the compact cassette has practically only historical significance.

construction

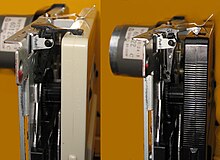

The compact cassette consists of a flat cuboid housing in which, among other things, the magnetic tape made of coated plastic, mechanical parts and small felt bags are housed. The housing of most types is made of plastic, very rarely also made of GRP , aluminum , brass or ceramic . To scan the magnetic tape, it is fed through the middle opening of the cassette to the tape head of the player. For mono recordings, the tapes contain two audio tracks , one for each direction. Tapes with stereo recordings contain four - correspondingly narrower - audio tracks, two for each direction. The audio heads of the playback and recording devices are aligned so that they only scan the lower two tracks (stereo) or the lower track (mono) of the tape. If you insert a mono cassette into a stereo device, both pickups pick up the same signal. Conversely, mono heads record the sum of the signals from both stereo tracks. After turning the cassette over, the lower half of the tape is scanned again.

The format of a (standing) cassette is 10.16 cm long × 6.35 cm high × 1.27 cm deep (at the thickest point) (4 ″ × 2½ ″ × ½ ″).

Some cassette recorders are able to scan both halves of the tape with a four-track tape head, as is also used in reading devices for magnetic stripes without a tape fork, so that they can play in both directions without having to turn the cassette. If the direction of travel is automatically switched at the end of the belt, this is known as “auto reverse”. Pure playback devices normally use a rigid four-track head or a laterally displaceable two-track head, while recorders have an erase and audio head combination that can be rotated through 180 °. In some devices from Nakamichi , Akai, etc. a. the cassette itself was also turned by a mechanism (UniDirectional AutoReverse (UDAR)).

The belt is 3.81 mm (0.150 ″) wide and moves at a speed of 47.625 mm / s. When the compact cassette drive via a close tolerance ground and polished steel shaft, is the so-called capstan ( English capstan ), achieved which projects into the cassette holder and with a balanced , belt-driven flywheel mass is provided. The tape is pressed against the capstan by means of a rubber pressure roller , transported through a force fit and thus pulled past the tape heads. The peripheral speed of the capstan, minus the slip , is the belt speed . The speed of the winding and unwinding mandrels, which are usually provided with slip clutches, adapts to this speed. As with vinyl records and most reel tapes from the consumer electronics sector, there is an A and a B side (front and back).

The first commercial (recorded) cassettes were sold in 1965, stereo sound was introduced in 1967. The playing time depends on the content of the longer side. In the case of empty cassettes, the name of the cassette results from the playing time of both sides in minutes; the most popular formats are C60 (nominally 30 min playing time per side), C90 (45 min / side) and C120 (60 min / side). There are also empty cassettes with 46, 50, 74, 100 and 110 minutes playing time. Overlong cassettes with 150 minutes are very rare, for a short time cassettes with 180 minutes were also available - the longer the playing time, the thinner and therefore more sensitive to tensile stress , self-demagnetization and copying effects . The tape of a C60 cassette is usually 15 to 17 µm thick. With C90 it is 10 to 12 µm and with C120 only 9 µm. As a rule, the actual term is 1 to 3 percent longer than stated.

Compact cassettes can be secured against overwriting (deletion) of the recording. An open slot on the left side of the top edge (the side opposite the tape openings) indicates that that side of the cartridge is protected. The protection is done by breaking out the respective plastic lip. Cassette recorders have a mechanical sensor to check this recess. A cassette protected in this way can only be played - but not simply used for new recordings. To re-record, the recess must be taped over or the recording button must be deactivated manually; On some recorders, the record button can be released by manually pressing the sensor before the cassette drawer is closed. On cassettes that have not been recorded, the recess is initially covered by a break-out tongue.

Optional mechanics

The tape rewind reliable, received the early 1970s, the BASF sub-class magnetic tape (from 1998 EMTEC Magnetics ) a patent on the advertised under the symbol SM Special Mechanism and Security Mechanism , which temporarily from Agfa was acquired under license. This feature includes a rail to guide the tape onto the spool and to prevent an unclean roll.

The other providers reacted by inserting additional deflection pins closer to the coils in the lower plastic housing half. Some cheaply made and pre-recorded compact cassettes were made without pulleys; the tape is pulled directly over the chamber for the capstan drive. A thinner felt on a glued-in foam block instead of the usual felt on a leaf spring ensures that the tape is pressed against the tape head.

history

Even before the cassette recorder was introduced in 1935, AEG introduced a tape recorder (" magnetophone ") that was based on the same technology, but operated with an open tape roll. The devices were comparatively expensive and complicated to use, which is why they were mainly used in radio and recording studios . Tape recorders were initially not very attractive to private users and only came into fashion from the 1950s. At prices between 700 and 1500 DM (which, based on the year 1955, corresponds to approx. 1,800 to 3,800 EUR adjusted for inflation), they were still too expensive for the mass market and also very bulky due to the electron tubes used. In the 1960s, however, prices fell, so that reel tape recorders were soon to be found in many better-equipped households.

The first attempts to establish compact audio cassettes on the market were made as early as the late 1950s. The first serious audio tape cassette was introduced by Radio Corporation of America (RCA) in 1958/59 : a two-hole cassette with a 6.3 mm wide tape and a tape speed of 3¾ inches per second = 9.525 cm per second, rounded: 9.5 cm / s. The RCA cassette was about three times the size of the compact cassette and could not establish itself in the home sound sector. Some companies in Europe were also working on compact audio cassettes. The Hanover-based company Protona GmbH , which manufactured miniature wire-tone devices and was later taken over by Telefunken , presented the magnetic tape recorder Minifon -attaché in 1959. The minifon cassette was hardly larger than the compact cassette. It was initially intended as a dictation system, but a technical improvement even brought hi-fi sound in 1961. The development was AEG / Telefunken in the 1960s, but one, as opposed Met agreements broke away among German manufacturers a provider and flirted with the already compact cassette. The Dutch Philips Group has been developing a single-hole cassette suitable for HiFi since 1961 in its Vienna tape recorder factory, WIRAG . The Viennese factory had years of experience in the development and production of dictation systems with a single-hole cassette. On this basis, the new cassette was to be created as a high-quality tape system for home use. In addition to Philips, Grundig AG as well as the record companies associated with Philips, the Philips Phonographic Industry and the Deutsche Grammophon Gesellschaft were involved in the development. This single-hole cassette already used a tape only 3.81 mm wide at a tape speed of 1⅞ inch = 4.7625 cm per second, rounded: 4.75 cm / s. All cassette systems reinvented at that time - with the exception of the Protona cassette - were primarily aimed at maintaining the familiar hi-fi sound of the reel tape, with design and handling being neglected. At first unnoticed, a small team led by Lou Ottens had been working in the newly built Philips factory in Hasselt in Belgium since 1960 on a handy tape medium that was internally known as a two-hole cassette. Ottens wanted a handy and robust sound carrier for music that would inspire a mass audience and so took an unconventional path. Ottens gave the order to make a piece of wood that would fit in his jacket pocket. That was the birth of the compact cassette, so to speak. The project was therefore given the name "pocket recorder". The log provided the dimensions for the later recording and playback device. The exchange medium - the cassette - also had to adapt to the specifications. The development of the compact cassette was a team effort. In retrospect, Lou Ottens sees himself as a team player: "I always worked with other people when developing new products." Jan Schoenmakers was responsible for the construction of the original cassette and the drive . He also had the idea of locking the cassette in the drive by inserting the tape and erase heads. The cassettes could not be removed from the drive during playback. The later compact cassette patent , which was filed under number 1191978 on January 31, 1964 at the German Patent and Trademark Office in Munich , was limited to precisely this detail . Peter van der Sluis developed the corresponding recorder. The magnetic head specialist Herman Cornelius Lalesse had the idea of dividing the 1.5 mm wide mono track on a playback side into two tracks for stereo.

After the development work in Hasselt had progressed very far, the Philips management had to decide between the one-hole and the two-hole cassette. The decision was made in favor of the two-hole cassette by Lou Ottens and team, although the first devices for the single-hole cassette had already been produced. Max Grundig , whose company was involved in the Austrian cassette, was informed very late by Philips about the end of the single-hole cassette. However, he got the offer - like Telefunken - to participate in the pocket recorder. Grundig was not happy about this and had the competing system DC-International developed without further ado . The basis for this was the construction drawings of the compact cassette that Grundig had taken with him after negotiations with Philips.

On August 28, 1963, Philips presented the compact cassette and the associated Philips EL 3300 cassette recorder equipped with transistors at the 23rd Great German Radio Exhibition in Berlin . It cost 299 DM (today corresponds to almost 600 EUR adjusted for inflation) and could only be operated with batteries (five baby cells ).

The Grundig AG then in 1965 took the alternative system DC International , out: the cassette unit C 100 with cartridges that something had were bigger than the compact cassette and the charm of a paperback book. However, the system could not prevail and was taken off the market in 1967.

Sears had its Sears Tape Cartridge built , a cassette based on the Compact Cassette with a matching recorder, the Sears Tape Cartridge deviated from the Compact Cassette in small details and dimensions, precisely in order to bypass utility model protection and to allow customers to use its special format bind, so the traces of the cassette sides on the tape were swapped.

In 1965, William P. Lear presented the 8-track cassette , which initially caught on in the USA and Great Britain in the car stereo sector, but was pushed out of the market by the compact cassette in the 1980s.

A few years later, Sony also tried to bring Elcaset, a cassette system onto the market that had better sound quality than the compact cassette. But this system did not have long success either.

Triumphant advance

While the response to the compact cassette was still subdued in the late 1960s, that changed in the following decade. This is thanks to the Japanese electronics companies. After the first public presentation at the radio exhibition , numerous Japanese manufacturers built the pocket recorder in different versions and formats. Philips tried to curb this uncontrolled wild growth. Lou Ottens and his team negotiated license agreements with the then Sony boss Norio Ohga in Japan . The Sony boss apparently knew about the dispute between Philips and Grundig and pretended that Max Grundig would grant the licenses for DC-International free of charge. In retrospect, Lou Ottens believes that Norio Ohga was bluffing. Philips gave in and issued the licenses free of charge, but insisted on international standardization . A wide variety of manufacturers brought out cassette recorders worldwide within a very short time .

Young people in particular were enthusiastic about the possibility of being able to record their favorite hits from the radio in a cheap and simple way , to which the music industry feared declines in sales that threatened existence and reacted with campaigns such as Home Taping Is Killing Music . Soon there were combination devices with radio ( radio recorder ), later also in stereo . With the technical progress of magnetic tapes, there was a corresponding progress in the sound quality of the compact cassette. In addition to the progress made with iron oxide strips, the introduction of chromium dioxide and later pure iron coatings also ensured a noticeable leap in quality.

The introduction of Dolby B noise suppression (1968), with the help of which the annoying tape noise could be significantly reduced, was also very important for the triumphant advance of the compact cassette . In 1968 Philips launched the first car radio with a cassette player function and in 1979 the Japanese company Sony launched the first Walkman , a portable cassette player.

At the end of the 1970s, the compact cassette became popular in the home computer sector as an inexpensive and easy-to-obtain mass storage device, before this application was replaced by the floppy disk in the course of the 1980s due to the drop in prices; see also the paragraph compact cassettes for digital data storage .

For background music , normal cassettes were occasionally recorded, but these only used the two stereo tracks individually and transported the tape at a reduced speed in order to achieve 240 minutes of playing time.

Digital successors

The successor to the compact cassette was the Digital Audio Tape (DAT), Sony introduced the MiniDisc (MD) and Philips introduced the DCC digital compact cassette, which is downwardly compatible with the CC, in the early 1990s . These new digital media enable the digital copying of music or data , with MiniDisc and DCC employing lossy audio data compression . With the MiniDisc there is no need to wait for fast forward and rewind and individual tracks can be selected directly. While DAT and MD slowly developed reasonably successfully, the DCC was a complete failure for Philips and was discontinued after a few years. With the widespread use of self-writable or recordable Compact Discs ( Compact Disc Recordable , CD-R) from the late 1990s, however, both the cassette and all of its digital successors (MD and DAT) fell behind completely and their further development was largely discontinued.

Current situation

The cassette has now largely been replaced by digital technology.

In Germany, the compact cassette is sometimes still used as a radio play cassette or audio book for children, and children's cassette recorders can still be found in stores. In the rap area, too , she is known by z. B. DJs spread individually composed mixtapes . The cassette is also used in (extreme) metal , punk or hardcore for demo and promotional purposes. In post-industrial and noise , it is also used for regular publications (with print runs in the two to three-digit range) and for purposes other than those intended as a musical instrument.

Because of the high flexibility of the medium, it is still in use for broadcast recordings without high quality expectations. There is also a small number of associations in Germany, such as the Ring der Tonbandfreunde (RdT) or the Bavarian Kaleidofon , which publish their own sound recordings on cassette every month.

Due to their robustness, cassette media are still very popular in the car. When there are vibrations, there are no dropouts and the medium can be changed easily and without looking. Corresponding devices were still offered by automakers and retrofitters until the 2010s. More comfortable devices also made it possible to skip individual tracks if the acoustic pause is long enough (approx. Four seconds). This partially compensates for the disadvantage mentioned below (winding process). This technique of skipping individual tracks was implemented by Sharp as an automatic program search system in set-top devices in the 1980s .

Disadvantages of the cassette are that, as with the tape recorder, “tape salad ” can occur (for example due to aging of the rubber rollers and belts or mechanically faulty playback devices). The sound loses quality over time due to the magnetization and wear of the head (especially highs). Dropouts - called " drop-outs " - increase over time due to belt dust and abrasion. In contrast to the CD, rewinding or fast forwarding is time consuming. The simple transfer of new content and the low hardware requirements compared to digital media left the cassette in everyday use for a long time in many cases.

However, the supply of brand-new empty cassettes and cassette tapes will be scarce in the future. In Germany, with the bankruptcy of the EMTEC Magnetics Group in 2003, the production of cassette tapes and empty cassettes was discontinued (EMTEC had taken over the empty cassette production from BASF in 1997). After the EMTEC plant in Munich was closed, the magnetic tape factory in Oosterhout , the Netherlands , which last traded as RMG International (RMGi), took over the production of the Munich recipes for professional audio tapes and cassette duplicating tapes based on iron oxide. Production in Oosterhout stopped in spring 2012 and the factory was demolished. The production facilities were transported to Pyral , a specialist in magnetic sound film and formerly part of the BASF / EMTEC Magnetics Group, in Avranches , France . Tapes continue to be produced there.

The only noteworthy manufacturer of empty cassettes worldwide is Panggung in Indonesia . The Korean manufacturer Saehan produces magnetic tapes with cobalt-doped iron oxide for both VHS video and compact cassettes. The cassette tapes are only intended for assemblers and are not available in Europe as conventional empty cassettes. Type II tape is offered by various media providers in the United States. Chromium dioxide tapes are no longer manufactured. After EMTEC Magnetics went bankrupt, BASF demolished its production facility for chromium dioxide in Ludwigshafen.

The number of assemblers is also falling. Manufacturers are companies that record cassette tapes and spool them into industrial cassettes, print and pack them. The last major manufacturer of pre-recorded cassettes, the Pallas Group in Diepholz, stopped production in 2010.

On September 16, 2011, the radio play label EUROPA announced that it would no longer produce MCs from 2012 onwards, only for the series with the most MC collectors ( Die Drei ??? ) production would continue. EUROPA cited the reason that the MC purchases continue to decline and the stocks of the tape material secured in time will not last long, so they want to concentrate on the MC collectors. Children’s series such as Bob the Builder , Thomas, Die kleine Lokomotive , Ritter Rost , Hui Buh , Die Teufelskicker , Hanni and Nanni as well as the well-known radio play series Five Friends and TKKG are mainly affected by the MC attitude . Optimal Media remained in Röbel / Müritz in Mecklenburg as the only cassette assembly company in Germany . There newer radio play cassettes of Die Drei ??? until the cassette production was stopped there in April 2015.

Since the mid-2010s, MCs have been gaining popularity again in the independent sector, especially with bands from a retro revival. Many medium-sized artists such as B. Allah-Las or Morgan Delt publish their albums on compact cassette in addition to the digital and vinyl market. Indie labels such as B. Burger Records have their own division for the publication of cassettes. The online music service Bandcamp saw cassette sales increase by almost 50 percent in 2016.

In 2016 the compact cassette is enjoying increasing popularity again in the indie scene in Malaysia .

In addition, record companies have released a few albums on music cassette in recent years. These are often released as limited editions; In addition, a download code is often supplied with which the music can be downloaded digitally. The soundtrack to the film Guardians of the Galaxy , in which a cassette actually plays a role, took a pioneering role in 2014 . Other mainstream releases on cassette in recent years include Purpose by Justin Bieber , various EPs by The Weeknd , World Be Gone by Erasure and Lust For Life and Norman Fucking Rockwell by Lana Del Rey . 2018 saw a 125% increase in cassette sales in England compared to 2017. Over 50,000 pre-recorded cassette tapes were sold, the highest since 2004. Kylie Minogue alone sold more than 6,000 cassettes from her 2018 album Golden .

Production of pre-recorded cassettes

The tape of prerecorded cassettes is normally recorded before it is wound into the cassette. The cassette tape is supplied on self-supporting rolls (pancakes) with a length of, for example, 2500 m each; these have a diameter of up to 36 cm and contain the tape for about 28 cassettes (varies depending on the playing time, since later only as much tape is wound into the cassette as is required for the specific release). They are recorded on copying machines from endless master tapes or (from 1994) also from digitally stored audio data at up to 128 times the speed on both sides at the same time. In the case of analog reproduction, there are up to five generations of copies between the master tape of the recording studio and the cassette produced, which means that digital processes, in principle, potentially offer better sound quality. As separating information between the pieces of tape intended for the individual cassettes, a short signal lasting a few seconds and a frequency of a few Hertz (in the infrasound range, i.e. to the left of the listening area ) is recorded by the copier .

The recorded tape reels are processed by automatic winding machines together with the empty cassettes ( C-0 cassettes, they only contain leader tape ). These thread the leader tape out of the cassette, cut and glue it to the recorded tape and rewind it into the cassette, based on the low-frequency separation signal mentioned above (which is in the audible frequency range at the high tape speed prevailing during rewinding). The ends of the tape are fed in and out as well as glued with compressed air and held in a vacuum.

The cassettes are then printed or labeled, followed by boxing (inserting the cassettes into the cassette boxes, i.e. the folding covers), possibly followed by packaging steps, e.g. B. Sealing in cling film and packing in cardboard boxes.

Special cassettes

- Adapter cassette : Has no tape, but has a transfer head and cable that connects to more modern playback devices (e.g. MP3 players, originally launched in the early 1990s for use with portable CD players) can. This makes it possible to magnetically transfer the music from the playback device directly to a cassette player. This is useful if you want to hear the music on the playback device loudly, but the existing loudspeakers can only be used via a cassette player (e.g. on a car radio).

- Endless cassette : Partly used for the announcement of answering machines or public address. The playing time varies from a few seconds to several minutes. In the Bernard Cousino method, the tape is pulled out from the inside on the loosely wound take-up roll, as with 8-track cassettes . Some of these cassettes had a drive for the winding mandrels in order to prevent the shutdown of some drives that detect tape end or tape salad when the thorns are standing. The cartridge case lacks holes for the capstan on the second side and for the top centering pins to prevent damaging operation in autoreverse drives or the second side.

- Mini and micro cassettes as miniature versions of the audio cassette were developed in 1967 and 1969, respectively. The belt speed was halved (2.38 cm / s) or quartered (1.19 cm / s). The devices are designed as dictation machines, i. H. simple or simplest devices. Combined with the low tape speed, there are sound properties that only meet the simplest quality requirements. The main uses were answering machines and dictation machines - applications which, thanks to advances in microelectronics and digital technology, nowadays do not require magnetic sound carriers. It was also used as a datasette in laptops such as the Epson HX-20.

- MP3 player in audio cassette form, which decodes the tracks read from an SD card and can inductively transfer them to the audio head of the cassette player.

- Cleaning cassette : optionally has a tape with a nonwoven surface, a mechanically moved lever with soaked nonwoven (Allsop-3) or a completely normal-looking tape that should attract magnetic particle deposits. It is played for a few seconds to minutes to clean the tape head and other tape-guiding parts.

- Demagnetizing cassette : demagnetizes the audio head (e.g. TDK Head Demagnetizer HD-01).

Compact cassettes for digital data storage

From the late 1970s onwards, since the cassette was cheap and mass-produced, it was also used to store computer data on home computers , occasionally in mechanical engineering and, in the GDR, also on professional computers (see Datasette ). With the triumphant advance of faster and more convenient floppy disks and hard drives in the home, the era of this application gradually came to an end from the late 1980s. For data storage there were cassettes with a special tape material. These have a mechanical coding on the underside so that data drives can set their parameters to the special tape. Such cassettes fit mechanically into any normal cassette recorder, but do not have sufficient sound quality for audio purposes. In addition, the runtimes were mostly much shorter (C10 to C20); Loading times over ten minutes for a single program were rather rare, especially when so-called fast chargers were used. The rewinding times have been shortened by the short belts.

Compact cassettes for digital data storage were also used by Blaupunkt in the 1980s for importing station data into car radios with a PCI system .

Further development

Better band types

The IEC standardized four types of tape. These types define the response behavior (nominal bias, recording frequency response) as well as the nominal flow. The band type only says something about the chemistry of the band to a very limited extent.

- Iron oxide (Type I / IEC I): The original tape in the cassette system, so to speak, was the iron oxide tape PES 18 from BASF, consisting of γ-Fe 2 O 3 particles. All tape manufacturers who made tapes for compact cassettes initially referred to this tape. The poor height control prompted many manufacturers to look for alternatives and to force the further development of alternative magnetic particles. Reference blank bands: R 723 DG (BASF), 1979; Y 348 M (BASF), 1995

- Chromium dioxide / CrO 2 (Type II / IEC II): Chromium dioxide is an invention by the US chemical company DuPont , which waspatented and marketedunder the name Crolyn . DuPont pursued a restrictive license policy. Belt manufacturers had to purchase the particles directly from DuPont - the exception was BASF: In May 1971, BASF was able to secure an exclusive license for the production of chromium dioxide. The first chromium dioxide tapes were available from Memorex and Agfa as early as 1970. Agfa used achromium dioxide developedby the parent company Bayer AG , which deviated from the patented DuPont process. In 1971, BASF presented the first complete range of chromium dioxide compact cassettes at the International Consumer Electronics Fair . The pure chromium dioxide tape lost its importance towards the end of the cassette era; in the type II class, the high bias bands dominated from 1990 onwards. BASF and its successor EMTEC Magnetics held onto chromium dioxide until its bankruptcy (2003). Reference blank tape: DIN reference blank tape C 401 R (BASF), 1971; S 4592 A (BASF), 1981

- Chromium dioxide substitutes / cobalt-doped iron oxide / high-bias tape (Type II / IEC II): The cobalt-doped iron oxide tapes, also known as high-bias tapes, belong to the same type II class. These tapes have different physical properties than real chromium dioxide tapes; despite IEC standards, both types of tape are not completely compatible with each other. The development of these alternative band types was fueled by DuPont's restrictive licensing policy. Also in protest to competitor Sony, who had secured a license for chromium dioxide, the Japanese tape manufacturers developed their own alternatives with cobalt-doped iron oxide. Even 3M accelerated this development. Although the chromium dioxide tape was standardized in 1981, reality caught up with the standard. Due to the extreme competitive situation in Japan, the original from BASF was not used for device calibration, but primarily the high-bias tapes from TDK or Maxell. As a result, the IEC II reference blank tape was adapted to reality and the original chromium dioxide reference blank tape was replaced by a tape that is comparable to the cobalt-doped iron oxide tapes (primarily TDK SA). Reference blank tape: U 564 W (BASF), 1987

- Ferrochrom / FeCr (Type III / IEC III): The type of tape consists of an upper layer of chromium dioxide and a lower layer of iron oxide . The extreme center dip in the frequency response is a major weakness. This type of tape disappeared from the market in the mid-1980s. Reference blank tape: CS 301 (Sony), 1981

- Pure iron tape / metal tape (Type IV / IEC IV): The development of metal tape for the compact cassette system began at the end of the 1960s. As early as 1972, 3M presented a metal band that put the newly introduced chromium dioxide band in the shade. In 1979 all well-known tape manufacturers came onto the market with their own metal tape cassettes. Despite the superior sound quality, demand remained at a low level, so that European manufacturers withdrew from research on metal tape in the 1980s. It was only with the success of the compact disc that the metal tape cassette became interesting again for use with music from digital sources. In Japan in particular, the local strap manufacturers introduced numerous Type IV models with high-quality and sometimes bizarre cases. Type IV cartridges disappeared from the Western European market around 1998. Reference blank volume: E 912 BH ( TDK ), 1981

So that the types of tape for the recording and playback devices can be automatically differentiated, there are symmetrical notches on the upper face of the compact cassette: Iron oxide (I): no notch; CrO 2 (II): two outside; FeCr (III): two inside; Metal (IV): four notches. Cassettes of the type FeCr (III) with notches for automatic detection are very rare, as are devices that can correctly evaluate the notches of type III cassettes (e.g. Dual C 814 and Dual C 824). During playback, the type III equalization setting is identical to that of type II and IV. In most devices with automatic tape type selection, type III tapes are recognized as type I, which causes a treble increase of around 4 dB.

The differences between the types of tape are due to their magnetizability: While iron oxide coatings are fully magnetized even at a relatively low magnetic field strength (amplitude or volume), metal coatings can also distinguish between stronger magnetic field strengths, which makes it possible to record higher (louder ), which increases the dynamic range and the signal-to-noise ratio : When playing back recordings with a higher level, the volume control can be turned down in comparison to low level recordings without changing the playback volume; While the volume of the useful signal (e.g. music) has remained the same, tape and device noise are turned down and thus reduced.

The differences between the types and qualities of the tape are also in the geometric area. Short, correctly aligned magnetic needles in the tape layer can emit a significantly higher level at the playback gap at shorter wavelengths (high frequencies at low tape speed). The height adjustment and thus the height dynamics of the tape increases significantly. Therefore, there were also complex two-layer tapes, the thinner layer on the surface was optimized for the high frequency range.

The strengths of the iron oxide coating lie in better depth control, while the chromium dioxide tape has better height control. For this reason, recording predistortion or playback equalization with a time constant of 120 µs is usually used for iron oxide tape, while 70 µs is used for the other types of tape. The equalization with 70 µs helps to reduce the noise in which the high frequency ranges dominate. If the tape type is incorrectly set, the frequency response of the recording will not be correct during playback, which means that the audio material is either too dull (Fe 2 O 3 tape with 70 µs (chrome) setting) or too sharp (e.g. CrO 2 with 120 -µs- (Ferro-) setting) sounds. In order to combine the advantages of iron oxide and chromium dioxide, the two-layer tape (ferrochrome tape) was developed, in which there is a chromium dioxide layer on top of an iron oxide.

Pre-recorded cassettes with chromium dioxide tape are often recorded with a recording pre-distortion of 120 µs; That is, the cassette recorder should be set to ferro tape when playing. (Note the label on the cassette.) With this procedure, the increased level control of the chromium dioxide tape compared to iron oxide tape is not used to reduce the noise by means of 70 µs equalization, but to better reproduce the sound material in the presence and high frequency range can. This technology accommodates the changed listening habits or rather production habits, according to which music today is often high-pitched, the level is set extremely high with less dynamism in modern productions at the same time. This results in the better compromise for the noise (see Loudness War ).

Due to the ferromagnetic properties of the tapes ( hysteresis ) is the so-called in the recording bias (engl. Bias ) is needed. The strength of the premagnetization must be optimized for the strip material used. Pure iron strips require a significantly stronger pre-magnetization than chromium dioxide strips, which in turn require a stronger pre-magnetization than iron oxide strips. If the pre-magnetization is set too high, the quality in the high-frequency range is reduced; (see also Dolby HX Pro ).

Measurement

Higher quality cassette decks measure themselves to the actual tape properties through test recordings (partly automatically), i. That is, they set the exact strength of the pre-magnetization or recording pre-distortion. In the case of very inferior cassette devices, instead of an electric erase head, a fold-away permanent magnet is often used to save money; at the same time, instead of high-frequency (alternating current) pre-magnetization, only pre-magnetization using a direct current is implemented. In this way the oscillator circuit is saved. The recordings of such devices sound fundamentally noisy (see also tape, pre-magnetization ).

Noise reduction

The problem of noise during playback was attempted to be overcome by means of noise suppression methods. The best known process is the Dolby -B system. The successor process, Dolby C, was also widely used, while the further improved Dolby S did not appear until the end of the cassette era and was therefore no longer of great importance. High Com from Telefunken as well as dbx from dbx and DNL from Philips were of little importance .

dbx and HighCom recorded the entire frequency range instead of just the treble range as with Dolby B. "Dbx" was known for its clearly perceptible "breathing", in which the rise and fall of the noise level could be heard before and after quieter passages. dbx was available as a stand-alone accessory that could be used with any recorder. The noise suppression was good here, as with HighCom , but often did not work fast enough. Tapes dynamically compressed with dbx therefore had to be adjusted carefully so as not to distort. The compression was only efficient for the better types of tape, chromium dioxide and pure iron (metal), tapes made of iron oxide had too weak a treble reproduction due to the material used. A purely playback-side noise suppression was DNL , while all other methods dealt with recording and playback.

Azimuth problems

A major weakness of the compact cassette system is that there are elements of the tape guide in both the drive and the cassette housing. Mechanical inaccuracies in the cassette housing and drive and their possibly unfavorable combination result in a dull sound. In order to be able to fully reproduce the high frequency range, the magnetic recordings must be scanned exactly as they were recorded during the recording. In both cases the gap between the head and the tape should be exactly perpendicular to the direction of travel or the edge of the tape. This vertical alignment is called azimuth , as in celestial geometry . In order to ensure that the belt runs exactly, all elements over which the belt runs must be designed, manufactured and adjusted with the greatest care. In addition to the azimuth problems with reel tape, there is also the influence of the cassette housing. The effect is intensified by the low tape speed of the compact cassette (associated with a short wavelength on the tape), but it is reduced by the narrow magnetic tracks. A case that is not made with the utmost precision cannot deliver high quality even with the best tape and equipment.

A dull playback is usually the result of a recording or playback head incorrectly adjusted in azimuth or a bad cassette housing. If a tape is played back on the same device on which it was recorded, the errors largely cancel each other out and the azimuth problem can then be neglected. With different drives, such as B. when playing in the car, it becomes critical. The recording device of the music cassette manufacturer can also be the cause or (more often) the cassette housing used there. The Dolby B noise reduction intensifies the problems of an existing azimuth problem, so that an azimuth error is very often the cause of dull Dolby B recordings. Since the tape travel always fluctuates slightly, the azimuth also varies. A fluctuating high-frequency reproduction is particularly noticeable and annoying.

Playing back your own “old” compact cassettes or music cassettes is often critical, as recording and playback devices differ. High-quality, well-maintained playback drives are often no longer available. This is particularly annoying with digital dubbing. A careful, slight readjustment of the sound head with a demagnetized screwdriver often helps , individually for each cassette side. A mono setting during the adjustment helps significantly.

Insertion, visual inspection, ejection, operation

Depending on the type of device, cassettes can be inserted into the playback devices (or recorders) from above or from the front. DJs tend to use cassette decks with one or two open pits on the upper side of which the cassette can be pressed flat by hand and locked into place, with the open side facing the operator's body, so that both the labeling for the content (usually only this one side of the cassette) can be read upright and the loose fitting of the tape to the cassette opening can be visually checked. Such devices could have small removable covers that only cover the pits or a large hinged cover on two hinges that covers the entire top of the device - as is often the case with turntables - against dust and drink splashes and ideally remains in the partially open swivel position.

Simple small transportable devices right up to the last step of miniaturization, the Walkman, required the same direct manual insertion behind / under an open small flap.

Originally and in floor-standing devices, however, the hinged lids formed guide grooves into which the cassette is inserted with the closed or open broad side first, depending on the type. The cassette is then brought into position by closing this “drawer”. The mechanism of these drawers ranged from a hinge with a spring and an audible click through hydraulic damping to the gentle, almost silent action of a servo motor.

The lid or drawer is transparent over the area of the cassette viewing window and there is a mirror film underneath in the device so that the position of the tape roll can be checked. The three-toothed tape spindles on both sides also remain visible and it can be observed - on the teeth or facets - whether they are standing still or turning slowly (depending on the tape position) or blurring fast when rewinding.

The fully inserted cassette penetrates these winding mandrels, two dowel pins and the tape drive shaft ( capstan ) at openings . The sound head is only pressed against the tape and the rubber pressure roller against the capstan shaft by pressing the mechanically acting, locking button to play, and at the end of the operating range the drive and thus playback is started.

To make a sound recording, in addition to pressing the start button (with arrow pointing to the right, the direction of tape travel), the recording button (usually marked in red) must also be pressed at the same time. If the anti-erasure tab is missing at the corresponding corner of the closed long side of the cassette, the sensor will feel into the void there and block the recording button.

For installation in car dashboards, devices have been developed into which the cassette can be pushed against the spring force of an ejector mechanism with a slot. Either with the wide open side of the cassette first or with a narrow side, then the shape of the slot shows where the slightly higher open side must be oriented.

In all cases, the desired side of the game (forward) A or B (sometimes 1 or 2 ) must be oriented with the label facing up, most shops also allow this label to be read. In the case of top loaders, the long side of the cassette open to the tape is almost always oriented towards the front, in the case of front loaders in the drawer towards the bottom.

Devices with a “reverse” function also allow playback by reversing the direction of travel of the tape, so that a cassette can be played completely on both sides without having to turn it manually, as can endless play. However, depending on the space at the end of the magnetic tape plus (twice) the length of the leader, there are certain pauses.

With the exception of the simplest children's toy device, in which a clutch slips and possibly squeaks, from the mid-1970s the devices had an automatic switch-off when the lap stopped when the end of the belt was reached. In the simpler case, only the motor is switched off. The audible servomotor solution is better, in which the magnetic heads and the rubber pressure roller that is to be protected are also moved away.

By pressing an eject button or opening the drawer by hand, the cassette is disengaged or lifted out a little. In the case of car devices with a slot, the cassette is pushed out a little; after manual removal, a flap closes the slot from the inside against dust.

Simple devices manage tape transport with a controlled constant speed and thereby variable, fast-running tape winding and fast rewinding with a single motor. Even the disengagement of the tape head etc. at the end of the tape can be driven by the same motor. More precise synchronization of the belt is achieved by a dedicated motor only for the belt transport.

Broadcast reports

- Sebastian M. Krämer: 50 years of compact cassette . In SWR2 “Knowledge” from December 9, 2013

literature

- Paul Arnold: Away from the record - towards the cassette? In: Ernst Günther, Heinz P. Hofmann, Walter Rösler (eds.): Cassette. An almanac for the stage, podium and ring (= cassette ). No. 5 . Henschelverlag Art and Society, Berlin 1981, p. 82-85 .

- Gerhard Heinrichs: Tape and cassette recorder service. Franzis, Munich 1988, ISBN 3-7723-5703-2 .

Web links

- Comparison of almost all magnetic tape cassettes

- A brief history of the history of magnetic tape technology

- The TESTcassette of the DHFI shows the possible state of the CompactCassette technology (1980, Arndt Klingelnberg).

- Photos of hundreds of compact cassettes, cooperation appreciated

- Instructions for digitizing audio cassettes

- Further article about the use of the compact cassette as a data carrier for computer games

- Michail Hengstenberg: Music cassette , one day on Spiegel Online from January 13, 2010

About the production of pre-recorded cassettes

- Taylor Williams: Tapematic Audio Cassette Winding machine , Youtube, April 5, 2013

Individual evidence

- ↑ Eric D. Daniel, C. Dennis Mee, Mark H. Clark: Magnetic Recording: The First 100 Years . The Institute of Electrical and Electronics Engineers, 1999, ISBN 0-7803-4709-9

- ↑ a b c Wierd Duk: Band salad that changed the world. Invention of the music cassette. In: Zeit Online . August 28, 2013, accessed September 11, 2016 .

- ↑ a b Sebastian M. Krämer: Ear lining out of a jacket pocket - 50 years of compact cassette . In: SWR2 knowledge. Dossier on the broadcast of December 9, 2013

- ↑ [1] , cassette turning mechanism in action (video, English)

- ↑ a b This figure was based on the template: Inflation was determined, has been rounded to a full 100 EUR and relates to the previous month of January

- ^ Friedrich Engel, Gerhard Kuper, Frank Bell: SIXTH VOLUME: Music from cassettes. In: Zeitgeschichten. Magnetic tape technology as a culture carrier. Edition 2010, p. 428ff.

- ↑ Techmoan: It's not a cassette - so what is it? , YouTube, August 23, 2019

- ↑ https://www.youtube.com/watch?v=OV2EhEd46BY

- ↑ www.digitalfernsehen.de Played out: audio cassettes hardly used anymore. August 10, 2007

- ↑ bndestem.nl

- ↑ RMGi website with press release

- ↑ panggung.com ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ saehanmedia.com

- ↑ pressrelations.de

- ↑ Thorsten Firlus-Emmrich: Production stop - the end of the compact cassette. In: Wirtschaftswoche . July 1, 2010, accessed February 10, 2014 .

- ↑ natuerlichvoneuropa.de ( Memento of the original from February 1, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ The music cassette survives in the nursery. In: Focus Online . September 10, 2012, accessed February 10, 2014 .

- ↑ Rewind? In: Now . September 18, 2015, accessed September 30, 2015 .

- ↑ http://www.rollingstone.com/culture/news/why-the-cassette-tape-is-still-not-dead-20160418

- ↑ Now sales of music cassettes are also increasing again . ( winfuture.de [accessed June 4, 2017]).

- ↑ http://video.tagesspiegel.de/comeback-der-kompaktkassette-in-sudostasien.html

- ↑ Music cassettes are in great demand again. Retrieved January 10, 2019 .

- ↑ Techmoan : Pre-recorded Cassettes' Last Stand , YouTube, January 24, 2017

- ↑ Techmoan : Cassettes: Lenticular Classics & Endless Loops , YouTube from September 13, 2016 ( picture )

- ↑ KAWAMURA2014: エ ン ド レ ス カ セ ッ ト の 構造 (construction of the endless cassette) 06/12/2015

- ↑ Patent DE 3235425 C2 Magnetic recording medium and process for its production , registered on September 24, 1982

- ↑ Gert Redlich: After a quarter of an inch there was another eighth of an inch ... online at the magnetbandmuseum.info, accessed on December 22, 2013

- ↑ Comments are based on: Friedrich Engel, Gerhard Kuper, Frank Bell: SIXTH BAND: Music from cassettes. The magnetic tape storage successor to iron oxide. In: Zeitgeschichten: Magnetic tape technology as a cultural medium . Edition 2010, p. 456ff; Table 31: IEC reference blank tapes for home and professional applications, p. 540

- ↑ Azimuth Precision of Compact Cassette Shells, AES Hamburg 1989 No.2808 , Arndt Klingelnberg