typesetter

The typesetter, or typesetter for short, was an apprenticeship in the printing trade and in the paper processing industry for the production and assembly or further processing of printable material (mainly typesetting ) for letterpress printing . The terms “hand setter” and, as a contrast, the “machine setter” working on machines were also common, both of which were colloquially called “lead setter”.

history

The typesetting can be traced back to Johannes Gutenberg , who invented book printing with movable and reusable letters in Europe around 1445 . However, the Koreans knew this technique about 200 years earlier (see: History of printing: Korea ). It replaced the hitherto common writing and copying of books by hand. Using this technique, Gutenberg managed to complete a Bible , the Gutenberg Bible named after him , in an edition of around 180 copies in just five years. He succeeded in making all lines the same length and at the same time all spaces between words being the same size, which he achieved with letters of different widths.

Professional content and training in German-speaking countries

The duration of the training in Germany was three to three and a half years (in Switzerland and Austria four years, in the GDR two years), with special talent the journeyman examination could be taken after two and a half years . After completing his training, the typesetter was able to carry out all the necessary steps to create a finished template for printing from a supplied manuscript . To do this, he had to provide the manuscript with typesetting instructions, make a draft and be able to produce the later printing form using the respective technical typesetting process. He also made corrections to the generated sentence and dismantled the printing form after printing ( filing ). Basically, the typesetter had to have typographical knowledge in order to create a legible sentence.

For the hot type, the structure of were as concrete contents of the training set system and the use of the tools of the work environment, such as the angle hook , the Setzerahle and the galley , an overview of the arrangement of the setting shelves and the division of Typecases / Font box and the exclusion box treated. (The machine setters were trained accordingly in the operation of the respective setting machine.)

In the training, after the intermediate examination, a final examination, the journeyman's examination, was taken, which ended the training. It comprised a skill and a knowledge part. In the skills part, skills in setting paragraph text and tables, in proofreading and in editing a line break were tested. The speed was assessed. The average after one hour of sentence was 30 to 35 lines over a width of 20 cicero (1 cicero = 12 point = 4.513 mm). Before starting with the paragraph text during the test, the alphabet was placed in a line until the line width was filled. The number of letters was used as the basis for calculating the amount of text created. In addition, there was the setting of a table with different degrees of difficulty plus the design and setting of a so-called "Akzidenz", which can be translated as family or small print (e.g. a flyer , an advertisement , a brochure or the like). After the time had elapsed, proofs were made with a hand press, which one was already familiar with, and read for errors. The written knowledge part consisted of a dictation , questions of specialist knowledge and questions about economics and social studies .

Although the profession of typesetter has always been adapted to current requirements over the years (the training content in the 1990s was, among other things, the design of web pages ), as part of a modernization of the apprenticeship professions, the professions typesetter for the design area of the industry, repro manufacturer, advertising and media template manufacturer, reprograph and photo engraver by § 14 of the "Ordinance on professional training for digital and print media" from 4 May 1998 ( Federal Law Gazette I p. 875 ) repealed.

The profession was trained in individual cases up to around 1980 (in the GDR up to 1990), but from around 1970 onwards, the typographical content was more important, as lead type was already in decline here. After letterpress printing was replaced by offset printing , many typesetters switched to photo typesetting and later to a computer workstation and digital typesetting. The typesetter is thus the forerunner of the digital and print media designer (Switzerland: Polygraf / -in, Austria: specialist in media technology). This job title has replaced the typesetter as an apprenticeship, but some book printers give special courses for graphic designers or students of typographically oriented subjects; there are also a number of museum print shops that show visitors the art of typesetting.

The typesetter apprenticeship lasted four years in Switzerland and Austria. At the final apprenticeship examination, the following practical work was tested in accordance with the vocational training regulations of 1949: smooth sentence one hour each in Garamond Antiqua and 1 hour in Fraktur (minimum performance 1,450 letters per hour with error-free typesetting, from approx. 1960 only in Antiqua), title sentence, breaking of 8 pages with entry and exit columns as well as footnotes and the inclusion of clichés , table typesetting, commercial typesetting, advertisement typesetting, correcting and filing. The theoretical examination included the oral questioning of professional knowledge as well as written work in the language used and a second national language.

Typesetters

While women were already working in this profession in the USA before 1900, it took until the mid-1960s and later for typesetters to work in Austria, Switzerland and the Federal Republic of Germany. Until then, exceptions were only possible for principal subsidiaries. In the GDR, however, there have been women in this profession since the 1950s at the latest. For a long time and in many countries, the job of the typesetter was one of the highest-paid jobs available to women and therefore very popular.

The setting

The oldest technique of setting was hand typesetting . The typesetter put fonts cast from lead and the space between words in a so-called angle hook, which he held in his left hand while the fingers of his right hand grabbed the individual letters / characters from the type case. Before setting, the width of the angle hook was set with the squares. He was then tensed with the so-called "frog". The setting line was then placed on top of this. As a rule, you could set 1,500 characters per hour in this way, but this depended on the font size (a 6-point font could not be set as quickly as a 10-point font).

Up until the 19th century, the “stretchable letters”, the so-called Litterae dilatabiles , which were mainly used for religious and theological writings in the Hebrew language, were a specialty . Since the Hebrew language did not have a word separation , an even margin could be created at the left end of the line. Letters that could be stretched in the middle or at the end of the line were Mem sofit , Taw , Lamed , He and Aleph .

Since the letters were made of lead, great care had to be taken to ensure that they were clean, because the risk of lead poisoning , which can be fatal, was very high. Before this danger was recognized, many typesetters suffered from the "lead disease". Many companies provided their trainees with half a liter of milk or cocoa free of charge in order to prevent lead disease through the calcium it contained .

The main focus of the typesetter's profession, however, was on design: typography. In addition, the production, but above all the introduction of picture elements into the sentence, was part of the training. This included dealing with clichés , i.e. printing blocks for the reproduction of images and graphic elements, which were produced in the etching process from zinc or washing process from plastic plates (nyloprint), less often as engraving , or as linoleum or lead cut . Typesetters also learned the art of writing, with which they could trace a script precisely, for example to apply it with paint or gold on leather or parchment, to prepare certificates or to present customers with suggestions in the form of " final artwork ". In larger printing works and in newspaper production, typesetters were specialized as so-called "mettlers" for newspaper make-up in order to combine the finished articles and headings in the mettage to form the page layout, or as commercial typesetters, and after in-house training, also as typesetters or proofreaders .

Type case and material

The case with its 125 compartments was originally made of wood, sometimes made of plastic or metal, and as a normal case weighed around 15 kilograms. Bread typeholders (as " body type " were the headlines and font sizes referred by which the body copy was set and paid by the set amount at times, which so to speak, the "bread" of the typesetter were) weighing up to kg to 50 when wider the body type in Boxes was housed. Large font sizes from 20 points, but also smaller font sizes, especially sensitive decorative fonts, were kept in plug-in font boxes in which the letters “stuck” upright. The individual characters were then pulled out with the fingers or tweezers. After printing the sentence, the letters were "put" back in the appropriate boxes, an activity that was happily left to the trainees, as learning how to divide the type case was one of the first training goals.

In the exclusion box were the spaces, the non-printing parts for the space between words. Quarter-point spaces (0.094 mm) were made from nickel silver, half-point spaces (0.188 mm) from brass. One-point spaces were made of copper or lead, all thicker spaces were predominantly made of an alloy of lead, tin and antimony, which was also used for the letters, with one-and-a-half and two-point spaces made of brass. The so-called squares were still in the exclusion box: exclusion material from two points thick and two, three or four cicero widths. As a further exclusion material, the typesetter had reglets and "bars" that were used as spacing between the lines and paragraphs. Reglettes were 1 to 12 points thick (1 cicero), bars were two, three or four cicero thick. Standard bars and racks were available from 8 to 24 cicero lengths in 4 cicero gradations. There were also squares as well as bars and reglets in 14, 16, 20 and 28 points. Since the exclusion material often took up more space in a set job than the font itself and thus contributed significantly to the weight, in the last decades of letterpress printing, this material was made from aluminum or hard plastic.

Large letters, for example for setting up posters , were mostly not made of lead, but made of wood or plastic (Plakadur), because the weight of the printing form would hardly have been able to carry it. Nevertheless, there were large lead scripts and letters made of brass that could also be used for embossing. These variants were partly cast hollow in order to save at least some weight and material.

Due to their widespread use, type cases and letters became superfluous in large numbers when the transition to more modern printing techniques took place. While lead letters were mostly melted down in order to be able to use the metal for other purposes, type cases and wooden letters found buyers on the antiques market: Disused type cases were sold at flea markets or in junk shops and often used by the new owners as shelves hanging on the wall, so the term type case came to be also established for a shelf divided into small compartments, which is used to store collectibles. Large wooden letters that were no longer used, on the other hand, were often put together to form abstract pictures, which in turn could also be used as doors of furniture and the like. Ä. Could be used.

Machine set

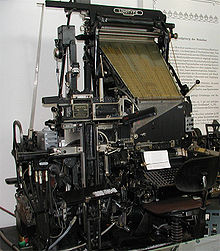

With the invention of the Linotype typesetting machine in 1886 and Monotype in 1897, the machine typesetter was born . The typesetter now entered texts on a keyboard. It lined up z. B. with the Linotype typesetting machine the corresponding letter matrices for the line. The word spacing was formed by "wedges" in order to automatically "exclude" the line to the nominal width. This was followed by casting the entire line of metal typesetting. The last automatic work step was the return of the matrices and word spacing wedges to their magazines, for which the matrices had character-specific serrations for the correct assignment. The Monotype worked according to the single-letter casting principle, with a separation of the typesetting process between text entry using punched tape and the casting process.

Font sizes

The common typographic system goes back to the French type founder François Ambroise Didot and his son Firmin Didot . In 1780, he established the smallest unit, the “point”, in its width according to the unit of measurement at that time, the “Paris foot”. The German type founder Hermann Berthold discovered in 1878 that this system also worked out to the millimeter: the platinum master meter gave exactly 2660 points. Since then this unit has been used in all Western European countries. Only the English and American type foundries used the pica point, which is now used on digital computers as a takeover from the USA (1 Didot point = 0.375 mm, 1 pica or DTP point = 0.352 mm ). The font size designations from small to large:

Quarter petit / Non plus ultra : 2 points; Microscopique : 2 ½ point; Brilliant / quarter cicero: 3 point; Diamond / semi-petite: 4 point; Pearl : 5 points; Nonpareille : 6 points; Insertio : 6 ½ point; Kolonel / Mignon: 7 points; Petit : 8 points; Borgis / Bourgeois: 9 points; Body / Garmond: 10 points; Rhinelander / Breviary: 11 points; Cicero : 12 points; Medium : 14 points; Tertia : 16 points; Paragon : 18 points; Text : 20 points; Double cicero: 24 points; Double mean: 28 points; Double tertia: 32 points; Canon / 3 Cicero: 36 points; Rough canon: 42 point; Concordance / Small Missal / 4 Cicero: 48 points; Rough missal: 54 points; 5 Cicero / Sabon : 60 points; Coarse Sabon: 66 points; 6 Cicero: 72 points; 7 Cicero: 84 points; 8 Cicero: 96 points.

Differentiation of the typesetter according to sub-areas of activity

The profession of the typesetter (typesetter) differed not only in the way of typesetting, whether by hand typesetting or with the help of typesetting machines (machine typesetting), but also in the content and goals of his typesetting activity. Accordingly, there was a differentiation into the following "disciplines":

- Work -

- Newspaper -

- Commercial -

- Tables -

- Formula - and

- Foreign language setters .

Further requirements and special features

In addition to manual work, the profession of typesetter also included a thorough knowledge of the origin of letterpress printing and the (classification of) fonts as well as the other printing processes. They also had to have very good spelling skills. An internal advancement was the employment as a proofreader ; he checked all typesetting for spelling and typographical errors as well as deviations from the manuscript. A proofreader in Germany received an increased wage of 107.5%, a machine setter corresponding to 120% of the basic wage .

Bleisetzer had to be able to read the text, even though it was mirrored and placed "upside down" away from the body in the angle hook. They also learned the balanced design of entire pages through to the use of tissue paper strips to adjust the spacing between individual letters and were considered the intellectuals among the craftsmen due to the good general knowledge that was also required. Those who worked in newspaper printing were also mostly seen as politically “left”.

A specialty of the graphic professions such as typesetter and printer was the so-called " couching ": After the journeyman's examination, the "mistakes" from the apprenticeship (from 1970: training) were symbolically washed off by dipping him into a vat with cold water.

To form it belonged on that older journeymen and master the typesetter newcomers to the existence of (non-existent) Lead lice pointed or raised too clean and tidy and the type area polish left. Another popular fun was sending newbies to the affiliated repro department to pick up screen dots by the bag .

Personalities

Many famous people learned the profession of typesetter:

- the publisher Heinz Bauer

- the politician Bolesław Bierut

- the radio journalist and writer Marion Brasch

- the linguist Herbert E. Brekle

- the comedian Karl Dall

- the politician Rudolf Dreßler

- the politician Björn Engholm

- the actor Ralph Gassmann

- the comedian Viktor Giacobbo

- the educator Josef Mahlmeister

- the artist HAP Grieshaber

- the politician Rudolf Gunkel

- the politician Franz Jonas

- the politician Paul Löbe

- the musician Roland Neuwirth

- the politician Philipp Scheidemann

- the cartoonist Tetsche

- the politician Wolfgang Thierse

- the writer Mark Twain

- the writer Heinz Rudolf Unger

- the typographer Kurt Weidemann

- the politician Stanisław Wojciechowski

- the artist Emil Zbinden

See also

- Desktop publishing

- Printer language

- Foreign language setters

- H. Berthold AG (type foundry)

- Ottmar Mergenthaler (inventor of the Linotype typesetting machine)

- Type caster

literature

- Friedrich Bauer: Handbook for typesetters. 5th edition. 1933.

- Friedrich Bauer: The starting point for typesetters. 11th edition. Polygraph Verlag, Frankfurt am Main 1961.

- Sepp Dußler, Fritz Kolling: Modern typesetting. 4th edition. Verlag Documentation Saur KG, Pullach 1974, ISBN 3-7940-8703-8 .

- Fritz Genzmer: The typesetter's book. 9th edition. Ullstein Fachverlag, Berlin 1967.

- Josef Buyer: The typesetting textbook. The basics of typesetting and its design. Otto Bliersch Verlag, Stuttgart 1956.

Web links

- Ordinance on the professional profile and on the examination requirements in the practical and in the specialist theoretical part of the master craftsman's examination for the typesetter (printer) trade of the Federal Ministry of Justice

- Druckhandwerk.de Information portal about black art

- Gutenberg Museum in Mainz (Germany)

- Gutenberg Museum in Freiburg im Üechtland (Switzerland)

- Typorama Museum and Printing House in Bischofszell (Switzerland)

Individual evidence

- ↑ The "work of books" - the 42-line Bible , GUTENBERG DIGITAL project, accessed April 23, 2018

- ↑ Johannes Kramer, Sabine Kowallik: Introduction to the Hebrew script . Helmut Buske Verlag , Hamburg 1994, ISBN 3-87118-986-3 , p. 57 .

- ↑ Uwe Steinacker: Metal typesetting and letterpress: Great workshop prelude in Dresden. TypeSCHOOL, July 22, 2015, accessed September 12, 2018 .

- ↑ Practical Tips, Deutsche Stempel AG, Frankfurt am Main, and Jägerlatein der Schwarzen Kunst, Hanseatische Verlagsanstalt, Bremen. See also: Font size!

- ↑ Weschke, H./Brandt, H./Etzel, A./Pauls, R .: Lexicon of graphic technology ; Fifth edition, Leipzig, 1979, p. 526, keyword: "Typesetter (Setzer)"

- ^ Richard, L. Niel: Typesetting technical pocket lexicon with consideration of the type foundry , 2nd edition, Vienna 1927, p. 834 f., Keyword typesetter

- ^ "Tariff Policy in the Future: Using the Example of the IG Druck und Papier" , supplement in Arbeiterpolitik, 5/1982, p. 5, PDF, 1.47 MB

- ^ Krzysztof Teodor Toeplitz : Bolesław Niejasny - Opowieść o Bolesławie Bierucie, Forreście Gumpie polskiego komunizmu, Lipiński Piotr . In: Gazeta Wyborcza . October 5, 2001 ( wyborcza.pl [accessed December 17, 2012]). Original quote: “ Był on także, co ważne, zecerem , który to zawód wytwarza szczególny stosunek do literatury i słowa drukowanego. "(German:" He was also, which is not to be belittled, a typesetter, a profession that creates a special relationship to literature and the printed word. ")

- ↑ In the beginning there was a lesson. With an apprenticeship at the University of Ursula Renold, Director of the Federal Office for Professional Education - PDF. Retrieved July 20, 2017 .

-

^ Stanisław Wojciechowski. In: Szkoła Główna Handlowa website . Archived from the original on January 3, 2012 ; Retrieved December 17, 2012 (Polish). , Original quote: “ Wyjechał do Zurychu, a następnie do Paryża. Pracował tam jako zecer , co traktował nie tylko jako sposób zarabiania na życie, ale również jako naukę przydatnego dla potrzeb konspiracji zawodu. "(German:" He traveled to Zurich and then to Paris. He worked there as a typesetter, which for him not only meant making a living, but also teaching a profession useful in conspiracy . ") Polska: Prezydentowe II RP : rewolucjonistka, feministka i sekretarka poprzedniczki. In: Polska Agencja Prasowa , Polonia dla Polonii. Archived from the original on April 16, 2013 ; Retrieved December 17, 2012 (Polish). , Original quote: “ Po konspiracyjnym, cichym ślubie młodzi osiedlili się w Anglii, gdzie Wojciechowski zaczął pracę zecera w drukarni PPS […]. "(German:" After a secret, silent wedding celebration, the bride and groom moved to England, where Wojciechowski started work as a printer in the PPS printer [...]. ")