Explosion of the Oppau nitrogen works

The explosion of the Oppau nitrogen plant occurred in the Badische Anilin- & Soda-Fabrik in Oppau , which today belongs to Ludwigshafen am Rhein . On the morning of September 21, 1921, at 7:32 a.m., there were two explosions in quick succession of around 400 tons of ammonium sulfate nitrate , a mixed salt of ammonium sulfate and ammonium nitrate used as a fertilizeris used. The cause of the accident was explosions in a storage silo, with which the hardened salt was loosened. Such explosions had already been carried out thousands of times and were considered safe until then. As a result of various process changes, the ammonium nitrate in the silo in Oppau had most likely accumulated above a critical concentration in places, causing one of the explosive charges to trigger the first detonation of 70 to 80 t of the fertilizer. Another explosive charge then initiated the second, more violent explosion four seconds later of 300 to 400 tons of ammonium sulfate nitrate, which had been heated and finely divided by the first explosion.

According to official figures , 559 people were killed or missing in the blasts, and another in 1977 were injured. The detonations damaged buildings 75 km from the scene of the accident and could be heard as far as Munich and Zurich. In terms of the number of victims, it was the biggest accident in the history of the German chemical industry to date and the largest civil explosion in Germany. Carl Bosch, Chairman of the Board of Management of BASF, ordered that ammonium nitrate production in Oppau be stopped immediately. It was not resumed until two decades later.

The history of the Oppau nitrogen works

The industrial synthesis of ammonia

The sufficient availability of nitrogenous fertilizers to improve the harvest was a pressing problem in the 19th and early 20th centuries. After only manure was initially used to fertilize the agricultural areas, sodium nitrate from Chile (Chile's nitrate) was added from the 19th century - one of the few natural occurrences of sodium nitrate . Since the quantities of Chile nitrate were limited, the production of synthetic nitrogen compounds became an important research area at the turn of the century . In addition to metal salts such as sodium nitrate, ammonium salts - which are made from ammonia as synthetic nitrogen fertilizers - can also be used.

Since around 1900 Fritz Haber has been concerned with the synthesis of ammonia directly from the elements nitrogen (which can be obtained in unlimited quantities from air ) and hydrogen with the help of various catalysts at elevated temperatures. In 1908 the Badische Anilin- & Soda-Fabrik applied for a patent for this process for the direct synthesis of ammonia. From 1909 onwards, Alwin Mittasch , who was busy optimizing the catalysts used , worked on the industrial implementation of the process in the newly established BASF ammonia laboratory, to which Carl Bosch was subordinate. In July 1910, the first 5 kg of ammonia were produced at the BASF plant in Ludwigshafen using the so-called Haber-Bosch process . After the commissioning of larger reactors, daily production rose to 30 kg in 1911 and then to 1000 kg in 1912.

The establishment of the nitrogen plant in Oppau

Convinced of the large-scale feasibility of these manufacturing processes for ammonia and ammonium sulfate fertilizers, BASF decided in November 1911 to build a nitrogen plant [note. 1] in Oppau. Construction began on the 1.5 km north of Ludwigshafen plant with a floor area of around 500,000 m² on May 7, 1912. After Krupp had in the meantime made special stainless steels that were not susceptible to decarburization , which, because of the high temperatures required for synthesis, were combined with pressure of up to 200 bar were required, in September 1913 the factory commissioned the world's first reactor for the industrial production of ammonia using the new Haber-Bosch process . The daily production output was around 30 t of ammonia, with which around 36,000 t of ammonium sulphate ( ammonium sulphate , AS ) could be produced per year.

The First World War

At the beginning of the First World War , the sea blockade of the Allies in the German Reich led to supply bottlenecks for sodium nitrate ( Chile's nitrate ) - which was now needed not only in agriculture, but all the more urgently as an oxygen-supplying component for explosives . In September 1914, BASF and the German government made the saltpetre promise , which ensured the supply of nitrates ( saltpeter ) to the German empire , initially in the form of sodium nitrate and later as ammonium nitrate ( ammonium nitrate , AN ). Carl Bosch promised to deliver 5,000 t of sodium nitrate within just six months. In return, the Reich government was ready to provide 6 million marks for the production plant, which was to reach a capacity of 7,500 tons within eleven months. In the same month, construction work began in Oppau on a pilot plant for the production of nitric acid through the oxidation of ammonia and in the following month (October 1914) work began on the white salt factory (so called because of the color of the nitric acid produced) in which the first kilns went into operation in February 1915. This was later replaced by an optimized system.

Due to its proximity to France, French air raids on the BASF plants in Oppau and Ludwigshafen began in May 1915 - Oppau supplied nitrates for explosives and Ludwigshafen produced chlorine gas , which was first used as a chemical weapon by German troops in April 1915 . Even if the damage in the two plants remained low overall, after negotiations with the government, BASF began building a second nitrogen plant in central Germany in April 1916 . The Leunawerke near Merseburg (later Ammoniakwerk Merseburg GmbH ) started operations in April 1917. In Oppau, the factory management decided to run the production facilities continuously despite the air raids, as production had already declined significantly. Although the capacity rose to 100,000 t in 1916/1917, the actual production volume was not much more than 61,000 t of nitrogen due to various problems caused by the war. In 1918, ammonia and saltpeter accounted for half of BASF’s sales. This used the profits to expand the Oppau plant. During this time, the two nitrogen plants in Oppau and Merseburg together produced products with a nitrogen content of 90,000 t, which were used almost exclusively for military explosives.

The time of the Weimar Republic

After the armistice, the Reich government canceled all orders for explosives and chemical weapons, which at the time made up almost 78% of BASF’s sales. The French army marched in on December 6, 1918. It was followed by inspectors and technical commands who were supposed to officially monitor disarmament, but were also out to procure the production technologies of the German chemical industry, especially ammonia synthesis. The two chemical plants on the left bank of the Rhine in Oppau and Ludwigshafen were then under French occupation until 1920 . The Versailles Peace Treaty , which came into force in January 1920, ended the direct occupation of these two BASF plants. At the same time, the two ammonia works in Oppau and Leuna were obliged to deliver reparations of 50,000 t of ammonium sulfate per year to the Allies, 30,000 t of which to France, which resulted in losses due to reduced production volumes due to strikes, a lack of fuel and a lack of machinery Oppau led. During the same period, the number of employees in Oppau rose by leaps and bounds due to those returning from the war, fluctuation rose to 70% by 1920 and there were repeated strikes, work stoppages and occupations. In 1921, an estimated 11,000 workers and employees were employed in Oppau.

| Fertilizer production in Oppau in t |

1917 | 1918 | 1919 | 1920 | 1921 |

|---|---|---|---|---|---|

| Potassium ammonium nitrate | 13 | 4,216 | 13 733 | 16 760 | 312 |

| Ammonium sulphate nitrate | 8 252 | 52 614 | 62 940 |

After the war, the fertilizer market was strategically more important to BASF than the dye market. Ammonia production alone accounted for around 59% of BASF’s sales in 1919.

Since ammonium nitrate (ammonium nitrate ) was more productive than the sodium nitrate ( Chile nitrate ) previously used in agriculture , ammonium nitrate production for fertilizer production was continued in Oppau after the war. The problem that ammonium nitrate is very hygroscopic and has a strong tendency to clump was initially countered by adding potassium chloride ( chlorinated potassium ), which formed ammonium chloride and potassium nitrate . The resulting product was sold under the name potassium ammonium nitrate . Later, the potassium chloride was increasingly replaced by ammonium sulfate (AS). This mixed fertilizer was sold under the name ammonium sulphate nitrate ( ammonium sulphate nitrate , ASN ) or mixed salt . With a nitrogen content of 27%, ASN contains as much effective nitrogen in 50 kg (one hundredweight) as 90 kg (180 pounds) of Chile nitrate. At that time, ammonium nitrate was primarily used in explosives as an oxygen-supplying component; its property that it can be made to explode simply by igniting it was not yet widely known. By adding blasting inert substances such as ammonium sulfate to the explosive ammonium nitrate, ASN - like AS - was no longer an explosive according to the findings of the time, but, as a civilian product, met the requirements of the Versailles Treaty.

Production process

Chemical basics

The ammonium sulphate nitrate (ASN) was produced in Oppau in a multi-stage process. First, ammonia (NH 3 ) from the Haber-Bosch process was oxidized to nitric acid (HNO 3 ) in a separate production building . This was then converted into ammonium nitrate with gaseous ammonia :

This resulted in a solution with a concentration of 55 to 58 g of ammonium nitrate in 100 ml of solution.

Ammonium sulphate was obtained by the Baden aniline and soda factory using a proprietary process. For this purpose, finely ground gypsum (calcium sulfate, CaSO 4 ), which was suspended in a dilute ammonium sulfate solution, was made to react with gaseous ammonia and carbonic acid ( carbon dioxide , CO 2 ):

The carbon dioxide required for this came from the synthesis gas process, which already supplied the hydrogen required for the ammonia synthesis . The mainspring for the conversion was the formation of the less soluble calcium carbonate .

In the early days of ASN production in Oppau, ammonium nitrate and ammonium sulfate were first dried separately. After simply mixing the two solid salts on a conveyor belt, the ASN double salt was formed from them during storage in the silo for several days :

In order to reduce costs, the process was changed shortly afterwards: the ammonium nitrate solution was first concentrated to 85 to 90% in cast iron vacuum evaporators and then the solid ammonium sulfate (or potassium chloride for potassium ammonium nitrate) was added in cast iron stirred vessels. This process change also had the advantage that the ammonium nitrate no longer had to be handled in dry form. The hot mixture was first transported with screw conveyors in air-cooled iron channels to a conveyor belt, where the desired ASN double salt crystallized. At the end of 1920, the process was modified again and the thin AN / AS solution was finely atomized at 110 to 120 ° C through a fixed 10 cm nozzle with compressed air . As a result, the remaining water evaporated faster, the salt cooled to 60 ° C and trickled to the ground as fine snow. The atomization resulted in a finer grained product with lower residual moisture (1.5 to 3%, instead of the original 7.5%). It was less prone to clumping.

The ASN double salt naturally crystallizes in a mixing ratio of 1 mol of ammonium sulfate and 2 mol of ammonium nitrate, which corresponds to a weight fraction of 54.8% ammonium nitrate. In order to be sufficiently far from the explosion limit (see handling section ), a 5% excess of ammonium sulfate was deliberately chosen in Oppau, so that the ratio of ammonium nitrate to ammonium sulfate was 50:50 ( Oppau salt or simply mixed salt ).

Production facility

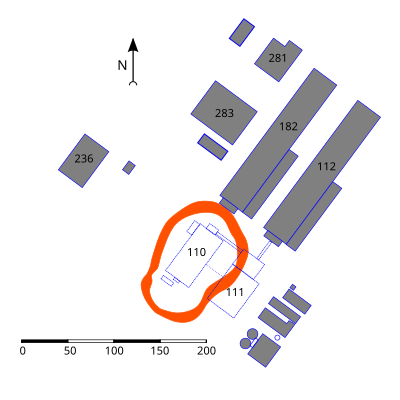

The plant in Oppau produced 600 tons of ammonium sulphate per day, of which 100 tons were used for the production of ASN. With an AS / AN mixing ratio of 50:50, this resulted in a daily production volume of 200 t ASN. The production and storage of ammonium sulphate nitrate in the Oppau plant was divided between the buildings Op 111, Op 110, Op 112 and Op 182. The actual production was housed in building Op 111. The subsequent drying, cooling and complete conversion into the double salt took place in the building Op 110, a 61 m × 31 m wooden building with a wooden vaulted roof, which rested on a 5 m high retaining wall made of reinforced concrete . To do this, the saturated solution was pumped through a pipe into the Op 110 building, where it was then sprayed. The material later reached the storage silo Op 112 via an underground conveyor belt and from there by another route to a second silo called Op 182. Both silos were 172 m long, 31 m wide and 20 m high. The capacity was 77,000 m³ each, which means that Op 112 and Op 182 together could hold around 100,000 t ASN. The high storage capacity was necessary because ASN was a seasonal product in agriculture that was initially produced in stock and then shipped in large quantities in spring and autumn.

handling

Due to the residual moisture and its hygroscopicity, the ASN clumped together in the silos and had to be loosened before being discharged (removed). This was usually done with the help of smaller explosions, since mechanical dismantling with a pick and shovel or excavator was only possible to a limited extent. It was already partially known that AN could be detonated - in July 1921 there was an explosion in Kriewald when AN was loosened by detonation. To assess the risk associated with the blasting, both BASF and Agfa had carried out extensive laboratory and blast tests in Wolfen . These explosive tests showed that the explosive properties of ammonium nitrate can "be made to disappear completely" by adding inert salts such as potassium chloride, sodium chloride or ammonium sulphate. It was found that ammonium nitrate decomposes at 170 ° C, but ASN only decomposes at 230 ° C. In numerous explosion tests according to Trauzl ( lead block bulging ) it was found that the limit of explodibility is at a proportion of at least 60% ammonium nitrate. The ammonium sulphate nitrate double salt with 54.8% AN and 45.2% AS proved - as did the Oppau salt , which consisted of equal parts AN and AS - to be non-explosive. In addition, no self-heating, which would have indicated chemical instability, was found. All tests carried out on the flammability of ASN were also negative. The loosening by means of an explosive charge was also considered very safe because it had already been used with superphosphate fertilizers and had been used around 20,000 times by BASF in Oppau and around 10,000 times by Agfa in Wolfen since the end of the war without any problems. The relevant supervisory authorities were aware of the procedure and approved it.

In Oppau, 2 to 5 explosive cartridges perastralite were usually used per borehole for loosening . They were detonated by a detonator with 2 g of explosive, which could be ignited electrically or with a fuse . Occasionally up to 18 cartridges per borehole or in certain cases 150 cartridges in 25 boreholes at the same time without any complications ever occurring.

Chronology of events

Before the unlucky day

While the salt slurry was sprayed in the so-called spraying stall in building Op 111 and from there the ASN was continuously transported via a conveyor belt into silo Op 112, various spraying methods were tried out in building Op 110 in the course of 1921. As of April 27, the ASN was initially sprayed onto different, constantly changing heaps. The material was left lying around, which caused the piles to overlap over time. This was hoped for better mixing in the event of slight material fluctuations. The residual moisture of the salt was around 4% during this time. At the end of May, after being loosened by 100 to 120 explosive shots, this material was relocated from the north-eastern area; a total of 3500 t remained in the south-western part and on the eastern side. In the second campaign, which ran from late May to September 19, the saline solution was then sprayed along the center line of the building over the floor opening for the conveyor belt. The nozzle was mounted unchanged at a height of 4.5 m at an angle of 45 °. Most of the salt fell directly onto the conveyor belt and was thus carried away immediately, the rest formed a wall and bridges over the floor opening and deposited as fine dust on the beams in a 35 to 45 cm high layer, especially near the outer walls of the bunker. In this campaign, the residual moisture could be reduced from 4% to an average of 2%. From September 2nd to 4th, around 150 t of pure AN were sprayed over the conveyor belt on a trial basis, onto which AS was then shoveled as it passed through the Op 111 building. Remnants of the contractor in building Op 110 were carefully scraped off and removed. On September 19, ASN production was then stopped so that the Op 110 building could be emptied. At this point in time, around 4500 t of ASN with various densities between 0.9 and 1.3 g / cm³ were stored there (another 7000 t were stored in the Silo Op 112). On September 20, the withdrawal by the civil engineering company Gebrüder Kratz , active in the work contract, began . Since the salt mass had hardened how often, the demolition master carried out the first explosions in the afternoon, whereby, according to witnesses, he had detonated more than thirteen times with 17 cartridges of the same explosive. Previously, 100 to 120 rounds were blown up in June.

The morning of September 21, 1921

At 7 a.m. on the morning of the accident, the demolition manager Hermann Humpe was busy preparing the next demolition. Humpe, who was considered a conscientious man, had been trained by a demolition technician from December 1920, was licensed as demolition engineer and employed by BASF. Blast holes were punched 80 to 120 cm apart around the top of the fertilizer heap at an angle to the outside with an iron pipe, two to three explosive cartridges and a detonator capsule were added and then dammed with salt. That day the detonators were detonated with a fuse and the demolition master had a maximum of 66 cartridges available in the morning.

Half an hour before the start of the day shift, around 820 employees were working in the plant, a total of 2,225 people had already entered the plant when there was a huge explosion at 7:32:14 a.m., followed four seconds later by another, even more violent, explosion [Note 2] . At the site of the Op 110 building, a crater 165 m long, 95 m wide and 18.5 m deep was created, which corresponds to an earth ejection of around 12,000 m³. In press publications eyewitnesses were quoted as saying "that a huge fire phenomenon shooting into the sky like a lightning bolt" expanded "into a giant ring" and a "huge gray-black" cloud of dust fell with "terrible rolling and pattering" "in all directions". Other newspapers reported that "bright flashing flames hundreds of meters high" or a "pillar of fire" could be seen.

Within a radius of 480 m, a third of 300 buildings were almost completely destroyed. In the nearby town of Oppau with 7,500 inhabitants, 1036 buildings were completely destroyed at a distance of 600 m from the explosion center and another 928 buildings were seriously damaged at a distance of up to 900 m, the remaining 89 buildings showed only slight damage. A total of 3 750 main and auxiliary buildings in Oppau were damaged or destroyed. Almost all people living in Oppau became homeless. In the BASF plant in Ludwigshafen, 1,500 m away, roofs were covered and window frames were torn out. In Edigheim , bordering on Oppau in the northwest, 678 of 2,138 buildings were completely destroyed and a further 1,450 were damaged.

On the opposite side of the Rhine, there was massive damage, especially on Friesenheim Island . Buildings and warehouses there collapsed or were badly damaged, several people were killed and many injured. In the vicinity of Ludwigshafen, the Vorderpfalz and Mannheim , great damage was also done and people were killed by collapsing buildings. It is reported that machine parts were thrown as far as Mannheim. In Worms Cathedral , 13 km away , all the medieval stained glass windows were broken. In Heidelberg , 25 km away , roofs were covered and a tram jumped off the rails. Damage to buildings was observed up to a distance of 75 km. The tremors could still be felt in Frankfurt and Mainz, and the explosions could be heard in northeastern France and even in Munich , Zurich and Göttingen .

The Ludwigshafen Police Department reported that 200 bodies had been recovered by 4 a.m., while no reliable statement could be made about the number of injured: the slightly injured rushed home shortly after the accident, while the seriously injured were driven to all of the hospitals in the surrounding towns and cities had been distributed.

Since everyone in the immediate vicinity of the explosion was killed, the course of the accident cannot be reconstructed from witness statements. What is certain is that around 400 t of the 4500 t ASN stored in warehouse Op 110 exploded [note 3] . In the first, weaker explosion, the blasting caused almost 70 to 80 t of loose material to be co-detonated. Due to the energy released, the material remaining in the building Op 110 was finely distributed and heated to such an extent that 300 to 400 tons exploded in the following explosion . 4] . The remaining material was thrown out by the force of the explosions and was found in the area in the form of a fine layer of salt, but also as chunks of up to 1.2 tons. In the afternoon, prolonged rain set in, which presumably quickly washed the aerosol particles of the clouds of smoke out of the air and cleared the air.

After the accident

The company, local authorities and the French occupation forces took part in the rescue and relief measures and ordered the available means of transport to the scene of the accident in order to transport the recovered wounded away. Colonel Mennetrier, the French commander in Ludwigshafen, appeared at 8:30 a.m., accompanied by General de Metz with the first military units. The medical services under Colonel Daugan and the French Red Cross moved from the French garrisons of the 30th and 32nd Corps in Speyer and Landau . To take care of the injured, the French Army on the Rhine deployed all available military doctors and vacated the quarters in Ludwigshafen. Paul Tirard , the High Commissioner of the Inter-Allied Rhineland Commission , personally arranged for ten Red Cross Sisters to be sent from Paris and donated 75,000 marks as first aid for the families of the victims. The Lord Mayor of Frankfurt, together with the Red Cross, organized an aid campaign with several fully occupied ambulances and 14 doctors. Fritz Haber, who was in Frankfurt 70 km away, perceived the explosion as a kind of earthquake. Carl Bosch, who had been Chairman of the Board of Management of BASF since 1919 and at that time was in his villa in Heidelberg, was alarmed by the rattling of the windows and the cloud of smoke that formed and immediately hurried to the Oppau plant. It is reported that he dealt with the resulting chaos in an exemplary manner, but collapsed physically a short time after the funeral service and did not appear for several months afterwards.

After the disaster, numerous rumors circulated about the disaster. The German press reported on some apocalyptic scenes, which, however, must often be viewed as exaggerated. As early as 10:30 a.m., BASF management announced that there was no risk of further explosions. In the following days she had to deny several press reports that the Oppau plant was completely destroyed, that the Haber-Bosch plant was involved in the explosion or that greenish gas clouds pouring out were over the plant. In an official announcement by the management , they named the camp with 4500 t ASN as the location of the explosion and asked the press to publish "only guaranteed facts":

“Unfortunately, we have to make the perception that the catastrophic explosion that struck our Oppau plant and which is difficult enough in any case is often greatly exaggerated in the press. In order to spare the population, which has already been too badly affected, unnecessary further agitation, we urge the press to only communicate verified facts and to refrain from reporting the numerous uncontrollable rumors that are in circulation. As on Wednesday, we will continue to provide news as soon as the cause and effects of the explosion have actually been determined, which will take some time given the size and scope of the disaster. According to the news that we received by Wednesday evening, a total of 244 deaths have been reported so far . A further increase in the number of dead and wounded is to be expected, especially since around 70 people are missing . The message that the whole Oppau factory has been destroyed is incorrect . The actual manufacturing facilities are relatively little damaged. We therefore hope that the production of ammonia water can be resumed in a few months. In the factories in Ludwigshafen, operations run undisturbed. "

On the day of the explosion, Carl Bosch ordered the immediate cessation of ammonium nitrate production in Oppau, which was only resumed two decades later. By order of the authorities, the access to the collapsed silo Op 112, in which 7,000 t of ASN was still stored, was cordoned off with barbed wire and guarded day and night. After a site inspection on September 30th, a group of experts decided that the withdrawal of the salt by purely mechanical processes does not pose a risk. The blasting of fertilizer mixtures was forbidden by the Prussian Minister for Trade and Industry Wilhelm Siering on December 16, 1921.

Funeral service

On Sunday, September 25, 1921, there was a memorial service in the Ludwigshafen cemetery, at which the Reich President Friedrich Ebert , the Bavarian Prime Minister Graf Lerchenfeld , the Baden State President, the President of the Bavarian State Parliament and numerous representatives of authorities and associations as well as around 70,000 People participated. The French Generals de Metz of the Inter-Allied Rhineland Commission and Daugan as the representative of the military commander were also present. Carl Bosch said in his funeral speech:

“No malpractice and no sin of omission caused the disaster. New, even now inexplicable properties of nature have mocked all our efforts. The very substance that was destined to provide food and life for millions of our fatherland, which we have produced and shipped for years, has suddenly turned out to be a grim enemy for causes we do not yet know. He laid our work in rubble. But what does it all compare to the victims the disaster has claimed! Here we stand completely powerless and impotent, and all that we can take for granted that we can do to comfort the grieving bereaved and the injured is nothing compared to the losses. "

The Reich President, the Bavarian Prime Minister, the Baden and Württemberg Prime Ministers and the Bavarian Trade Minister then visited the site of the accident under the guidance of the directors of BASF, met there with representatives of workers and employees and visited victims in the hospitals. The mayor's office of Ludwigshafen reported in the evening that up to this point 235 dead had been identified and a further 75 dead had been buried unknown. Another 90 people are still missing. On the same day the Reich Assistance Committee for Oppau-Ludwigshafen was founded in the Reich Labor Ministry.

Accident victim

The exact number of dead and injured is not known. According to official figures, 559 people were either killed or permanently missing. The fatalities included 140 BASF employees, 298 employees from other companies and 22 other people from the local area of the plant. 38 factory employees and 61 employees from external companies remained missing. A total of 1977 people were injured. The report of the Bavarian Commission of Inquiry, on the other hand, speaks of 509 dead and 1917 injured, the report in the BASF works newspaper of October 1921 gives 586 dead and missing and 1952 injured. Lothar Wöhler from the TU Darmstadt recorded 565 deaths in 1923, the French ARIA report from 2008 lists 561 dead and 1952 injured, while the FFI report from 2016 only roughly speaks of more than 500 deaths. However, the number of victims could have been significantly higher if the explosion had taken place a little later, after the start of the regular day shift, because many workers were not yet at their workplaces at the time of the accident.

First aid and claims settlement

Donations in money and in kind were collected throughout the German Reich and abroad. Dance halls and schools in the region were used to provide emergency accommodation for those who had become homeless. BASF made its company kitchens available for supply. The French occupation forces ordered four mobile field kitchens to Oppau. The Red Cross organized meals in the people's kitchens in Mannheim and Ludwigshafen, and the Salvation Army also supported the distribution of food to the needy.

On September 22nd, the Reich President allocated 250,000 marks to the relief organization from his disposition fund. By September 24th, donations to the value of 24 million Reichsmarks had been received. All daily newspapers printed in their Sunday and Monday editions the appeal of the Reich Aid Committee Oppau : "Give quickly and give plenty for the victims of the Oppau disaster!" Post offices, savings banks and banks put up appropriate posters and set up collection points. The Mannheim Trappist Eugen Rugel organized a street collection with the support of regional newspapers and the city administration. The municipal vehicle fleet and 100 policemen were parked for the two-day collection, after which four Mannheim gyms were filled with donations: 500 quintals of food were collected, as well as furniture, household items and clothing, which filled a total of 45 trucks. The Siemens-Schuckert set 2 million marks available, a public collection in Frankfurt brought to 27 September an already 1.2 million marks. The Oppau relief organization was responsible for distributing the donations. The German homeland Film GmbH presented the Labor Minister Heinrich Brauns recordings available to in movie theaters referencing created from movies for donations. The Deutsche Reichsbahn announced that "gifts of love" for the survivors of the Oppau catastrophe will be transported free of charge. The Central Relief Committee in New York provided 500 boxes with milk and other groceries worth 1 million marks and 500,000 marks in cash, which the German Red Cross and the mayor of Ludwigshafen were supposed to distribute among those in need. The Swedish Red Cross donated 100,000 marks. But it was also warned about fraudsters: The Reichsanzeiger reported on "unscrupulous crooks" who pretend to be "heavily afflicted citizens of Oppau" in order to swindle themselves into providing assistance.

As early as September 23, BASF management developed a six-point plan to help victims' relatives and survivors. Of the families whose houses were destroyed, 93 were able to move into vacant company apartments. From the outset, BASF rejected any legal responsibility and legal claims, as the explosion was not due to negligence, but rather a kind of natural disaster. Nevertheless, she voluntarily paid smaller compensation to survivors and the relatives of the victims and a larger amount to the Oppau charity , which was founded to manage the aid and donations. BASF paid the relatives of the dead a one-time payment of 2,000 marks and the widows continued to pay 50% of the standard salary. The employees of BASF donated 400,000 marks, the Reich government made 10 million marks available at short notice. Non-factory workers among the victims received a one-off sum totaling 20,000 marks from BASF, which, however, quickly lost value due to the ongoing hyperinflation .

By December 1921, the Reich Property Management and the German Red Cross had built barracks for a total of 1,100 people, which could be used for the homeless and the recruited unskilled workers. Accommodation could be made available to all homeless families in Oppau until the end of October 1921.

reconstruction

According to initial estimates, the damage to the factory amounted to at least 570 million inflation marks , less than a third of which was covered by insurance. The engineers at BASF estimated that the reconstruction of the Oppau plant could take up to a year and that it would require 10,000 workers. Carl Bosch entrusted the work to Carl Krauch , who managed to conclude contracts with companies from all over Germany for the provision of workers. Existing work at these companies was interrupted and entire shifts were sent to Oppau with their foremen. The Oppau plant was rebuilt in record time; it was provisionally restored within eleven weeks. Operations were resumed as early as the first week of December 1921 and in February 1922 they were back at full capacity.

There is different information about the damage to the surrounding communities. Some sources put it at 100 to 200 million marks, others calculated damage to the 3750 damaged buildings in Oppau alone of over 360 million marks. The settlement of property damage was handled very differently. On the right bank of the Rhine, as in Mannheim and Heidelberg, Baden law applied. There, explosion damage was fully covered, as there was a legal obligation to insure buildings at the customary local building value. In the Bavarian Palatinate, Bavarian law applied, under which the state insurance company only paid if a crash insurance had been taken out. Otherwise, only the building in which the explosion occurred was insured. In total, the insurance contracts only covered 70 million marks of the property damage estimated at 321 million marks in Oppau.

Municipal building authorities formed committees, had the damage documented with photographs, and limited prices for building materials to prevent overgrowth . The aim was to make the houses habitable again in the winter months. On October 6th, the Ludwigshafen mayor's office issued a leaflet for homeowners and asked those affected to report damage using a form. Karl Stützel from the Oppau relief organization worked time and again to ensure that BASF would cover most of the costs - which were not covered by the insurance. In January 1922, they agreed, without acknowledging any fault or obligation, to assume the costs of rebuilding the building. The work was carried out under the responsibility of the relief organization but under the supervision of BASF and required 16 million gold marks . Ultimately, the reconstruction of the destroyed town of Oppau took a good three years. The new building guidelines stipulated that houses in the immediate vicinity of the Oppau plant should not be rebuilt and that the streets should be expanded for the current traffic situation. The eastern part of Oppau, which was particularly close to the explosion center, remained undeveloped as a danger zone and area of interest for the factory ; instead, a new area was developed in the south. A number of streets were relocated, a street parallel to the main street was built and a new market square was created. New houses were built according to new hygienic and sanitary requirements. By the end of 1921, 230 main and 140 auxiliary buildings had been demolished and 600 apartments and 700 auxiliary buildings restored. The start of the new building activities was in the spring of 1922. Furniture repairs were awarded to a total of 655 regional companies by the carpentry workshops of the aid organization. The procurement of building materials for the largest construction company in the German Reich and the ever faster inflation were constant challenges. Constant labor disputes, the closure of the Rhine bridges by the French troops and the battle against the Ruhr in 1923 exacerbated the supply problems. By the time the relief organization was dissolved in November 1924, 2,647 new buildings had been erected.

The architect Albert Boßlet made a name for himself during the reconstruction of the village of Oppau , who at this time worked as a state building officer in the Bavarian Ministry of the Interior and was mainly known as a church builder.

Root cause research

The Bavarian State Government responsible for the administration of the Bavarian Palatinate at the time decided on the afternoon of the accident to set up a five-person investigation committee to clarify the cause. A week later, on September 28, 1921, the Reich government set up an eight-person commission of inquiry, which met for the first time in Ludwigshafen on October 6. The members of the Bavarian Commission of Inquiry also took part in the other five meetings in Ludwigshafen and six in Berlin. BASF itself also took part in researching the causes. The Frankenthal public prosecutor initiated criminal proceedings against the members of the management team Carl Krauch (deputy director), Johann Fahrenhorst (authorized signatory) and Franz Lappe (deputy director) for negligent homicide and bodily harm. On September 30, 1921, in the presence of the examining magistrate and public prosecutor, the experts from the Chemisch-Technische Reichsanstalt and Ernst Richard Escales , a meeting took place in Frankenthal and then a site inspection with the participation of the trade supervisory authority and the employers' liability insurance association.

The official investigation committees agreed on a division of labor and the involvement of various experts: chemical-technical tests were carried out on the spot by the Bavarian investigation committee. Physical-technical investigations were carried out by Alexander Gutbier , head of the laboratory for inorganic chemistry at the Technical University of Stuttgart . The analytical and explosive tests were carried out by Lothar Wöhler from the TU Darmstadt and in particular the Chemisch-Technische Reichsanstalt under the direction of Hermann Kast . The chemist and longtime editor of the journal for the entire shooting and blasting , Ernst Richard Escales, took a special position as an expert for the district court Frankenthal, because a large part of the investigation results were published in his journal. In addition, were Emil Bergmann , director and Fritz Lenze , another employee of the Chemical-Technical involved Reichsanstalt as experts. The operating and analysis books were recovered from the ruins of the plant. This made it possible to calculate the quantities of processed ammonium nitrate and sulphate as well as of manufactured fertilizer. Various samples from the remains of the building Op 111, the destroyed building Op 110 and the collapsed silo Op 112 as well as remains of explosives were secured in order to examine them extensively.

On November 30, 1921, the Chemisch-Technische Reichsanstalt published an initial report and detailed information on explosive tests. A second report was published on June 24, 1922. From 1925 onwards, the collected data was published in several special supplements by Hermann Kast in the magazine for the entire shooting and explosive system .

On April 10, 1923, the Frankenthal Regional Court closed the proceedings against the management of BASF, as testimonies and expert opinions had not provided any evidence of guilt or negligent behavior.

Causes and course of the accident

Speculations that the Haber-Bosch plant, a large gas compressor, one or more of the large hydrogen gas containers, a boiler house or one of the laboratories were the source of the explosion could already be rejected during the site visit immediately after the accident. An attack or the secret storage of ammunition in the Op 110 building was ruled out relatively quickly, since the necessary amount of over 100 t of explosives could not have been hidden from the workers. The assumption of the Communist MP Hermann Remmele that the bonus system in place in Oppau, which provided for special payments depending on the production volume, led to careless work and thus to irregularities in production, could not be confirmed after a review of the operating books. After ruling out various other causes, such as self-heating of the ASN, which ended in the explosion, the most likely main cause for the accident remains the recently made change in production to the spraying process and the expansion of production into the Op 110 building. The new spraying process the ASN became drier, looser and finer, making it easier to break down as desired. All three factors simultaneously increased the ASN's explosiveness. When spraying in the Op 110 building, a large part of the mass quickly fell to the ground, while a small part of very fine material (<1%) floated in the air for a longer period and only gradually and further away from the conveyor belt formed a loose 35 to 50 cm thick layer deposited, which consisted increasingly of AN. This possible segregation was confirmed by investigations by Gutbier, who found that the double salt did not even form at 120 ° C and only partially formed under the prevailing spraying conditions (more than 60 ° C). In the course of blasting tests, Kast was finally able to show that even commercially available Oppauer ASN with the correct mixing ratio can be made to explode with loose fill (density ≤ 0.9) and strong damming. The explosiveness increases with the amount; a smaller amount, as in the BASF tests, did not lead to an explosion. Kast also found that with the same chemical composition, the explosiveness increases simply because the AS is in the form of coarser crystals and the AN as finer crystals. In addition to the chemical composition, the physical properties and the circumstances of the ignition are also largely responsible for the explosiveness of ASN. With regard to the two successive explosions, Kast came to the conclusion that they were caused by two successive explosive shots, the first explosion “having put the remaining salt in a state that was favorable for the development of a larger explosion, so that a second , explosive shot that went off later had a much greater effect than the first one. "

Based on the research results collected by the various commissions and experts, various factors came together that most likely led to the catastrophe: The introduction of spray drying at the beginning of 1921 led to a change in the physical properties that made the ASN more sensitive to initial ignitions.

| parameter | Explosiveness | Influence from the spray process |

|---|---|---|

| Particle size | increases with decreasing particle size | Reduction in particle size |

| density | increases with decreasing density | Density becomes lower |

| humidity | increases with decreasing residual moisture | lower residual moisture |

The coarsely crystalline AS added to the AN solution presumably did not completely dissolve, which means that it fell to the ground more quickly when sprayed than the AN which crystallized in fine particles. This resulted in the enrichment of a small amount (0.1 to 0.2% of the production amount) of a fine fraction with an AN content of> 55%, which was sufficiently sensitive to the explosion pressure of the perastralite explosive charges. This fraction was deposited in particular in the edge areas of the OP 110 building, which is why it was not regularly removed and reached a thickness of around half a meter (around 100 t). An explosion that occurred at least partially within this AN-rich layer triggered the first explosion. The fine distribution and thermal excitation of a larger amount of ASN - with the correct mixing ratio but changed physical values - then led to a second explosion through another detonator.

conspiracy theories

Although the Allied intelligence services came to the conclusion that there had been no clandestine war research or storage of explosives at BASF, claims to the contrary kept circulating, fueled by speculation and rumors, that Germany was still clandestinely researching weapons. The New York Times wrote on October 31, 1921:

"[...] it might reasonably be suspected that experimenting of a secret nature was going on at the Oppau factory, which, it will be recalled, manufactured most of the chlorine and phosgene used by the Germans in their gas attacks during the war. The burden of proof should be upon the Badische Company to make out a case of confining its researches and energies to products of peaceful industry. [...] but when the fact is well known that there is an unrepentant and revengeful military party in Germany that looks to another war to restore her baleful power, and when the world believes that these dangerous reactionaries would welcome the discovery by their chemists of annihilating gases of enormous power, it is not inconceivable that the disaster at Oppau may have been due to covert experimenting by those chemists. "

“[…] It seems reasonable to assume that there were secret experiments in the Oppau factory which, as you will remember, produced most of the chlorine and phosgene used by the Germans in the gas attacks during the war. The burden of proof should lie with the Badische Fabrik to show that the research and energies are limited to a peaceful industry. […] But when it is well known that there is an unrepentant and vengeful military group in Germany that is seeking another war to regain its pernicious power, and when the world believes that these dangerous reactionaries are developing a gas of annihilation of enormous strength would be welcomed by their chemists, then it is quite conceivable that the disaster at Oppau was caused by secret experiments by these chemists. "

The Daily Telegraph and the Wall Street Journal speculated immediately after the explosion that in Oppau new "gas with a terrible explosion effect" had been prepared one. In 1961 an Australian newspaper reported that the city of Oppau had been completely destroyed by the explosion of a secret German weapons depot and that it had been rebuilt in a new location.

Commemoration

Main cemetery in Frankenthal : collective grave

Main cemetery in Neustadt : memorial

A memorial stone was erected on the Oppau cemetery. To commemorate the catastrophe, a street within the BASF factory site bears the name “Trichterstraße”; Many manufacturing facilities in which fertilizers are produced are still located here today. At the main cemetery of Frankenthal there is a separate collective grave with a memorial stone in which 42 victims of the accident who came from this neighboring town were buried together. In the main cemetery in Neustadt an der Weinstrasse , a memorial commemorates the 14 people who died from the city. On the occasion of the 100th anniversary of the accident, a special exhibition on the silo explosion with text panels, historical photographs, non-fiction books and old newspaper clippings opened on August 22, 2021 in the Karl Otto Braun Museum in Ludwigshafen-Oppau, which runs until October 24, 2021 . The Ludwigshafen City Archives also keep information material on the subject. The expressionist poet Franz Richard Behrens (1895–1977) wrote a poem about misfortune under the title Oppauammoniak .

Audio

- Dangerous fertilizer - explosion disaster in Oppau , 5:10 minutes, by Heiner Wember, Deutschlandfunk Kultur , September 9, 2020

literature

- Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, pp. 1–67 , accessed on January 1, 2020 .

- Christian Haller: The explosion at BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 325-375 ( boa-bw.de [PDF]).

- Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219 ( limited preview in Google Book search).

- Otto Köhler: ... and today the whole world. The history of IG Farben and its fathers . Rasch and Röhring, Hamburg and Zurich 1986, ISBN 3-89136-081-9 .

- Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 (dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial disasters in post-war times ).

- Lothar Wöhler: Mishaps from my explosive chemical work in recent years . In: Journal for Applied Chemistry . tape 37 , no. 29 , July 17, 1924, pp. 497-502 , doi : 10.1002 / anie.19240372904 .

- H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . Vol. 20, No. 11, 1925, pp. 1-4; Vol. 20, No. 12, 1925, pp. 5-8; Volume 21, No. 1, 1926, pp. 9-12; Volume 21, No. 2, 1926, pp. 13-16; Volume 21, No. 3, 1926, pp. 17-20; Volume 21, No. 4, 1926, pp. 21-24; Vol. 21, No. 5, 1926, pp. 25-28; Volume 21, No. 6, 1926, pp. 29-32; Volume 21, No. 7, 1926, pp. 33-36; Volume 21, No. 8, 1926, pp. 37-40; Volume 21, No. 9, 1926, pp. 41-43 ( PDF document ).

See also

- Explosion in Toulouse on September 21, 2001

- List of the largest man-made, non-nuclear explosions

- List of chemical disasters

Web links

- Contemporary photography of the explosion crater on PBase.com

- Explosion catastrophe 1921 , pictures after the explosion on oppau.info

- State Archives Administration Rhineland-Palatinate: September 21, 1921. Explosion accident at BASF. ( Memento from August 11, 2020 in the Internet Archive )

- Sven Felix Kellerhoff: The rumbling could still be heard in Munich. welt.de, August 5, 2000

- Heiko Wirtz: BASF disaster of 1921: bang to be heard as far as Munich. SWR aktuell, September 15, 2021

Remarks

- In this context, the term nitrogen is not used for the gaseous element nitrogen, but for the products made from it.

- The time interval of four seconds between the two explosions was recorded by the earthquake control centers in Göttingen, Durlach and Heidelberg. The seismometers of the other German earthquake stations, on the other hand, only recorded the second explosion as a very weak signal, which rules out the registration of the first weaker shock wave. On the recording paper of the earthquake monitoring station in Strasbourg , the signals following each other could not be resolved due to the low feed rate (16 mm per minute). From the difference in time between the arrival of the ground and sound waves of 82 seconds, the Heidelberg earthquake monitoring station calculated a distance of 27 km to the source of the explosion.

- In a first press release, the BASF management spoke of a stored quantity of 4,000 quintals of ammonium sulfate nitrate. This was changed in the following announcements to a storage quantity of 4500 t.

- The different strengths of the explosions result among other things. from the measurements of the Heidelberg earthquake monitoring station. The ratio of the amplitudes was 1: 4 to 1: 5, which roughly corresponds to the underlying amounts of energy.

Individual evidence

- ^ Underwood & Underwood : Part of the ruins of Oppau after the desatreous explosion . In: Popular Mechanics Magazine . December 1921, p. 826 ( limited preview in Google Book search).

- ↑ F. Haber, G. Van Oordt: About the formation of ammonia from the elements. (Preliminary communication.) . In: Journal of Inorganic and General Chemistry . tape 43 , no. 1 , January 16, 1905, p. 111-115 , doi : 10.1002 / zaac.19050430111 .

- ↑ F. Haber, G. van Oordt: About the formation of ammonia the elements . In: Journal of Inorganic and General Chemistry . tape 44 , no. 1 , April 4, 1905, p. 341-378 , doi : 10.1002 / zaac.19050440122 .

- ↑ F. Haber, G. Van Oordt: About the formation of ammonia from the elements . In: Journal of Inorganic and General Chemistry . tape 47 , no. 1 , October 3, 1905, p. 42-44 , doi : 10.1002 / zaac.19050470106 .

- ↑ Patent DE235421A : Process for the synthetic preparation of ammonia from the elements. Published on October 13, 1908 , applicant: Badischen Anilin- & Soda-Fabrik.

- ↑ a b Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, pp. 16-17 , accessed on January 1, 2020 .

- ^ A b Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 347-348 .

- ↑ 1913 / First Ammonia Synthesis Plant. In: basf.com. 2020, accessed on January 12, 2020 .

- ↑ Max Appl: Ammonia, 2. Production Processes . In: Ullmann's Encyclopedia of Industrial Chemistry . tape 3 . VCH Verlagsgesellschaft mbH, Weinheim 2012, p. 141 , doi : 10.1002 / 14356007.o02_o11 .

- ↑ a b story. 1902-1924. In: basf.com. Archived from the original on February 28, 2017 ; accessed on April 1, 2015 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117-219, here pp. 171-172 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219, here p. 176 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117-219, here pp. 179-180 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219, here p. 177 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219, here p. 173 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219, here p. 188 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117-219, here p. 189 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219, here p. 195 .

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 349 .

- ^ A b c Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 351-352 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219, here p. 196 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117-219, here pp. 206-208 .

- ^ A b c d e Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 327-328 .

- ↑ a b c d e f g h H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 20 , no. 12 , 1925, pp. 6 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219, here p. 194 .

- ↑ Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117–219, here p. 204 .

- ↑ a b c d e f H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 20 , no. 11 , 1925, pp. 3-4 .

- ↑ a b Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, p. 20 , accessed January 1, 2020 .

- ↑ a b c d e Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117-219, here pp. 209-210 .

- ^ A b c Lothar Wöhler: Mishaps from my explosive-chemical work in recent years . In: Journal for Applied Chemistry . tape 37 , no. 29 , July 17, 1924, pp. 500 , doi : 10.1002 / anie.19240372904 .

- ^ A b c Lothar Wöhler: Mishaps from my explosive-chemical work in recent years . In: Journal for Applied Chemistry . tape 37 , no. 29 , July 17, 1924, pp. 498 , doi : 10.1002 / anie.19240372904 .

- ^ H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 20 , no. 12 , 1925, pp. 5 .

- ↑ a b Lothar Wöhler: Mishaps from my explosive-chemical work in recent years . In: Journal for Applied Chemistry . tape 37 , no. 29 , July 17, 1924, pp. 497 , doi : 10.1002 / anie.19240372904 .

- ↑ Explosion of 30 t of ammonium nitrate. N ° 17974 - 07/26/1921 - POLOGNE - 00 - KNUROW (KRIEW FOREST). In: ARIA No. 17974. BARPI - Bureau d'Analyse des Risques et Pollutions Industriels, accessed on August 11, 2020 .

- ↑ a b Oppau - [Rhénanie] Germany. (PDF) Explosion in a nitrogenous fertilizer plant September 21, 1921. In: ARIA No. 14373. French Ministry of Environment - DPPR / SEI / BARPI, March 2008, accessed January 3, 2020 .

- ↑ a b c H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 20 , no. 12 , 1925, pp. 7 .

- ^ Badische Anilin und Sodafabrik: The explosion accident in Oppau . In: Journal for Applied Chemistry . tape 34 , no. 79 , October 4, 1921, p. 489 , doi : 10.1002 / anie.19210347902 .

- ^ A b H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 3 , 1926, pp. 18-19 .

- ^ H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 20 , no. 11 , 1925, pp. 2 .

- ^ A b c d Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 362-363 .

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 342 .

- ↑ Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, p. 30 , accessed on January 1, 2020 .

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 366 .

- ↑ Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, p. 9 , accessed January 1, 2020 .

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 356 .

- ↑ a b c Oscar Hecker: The explosion disaster in Oppau on September 21, 1921 according to the records of the earthquake stations . In: Publications of the Reich Institute for Earthquake Research in Jena . tape 2 . Publishing house by Gustav Fischer, Jena 1922, p. 9-11 .

- ↑ a b c d H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 20 , no. 11 , 1925, pp. 1 .

- ↑ a b c d e f Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 105-106 (dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in the post-war period ).

- ↑ a b c d e Manifold . In: Deutscher Reichsanzeiger and Prussian State Gazette . No. 222 , September 22, 1921, pp. 3 ( uni-mannheim.de [accessed on January 28, 2020]).

- ↑ a b c Serious explosion in Oppau (dfg-viewer.de). In: Deutsche Allgemeine Zeitung . September 21, 1921, p. 1 , accessed May 16, 2021 .

- ↑ The destruction of the original cathedral windows. In: worms.de , accessed on August 11, 2016.

- ↑ 09.21.1921: Disaster at BASF. Deutsche Welle, KalenderBlatt September 21, September 21, 2005, accessed on October 6, 2013 .

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 326 .

- ↑ a b c d State Archives Administration Rhineland-Palatinate: 09/21/1921 ( Memento from August 11, 2020 in the Internet Archive )

- ^ RM Goody: The Physics of the Stratosphere . Cambridge University Press, 2014, ISBN 978-1-107-69606-8 , pp. 32 ( full text in Google book search).

- ↑ a b c d Ulrich Hörcher: Oppau 1921: Old Facts Revisited . In: Chemical Engineering Transaction . tape 48 , 2016, p. 745–750 ( PDF [accessed January 26, 2020]).

- ^ A b Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 364 .

- ^ A b Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 337 .

- ↑ a b c d Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 73-74 (dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in the post-war period ).

- ↑ a b The explosion in Oppau (dfg-viewer.de). In: Deutsche Allgemeine Zeitung . September 22, 1921, p. 2 , accessed May 16, 2021 .

- ↑ a b c d The explosion near Ludwigshafen (dfg-viewer.de). In: Deutsche Allgemeine Zeitung . September 22, 1921, p. 1 , accessed May 16, 2021 .

- ↑ Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, p. 19 , accessed January 1, 2020 .

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 333 .

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 334-335 .

- ↑ Manifold . In: Deutscher Reichsanzeiger and Prussian State Gazette . No. 223 , September 23, 1921, pp. 3 ( uni-mannheim.de [accessed January 20, 2020]).

- ↑ a b c d e Jeffrey Allan Johnson: The Power of Synthesis (1900-1925) . In: Werner Abelshauser (Ed.): The BASF - A company history . 2nd Edition. CH Beck, Munich 2003, ISBN 3-406-49526-5 , p. 117-219, here pp. 211-212 .

- ^ H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 1 , 1926, pp. 11 .

- ^ A b c Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 367-369 .

- ^ A b c Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 339-340 .

- ↑ a b c d Manifold . In: Deutscher Reichsanzeiger and Prussian State Gazette . No. 225 , September 25, 1921, pp. 4 ( uni-mannheim.de [accessed on January 20, 2020]).

- ↑ Manifold . In: Deutscher Reichsanzeiger and Prussian State Gazette . No. 224 , September 24, 1921, pp. 3 ( uni-mannheim.de [accessed January 20, 2020]).

- ↑ Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, p. 3 , accessed January 1, 2020 .

- ↑ Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 90-91 (dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in the post-war period ).

- ↑ Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 82-83 (dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in the post-war period ).

- ↑ a b Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 84-85 (dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in the post-war period ).

- ↑ a b c Manifold . In: Deutscher Reichsanzeiger and Prussian State Gazette . No. 226 , September 27, 1921, pp. 4 ( uni-mannheim.de [accessed on January 20, 2020]).

- ↑ Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 86-87 (dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in the post-war period ).

- ↑ Manifold . In: Deutscher Reichsanzeiger and Prussian State Gazette . No. 227 , September 28, 1921, pp. 3 ( uni-mannheim.de [accessed January 20, 2020]).

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 341 .

- ^ A b Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 344-345 .

- ↑ a b Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 92 (Dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in post-war times ).

- ^ Joseph Borkin: The crime and punishment of IG Farben . 1979 (English, bibliotecapleyades.net [accessed February 1, 2020]).

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 358 .

- ↑ Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 88-89 (dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in post-war times ).

- ↑ a b Lisa Sanner: "As if the end of the world were here". The catastrophic explosions at BASF in 1921 and 1948 . Ed .: Stadtverwaltung Ludwigshafen am Rhein (= Publications of the Stadtarchiv Ludwigshafen am Rhein . Volume 42 ). Ludwigshafen 2015, ISBN 978-3-924667-47-4 , pp. 107 (Dissertation LMU Munich under the title: The Oppauer Explosion [September 21, 1921] and the Ludwigshafen tank car explosion [July 28, 1948] at BASF - a comparative study of industrial catastrophes in post-war times ).

- ^ A b Klaus J. Becker, Bernhard Kukatzki: Ludwigshafen in the Weimar Republic and in the "Third Reich" . Sutton Verlag GmbH, 2015, ISBN 978-3-95400-487-4 , p. 115 ( limited preview in Google Book search).

- ↑ Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, p. 12 , accessed January 1, 2020 .

- ^ A b Christian Haller: The explosion accident in BASF on September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 359-360 .

- ↑ Tor E. Kristensen: A factual clarification and chemical-technical reassessment of the 1921 Oppau explosion disaster the unforeseen explosivity of porous ammonium sulfate nitrate fertilizer. (PDF; 1.6 MB) In: FFI-RAPPORT 16/01508. Norwegian Defense Research Establishment / Forsvarets forskningsinstitutt, October 4, 2016, p. 13 , accessed January 1, 2020 .

- ^ A b H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 5 , 1926, pp. 25-28 .

- ^ H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 6 , 1926, pp. 29-32 .

- ^ A b H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 7 , 1926, pp. 33-36 .

- ^ A b H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 8 , 1926, pp. 37-40 .

- ^ A b H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 9 , 1926, pp. 41-43 .

- ^ H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 20 , no. 11 , 1925, pp. 1-4 . ; Vol. 20, No. 12, 1925, pp. 5-8; Volume 21, No. 1, 1926, pp. 9-12; Volume 21, No. 2, 1926, pp. 13-16; Volume 21, No. 3, 1926, pp. 17-20; Volume 21, No. 4, 1926, pp. 21-24; Vol. 21, No. 5, 1926, pp. 25-28; Volume 21, No. 6, 1926, pp. 29-32; Volume 21, No. 7, 1926, pp. 33-36; Volume 21, No. 8, 1926, pp. 37-40; Volume 21, No. 9, 1926, pp. 41-43 ( PDF document ).

- ↑ Lothar Wöhler: Mishaps from my explosive-chemical work in recent years . In: Journal for Applied Chemistry . tape 37 , no. 29 , July 17, 1924, pp. 501 , doi : 10.1002 / anie.19240372904 .

- ^ Christian Haller: The explosion accident in BASF from September 21, 1921. Disaster perception and processing in the press, politics and experts . In: Journal for the history of the Upper Rhine . No. 161 , 2013, p. 365 .

- ^ H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 3 , 1926, pp. 20 .

- ^ A b H. Kast: The explosion in Oppau on September 21, 1921 and the activities of the Chemisch-Technische Reichsanstalt . Special edition. In: Journal for the entire gunnery and explosives industry . tape 21 , no. 4 , 1926, pp. 21-22 .

- ↑ Times Machine. (PDF) In: The New York Times. The New York Times, October 31, 1921, accessed January 19, 2020 .

- ↑ Explosion at Oppau: Day the Rhine was filled with Thunder . In: The News . May 23, 1961 (reproduced accordingly from: Werner Abelshauser (Ed.): Die BASF - Eine Unternehmensgeschichte , 2002, p. 212, note 269).

- ↑ Wormser Zeitung , No. 204, Volume 246, September 3, 2021: "100 years ago the explosion at BASF" Article by Christian Hoffmann. VRM GmbH & Co. KG , Mainz. P. 14 (metropolitan region)

- ↑ Carsten Heinisch: 101 retrospectives: memories of days . Oppauammoniak. BoD - Books on Demand, 2010, ISBN 3-8391-2895-1 , pp. 149 ( limited preview in Google Book search).

Coordinates: 49 ° 31 ′ 4 ″ N , 8 ° 25 ′ 6 ″ E