Sewage treatment plant

A sewage treatment plant , also known as a wastewater treatment plant , in Switzerland and Austria also called a wastewater treatment plant (ARA), is a technical plant for the purification of wastewater . For cleaning the waters contaminating constituents of the waste water is mechanical (also called physical), biological and chemical methods are employed. Since these types of processes are used one after the other in different purification stages, modern conventional sewage treatment plants are usually called “three-stage”. In the meantime, sewage treatment plants are also being equipped with a fourth purification stage, whereby micropollutants (e.g. drug residues , microplastics ) are removed from the wastewater using various processes (e.g. ozonation , activated carbon filtration ) . The first sewage treatment plant on mainland Europe was put into operation in Frankfurt-Niederrad in 1882 .

As of 2018, around 1000 cubic kilometers of wastewater were generated worldwide. Around 70% of this is cleaned by sewage treatment plants in the industrialized countries, but only around 8% in less developed countries.

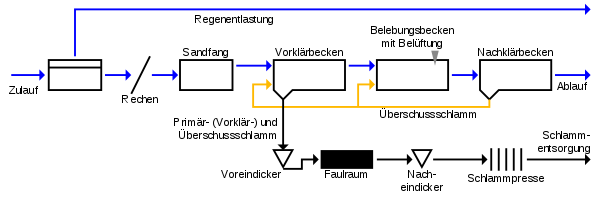

Flow diagram

Plant parts

Intake

The wastewater collected by the sewage system and transported to the sewage treatment plant in the course of the sewage disposal is fed to the sewage treatment plant, where there is usually a device for measuring the inflow quantity and a pumping station for lifting the sewage.

Rain relief

If rainwater and wastewater are fed to the sewage treatment plant in a sewer ( mixed system ), the sewer network usually has to be supplemented by a rain relief system. This relief system can consist of the following technical structures (individually or in combination):

Such structures can either be arranged in the sewer network or in the sewage treatment plant. The rain relief system serves the purpose of achieving an economical dimensioning of the sewage treatment plants, in that they only have to process a hydraulic load up to a certain rain event . If no such facilities are available, the individual structures of the sewage treatment plant must subsequently be larger and the technical equipment, such as pumps , have a higher capacity .

In contrast, there is the separation system . Here the wastewater is fed to the sewage treatment plant in a specially laid pipeline . In this case, only the connection of waste water house connection lines is permitted. The rainwater hitting sealed surfaces (streets, paths, roofs) can be channeled directly into surface water through a separate channel, if necessary after cleaning in a rainwater clarification basin , or it can be fed into the groundwater through various infiltration systems.

Mechanical pre-cleaning

Rake

In the rake system, the wastewater is passed through a rake or sieve. Coarse dirt such as monthly hygiene items , condoms , stones, but also branches, twigs, leaves and dead animals get stuck in the rake . These coarse materials would clog or even damage the pumps of the sewage treatment plant and also worsen the efficiency of the biological treatment stage. A distinction is made between fine and fine screens with a few millimeters and coarse screens with a gap width of several centimeters. The screenings are thrown into the screenings press, where they are machine washed and dewatered (weight saving). Then it is usually burned (more rarely: composted).

Sand trap

A sand trap is a settling basin with the task of removing coarse, settling impurities from the wastewater , such as sand , small stones or glass splinters . These substances would lead to operational disruptions in the system (wear, clogging, deposits). As a design is

- a long sand trap,

- a ventilated long sand trap in which fats and oils are separated on the surface,

- a round sand trap or

- a deep sand trap possible.

The ventilation of the sand trap (installed just above the bottom of the basin) creates a roller flow as a secondary flow, making it independent of flow fluctuations. The turbulence of this secondary flow keeps organic particles in suspension, while heavier particles are carried on a sedimentation track directly into the sand trap. With deep sand trapping, the wastewater flows into the basin from above and, due to its depth, has a relatively long retention time, which means that the heavier sand settles on the basin bottom (sand funnel). In modern systems, the sand traps are washed after they have been removed from the sand trap, i.e. largely freed from accompanying organic substances in order to enable better drainage and subsequent usability (for example in road construction).

Primary clarifier

A primary clarification tank is also a settling tank, ie the flow rate of the wastewater is reduced by adapted geometric dimensions in such a way that some of the undissolved, organic substances ( faeces , paper ) can settle (settable substances). The resulting primary sludge must then be sent to further treatment, such as a digestion tower .

Primary clarifiers are mainly used in sewage treatment plants, where the excess sludge is anaerobically stabilized.

In modern systems with nitrogen removal, this system part can be omitted or is small, because the organic substances in the wastewater act as reducing agents for nitrogen removal by means of denitrification (reduction of nitrate (NO 3 - ) to nitrogen (N 2 )) in the anoxic part or in the anoxic phase the biological stage are required.

Biological level

The impurities remaining in the wastewater after mechanical pre-treatment are biodegraded with the help of microorganisms (primarily bacteria , fungi and protozoa ). In general, this degradation takes place under aerobic conditions (ie with the addition of oxygen ). Rarely are reactors used in which anaerobic conditions prevail (so-called UASB reactors ) and in which methane is produced as a by-product . Usually, however, the biological stage consists of (one or more) aeration tanks and (one or more) secondary clarifiers. The SBR process combines activation and secondary clarification in one tank. Other special forms, which are used in particular as small sewage treatment plants, are the trickling filter process , the immersion filter process , the fixed bed reactor process and the MBR process .

Aeration tank

Most of the municipal sewage treatment plants in Central Europe are operated using the activated sludge process. In this way, in so-called activated sludge tanks, the wastewater that has been mixed with activated sludge (masses of flocculent aggregated bacteria) is biotically and oxidatively degraded. In this case, of be aerobic (consuming oxygen) bacteria and other microorganisms (for example, yeasts such.) Carbon compounds mostly decomposed to carbon dioxide, as well as biomass reacted and the nitrogen of the organic compounds is first bacteria other than ammonia split off and then reacted with oxygen to nitrates oxidized ( Nitrification ). The activated sludge process is mostly operated with continuous flow, that is, wastewater continuously flows into the activated sludge tank and water containing activated sludge continuously runs off to the same extent. By adding precipitating agents, the nutrient phosphorus can also be removed by means of chemical reactions , possibly by simultaneous precipitation . This also improves the settling properties of the activated sludge in the secondary clarifier .

There are various technical variants of the activated sludge process, in particular upstream, downstream and simultaneous denitrification. Here, nitrification and denitrification take place either in the same or in separate tanks, here in a different arrangement to one another.

A special form is the SBR process (SBR = Sequencing Batch Reactor), which combines biological cleaning and the subsequent clarification described below in a single tank. The wastewater does not flow in continuously, but only in a limited amount, which is then cleaned using the activated sludge process (nitrification and denitrification). The settling phase (i.e. the final clarification) then takes place in the same basin. The resulting excess sludge is then either time-controlled or withdrawn depending on the increased sludge level (assuming the appropriate measuring technology). This ends a cycle and the next batch of wastewater is initiated and cleaned. The SBR process requires at least two basins, either a second aeration basin or a preliminary storage tank (buffer basin) in which the amount of wastewater flowing in during the cleaning process is already pre-cleaned or at least temporarily stored. As a rule, it is also advantageous to build a third basin in which the excess sludge and any previously separated primary sludge are stored. This sludge is then fed to larger sewage treatment plants, which are equipped with further sludge treatment.

Secondary clarifier

The secondary clarifier forms a process unit with the activated sludge tank. In it, the activated sludge is separated from the wastewater by settling. The greater part of the sludge is returned to the aeration tank (return sludge) in order to keep the concentration of microorganisms in the aeration tank sufficiently high. Otherwise the degradation rate would be too low. The excess (increase in biomass, excess sludge) is discharged together with the primary sludge from the primary clarifier for further treatment in the pre-thickener.

The activated sludge must have good settling properties. If this is not the case, for example due to the massive growth of thread-like microorganisms, which leads to the formation of bulky sludge, the activated sludge can drift from the secondary clarifier into the receiving water . This not only affects the water. Since not enough sludge can then be kept in the activated sludge tank / secondary clarifier system, the sludge age (the mean length of time the biomass stays in the system) and thus the cleaning performance decreases . First of all, the slowly growing bacteria (for example the nitrifying bacteria , which oxidize ammonia to nitrate) are affected. Wastewater with easily degradable organic substances (e.g. from the food industry) in particular has a tendency to form bulky sludge. The installation of small, non-aerated or poorly aerated basins in front of the aeration basin (selectors) can prevent bulking sludge from forming.

A special form of the secondary clarifier is the funnel-shaped Dortmund fountain .

Fixed bed process

The fixed bed process is another special form of the activated sludge process, which is mainly used for small connection sizes (see also small sewage treatment plant ). Different shaped solids serve as the basis for the growth of microorganisms that break down the pollutants. These solids are alternately immersed in wastewater and air or charged with wastewater at regular intervals so that the microorganisms come into contact both with the pollutants and with the oxygen required for their oxidative degradation.

Sludge treatment

The excess sewage sludge produced during the wastewater treatment process is then treated. This treatment takes place in two steps

- Stabilization and

- Quantity reduction.

Stabilization here means the extensive breakdown of the organic matter contained in the sewage sludge ( mineralization ) and takes place aerobically in the activation process on small sewage treatment plants and anaerobically in digestion towers on large sewage treatment plants. The stabilization thus already includes a certain reduction in the amount of sewage sludge. The aim of stabilization is to ensure that subsequent biological or chemical conversion processes only take place to a limited extent or very slowly so that sewage sludge can be recycled.

The actual volume reduction is achieved by separating water from the sewage sludge. The usual methods here are sludge thickening or dewatering with appropriate machines. The efficiency of sludge dewatering generally increases with increasing degree of stabilization.

Aerobic sludge stabilization

The process principle of aerobic sludge stabilization is based on the fact that the microorganisms contained in the sewage sludge are exposed to a constant "state of hunger" in the presence of oxygen , which forces them to process almost all available reserve, storage and other usable substances as food. The sludge is thus stabilized in an aerobic way in such a way that there are no further degradation processes and therefore no unpleasant odors during the subsequent disposal. This condition is achieved through a high sludge age, ie a sufficiently high TS concentration in the activation.

The greatest advantage of this process lies in the simple construction and process technology. This is because biological wastewater treatment and sludge stabilization take place at the same time (simultaneously) in the aeration tank. The disadvantage is the relatively high energy consumption that results from the ventilation required for this process.

Anaerobic sludge stabilization

From a connection size of 30,000 population equivalents, anaerobic sludge stabilization is usually implemented in sewage treatment plants. This is also called sludge digestion and requires a digestion tower. As a rule, anaerobically stabilizing sewage treatment plants are also equipped with a primary treatment. The primary sludge separated in it is broken down together with the excess sludge from the activation under low-oxygen conditions by anaerobic bacterial strains and methanogenic archaea into digested sludge and combustible digester gas . The mixture of primary and excess sludge that goes into digestion is called raw sludge.

There are four degradation phases in the digestion tower: hydrolysis phase, acidification phase, acetogenic phase and methanogenic phase.

In practice, the 70 percent organic dry matter contained in the raw sludge is reduced to around 50 percent during sludge digestion. Theoretically, the breakdown would go further, but it would proceed much more slowly, since the remaining organic matter is difficult to break down. In the technical sense, the sludge is considered to be very well digested and stable with a loss on ignition of around 50 percent. It is then called sludge.

Digestion gas is produced as a degradation product during digestion. It is a gas mixture that is composed roughly as follows:

- Methane : 60 to 70 percent

- Carbon dioxide : 26 to 36 percent

- small amounts of hydrogen and hydrogen sulfide .

This process corresponds to the generation of biogas in a biogas plant . Conventional digesters are usually egg-shaped (see illustration). Based on biogas plants, there are now increasingly simpler and therefore less costly designs.

The digester gas is used in purified form (for example after removal of hydrogen sulfide ) in gas engines or in block-type thermal power stations to cover our own needs for electricity and heat. Micro gas turbines are now also being used to utilize the digester gas. If these units fail, the gas is flared .

Sludge thickening

The digested sludge or excess sludge is then thickened (see diagram above). This can be achieved with various technical processes. Often there is a static sludge thickener, which is a structure in which the sludge flakes can sediment. In this way, TS concentrations of up to 4% can usually be achieved. In addition, there are technical systems such. B. drum thickeners, which use flocculants and energy to achieve a faster separation and at the same time higher dry matter concentrations (up to 8%). The excess water from the thickening process is called cloudy water and is returned to the sewage treatment plant.

Sludge dewatering

A further reduction in quantity takes place in the sludge dewatering. For this, an even higher technical and energetic effort has to be made. In addition, the necessary use of chemicals (flocculants, sometimes also lime) is increasing. Filter presses or decanter centrifuges are usually used to dewater the sewage sludge . The Sewage sludge also serves to dewatering, but uses for substantially natural principles ( sedimentation , filtration , evaporation ) without the use of chemicals.

procedure

After the secondary clarification, the purified water flows through the sewage treatment plant drain into the receiving water . Many sewage treatment plants also need a drainage pumping station for this purpose, if drainage is not possible on a free slope.

Sludge recycling

Since 2005, sewage sludge has not been allowed to be stored in landfills in Germany because it has an ignition loss of more than 5%.

Therefore, the sewage sludge is mainly recycled :

- thermal

- Mono- incineration plants or waste incineration plants are provided for thermal recycling , but coal-fired power plants and cement plants are also used. The sewage sludge from sewage treatment plants with a connection size of 50,000 population equivalents or more must be treated in mono- incineration plants in accordance with the Sewage Sludge Ordinance, so that the phosphates concentrated in the ash in this way can one day be returned to the cycle . There is currently no large-scale process for this that can be operated economically.

- agricultural

- In addition to the Sewage Sludge Ordinance, recycling in agriculture is also subject to the Fertilizer Ordinance and the Fertilizer Ordinance .

Even if the legally compliant sludge recycling is still the responsibility of the sewage treatment plant operator, its technical implementation usually does not take place in the sewage treatment plant itself. For example, there are only a few sewage treatment plants that operate their own mono-incineration plant for sewage sludge.

Cleaning processes

- 1st stage

- Mechanical processes usually form the first cleaning stage. About 20 to 30 percent of the solid (undissolved) floating and suspended matter is removed here. Adsorption , filtration and stripping are used in more extensive wastewater treatment and industrial water management.

- 2nd stage

- Biological processes are used in the second treatment stage of municipal wastewater treatment plants and for the degradation of organically highly polluted wastewater in aerobic and anaerobic wastewater treatment. They use microbiological degradation processes. Degradable organic wastewater components are mineralized as completely as possible, that is, degraded in aerobic wastewater treatment down to the inorganic end products water , carbon dioxide, nitrate, phosphate and sulfate . In anaerobic wastewater treatment, they are converted into organic acids, methane and carbon dioxide. This usually removes the carbon compounds from the wastewater. Organically bound nitrogen and ammonium are also removed by bacterial nitrification and denitrification . Increasingly, the phosphorus content in bacteria is also being reduced in medium-sized and large sewage treatment plants .

- 3rd stage

- Abiotic chemical processes make use of chemical reactions such as oxidation and precipitation without the involvement of microorganisms. In municipal wastewater treatment, they are primarily used to remove phosphorus through precipitation reactions ( phosphorus elimination ). This process is of great importance for preventing eutrophication of the receiving waters . In addition, abiotic chemical processes are used for precipitation in industrial water management and for further wastewater treatment (e.g. flocculation / precipitation / filtration).

- 4th stage

- Since the end of the 1980s, more extensive cleaning processes have been developed that are already ready for series production, but have not yet been able to establish themselves due to their sometimes high operating costs. For example, wastewater filtration and disinfection should be mentioned here. In Switzerland, due to the revision of the Water Protection Act, which came into force on January 1, 2016 , an additional cleaning stage against trace substances must be installed in around 100 of the more than 700 Swiss sewage treatment plants in polluted waters over the next twenty years . Sewage treatment plants with more than 80,000 connected people are affected.

The processes in sewage treatment plants can be described mathematically by their reaction kinetics ( macrokinetics ).

| process | Sewage treatment plant component | purpose |

|---|---|---|

| Physical procedures | ||

| Sieving | Rake , drum screen, microscreen | Removal of larger solids and floating matter |

| Deposition | Float or oil separator | Removal of fats and oils |

| sedimentation | Sand trap, settling basin , centrifugal separator, preliminary and secondary clarifier | Removal of small floating matter, sand, flocculated suspended matter |

| Separation | Secondary clarifier | Removal of the activated sludge from the treated wastewater |

| Filtration (separation process) | Sand filter | Removal of suspended matter |

| Flotation | Flotation tank | Removal of fine dirt particles by blowing in air |

| adsorption | Activated carbon filter | Accumulation of, for example, halogenated hydrocarbons ( AOX ) or dyes ( trace substances ) |

| Thermal disinfection (see disinfection ) |

Thermal disinfection system | Pathogens are killed by increased temperature (hospitals, laboratories, pharmaceutical industry). |

| Strip | Stripping pool | Removal by blowing in air / gases. In this way, dissolved wastewater constituents are converted into the gaseous phase in accordance with the vapor pressure and thus removed from the water. |

| Decrease in radioactivity | Decay system | The radioactive contamination of wastewater is reduced by a correspondingly long residence time in accordance with the half-life of the radionuclides. Use in laboratories, hospitals. |

| cooling | Cooling tower , cooling pond , heat exchanger. | Reduction of the temperature in order to enable subsequent cleaning processes or the discharge into the receiving water. Can be used for heat recovery. |

| Biological process | ||

| Biochemical oxidation | Activated sludge process, trickling filters | Aerobic degradation of organic components to inorganic end products (H 2 O, CO 2 , NO 3 - , N 2 , PO 4 3− , SO 4 2− ) by activated sludge (aeration basin) or bacterial lawn (trickling filter). The absorption of phosphorus in the biomass can be optimized (Bio-P) through appropriate management of the activated sludge plant. This means that less precipitant is required to eliminate phosphorus. The basic aim is always to convert waste water constituents to be removed into forms using biological processes (respiration, biomass growth), which can be removed from the waste water by sedimentation or stripping (gaseous expulsion) and are also as harmless as possible. |

| Biochemical oxidation in small wastewater treatment plants | Herbal sewage treatment plant , sand filter sewage treatment plant , activated sludge process, trickling filter | Aerobic and anaerobic degradation in shallow basins and subsequent floor passage in plant-based wastewater treatment systems or degradation by activated sludge in aeration basins or by bacterial lawns in trickling filters |

| Sludge digestion | Digestion tower | Anaerobic degradation of organic components of the primary or excess sludge to inorganic end products: carbon dioxide (CO 2 ), methane (CH 4 ), ammonia (NH 3 ), hydrogen sulfide (H 2 S) |

| Anaerobic wastewater treatment | reactor | Anaerobic degradation of organic components to inorganic end products: carbon dioxide (CO 2 ), methane (CH 4 ), ammonia (NH 3 ), hydrogen sulfide (H 2 S). Particularly suitable for organically highly polluted wastewater (e.g. food industry, animal carcass disposal). |

| Chemical process | ||

| Flocculation | Flocculation basin | Removal of colloid matter and fine dirt particles by adding flocculants or adjusting the pH value |

| Neutralization / pH adjustment | Neutralization basin | Adjustment of the desired pH value by adding acid or base |

| precipitation | Precipitation basin | Precipitation of phosphate ions (PO 4 3− ) with iron and aluminum salts |

| Simultaneous precipitation | Aeration tank / secondary clarifier | Removal of phosphorus (as phosphate) by adding iron or aluminum salts to the activated sludge |

| Pre-precipitation | Mixing basin / primary clarifier | Removal of phosphorus (as phosphate) by adding iron or aluminum salts in front of the primary clarifier |

| Post-precipitation | Mixing basin / settling basin after the secondary clarifier | Removal of phosphorus (as phosphate) using iron or aluminum salts after the primary clarifier |

| Abiotic oxidation | Special basin | Destruction of biotically non-degradable organic compounds, for example by means of ozone or ultraviolet radiation , possibly with the aim of being able to biotically degrade the residues (e.g. decolorization of waste water) |

| disinfection | Special basin | Killing of pathogens by adding chlorine or ozone or by ultraviolet radiation |

Load parameters

The pollution of sewage treatment plants is determined according to the population equivalents (PE). This is the sum of the actual inhabitants (number of inhabitants , EZ) and the population equivalents (EGW). The population equivalent is the agreed size of the wastewater emissions to be assumed for a “standard resident” . For commercial , industrial and agricultural production , loads related to production sizes (e.g. 10 PE BSB 5 per hectare of vineyards) are given. It should be noted, however, that the relationships between the individual parameters can shift. Wastewater can be more concentrated (less wastewater volume with the same pollution load), or it can be rich in organic carbon compounds and therefore poor in nutrients. The content of biotically degradable substances is quantified with the sum parameter biochemical oxygen demand , abbreviated BOD. As a rule, it is measured with the biochemical oxygen consumption in milligrams within five days under standard conditions and referred to as BOD 5 (see below). For biotic degradation, a nutrient ratio of BOD 5 : N: P of around 100: 5: 1 must be given so that the microorganisms are adequately supplied with nitrogen and phosphorus. This is based on the assumption that around half of the decomposed organic substances are used for biomass growth and that biomass in the dry matter consists of around twelve percent nitrogen and around two percent phosphorus.

Amount of wastewater

A waste water accumulation of 150 to 200 liters per inhabitant and day was previously assumed to pollute the sewage treatment plant. The amount of dirty water roughly corresponds to the water consumption . For new planning or advance planning, the site-specific water consumption is now being determined and an estimate for the future is attempted. Typically, wastewater amounts of around 130 liters per inhabitant per day are assumed.

This value takes into account the values usual in Central Europe for dense sewer networks. For the dimensioning of the sewage treatment plant, however, a surcharge for extraneous water (leaky channels, discharges from drainage and the like) is usually taken into account. This can amount to up to 100 percent of the wastewater accumulation. The amount of external water is related to the connected sealed area and should not be more than 0.15 l / (s × ha).

In the case of mixed sewer systems (rainwater and waste water in one sewer), corresponding surcharges for processing the rainwater must be taken into account, which are usually set at 100 percent of the daily peak in dry weather.

For the hydraulic calculation (number and size of the feed pumps) of the sewage treatment plant, the daily cycle of the load is also important. The average daily load should therefore not be divided by 24 hours, but by a smaller number (10 to 14) for the maximum hourly value.

Degree of pollution

BOD 5

The BOD 5 value, the biochemical oxygen demand during a measurement period of five days at 20 ° C, records the oxygen demand that arises during the oxidation of organic substances by aerobic microorganisms. It is one of the so-called sum parameters , since it cannot be used to determine the breakdown of individual connections.

The bacterial oxidation of ammonia (NH 3 ), ammonium (NH 4 + ) and nitrite (NO 2 - ) to nitrate (NO 3 - ) - called nitrification - should not be recorded and is detected during the measurement by an inhibitor, for example allyl thiourea ( ATH) or sodium hydroxide biscuits.

The usual value for the BOD 5 is set at 60 grams per inhabitant value and day. About 20 grams of this can be removed in the primary clarification by sedimentation. The following requirements are necessary to determine the BOD:

- The prepared sample must contain sufficient oxygen during the entire consumption period, i.e. at least two milligrams per liter.

- The prepared sample must contain enough bacteria. They are abundant in normal sewage. In the case of special waste water from commercial operations (e.g. landfill leachate cleaning), bacteria must be added. One "inoculates" with 0.3 milliliters of domestic wastewater per liter of sample.

- The prepared sample must contain sufficient nitrogen and phosphate as nutrients.

- The prepared samples must be stored as precisely as possible at 20 ° C and in the dark, preferably in a thermal cabinet, for the five days.

With the appearance of the new DWA worksheet 131 in June 2016, the BOD 5 was no longer used as a dimensioning parameter for single-stage activated sludge plants , as the BOD 5 does not allow a complete accounting of the sludge accumulation and the oxygen demand and is no longer measured across the board in practice.

Chemical Oxygen Demand

The chemical oxygen demand, abbreviated as COD, is also one of the sum parameters, since it cannot quantify individual compounds. It is determined by the oxidation of the wastewater constituents by potassium dichromate and records the oxygen requirement for the oxidation of a large part of the organic substances. If the wastewater also contains oxidizable inorganic compounds such as sulphites, these are also recorded as chemical oxygen demand. This parameter is used to balance the system. A value of 120 grams per inhabitant per day is assumed for the chemical oxygen demand.

nitrogen

Nitrogen in raw wastewater is mainly organically bound (e.g. in proteins , nucleic acids , urea ) and in the form of ammonium ions (NH 4 + ) and, to a small extent, also in the form of nitrate (NO 3 - ) and nitrite ions (NO 2 - ) before. Approximately ten to twelve grams per inhabitant value and day are used for this.

phosphorus

Phosphorus is organically bound as a phosphate group and is present as free phosphate. For Germany, around 2 grams of phosphorus per inhabitant and day are assumed. In Switzerland, phosphorus from sewage treatment plants must be recycled from 2026.

Microplastics

According to a review article , the retention efficiency of microplastics in sewage treatment plants is 83–99.9%, whereby it was higher than 95% in the majority of the studies considered.

The further reduction in emissions can e.g. B. be done by means of cloth filtration.

The Münster sewage fields are irrigated with the purified water from the Münster sewage treatment plant, which contains a relatively large amount of microplastics. Research is currently being conducted into the effects of invertebrates such as snails and crabs when they eat the plastic particles.

From a global perspective, the main entry paths of primary microplastics into the oceans are road gullies (66%), wastewater treatment systems (including rain overflow , 25%) and wind transport (7%).

Environmental aspects

power consumption

For many municipalities worldwide, sewage treatment plants are the facilities with the highest energy consumption. It is estimated that using conventional technology they account for up to around 3% of global electricity consumption. On average, sewage treatment plants are responsible for around 20 percent of municipal energy consumption. For this purpose, 4400 gigawatt hours of electrical energy are consumed nationwide (2009). Part of this energy can be generated in a block-type thermal power station by converting the energy-rich sewage gas from the sewage process into electricity. In 2014, around one eighth of around 10,000 German sewage treatment plants were equipped with a CHP unit for self-supply with electricity and heat. These provided around 1,340 GWh of electrical energy, more than 90% of which was consumed in the sewage treatment plants themselves. This could theoretically supply all households in a large city like Frankfurt am Main .

As a rule, the pressure aeration system in the aeration basin requires by far the greatest amount of energy of all process steps in a municipal wastewater treatment plant. The energy consumption for ventilation averages around 50 percent of the total energy requirement. This is followed by the continuously running pumps, and the third largest consumer group usually consists of the continuously working agitators. These three main components consume over 80 percent of the energy in normally operated systems.

Under optimal conditions, it is possible to operate sewage treatment plants with energy generation. The wastewater treatment plant of Stadtwerke Bad Oeynhausen has been generating energy surpluses since a renovation in 2014. According to estimates, the chemical energy in wastewater is around nine times as high as the energy required for the treatment process.

The following measures to increase energy efficiency are proposed, among others:

- By exchanging, optimizing and controlling the aerators, more than 50 percent of the ventilation energy can be saved

- Improvement of the operational management to avoid pressure losses

- Use of modern pumps of the highest efficiency class (EFF 1)

- transparent monitoring ( Monitoring ), more electricity meters, pressure loss detection at the aerators, clear arrangement of the measuring instruments

- mechanical drainage prior to introduction into the digester to reduce the heating energy

- efficient use of digester gases to generate electricity

- Drying processes using solar energy or waste heat

- Establishment of a block-type thermal power station to generate electricity from digester gas - this achieves a level of self-sufficiency of around 33% of the electricity requirement (as of 2009).

In addition, the thermal energy contained in the wastewater can be raised to a higher temperature level with the help of (large) heat pumps and then fed into district heating systems. A review study published in 2017 found a total of 54 large heat pumps with a cumulative heat output of around 900 MW in operation, which generally use wastewater at a temperature of 10–20 ° C. The most powerful systems of this type are located in Scandinavia , with particularly large systems installed in Stockholm with 230 MW and Gothenburg with 160 MW. Similar systems could now be used in other European cities. The authors see the long-term availability of the wastewater heat source as a particular advantage of using wastewater heat, which is hardly affected by economic uncertainties.

Greenhouse gas emissions

Sewage treatment plants are issuers of greenhouse gases that arise in the treatment process. Both carbon dioxide and other highly potent greenhouse gases such as methane or nitrous oxide are released . Estimates for 2010 determined greenhouse gas emissions of around 0.77 billion tons of CO 2 equivalent, which corresponds to around 1.57% of global equivalent emissions of 49 billion tons. The underlying carbon comes largely from natural organic substances, which is why the released carbon dioxide is considered greenhouse gas neutral; Methane and nitrous oxide emissions are particularly problematic, as these have a greater effect than carbon dioxide by a factor of 25 and 298 respectively. With around 0.56–0.71 billion tons of CO 2 equivalent, these emissions from sewage treatment plants are responsible for around 4.6% - 5.2% of global non-CO 2 emissions.

At the same time, sewage treatment plants also reduce potential greenhouse gas quantities. If wastewater were to be discharged into a body of water without being cleaned, this would lead to a considerable increase in greenhouse gas emissions in addition to the corresponding pollution with the usual side effects ( eutrophication , fish deaths ). The natural degradation processes initially take place with the consumption of dissolved oxygen, with carbon dioxide being released. After the oxygen has been used up, the further breakdown processes take place under anaerobic conditions. This leads to increased methane, hydrogen sulphide and nitrous oxide emissions, which in turn (see above) have a higher global warming potential.

Due to the large amounts of carbon-containing wastewater produced, their location in densely populated areas and the largely existing infrastructure, sewage treatment plants are considered to be promising locations for the installation of carbon dioxide separation systems for final storage or the further industrial use of CO 2 . In this way, the resulting carbon dioxide could either be permanently removed from the atmosphere in order to achieve negative emissions that are desirable in terms of climate policy , or it could be used as an industrial raw material for various applications. A particular advantage of sewage treatment plants is that the technology already in place means that no additional land is required for separation and transport infrastructure. Possible concepts for such plants include the use of microbial electrolytic CO 2 separation, microbial electrosynthesis , the creation of microalgae cultures, the creation of artificial wetlands, the production of biochar from sewage sludge or the upgrading of the biogas produced by methanation of the carbon dioxide contained ( Power -to-gas concepts).

Special forms

- The small sewage treatment plant is a special form for decentralized wastewater treatment .

- Non-technical systems for wastewater treatment are described under the term plant-based sewage treatment system .

Web links

- Klärwerk.info Current specialist information about sewage treatment plants

- VSA platform "Process engineering micropollutants" Association of Swiss wastewater and water protection experts

- Dresden's virtual sewage treatment plant. In: Stadtentwässerung Dresden. (Interactive sewage treatment plant)

- Historic sewage treatment plant in Frankfurt. In: Frankfurt360.de. (360-degree all-round views)

- Construction of a sewage treatment plant and function of the individual stations. In: Wasserverband Neufelderseen area. (Video on how a sewage treatment plant works) ( page no longer available )

- How a fully biological sewage treatment plant works - educational film

- How a fully biological wastewater treatment plant works - 360-degree virtual tour

Individual evidence

- ↑ Manufacturers should pay for wastewater treatment . In: Frankfurter Allgemeine Zeitung for Germany, number 227/2019 of September 30, 2019, p. 15.

- ↑ a b c d e Lu Lu et al .: Wastewater treatment for carbon capture and utilization . In: Nature Sustainability . tape 1 , 2018, p. 750-758 , doi : 10.1038 / s41893-018-0187-9 .

- ↑ The biological purification stage. In: System S&P. (Fixed bed and activated sludge process).

- ↑ Risky cargo entered the research network . In: Mittelbayerische.de , September 5, 2018, accessed on September 22, 2018.

- ↑ Feasibility study for an additional clarification stage presented: Invisible danger in the water . In: wn.de , September 22, 2018, accessed on September 22, 2018.

- ↑ Because pollutants on the Rhine are clogging the river . In: verlagshaus-jaumann.de , September 22, 2018, accessed on September 22, 2018.

- ↑ Fourth cleaning stage: status and outlook . In: initiative-mikroplastik.de, accessed on September 22, 2018.

- ↑ 100 sewage treatment plants need to be upgraded - Eawag Info Day 2015 , eawag , September 3, 2015, accessed on September 23, 2018.

- ↑ Christoph Zweili: Thanks to the fourth cleaning stage, the Altenrhein ARA is one of the most modern in Europe. In: tagblatt.ch . September 5, 2019, accessed September 6, 2019 .

- ↑ Winznau sewage treatment plant - brand new does not necessarily mean ultra-modern. In: srf.ch . August 30, 2019, accessed August 31, 2019 .

- ↑ Research report on phosphorus production from sewage sludge on behalf of the Federal Environment Agency , page 38

- ↑ Stefan Hartmann: Phosphorus utilization: recycling fertilizer from sewage treatment plants. In: bafu.admin.ch . 2019, accessed August 17, 2020 .

- ^ Joana Correia Prata: Microplastics in wastewater: State of the knowledge on sources, fate and solutions . In: Marine Pollution Bulletin . tape 129 , no. 1 , 2018, p. 262–265 , doi : 10.1016 / j.marpolbul.2018.02.046 .

- ↑ Stefan Idel: Investment in Wildeshausen: basin demolished - large sandpit in the middle of the sewage treatment plant . In: nwzonline.de , January 8, 2020, accessed January 8, 2020.

- ↑ WWU researchers are studying microplastics in the sewage fields . In: uni-muenster.de , May 4, 2018, accessed on May 27, 2018.

- ↑ Julien Boucher, Damien Friot: Primary Micro Plastics in the Oceans: A global evaluation of sources . In: IUCN . 2017, p. 24 , doi : 10.2305 / IUCN.CH.2017.01.en .

- ↑ Energy efficiency of municipal sewage treatment plants , Federal Environment Agency, October 2009, p. 3 (PDF; 2.7 MB).

- ↑ 1,340 gigawatt hours of electricity generated from sewage gas . Press release of the Federal Statistical Office of July 10, 2015. Accessed July 10, 2015.

- ↑ Energy efficiency of municipal sewage treatment plants , Federal Environment Agency, October 2009, pp. 4–5 (PDF; 2.7 MB).

- ↑ http://www.stadtwerke-badoeynhausen.de/cms/Abwasser/Klaeranlage_/Klaeranlage_.html . Website of the Stadtwerke Bad Oeynhausen. Retrieved September 8, 2016.

- ↑ Energy efficiency of municipal sewage treatment plants , Federal Environment Agency, October 2009, pp. 6–8 (PDF; 2.7 MB).

- ^ Andrei David et al .: Heat Roadmap Europe: Large-Scale Electric Heat Pumps in District Heating Systems . In: Energies . tape 10 , no. 4 , 2017, p. 578 ff ., doi : 10.3390 / en10040578 .

- ↑ Hartmut Bick: Basic features of ecology . 1998, p. 138 ff .