Focke-Wulf Ta 154

| Focke-Wulf Ta 154 "Mosquito" |

|

|---|---|

| Type: | Multipurpose aircraft |

| Design country: | |

| Manufacturer: | |

| First flight: |

July 1, 1943 |

| Commissioning: |

Series start stopped |

| Production time: |

July 1, 1943 to August 1944 |

| Number of pieces: |

30 to 50 |

The Focke-Wulf Ta 154 "Mosquito" was a twin-engine multipurpose aircraft of the Luftwaffe in shoulder- wing design built towards the end of the Second World War . Originally planned as a high speed bomber , then as a night and day fighter, use as an observer or reconnaissance aircraft was also considered. Ultimately, she was used as a night fighter. The model and counterpart was the British de Havilland DH.98 Mosquito . As with this one, the fuselage, guide and wing components of the Ta 154 consisted of a wooden construction. The maiden flight of the Ta 154 V1 took place on July 1, 1943. There are various details about the number of machines produced (with all variants and test types); accordingly there were between 30 and 50 pieces.

On August 14, 1944, the start of series production of the Ta 154 was stopped by the Reich Aviation Ministry (RLM) in favor of the Do 335 . So only a few specimens were used in night fighter squadrons or night fighter groups until the end of the war .

history

| Short chronology | ||

|---|---|---|

| date | comment | |

| October 1942 | Project start | |

| July 1, 1943 | First flight of the V1 | |

| September 17, 1943 | First flight V2 | |

| November 25, 1943 | First flight V3 | |

| February 10, 1944 | First flight V4 | |

| February 25, 1944 | First flight V5 | |

| March 17, 1944 | First flight V6 | |

| March 25, 1944 | First flight V7 | |

| April 8, 1944 | First flight V8 | |

| April 16, 1944 | First flight A-0 | |

| April 18, 1944 | First flight V9 | |

| June 4, 1944 | First flight V10 | |

| June 12, 1944 | First flight V22 | |

| June 16, 1944 | First flight A-2 | |

| July 14, 1944 | First flight V23 | |

| August 1944 | Project stop | |

The Luftwaffe saw no need for the development of a high-performance night fighter at the beginning of World War II. Based on this assessment, the existing retrofitted Bf 110 , Do 217 and Ju 88 faced the increasingly massive air raids of the British Bomber Command under Arthur Harris on major German cities and industrial centers. In addition, the Royal Air Force owned the de Havilland Mosquito , also known as the “Wooden Wonder”, a fighter-bomber that flew so high that it could not be reached by any German interceptor or anti-aircraft gun .

In order to be able to counteract such air attacks, the Technical Office of the Reich Aviation Ministry (RLM) awarded the Heinkel-Werke Oranienburg , the Junkers Flugzeug- und Motorenwerke and Focke-Wulf development contracts for an all-weather night fighter, which with the economical use of light metal with a Serial engine and should achieve a flight time of 105 minutes with four forward-pointing machine guns .

While Heinkel and Junkers were able to further develop existing studies or programs ( He 219 and Ju 188R ), Focke-Wulf had no concept available. The group therefore resorted to the already decommissioned Fw 187 project to redesign it as a destroyer . Kurt Tank , chief developer and test pilot at Focke-Wulf, designed the sub-variant Fw 187C , which was supposed to function as a destroyer, night fighter and high altitude fighter. This plan was rejected on August 18, 1942 during a conversation between Focke-Wulf and the RLM. Field Marshal Erhard Milch is said to have inquired about the possibility of using the Jumo 211 engine, which is more readily available than the DB 600A engine of the Fw 187 .

On August 31, 1942, work on the Fw 187C was stopped on the grounds that it was basically suitable for its purpose, but that it did not promise any significant improvements compared to the Me 210 and that its use as a night fighter was severely restricted due to its limited range and insufficient visibility be. On September 16, 1942, Milch emphatically demanded the development of a high-speed night bomber made of wood, which was to be based on the British de Havilland Mosquito .

On September 22, 1942, Focke-Wulf presented the RLM with a corresponding concept, whereby Kurt Tank succeeded in demonstrating the general feasibility of a wooden fighter using the British Mosquito . Its conception provided for a high-speed bomber in composite construction . The machine was supposed to be powered by two hanging piston motors of the type Jumo 211F. Planned as a shoulder-wing decker, the machine was not to receive either a defensive or an offensive armament, as it was assumed that it could escape the enemy simply because of its speed. On October 9, 1942, the processing of this "high-speed bomber concept" was transferred to Kurt Tank, but in the same month the conversion of the concept to a fighter destroyer was ordered and an order was given to accelerate the development of this fighter machine.

In November 1942, Focke-Wulf received the official development contract from the RLM without a public tender.

The design of the aircraft was initially called Ta 211 , derived from the abbreviation Ta for its designer Kurt Ta nk and the Jumo 211 engines to be used . Following the designation system of the RLM , the machine would have been called 8-211 and the motors 9-211 . Since there was fear of confusion due to the similarity, the designation Ta 154 was chosen from the available RLM numbers 152 , 153 and 154 , the first two were reserved by Focke-Wulf for further developments of the Fw 190 (152 = Focke-Wulf Ta 152 , 153 = Focke-Wulf Ta 153 ). For propaganda reasons, the nickname "mosquito" was also given, based on the successful English wooden airplane Mosquito . The vacated number 211 was assigned to the height reconnaissance aircraft Hü 211 , a variant of the He 219 .

On January 8, 1943, the start-up meeting for the Ta 154 took place in Berlin . The emerging shortage of skilled workers and the insufficient performance of the Jumo 211 were discussed. In this context, Erhard Milch explained that he actually considered the Ta 154 and the Bf 110 G as an interim solution until the He 219 was ready for series production .

Construction development

|

Draft overview Focke-Wulf TA 154 |

|||||||||||||

| Construction feature | Draft 1 October 6, 1942 |

Draft 2 October 6, 1942 |

Draft 3 October 14, 1942 |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| crew | 1 | 2 | |||||||||||

| Wing area | 25 m² | 32.4 m² | |||||||||||

| span | 14.00 m | 16.00 m | |||||||||||

| length | 11.40 m | 11.75 m | 12.80 m | ||||||||||

| height | 3.10 m | 3,475 m | |||||||||||

| Gauge | 4.60 m | 5.00 m | |||||||||||

| Propeller diameter | 340 cm | ||||||||||||

| V max | 680 km / h | 650 km / h | o.A. | ||||||||||

| Service ceiling | 10,100 m | 9,700 m | 10,500 m | ||||||||||

| Range | 1,900 km (615 km / h, 6,000 m altitude) 2,250 km (470 km / h, 6,000 m) |

||||||||||||

With the conception of a wooden high-performance fighter with top speeds of around 700 km / h, Tank and his development team broke new technical ground in Germany, as experience from the timber construction of fighter planes from the First World War (1914-1918) was not easily transferable. Tank himself mentioned in a lecture in 1943 the thickness of the wooden walls, which was 2-3 mm in the First World War. For the Ta 154, however, wood with a thickness of up to 50 mm had to be used because of the higher stress.

A composite construction with a wood content of around 50% was aimed for. According to one statement, this was also achieved (with a steel content of 39% and 11% of the rest of the materials), other sources give a wood content of around 57%. Tank stated for an early prototype in the summer of 1943 that the airframe was made of 53% wood, 30% steel and 17% other materials such as light metals. The engine and its fairing, the landing gear, the landing flaps as well as elevators, ailerons and rudders were made of metal. The pulpit was made of wood, but there were also plans for a version with a sheet metal pulpit .

The Jumo 211 was to serve as the engine, which was available in large numbers, but had a performance deficit compared to the opposing engines. The Jumo 213 , which was only being tested in mid-1943 , was not yet available. In October 1942, Tank received instructions from Erhard Milch to design the aircraft in such a way that the Jumo 213 could later be installed instead of the Jumo 211. At the same time it was decreed that the Fw 154 should no longer be designed primarily as a bomber, but as a night fighter.

Tank was aware that wood would always have a lower load capacity than a metal version, so the team around Tank first examined selected types of wood for their strength values. Ultimately, the choice fell on a plywood shell construction method of compaction. At the same time, wind tunnel tests were carried out with various model sizes. On the basis of these initial considerations for the Ta 154 , three designs with slightly different dimensions were created by mid-October 1942 (see table on the right).

Then the construction of a model Ta 154 began under the direction of chief engineer Ernst Nipp. Senior engineer Ludwig Mittelhuber was responsible for the design. The performance calculations were carried out by graduate engineer Herbert Wolf and senior engineer Gotthold Mathias was responsible for aerodynamics and flight characteristics.

The wooden stabilizer caused the greatest difficulties, because transitions and separation points had to maintain their strength even with high shear forces . For this reason, the two-spar wooden surface was constructed throughout. The structure was then connected to the hull of the machine with four bolts. In order to reinforce the wooden structure, the sensitive separation points were either glued, riveted or screwed in the manufacturing process by pressing Dural or steel fittings. However, these measures proved to be unsuitable.

The design team solved this problem by subjecting the individual layers of plywood to high compaction during the production process. If this measure was not sufficient in various places, fittings made of Lignofol L90 or Dynal Z5 (similar elasticity modes as wood) were used. This enabled the construction team to achieve an exact and resilient glued construction. The outside of the machine was clad with parts from Porsche .

The fuselage of the machine was oval in cross-section. Like the rest of the machine, it was encased in laminated plywood. Only the landing gear, the engine mounts, the rudder surfaces and the engine casing were made of metal. The nose wheel , which was unusual for that time, was hydraulic; it was rotated 90 degrees when it was pulled in and found its place entirely in the front fuselage. The main landing gear was pulled into the two engine nacelles.

The aeronautical research company "Graf Zeppelin" (FGZ) was responsible for testing the dummy fuselage . The pressure and load tests carried out by the FGZ on a model of the fuselage and the cockpit canopy took place in the Alatsee near Füssen with six underwater towing tests . The test revealed the general weaknesses of a wooden construction, because on the second attempt the glue connection of the lower wing broke, with the last one the rivet connection to the wing stub came loose. It was also found that the wooden hull became unstable with moisture absorption. Focke-Wulf was nevertheless satisfied, because the Ta 154 partially fulfilled the expectations placed on it, and the basic strength of the wooden airframe and the tail unit had been confirmed.

Due to the lower strength of wood compared to metal, the flight weight was similar to that of other fighter aircraft, which, in contrast to the Ta 154, have defensive armament. A construction made of light metal comparable to the Ta 154 would have been around 15% lighter according to Tanks.

Prototypes

|

Overview of the prototypes Focke-Wulf Ta 154 |

|||||

| designation | Mark | Work number | Maiden flight | Whereabouts | Remarks |

|---|---|---|---|---|---|

| V1 | TE+FE |

0 001 | July 1, 1943 | Destroyed August 5, 1944 | The V1 took off on its maiden flight on July 1, 1943, two weeks earlier than originally planned . The pilot was Hans Sander and his companion Walter Schorn. Kurt Tank accompanied this maiden flight with an Fw 190 B. There are different statements about the engine specification, both the Jumo 211N (each 1500 HP) and the Jumo 211F (each 1340 HP) are specified as the engine. The engine numbers were 104 129 2426 and 104 129 2434.

The one-hour flight went without major problems, but the nose wheel could not be fully retracted due to a misalignment of the nose wheel flap. The hydraulics later failed, but the pilot Sander was able to extend the landing gear by means of an emergency system, operate the landing flaps and land safely. On July 7, 1943, the V1 was flown by Kurt Tank and on July 28, 1943, the V1 flew for the first time at the Rechlin test center . There the V1 won a comparison flight against a He 219 and a Ju 388 . By the end of July 1943, a further 25 test flights with the Ta 154 V1 followed , with a crash landing on July 31, 1943 with damage to the machine. But the plane was repaired. In February 1944 the V1 was converted to Jumo 211 N engines, received VS 9 propellers and the designation V1a . Until March 14, 1944 the V1 flew 180 test flights. On August 5, 1944, the Ta 154 V1 was destroyed in a bomb attack on the warehouse in Langenhagen. |

| V2 | TE+FF |

0 002 | September 17, 1943 | The V2 flew for the first time on September 17, 1943. It had dummy weapons, a new nose wheel with enlarged caster, a flame destruction system (Fla-V system) and a FuG-212-C-1 radar system with four antennas. Due to its higher air resistance, the V2 lost 20 to 32 km / h compared to the V1 .

By January 14, 1944, the machine had completed 61 test flights, which were mainly used to determine the vibration behavior. On August 5, 1944, it was also destroyed in a bomb attack on the warehouse in Langenhagen. |

|

| V3 | TE+FG |

0 003 | November 25, 1943 | The V3 was the first test machine with armament (four MG 151) and served as a model aircraft for the A-0 series. Two Jumo 213 A were used as engines. The V3 reached 620 km / h in its first flight. It was found that the use of the armament caused damage to the wooden bow of the machine because of the muzzle exhaust gases. Changes to the bow were the result.

After the V3 was converted into a night fighter, it was given the designation A-0 / U1 . The night hunting equipment consisted of the components Peil G6 (target flight direction finding system), FuG 212, FuG 101, FuG 16ZE, FuBl 2 F, FuG 25a and an automatic course control system. Due to the weapons and FuG installations as well as the flame destruction system, about 12 percent of the speed was lost compared to the V1. On November 30, 1943, the machine was presented at a flight demonstration. On February 24, 1944, the V3 was flown by pilots of the NJG 4 , whereby several deficiencies were pointed out. The aircraft was damaged as a result of a broken nose wheel during the approach on February 28, 1944 and pilot Georg Carl was slightly injured. On August 5, 1944, the Ta 154 V3 was destroyed in a bomb attack on the warehouse in Langenhagen. |

|

| V4 | TE+FH |

0 004 | February 10, 1944 | Destroyed June 20, 1944 | The V4 was a test vehicle for the A-series, which is in the planning stage. She had two MG 151 with 200 rounds each and two MK 108 with 110 rounds each. After completion, the machine was handed over to Erprobungskommando 154 (EK 154) for front testing, where it flew for the first time on February 10, 1944.

In January 1944, parts of the engine cowling came loose during flight operations and in February there was an engine fire. Due to the ammunition weight and the two 300-liter additional tanks, the machine lost around 40 km / h compared to the V1 , so it reached 520 km / h near the ground. The additional tanks increased the flight time to three hours. Like its predecessors, the V4 suffered from chassis problems . In June 1944, the nose wheel fork broke while approaching Tarnewitz ; the machine overturned and was severely damaged. |

| V5 | TE+FI |

0 005 | February 15, 1944 | NJG 3 | The V5 completed its maiden flight on February 25, 1944. It served as a second weapon test vehicle, was equipped with four MK 108s of 110 rounds each and two Jumo 211N engines (1450 hp each).

During several test flights, glaring defects in the gluing in the fuselage area were found. The machine also suffered from water ingress during heavy rainfall. On April 7, 1944, the V5 also crash-landed because of a problem with the main landing gear. After the repair and conversion to a night fighter with reinforced Jumo 213 A engines, the transfer to Detmold took place on August 5, 1944 , where it flew with the new serial number 100 005 in Nachtjagdgeschwader 3. |

| V6 | TE+FJ |

0 006 | March 17, 1944 | Langenhagen | The V6 was a radio technology test vehicle and completed its first flight on March 17, 1944. From June onwards, extensive tests were carried out at the Rechlin test center and a flight demonstration in front of senior representatives of the RLM on June 12 and 13, 1944.

The V6 was relocated from Rechlin to Langenhagen on September 22, 1944, and the day after it was relocated to Detmold, where it was equipped with two Jumo 213 A for night hunting. |

| V7 | TE+FK |

0 007 | March 25, 1944 | Destroyed August 5, 1944 | The V7 was intended for troop trials at Erprobungskommando 154; the first flight with two Jumo 211 Ns took place on March 25, 1944.

On April 9, 1944, the machine was badly damaged by enemy action and destroyed on August 5, 1944 by the bombing raid on Langenhagen. |

| V8 | TE+FL |

0 008 | May 6, 1944 | Destroyed April 8, 1944 | Also called Ta 154A-01 . The Jumo 213 A engine was tested with the V8 with a VS 111 three-bladed wooden propeller. Because of a fire in the right engine, the fifth flight of the machine ended on May 6, 1944 with a total loss. The two crew members, pilot Luitpold Otto and flight engineer Rolf Rettig, perished. |

| V9 | TE+FM |

0 009 | April 18, 1944 | Destroyed April 18, 1944 | Also called Ta 154A-02 . The V9 was the last test model with Jumo 211 engines. The final assembly took place in Erfurt and was completed on April 18, 1944.

The subsequent flight test by the pilot Werner Bartsch and his radio operator Hermann Meyer initially ran smoothly. However, there were problems during the landing phase that led to the crash. The landing aids drove unevenly and caused the machine to hang heavily to the right with subsequent ground contact. Both men were thrown out of the machine by the impact. Bartsch suffered a broken lower leg, Mayer a broken neck which resulted in death. |

| V10 | TE+FN |

0 010 | June 4, 1944 | Destroyed July 13, 1944 | The V10 was a test vehicle for Jumo 213 A engines and was completed on May 10, 1944. The service ceiling was 11,500 m. On July 13, 1944, the machine had to make an emergency landing due to a seizure of the connecting rod and it burned out. |

| V11-V14 | no | not applicable | no | not applicable | The V11 , V12 and V13 were break cells for the Fw Ta 154-A . The V 14 a break cell for the Fw Ta 154-C . |

| V15 | The V15 was a planned model aircraft for the A-2. According to another publication, it was a model aircraft for the Ta 154 A-1 , also Ta 154 A-0 / U2 and was designated as Ta 154A-08 . However, registration number and maiden flight are not mentioned. | ||||

| V16-V21 | No information is available about the V16 , V17 , V18 and V19 . Possibly they were samples for the Ta 154-B . The V20 was planned as a model aircraft for the Fw Ta 154 C-1 , the V21 for the Ta 154 C-2 . | ||||

| V22 | TQ+XA |

0 011 | June 12, 1944 | Destroyed August 5, 1944 | The V22 , the third test machine with Jumo 213 F engines, was an unarmed test vehicle ; the first flight took place on June 12, 1944.

On August 5, 1944, this machine was also destroyed in the air raid on Langenhagen. |

| V23 | TQ+XC |

0 013 | July 14, 1944 | NJG 3 | The V23 was an unarmed test vehicle with a Jumo-213-A engine. In addition to the first flight on July 14, 1944, three flights are known (August 5, 12 and 17, 1944). The machine was then transferred to Detmold and converted for night hunting at NJG 3 . |

| V24 | no | not applicable | no | not applicable | Fifth rupture cell for static tests. |

Test Command 154

As usual for the introduction of new aircraft types and the testing of their suitability for the front, a test command was set up for the Ta 154 . On November 29, 1943, the general of the fighter pilots (GdJ), Adolf Galland , submitted a corresponding request to the air force command. The order to set up Erprobungskommando 154 ( EK 154 ) at Evershorst Air Base near Hanover (today: Hanover-Langenhagen Airport ) was issued on December 9, 1943, initially for a period of six months. In terms of service and technology, it was subject to the command of the test center (KdE), operationally to the general of the fighter pilots and economically to the airfield command 88 / X1. According to various sources, the number of staff at the command fluctuated between 21 and 24 people. The command leader was First Lieutenant Vohl.

The activities of EK 154 comprised practical test flights, primarily with the V-types V3 , V4 , V5 , V7 and V10 . Initially, however, the command only received three machines. In the following test flights, devices for flame extinguishers were tested and weapons and cooler tests were carried out. The latter problem in particular preoccupied EK 154 for a long time. In order to save brass , radiators from Opel were first tested before the aluminum ones were used. In addition, the machines were subjected to a test of their tactical suitability. This range of tasks largely corresponded to that of the Rechlin test center , which had to test the Ta 154 for its front-panel use.

The successive failure of several V-patterns was problematic. In July 1944 only one single airworthy machine was available. Therefore, on July 15, 1944, the command leader asked the Rechlin test center what was to become of the EK 154 . In the same month, the test command asked the air force command whether it could be converted into a squadron with the addition of additional personnel.

When the Ta 154 was deleted from the aircraft program on August 1, 1944, the Air Force High Command (OKL) also decided to dissolve the test command . The production facilities in Langenhagen were bombed on August 5, 1944, with all hangars , the test models V1 , V2 , V3 , V7 and V22 and four other A-0 aircraft being destroyed or damaged.

On August 7, 1944, the Rechlin test center followed the OKL order and also recommended the dissolution of the test command. The personnel has now been distributed to other offices, including the test command Me 262 . It was also intended to transfer the still existing Ta 154 there and to train future jet fighter pilots on it.

This did not happen, however, and the remaining aircraft were transferred to Detmold for night fighter conversion. Specifically, these were the serial numbers 320 008, 320 009 and 320 010 of type A-2 and of type A-0 the V5, V6, V23 and the serial number 0 015.

Series

|

Brief overview of the Focke-Wulf Ta 154 series |

||||

| Surname | Engine / power unit | Intended use | crew | Remarks |

|---|---|---|---|---|

| A-0 | Jumo 211F | Night fighter | 2 | Pre-series for front testing. Eight machines were manufactured at the Mitteldeutsche Metallwerke in Erfurt. |

| A-0 / U1 | A further planning of 14 aircraft, which were to be given the designation Ta 154 A-0 / U1 (serial numbers 0 021 to 0 034), was not implemented. This type was designed with a new radiator head and new propellers. The armament should consist of four MK 108. One publication states that the serial number 0 015 ( TQ+XE) was used in the NJG 3 as A-0 / U1 at the beginning of January 1945 .

|

|||

| A-0 / U2 | Jumo 211N | Bulk destroyer | 1 | The name concretized the bulk destroyer principle of the Ta 154 . |

| A-1 | Day hunter | 2 | The series largely corresponded to the A-0, but was designed with the Jumo 211 R. | |

| A-1 / R1 | The A-1 / R1 differed from the A-1 in that a GM-1 system was installed to increase the performance of the engines at great heights. | |||

| A-2 | Day hunter | 1 | The A-2 was the basis of the Ta 154 with GM-1 system. The machine was later converted to the Jumo 211 R. The V15 acted as a prototype. With a take-off mass of 8850 kg, it reached a speed of 613 km / h at an altitude of 5800 m, with the later Jumo 211 R even 632 km / h at an altitude of 8000 m. Its fuel content was 1630 liters. | |

| A-2 / U3 | Explosives carrier | - | The name specified the mistletoe principle of Ta 154 . | |

| A-2 / U4 | Jumo 213A | Night fighter | 2 | The A-2 with the serial numbers 320 008, 320 009, 320 010 and 320 011 were transferred to Detmold and converted there to night fighters. After their conversion, these were given the designation A-2 / U4 . The 320 011 suffered a crash landing when it was brought back to Langenhagen and was destroyed. |

| A-3 | Jumo 211N | Training aircraft | The A-3 was designed as a school machine. For this purpose, twenty A-1 machines were to be converted into trainer aircraft. In addition to the basic equipment of the A-1 , the installation of a second control stick for the flight instructor was planned. In May 1944 the series was postponed. | |

| A-4 | Night fighter | Corresponded in large parts to the A-1. The machine with the registration D5+HDflew in Nachtjagdgeschwader 3 and fell into British hands at the end of the war.

|

||

| B-1 | Was planned with a metal front fuselage, but deleted in favor of the Ta 154 C. | |||

| B-2 | Day hunter | 1 | Construction canceled. | |

| C-1 | Jumo 213 A | Night fighter | 2 | The C-1 was to have a 76.2 cm longer fuselage, additional tanks and an ejection seat. The prototype was the V20 . The DB 603 E was later planned as the engine, but this was not implemented. The calculations with DB 603 E were called Ta 154 Ra2 . The C-1 should get an improved canopy and a metal fuselage. The radio equipment provided was the FuG 10P + APZ A6, FuG 16 ZY (VHF transceiver system), FuG 25a (detection device), FuBl 2F (blind landing system remote-controlled), FuG 101 (electrical height measuring device), FuG 220 and FuG 135. In terms of armament, four MK 108 were planned, which was later changed to two MG 151 and two MK 108. In addition, two MK 108s were to be installed in the rear of the machine as inclined music . |

| C-2 | Fighter bomber | 1 | The C-2 was a planned fighter-bomber (Jabo). The V21 served as the prototype . The jumo engines were equipped with a GM-1 system. Use with the DB 603 E engine was planned, but was not implemented. The machine should also carry a bomb load of 2 × 500 kg. The radio equipment should consist of the FuG 16 ZY, Fug 101, Fug 25a and the FuBl 2 F. No machine of the C-2 was completed. | |

| C-3 | spotter | 2 | The C-3 series was designed as a reconnaissance aircraft. For this purpose, an additional viewing window should be installed downwards. It should have two RB 75 / 3O or two RB 50/30 on image devices. The armament should consist of four MG 151 to the front and two MG 131 to the rear. The reconnaissance variant was rejected by the RLM in January 1944. | |

| C-4 | k. A. | Fighter bomber | No data are available from the C-4 series. | |

| D-1 | Jumo 213 E. | Night fighter | The internal designation was Ta 154 Ra-3 . It provided for a trunk extension. At the same time, the wing area increased to 42 m². The D series should be powered by Jumo 213 E, which should be provided by Auto Union . The D-1 became the Ta 254 A-1 . | |

| D-2 | destroyer | Renamed to Ta 254 A-2 . | ||

|

Brief overview of the Focke-Wulf Ta 254 series |

||||

| Surname | Engine / power unit | Intended use | crew | Remarks |

|---|---|---|---|---|

| A-1 | Jumo 213E | Night fighter | 2 | The A-1 , formerly Ta 154 D-1 , should theoretically reach a speed of 719 km / h. In addition to a sheet metal front fuselage part and a folding hood, an ejection seat , a GM-1 system and an armament of two MG 151/20 and MK 108 each were provided for the machine . The A-1 did not get past the drawing board stage. |

| A-2 | Day hunter | The A-2 , formerly Ta 154 D-2 , had a MW-50 system ( water-methanol injection ). In terms of armament, the A-2 had four MK 108 and two MK 103. It was not implemented. | ||

| A-3 | 1 | The A-3 should get a sheet metal fuselage front part. Mathematically, it should reach 740 km / h at an altitude of 10,590 m. With the DB 603L engine (2,000 hp each) and a VDM propeller, it should achieve even higher speeds. No A-3 was built. | ||

| B-1 | DB 603L | Night fighter | 2 | Version corresponds to A-1 , with engine from Daimler-Benz. |

| B-2 | Day hunter | Design corresponds to A-2 , with engine from Daimler-Benz. | ||

| B-3 | 1 | Design corresponds to A-3 , with engine from Daimler-Benz. | ||

production

The production of the Ta 154 was ordered “decentrally” by the RLM on June 18, 1943. This reduced the risk of production downtime as a result of bombing a central production site. Focke-Wulf followed suit. Most of the production should take place outside the traditional aircraft industry, which Erhard Milch saw as an advantage. The cost estimate calculated by Focke-Wulf assumed 7,376 man hours per aircraft. 3866 workers should produce 100 machines per month; of these workers alone, 880 should be carpenters .

In order to implement the decentralized production arranged by the RLM, Focke-Wulf decided on production in so-called "production rings". There should be a central final assembly in the production rings, which should be supplied by corresponding smaller workshops in the area. These production rings were to produce 500 aircraft per month independently and independently of the rest of the aircraft industry. However, these production rings only made sense if there were corresponding suppliers and wood industry in the local area. Another criterion for the future production rings was their location. In order to avoid enemy bombing attacks, the planned settlements had to take place in relatively safe areas of the Reich.

After determining these conditions, Focke-Wulf initially decided on four production areas: the Warthegau production area ( Posen ), the Thuringia production area ( Erfurt ), the Silesia production area ( Bunzlau ) and the Teutoburg Forest ( Detmold ) production area, which, however, took place before production began was dissolved in the spring of 1943. However, the Detmold plant was still used to build prototypes. Tank wanted to use the capacities of the wood processing industry located in the Teutoburg Forest .

In the manufacturing areas of Posen and Silesia, production was taken over by the Focke-Wulf aircraft factory in Posen-Kreising and Sorau, respectively, in the manufacturing area of Thuringia by the Mitteldeutsche Metallwerke in Erfurt (Erfurt repair shop = REWE) and the Allgemeine Transportanlagen-Gesellschaft (ATG) in Leipzig . The decision criterion for the Poznan production group was the use of Polish and 2000 Jewish forced laborers . The latter set up two new factories for the construction of the Ta 154 . After this work was completed, the Jewish forced laborers were deported to Auschwitz concentration camp in September 1943 . Ultimately, 96% of the workforce in the Poznan production area were Polish and 4% German, which Kurt Tank complained about.

Another production line was to be built in 1944 in an underground relocation of the Gothaer wagon factory in a salt mine . Secondary manufacturing locations were Bunzlau and Cottbus . The final assembly should run on two parallel belts. 17 production stations were planned, each with four workers. Focke-Wulf calculated that with two-shift operation, 200 aircraft per month or one aircraft every four hours would be produced. 500 aircraft per month were planned as a minimum for all production rings.

In 1944 the Volkswagen factory near Fallersleben was integrated into the production processes. In 1943, the proportion of forced laborers deployed at the VW main plant was around 75 percent. Initially, the factory was commissioned to build parts for engine carriers. The VW plant and the RLM hoped to produce entire aircraft, initially in free areas in the Volkswagen plant, and later in free areas of the underground V1 production in an ore mine in Tiercelet ( Département Meurthe-et-Moselle ), because this production is based on Dora-Mittelbau was relocated. The Volkswagen factory, now a major subcontractor of Focke-Wulf, sent a few technicians and draftsmen to the Peugeot factory in Sochaux to prepare the production of the parts and components required there, in particular to instruct the French workers.

The delivery program 223/1 set up by the RLM on April 15, 1943 was based on the start of large-scale production in October 1943. The targeted production levels were not taken into account due to the lack of trained personnel. In addition, there was a lack of adequate equipment to manufacture the wooden components. Series production was planned to be staggered. At the end of 1943 this was 200 machines per month on paper. In July 1944 it rose to 300 and from November 1944 to 500 machines per month. By January 1945, 600 aircraft were to leave the assembly halls every month. As of June 1945, the Ta 154 should run off the assembly line alongside the He 219 as the sole night fighter aircraft . On May 6, 1943, the general of the fighter pilots Galland instructed that the aircraft of the A and B series up to production number 1500 should be produced exclusively as destroyers.

A series

|

Machines manufactured by REWE-Erfurt (after Griehl) |

||||||

| Construction pattern |

Work number |

Admission | First flight / first mention |

Whereabouts | ||

|---|---|---|---|---|---|---|

| A-1 | 320002 | KU+SO |

June 12, 1944 | Crash on June 28, 1944 | ||

| 320003 | KU+SP |

June 30, 1944 | Mission III. Group of the EJG 2 in Lechfeld | |||

| 320004 | KU+SQ |

June 1944 | Crash on June 16, 1944 | |||

| 320005 | not known KU+SR? |

not known | Unknown execution | |||

| 320006 | KU+SS |

July 6, 1944 | Remaining unknown from August 1944 | |||

| 320007 | KU+ST |

July 1944 | July 28, 1944 Damage due to breakage | |||

| A-2 | 320008 | KU+SU |

August 1, 1944 | Crash landing on April 30, 1945 | ||

| 320009 | KU+SV |

Blasted at NJG 3 in April 1945 | ||||

| 320010 | KU+SW |

August 14, 1944 | ||||

| 320011 | KU+SX |

August 28, 1944 | Destroyed by crash landing on September 28, 1944 | |||

| 320012 | not known | not known | Completion unknown | |||

| 320013 | ||||||

| 320014 | ||||||

| 320015 | ||||||

| 320016 | ||||||

| 320017 | August 1944 | Parked on August 1, 1944 at the Kölleda airfield | ||||

| 320018 | not known | Construction unknown | ||||

| 320059 | Parked in Langenhagen on October 30, 1944 | |||||

The production of eight A-0 took place at the Mitteldeutsche Metallwerke in Erfurt, according to another publication also in the Gothaer Waggonfabrik in a production relocation in a salt mine. On January 15, 1944, Gauleiter Fritz Sauckel visited the Posen plant. He had been commissioned by the NSDAP to manage the hunter emergency program . Due to the insufficient number of wings and tail units manufactured, he threatened plant manager Schnebel with concentration camp imprisonment if he did not increase production. Schnebel suffered a collapse, so that plant manager Gieschen from the Focke-Wulf plant in Cottbus had to take over his official duties at short notice.

- A-1

The plans provided for the production of 102 machines of the two-seat day fighter A-1 in the Posener Ring from March to September 1944. Furthermore, a sub-variant of the A-1 called Ta 154 A-1 / R1 was later planned with 410 machines, which should run off the assembly line in all three production circles .

- A-2

In the production planning for January 1944, the single-seat day fighter A-2 was to be manufactured from March 1944 to January 1945 in a series of 637 units. The manufacturing area Warthegau 203, the manufacturing area Thuringia 217 and the manufacturing area Silesia 157 machines. However, series production only started at the Rewe plant in Erfurt. Production consisted of at least 18 machines before the plant was bombed on July 20, 1944. Another publication assumes four units were produced.

The first machine produced was given the serial number 320 001 and the registration number KU+SN. Its maiden flight took place on June 16, 1944. After the aircraft had been transferred to Langenhagen, the chief test pilot Hans Sander flew the machine on June 13 and 20, 1944. In addition to other minor defects, excessive aileron forces were found. The machine fell victim to the bombing raid in Erfurt on July 20, 1944 and burned.

The second machine 320 002 ( KU+SO) crashed on June 28, 1944 after breaking a wing due to inadequate gluing.

The Erfurt machine with the serial number 320 004 ( KU+SQ) crashed during its test flight on June 16, 1944. The pilot was seriously injured in the crash and succumbed to his injuries a few days later. A piston seizure in the left engine was determined to be the cause of the crash.

After the bombing on July 20, 1944, Focke-Wulf was instructed by the RLM to transfer the four remaining machines (serial numbers 320 008, 320 009, 320 010 and 320 011) to Langenhagen.

The fifth and sixth machines (320 017, 320 003) were also transferred from Kölleda to Langenhagen. The latter - equipped as a night fighter - was captured there after the end of the war.

- A-4

In the manufacturing area of Thuringia, 240 pieces of the A-4 were to be built as two-seat night fighters according to the planning of January 1944 .

C series

Following the industrial program No. 225 of June 18, 1943, 6598 machines of the C series were to be manufactured, which Focke-Wulf would have had to deliver by September 1945, of which 4,285 machines of the type C-1, C-2 and C alone were to be manufactured -4. There would have been 1305 type C-1 fighters in the Silesia manufacturing area, as were the C-2 type in the Thuringia manufacturing area. 1675 type C-4 machines were planned for Poznan .

In May 1944, however, the planned production figures were corrected, now a total of 3450 machines was targeted. The distribution looked like this:

- C-1: Production area Silesia with 685 machines from September 1944 to September 1945

- C-1: Poznan production circle with 1140 machines from September 1944 to September 1945

- C-3: Thuringia manufacturing area with 940 machines from December 1944 to October 1945

- C-3: Production area Silesia with 685 machines from October 1944 to September 1945

The start of series production of the C-1 was planned for September 1944, this start date was also confirmed by Focke-Wulf. In the Posen manufacturing area, 1148 and in the Thuringia manufacturing area 595 machines were to go into series production and delivered by October 1945. For this purpose, Daimler was to have 1834 DB 603 E engines available. With these production figures, the C-1 series would have become the standard night fighter of the Air Force.

Because the Ta 154 program was discontinued in August 1944 - before the planned start of series production - not a single machine in the C series was ultimately completed.

Allied reactions

| Chronological listing of aviation accidents | ||

| date | machine | Cause of accident |

| July 31, 1943 | V1 | Buckle strut fracture main landing gear |

| February 18, 1944 | V4 | Main landing gear failure / broken strut |

| February 28, 1944 | V3 | Transverse position of the nose wheel |

| April 7, 1944 | V5 | Buckle strut fracture main landing gear |

| April 8, 1944 | V8 | Right engine fire |

| April 18, 1944 | V9 | Leaning to the right after landing aid experience with ground contact |

| April 18, 1944 | 0 012 | Failure when extending the nose wheel |

| June 16, 1944 | 320 004 | Piston seizure on the left engine |

| June 28, 1944 | 320 002 | Reason for crash according to Hermann unknown. Redemann cites poor gluing as the cause. |

| July 18, 1944 | V10 | Connecting rod bearing seizure |

| September 28, 1944 | 320 011 | Landing gear extension failure |

| April 30, 1945 | 320 008 ( D5+HD) |

Crash landing due to failure of the deployment mechanism or the landing flaps |

The Allies were informed about the development and construction of the Ta 154 from the start through their aerial reconnaissance . As part of several preventive strikes against the testing and production facilities of Focke-Wulf, where mainly B-17 and B-24 bombers were used, the sites for the development and testing of the Ta 154 were hit, including those responsible for glue production Th. Goldschmidt company in Wuppertal.

- On April 8, 1944, the Evershorst Air Base ( Langenhagen ) was bombed with the test squadrons stationed there.

- On April 9, there were bombing raids on the two Focke-Wulf plants in Marienburg ( Königsdorf airfield ) and Posen. The production facilities for components of the Fw 190 were destroyed.

- On April 11, 1944, Sorau was bombed.

- On May 29, 1944, there were further attacks on Bremen , Cottbus and again Posen and Sorau. The plant was almost completely destroyed within four minutes. This meant that it was initially no longer possible to produce any further aircraft there.

- Another attack on Mitteldeutsche Metallwerke Erfurt on July 20, 1944 resulted in the loss of seven Ta 154s . Another three were severely damaged. In addition, 18 hulls and 18 structural surfaces each under construction were burned. This permanently disrupted the production of the Ta 154 in Erfurt.

- On August 5, 1944, there was a heavy bombing raid on the Ta 154 test sites in Langenhagen, where seven Ta 154s were destroyed. Two other machines were badly damaged.

The British Interpreation Report of March 12, 1945 repeatedly refers to the presence of Ta 154 . During aerial reconnaissance missions on February 22, 1945, two Ta 154s were found at the Stade airfield. On March 9, 1945, two more machines were identified. Three of these machines were painted light-colored. The fourth machine ( D5+HD) had stain camouflage. At least two Ta 154s were "ready for action" at this point. One was on the weapon adjustment stand and the other was on the compensation stand.

It D5+HDcrashed on April 30, 1945, causing the tail unit to break away. After the machine was abandoned by the crew, German civilians looted the plane. On May 6, 1945, the machine was secured by British units and then logged. The investigation report is called: ATI 2nd TAF Report A 685 10/5/45 . It mainly contains technical features on the equipment and the dimensions of the machine. Strangely enough, the British do not identify the machine with the factory number 320 008, but with 320 009 with the application identification D5+HDand the factory identification KU+SO.

One of the reasons for this discrepancy cannot be explained, as the 320 002 ( KU+SO) has been proven to have crashed on June 28, 1944.

Production problems

The Ta 154 has suffered from design defects since its first prototype. The main concern of the team around the tank remained the landing gear, the engines and the basic structure of the aircraft as well as the quality control in the production of the prototypes.

The wood moisture problem could never be resolved until the project was discontinued. The rivets between wood and metal connection points kept knocking out when moisture was absorbed, which meant increased maintenance costs. The suspension problem could only be partially resolved even after numerous changes. The propeller blades of the Ta 154 could touch the ground if the main landing gear was too soft.

Other problems arose in early 1944 with the gluing of the aircraft. Th. Goldschmidt AG from Essen , which manufactured the “Tego-Film” adhesive used in the production of the Ta 154 , was bombed and destroyed by the Allies. As a result, production switched to the “Kaurit” glue produced by Leverkusener Dynamit AG, which is still in the development stage. However, this had a different acidity than the hardener and had a corrosive effect on the wood structure. Tests have confirmed a decrease in strength of up to 50 percent. Although the problems with the glue could be solved, they nevertheless caused the mood in the Reich Aviation Ministry to change, which ultimately led to the termination of the large-scale Ta 154 project.

Bad gluing was also the cause of the accident of the Erfurt machine with the serial number 320 002 ( KU+SO) on June 28, 1944.

After the crash, Tank had production in the Erfurt plant stopped. After this stop, he was accused of sabotage by a worker . The incident was reported to Gauleiter Fritz Sauckel and passed on to Göring. The discussion between the two people took place a short time later in the Hotel Deutscher Kaiser in Nuremberg . In the course of this, Tank faced serious accusations from the Reichsmarschall. Tank was able to rebut the allegations of sabotage, so the matter was not pursued further. However, the glue problem led to a considerable delay in the preparations for series production. A total of twelve aircraft accidents have become known at the Ta 154 .

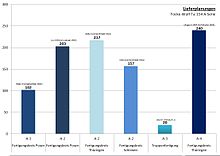

Production numbers

|

Production figures (according to different sources) |

||||||||||||||

| Construction series | Hermann | Merrick | Talking man | Donald | Munson | Nowarra | Berger | Aircraft from A to Z |

Becker / Swoboda | Griehl | Griehl II | Arnold | Ring letter | Long |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V pattern | 12 | o.A. | 7th | o.A. | o.A. | o.A. | o.A. | o.A. | o.A. | 12 | 12 | 3 | 12 | 12 |

| A-0 | 8th | o.A. | 8th | 8th | o.A. | 8th | 15th | 8th | 20th | ~ 10 | 7th | 12 | 7th | 11 |

| A-1 | o. A. | at least 6 | 10 | o.A. | o.A. | 10 | o.A. | 10 | small number | 6th | o. A. | 10 | Quite a few | o. A. |

| A-2 | at least 18 | 4th | o.A. | o.A. | o.A. | o.A. | o.A. | 6th | o.A. | 6-10 | oA | o. A. | o. A. | o. A. |

| total | ~ 50 | o.A. | 31 | o.A. | Dozens | o.A. | o.A. | o.A. | > 50 | o.A. | 30th | o.A. | 30th | 31 |

Cessation of production

| Performance data comparison of various main competitors | ||||

| Data | Ta 154 A-1 | Thu 335 A-6 | He 219 A-7 / R2 | Mosquito NF XIX |

|---|---|---|---|---|

| All-up weight | 11,500 kg | 10,100 kg | 15,100 kg | 10,115 kg |

| span | 17.80 m | 13.80 m | 18.50 m | 16.51 m |

| length | 13.70 m | 13.85 m | 16.34 m (with antenna) | 12.30 m |

| height | 3.67 m | 5.00 m | 4.10 m | 4.66 m |

| Wing area | 32.00 m³ | 38.50 m³ | 44.50 m³ | 43.00 m³ |

| engine | 2 × Jumo 213 E | 2 × DB 603 E | 2 × DB 603 E | Rolls-Royce Merlin 25 |

| Engine power | 2 × 1,750 hp | 2 × 1,800 hp | 2 × 1,800 hp | 2 × 1,635 hp |

| Fuel supply | 2,300 l | 1,720 l + 150 l MW-50 | unknown | 2,346 l |

| Additional tanks | 2 × 300 l | 2 × 300 l | unknown | 2 × 227/2 × 454 l |

| Range | 1,615 km | 1,510 km | 1,850 km | 1,940 km |

| with additional tanks | 1,875 km | 2,540 km (economy flight) | unknown | 2,944 km |

| Top speed | 678 km / h at 10,000 m | 692 km / h at 5,500 m | 586 km / h at 9,800 m | 612 km / h |

| Service ceiling | 11,500 m | 10,800 m | 9,800 m | 10,516 m |

| Hull armament | 2 × MK 108 and 2 × MG 151/20 | 1 × MK 103 and 2 × MG 151/20 | up to 6 × MG 151/20 | 4 × MK 20 mm (Hispano) |

Development, manufacture and flight testing of the Ta 154 have been under criticism since the beginning of the project. The project was burdened by the unreliability of the main landing gear, the problem of inadequate gluing and insufficient engine power. In addition, this type of aircraft did not meet with any sympathy from the responsible authorities at the RLM or from the test pilots at the Rechlin test center.

On May 25, 1944, an excited meeting between Göring, Tank, Galland and Karl Saur took place on the Obersalzberg , at which the aim was to remedy these deficiencies. In the conversation Göring is said to have turned to Tank harshly:

“The machine should already be running in the program today, but I notice that it is not there. It cannot be glued either and the services are far behind. "

Adolf Galland, the general of the fighter pilots, did not expect a significant increase in performance despite the installation of the more powerful Jumo 213. In addition, Galland complained about the poor flight characteristics of the machine, the unsatisfactory single-engine flight and the risk of a belly landing with the wooden fuselage. Tank did not succeed in completely refuting these arguments in the further course of the conversation, only he was able to alleviate the glue problem by announcing the new glue type "Polystal".

However, interest in the Ta 154 continued to decline. On June 17, 1944, the delivery schedule drawn up by the Jägerstab no longer provided for the Ta 154 , which was equivalent to a discontinuation.

At the beginning of July 1944, the still existing problem with the chassis and the gluing was pointed out again, and on July 6, 1944 Erhard Milch announced to Focke-Wulf that, in agreement with Göring and Hitler, the Ta 154 and the improved Ta 254 had been deleted from the planning. On August 1, 1944, Erprobungskommando 154 was also disbanded. On August 2, 1944, Milch ordered that all machines completed by that time be "shut down". He also forbade building larger components and wasting more fuel on the project.

Tank's efforts to keep his Ta 154 project alive ended with the V14 being handed over to Galland and Werner Streib for further test flights . But this attempt also failed. In addition, Langenhagen was bombed on August 5, 1944 and most of the last Ta 154s were destroyed. The next day, Karl-Otto Saur announced that the Ta 154 was no longer needed in the company's interests. On August 14, 1944, the Air Force High Command at Focke-Wulf banned any new construction and any repairs to existing machines. All machines under construction at this point were to be handed over to the Quartermaster General. In September and October 1944, however, further machines were produced and completed in Erfurt based on a permit from Saur. In autumn 1944, contrary to existing orders, the flight tests of the Ta 154 were resumed; they were continued in the ranks of Nachtjagdgeschwader 3 until April 1945.

Mistletoe and bulk destroyer variants

|

Planning for the mistletoe principle Focke-Wulf TA 154 |

|||

| designation | Draft 1 | Draft 2 | Draft 3 |

|---|---|---|---|

| Mass Ta 154 | 9,920 kg | 10,430 kg | 11,030 kg |

| Mass explosive charge | 2,500 kg | 3,000 kg | 3,500 kg |

| Mass Fw 190 A-8 | 4,100 kg | ||

| Total mass | 14,030 kg | 14,630 kg | 15,130 kg |

After the production stop of the Ta 154 became apparent, Focke-Wulf developed ideas to use existing aircraft and assemblies for a new, more radical purpose. This resulted in three possible uses - a mistletoe principle and that of a bulk destroyer in two versions.

- Mistletoe principle

The mistletoe principle was developed by the Schöffel group at Focke-Wulf and was given the name Mistel Ta 154 A - FW 190 A-8 "Beethoven explosive carrier" . It comprised the conversion of at least 6 Ta 154 A-0 pre-series machines, which were given the designation Ta 154 A-0 / U2 for this purpose . The project was presented to the RLM in July 1944. The “mistletoe principle” was based on a combination of a Ta 154 as an explosive carrier , which was to be connected to the lead aircraft, a Fw 190 A-8 , by a strut frame . Alternatively, a Fw 190 A-4 was also being discussed. For this purpose, the selected machines received a modified fuselage tip with a shaped charge . The measurements vary, depending on the source used, between 2000 and 3500 kg. The maximum take-off weight was 15.13 t. Once in the air, the Ta 154 should separate itself from the lead aircraft on its approach to the target and plunge into the incoming bomber formations as an aerial torpedo in the orbit flight . There the explosive charge was then to be detonated remotely using a radio signal , with the total loss of the machine being taken into account.

At the end of the war, the conversion of six mistletoe harnesses is said to have been completed and training flights had taken place. Other publications indicate that the idea of the mistletoe principle was discarded when investigations revealed that the ratio of the Fw 190 and Ta 154 would not have allowed a proper separation from the explosive carrier. Then the idea of the "bulk destroyer" is said to have been taken up.

- Bulk destroyer scheme Fw 190 - Ta 154

The idea of using the Ta 154 as a "bulk destroyer" was developed by Focke-Wulf in February 1944. Investigations had shown that detonating a 2,000 kg explosive charge at a distance of 140 meters would have to be sufficient to bring down a four-engine bomber. Tank concluded from this that the bomber formations flying in close formation could be broken up. He submitted his study to the RLM on May 7, 1944, which approved this plan. For this purpose, six type A-1 machines were built as single-seat, unarmed variants at the Poznan plant . In addition to the 2000 kg explosive charge, the machines received three detonators that worked independently of each other: an acoustic, a time and an impact fuse. As an option, the machines had a rotating ejection seat so that the pilot could catapult himself out of the machine on the target approach. However, flight tests did not take place. According to another publication, this principle was rejected and replaced by the following concept.

- Bulk destroyer scheme Ta 154 - Ta 154

This alternative to the bulk destroyer scheme involved the use of two Ta 154s , whereby the machine with the 2500 kg shaped charge was to be steered into the bomber bulk by a wire control. Once it reached the appropriate position, the wire should be cut and the aircraft should be detonated by a radio signal. The project was not implemented.

Overpass and front operations

In August 1944, Focke-Wulf and the Nachtjagdgeschwader 3 held initial talks regarding a possible use of the Ta 154 . Squadron commodore Helmut Lent was interested in the performance of the machine. However, the bombing raid on Langenhagen prevented further activities. After the production stop and the dissolution of the test command, all the remaining six Ta 154s were transferred to Detmold and converted there for night hunting. On November 19, 1944, the machine with the serial number 120 005 (license plate TQ+XE) was transferred from Langenhagen to Stade, the headquarters of the squadron staff, by a pilot of NJG 3 . There the machine was given night hunting identification D5+ED. Then this machine flew in the III. Group of the NJG 3 . The crew consisted of the pilot Gottfried Schneider and his radio operator Ernst Hammer. Both flew with D5+ED44 enemy flights until the end of the war , 13 of which were night hunting missions . Further transfer flights to Stade took place on November 27, December 12 and 23, 1944 and January 29, 1945. In November 1944, the III. Group of the NJG 3 three Ta 154 . This figure is confirmed by the testimony of the last squadron adjutant Jochen Jarow. The unsuccessful use of these machines is documented in a Junkers note dated March 16, 1945.

In addition to their use in NJG 3 , other machines flew in Nachtjagdgruppe 10 (NJGr 10) and in supplementary hunting squadron 2 (ErJG 2). Operations of the Ta 154 against the de Haviland Mosquito were disappointing because the engines used were not suitable for use at great heights.

Overall, the crews of the Ta 154 are said to have achieved two unconfirmed kills of enemy aircraft.

There are no records of operations of Ta 154 in the last months of the war. Their whereabouts at the end of the war are nebulous. The remaining machines - there should have been five or six - were parked unused and undisguised at the edge of the forest in Agathenburg for the last weeks of the war . Three machines are said to have been blown up there in April 1945. These are the machines with the serial numbers 120015, 320009 and 3200010. A fourth machine is said to have remained in Stade until the end of the war, another was in Lechfeld and a sixth in Langenhagen.

Other publications state that some machines survived the war unscathed and are said to have fallen to the victorious powers as spoils of war. According to this, one of these machines is said to have been seized by US troops in Lage after the end of the war and shipped to the USA, where it is said to have been shown on Freeman Field at the booty exhibition there in September 1945. Three more Ta 154s are said to have been seized by British troops in the Paderborn Air Park and brought to England.

Rating

The planning, conception and construction of the Ta 154 was one of the most complex projects of the last years of the war for both the Luftwaffe and Focke-Wulf. Originally, the machine designed by Kurt Tank was supposed to replace most of the twin-engine aircraft of the Luftwaffe by 1944, especially in the night fighter role. It consisted of more than 50 percent wood and was therefore cheaper and easier to produce than metal airplanes, the production of which was becoming increasingly difficult due to the lack of aluminum.

Development of the wooden Ta 154 began as a replacement for most of the Luftwaffe's twin-engine aircraft, but it quickly became clear that due to the Allied air dominance, it could only be used for night operations. When the series production of the machine was supposed to start in full in mid-1944, the Air Force ordered a construction freeze.

At that time, night hunting had three night hunting models.

- The Bf 110 was technically obsolete by 1944 at the latest.

- The He 219 "Uhu" was only available in small numbers.

- The Do 335 was not yet operational due to its complex construction.

The “German mosquito”, on the other hand, was developed after the then prevailing experience of night hunting and was superior to all previously used German night hunters. Kurt Tank, who had flown the machine often and with great pleasure, described it as a "good airplane". In direct performance comparison with its main competitor, the He 219 , it was more climbing and maneuverable, but the Ta 154 lacked sufficient armament and its flight duration was inadequate.

Another shortcoming of the Ta 154 was the poor visibility of the pilot to the right and left. The reason was that the control pulpit and engines were about the same height. The rear pilot, usually the radio operator, saw nothing. For this reason, the machine was not suitable for formation flights.

In addition to the problems mentioned, there were difficulties with the hydraulics and the handling of the unfamiliar nose wheel. The “wooden bird” was unpopular with members of NJG 3 because of these peculiarities. In this context, the saying “The mosquito doesn't bite!” Brings the whole problem of Ta 154 to bear. Even when the He 219 was ready for the front, Milch still insisted on the continuation of the Ta-154 project , mainly for production -related reasons .

The reasons for the failure of the project were not of a production-related nature, but rather the consequence of a lack of detail construction, coupled with the impatience of the air force command.

Overall, the Ta 154 is viewed as a "costly failure", a repetition of the debacle surrounding the Me 210 (classified by the RLM as unfit to fly at the end of 1941) and He 177 (uncontrollable engine fires and hull ruptures). With the construction of the previous models Fw 187, Me 210 and He 177 and now also the Ta 154 , the Luftwaffe robbed itself of its few possibilities to oppose the Allies with an effective night fighter. This decision is seen as a military mistake.

A total of around 10,000 workers wasted a year on the Ta 154 project . Instead, the air force leadership distributed its limited resources to countless other aircraft projects. It lost almost two years of production time for the Fw 187 and another year for the Ta 154 .

The resulting deficit of strength, comprising several thousand machines, further accelerated the demise of the night hunting weapon. After the construction of the Ta 154 was stopped , the RLM turned to the favored Do 335 , convinced that it still had enough time for the development of this fighter. This misjudgment is seen as a further indication of the lack of concept of the Luftwaffe leadership, because at the end of the war this machine was only at the beginning of its series production and thus twelve months behind the Ta 154 .

At the end of the war, the Ta 154 was already technically obsolete and, in contrast to the rocket fighter Me 163 or jet aircraft such as the Me 262 , hardly attracted any interest from the Allies.

A partial replica of the Ta 154 V3 is on display in the Aviation Museum in Rechlin.

Technical appendix

A series

|

Technical data Focke-Wulf Ta 154 A-1 (selection based on different publications) |

||||||

| equipment | Nowarra | Berger | Talking man | Aircraft from A to Z | Types of aircraft in the world | Long |

|---|---|---|---|---|---|---|

| Usage | Twin-engine night fighter | Fighter / night fighter | Night fighter | |||

| Engine | 2 × Jumo 211 R (1,500 hp each) | 2 × Jumo 213 E (1,750 hp each) | 2 × Jumo 211 R (1,500 hp each) | 2 × Jumo 213 E (1,750 hp each) | ||

| span | 16.00 m | |||||

| length | 12.60 m | 12.10 m | 12.57 m | |||

| height | 3.67 m | k. A. | 3.60 m | 3.50 m | 3.60 m | |

| Service ceiling | 10,920 m | 10,900 m | ||||

| Range | 1,370 km | 1,860 km | 1,365 km | 1,375 km | ||

| Max. Takeoff mass | 8,845 kg | 8,920 kg | 8,930 kg | 8,250 kg | ||

| Fuel supply | 1,500 l | k. A. | k. A. | k. A. | k. A. | k. A. |

| V max | 632 km / h | 648 km / h | 650 km / h | 642 km / h | ||

| Armament | 2 × MG 151/20 mm 4 × MK 108/30 mm (weird music ) |

4 × MK 108/30 mm 2 × MG 151/20 mm |

2 × MG 151/20 2 × MK 108 |

2 × MG 151/20 1 × MK 108 (weird music) |

2 × MG 151/20 mm 2 × MK 108 1 × MK 108 (weird music) |

2 × MG 151/20 2 × MK 108 |

Comparison overview

|

Comparison overview of selected Focke-Wulf Ta 154 series |

|||||||||||||

| Surname | crew | Wing area | span | Takeoff mass | length | height | Engine | Tank capacity | Range | V max | Service ceiling | Armament | source |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V1 | 2 | 32.40 m² | k. A. | 7,700 kg | k. A. | k. A. | 2 × Jumo 211 F (1,340 hp each) | 1,944 l | k. A. | 618 km / h | k. A. | 2 × MG 151 and 2 × MK 108 | |

| V2 | 16.00 m | 9,450 kg | 12.75 m | 3.65 m | k. A. | k. A. | 615 km / h | 9,400 m | 2 × or 4 × MG 151/20 | ||||

| V3 | 8,490 kg | 12.57 m | k. A. | 1,600 km | 574 km / h | 9,250 m | 4 × MG 151 | ||||||

| V6 | k. A. | k. A. | k. A. | k. A. | k. A. | 2 × Jumo 211 N (1,450 HP each) | 1,500 l | k. A. | k. A. | k. A. | 4 × MG 151/20 | ||

| A-0 | k. A. | 16.00 m | 8,250 kg | 12.57 m | 3.65 m | 2 × Jumo 211 F (1,340 hp each) | k. A. | 1,365 km | 600 km / h | 10,500 m | |||

| A-1 | 42.00 m² | 17.80 m | 11,500 kg | 13.70 m | 3.67 m | 2 × Jumo 211 E (1,750 hp each) | 2,300 l | 1,615 km | 678 km / h | 11,500 m | k. A. | ||

| A-2 / U4 | k. A. | 16.46 m | 8,450 kg | 13.20 m | k. A. | 2 × Jumo 213 A (1,750 hp each) | 1,500 l | 1,485 km | 645 km / h | 11,300 m | 2 × MG 151/20 | ||

| A-4 | 25.00 m² | 16.00 m | 8,250 kg | 12.45 m | 3.40 m | k. A. | k. A. | 1,365 km | 635 km / h | 10,000 m | k. A. | ||

| C-1 | k. A. | 9,000 kg | 13.70 m | 3.67 m | 2 × Jumo 213 A (1,750 hp each) | k. A. | 1,370 km | 685 km / h | 10,920 m | 6 × MK 108 | |||

| C-3 | 1 | 32.40 m² | 10,735 kg | 3.65 m | 1,830 l | 1,375 km | 652 km / h | 10,500 m | k. A. | ||||

| 254 A-1 | 42.00 m² | 17.80 m | 11,500 kg | 3.67 m | 2 × Jumo 213 E (1,750 hp each) | 2,300 l | 1,615 km | 678 km / h | 11,500 m | k. A. | |||

| 254 A-2 | 2 | 16.00 m | k. A. | 1440 km | 736 km / h | 2 × MG 151, 2 × MK 108 | |||||||

Graphic appendix

Comparable types

-

United Kingdom : de Havilland DH.98 Mosquito

United Kingdom : de Havilland DH.98 Mosquito

-

United States : Northrop P-61 Black Widow

United States : Northrop P-61 Black Widow

-

Soviet Union : Petlyakov Pe-3

Soviet Union : Petlyakov Pe-3

-

Japan : Kawasaki Ki-102 Randy , Nakajima J1N1 -S / C Kai Gekko

Japan : Kawasaki Ki-102 Randy , Nakajima J1N1 -S / C Kai Gekko

-

German Empire : Heinkel He 219 eagle owl

German Empire : Heinkel He 219 eagle owl

literature

- Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Luftwaffe 1933-1945. Motorbuchverlag, Stuttgart 2005, ISBN 3-613-02524-8 .

- Heinrich Beauvais, Karl Kössler , Max Mayer, Christoph Regel with the assistance of Heinz Borsdorff, Matthias Jens, Volker Koos, Hanfried Schliephake: Flight test sites until 1945 - Johannisthal, Lipezk, Rechlin, Travemünde, Tarnewitz, Peenemünde West. Bernard & Graefe Verlag, Bonn 1998, ISBN 3-7637-6117-9 .

- Manfred Griehl: The History of the German Mosquito. In: Airplane Profiles. No. 25, year 1995.

- Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 “Mosquito” - development, production and troop testing. Stedinger, Lemwerder 2006, ISBN 3-927697-46-X .

- Herbert Kruse: Ta 154 - Germany's “plywood mosquito”. In: airplane. No. 1, born in 1988.

- Herbert Kruse: Ta 154 - Germany's “plywood mosquito”. In: airplane. No. 2, born in 1988.

- Gerhard Lang: Fighter aircraft of the Second World War. Motorbuchverlag, Stuttgart 2011, ISBN 978-3-613-03266-8

- Heinz J. Nowarra : The German Air Armament 1933–1945. Volume 2, Bernard & Graefe Verlag, Koblenz 1993, ISBN 3-7637-5466-0 .

- Without author: Chronicle of the fighter planes. Heel Verlag, Gut Pottscheid 2009, ISBN 978-3-86852-207-5 .

- David Arnold: Types of Airplanes in the World - Models. Technology. Data. Bechtermünz-Verlag, Augsburg 1998, ISBN 3-86047-593-2 .

- Hans Redemann: Focke-Wulf Ta 154. Part I In: Flight Revue . Born 1978, issue 5.

- Hans Redemann: Focke-Wulf Ta 154. Part II In: Flight Revue. Born 1978, issue 6.

- Herbert Ringsletter: Night fighters and bombers - German Air Force 1935-1945. GeraMond, Munich 2012, ISBN 978-3-86245-326-9 .

- Reinhold Thiel : Focke-Wulf aircraft construction. Verlag HM Hauschild, Bremen 2011, ISBN 978-3-89757-489-2 , pp. 181-195.

- Daniel Uziel: Arming the Luftwaffe - The German Aviation Industry in World War II. Mcfarland & Co, 2012, ISBN 978-0-7864-6521-7 .

- Wolfgang Wagner: Kurt Tank - designer and test pilot at Focke-Wulf. Bernard & Graefe Verlag, Bonn 1991, ISBN 3-7637-6102-0 .

Web links

- Website of the aeronautical museum Rechlin

- Brief description of the Ta 154 on google.books (English)

- Manufacturing process of the Ta 154 on youtube.com

Individual evidence

- ↑ Hans Redemann: Focke-Wulf Ta 154. Part I, p. 125.

- ↑ a b c d David Arnold: Airplane types of the world - models. Technology. Data. P. 427.

- ↑ a b c Wolfgang Wagner: Kurt Tank - designer and test pilot at Focke Wulf. P. 193.

- ↑ a b c Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Air Force 1933-1945. P. 200.

- ↑ a b c d Hans Redemann: Focke-Wulf Ta 154. Part I, p. 126

- ↑ a b c Chronicle of the fighter planes. P. 160.

- ↑ a b c Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 5.

- ↑ Dr. Heinz Mankau in Jet & Prop issue 02/2012

- ↑ Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 3.

- ↑ a b c d e f g h i j k l m Daniel Uziel: Arming the Luftwaffe - The German Aviation Industry in World War II. P. 91.

- ↑ Daniel Uziel: The People's Hunter. Rationalization and rationality of Germany's last fighter plane in World War II. In: Andreas Heusler, Mark Spoerer, Helmuth Trischler : Armaments, war economy and forced labor in the Third Reich. Oldenbourg, Munich 2010, ISBN 978-3-486-58858-3 , p. 70.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 8.

- ↑ a b c Chronicle of the fighter planes. P. 161.

- ^ A b Heinz J. Nowarra: The German Air Armament 1933–1945. P. 109.

- ^ A b Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Luftwaffe 1933-1945. P. 201.

- ↑ Stephen Bull: Encyclopedia of Military Technology and Innovation. Wesport, Greenwood 2004, p. 182.

- ↑ Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 6.

- ↑ a b c d Reinhold Thiel: Focke-Wulf aircraft construction. P. 182.

- ↑ a b c d Hans Redemann: Focke-Wulf Ta 154. Part II, p. 56.

- ↑ a b c Rüdiger Kosin: The development of the German fighter aircraft. Bernard & Graefe, Koblenz 1983, ISBN 3-7637-5275-7 , pp. 169-171.

- ↑ a b Reinhold Thiel: Focke-Wulf aircraft construction. P. 181.

- ↑ a b Herbert Ring Letter: night fighters and bombers - German Air Force from 1935 to 1945. P. 144.

- ↑ a b c Hans Redemann: Focke-Wulf Ta 154. Part II, p. 57.

- ^ Reinhard Osteroth: Ferdinand Porsche. The pioneer and his world. Rowohlt, Reinbek 2004, ISBN 3-498-05036-2 , p. 257.

- ↑ a b c d Wolfgang Wagner: Kurt Tank - designer and test pilot at Focke Wulf. P. 195.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 20.

- ↑ a b Wolfgang Wagner: Kurt Tank - designer and test pilot at Focke Wulf. P. 194.

- ↑ a b c Reinhold Thiel: Focke-Wulf aircraft construction. P. 193.

- ↑ a b c d Without author: Aircraft from A to Z - The comprehensive encyclopedia in three volumes. Volume 2: Consolidated PBY - Koolhoven FK 55. Bernard & Graefe Verlag, Koblenz 1988, ISBN 3-7637-5905-0 , p. 249.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 36.

- ↑ Heinz J. Nowarra: The German Air Armaments 1933-1945. P. 110.

- ↑ a b c d e f g h i Hans Redemann: Focke-Wulf Ta 154. Part I, p. 128.

- ↑ Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Luftwaffe 1933-1945. P. 202.

- ↑ a b c d e f Reinhold Thiel: Focke-Wulf Flugzeugbau. P. 194.

- ↑ Heinz J. Nowarra: The German Air Armaments 1933-1945. P. 111.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 50.

- ↑ a b c Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Air Force 1933-1945. P. 203.

- ^ A b Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 52.

- ↑ a b c d Wolfgang Wagner: Kurt Tank - designer and test pilot at Focke Wulf. P. 196.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 207.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 54.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 120.

- ^ A b Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 208.

- ^ A b Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Luftwaffe 1933-1945. P. 204.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 132.

- ↑ a b c Heinrich Beauvais and others: Flight test sites until 1945 - Johannisthal, Lipezk, Rechlin, Travemünde, Tarnewitz, Peenemünde West. P. 287.

- ↑ a b c d e f g h Chronicle of the fighter planes. P. 162.

- ↑ a b c Herbert Kruse: Ta 154 - Germany's “plywood mosquito”. In: airplane. P.56.

- ↑ Chronicle of the fighter planes. P. 163.

- ↑ Heinrich Beauvais et al.: Flight test sites until 1945 - Johannisthal, Lipezk, Rechlin, Travemünde, Tarnewitz, Peenemünde West. P. 288.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 60.

- ↑ a b c Manfred Griehl: Typenkompass - Focke-Wulf from 1925. Motorbuch-Verlag, Stuttgart 2009, ISBN 978-3-613-03006-0 , p. 113.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 38.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 194.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 206.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 152.

- ↑ Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Luftwaffe 1933-1945. P. 206.

- ^ A b Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 139.

- ↑ a b Manfred Griehl: German military aircraft until 1945. Motorbuchverlag, Stuttgart 2008, ISBN 978-3-613-02850-0 , p. 54.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 171.

- ^ A b Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 175.

- ^ A b Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 176.

- ^ Peter Kohl, Peter Bessel: Auto Union and Junkers. Steiner, Stuttgart 2003, ISBN 3-515-08070-8 , p. 109.

- ↑ a b c d e Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Luftwaffe 1933-1945. P. 207.

- ↑ Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 16.

- ↑ a b c d e Daniel Uziel: Arming the Luftwaffe - The German Aviation Industry in World War II. P. 90.

- ^ Reinhold Thiel: Focke-Wulf aircraft construction. P. 183.

- ^ Reinhold Thiel: Focke-Wulf aircraft construction. P. 186.

- ^ Reinhold Thiel: Focke-Wulf aircraft construction. P. 187.

- ↑ luftarchiv.de Locations Focke-Wulf

- ↑ brandenburg.rz.htw-berlin.de

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 148.

- ↑ Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 6.

- ^ Jens Weis: The German automobile industry in the National Socialist war economy - Opel, Daimler-Benz and Volkswagen. Grin Verlag, Munich 2008, p. 23.

- ↑ Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 6.

- ↑ a b Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 30.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 58.

- ↑ a b c Reinhold Thiel: Focke-Wulf aircraft construction. P. 191.

- ^ A b Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 141.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 147.

- ↑ a b c Kenneth A. Merrick: German Airplane Cockpits 1935-1945. Heel Verlag, Gut Pottscheid 2001, ISBN 3-89365-845-9 , p. 156.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 151.

- ↑ Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 16.

- ^ A b Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 178.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 210.

- ↑ a b Herbert Kruse: Ta 154 - Germany's “plywood mosquito”. In: airplane. P. 19.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. Pp. 144-147.

- ↑ Herbert Kruse: Ta 154 - Germany's “plywood mosquito”. In: airplane. P. 20.

- ↑ a b c Reinhold Thiel: Focke-Wulf aircraft construction. P. 192.

- ↑ Wolfgang Wagner: Kurt Tank - designer and test pilot at Focke-Wulf. P. 197.

- ↑ a b c Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 193.

- ↑ Hans Redemann: Focke-Wulf Ta 154. Part II, p. 55.

- ↑ Kenneth Munson: The World War II Planes. Motorbuch-Verlag, Stuttgart 1995, ISBN 3-87943-302-X , p. 423.

- ↑ a b c d e Heinz J. Nowarra: The German Air Armament 1933–1945. P. 112.

- ^ A b Rolf Berger: 1000 aircraft - the most famous aircraft of all time. Naumann & Göbel, Cologne 2006, ISBN 3-625-10373-7 , p. 237.

- ↑ Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 29.

- ↑ a b Herbert Ring Letter: night fighters and bombers - German Air Force from 1935 to 1945. P. 148.

- ^ Gerhard Lang: Fighter aircraft of the Second World War. P. 50.

- ↑ a b c Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 192.

- ↑ Do 335 A-6 building description (November 20, 1944, appendix from January 15, 1945)

- ^ A b Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 182.

- ↑ a b Manfred Griehl: The history of the German Mosquito. In: Airplane Profiles. P. 12.

- ↑ Dietmar Hermann: Focke-Wulf Nachtjäger Ta 154 "Mosquito" - development, production and troop testing. P. 135.

- ↑ Hans-Jürgen Becker, Ralf Swoboda: Airplanes and helicopters of the Luftwaffe 1933-1945. P. 205.