Fuel cell vehicle

Fuel cell vehicles are means of transport in which electrical energy is generated from the energy sources hydrogen or methanol by a fuel cell and converted directly into motion with the electric drive or temporarily stored in a traction battery . On the one hand, the electrical storage enables recuperation and , on the other hand, it relieves the fuel cell of load changes. The drive structure thus corresponds to a serial hybrid drive . Internationally, the abbreviation FC (E) V for fuel cell (electric) vehicle is common.

This type of drive is no longer just considered experimental in road vehicles, but is manufactured in small series despite restrictions in operation. Restrictions result from the still thin network of hydrogen filling stations . In 2019 there were 75 publicly accessible hydrogen filling stations in Germany (approx. 0.5% of the entire filling station network in Germany). Compared to conventional battery-powered electric cars , the refueling process is much faster, comparable to a vehicle with a combustion engine.

Energy supply through fuel cells

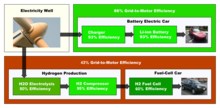

According to a report from 2011, a fuel cell could convert chemically bound energy directly into electrical energy with an efficiency of up to 60%. The electrical energy obtained in this way is stored in traction batteries, which also store braking energy recovered through recuperation . The electrical energy is converted back into kinetic energy via electric motors . The fuel cell recharges the drive battery during operation and thus works as a " range extender " to increase the range of a vehicle with an electric drive . Due to the additional energy conversion, the efficiency of the fuel cell vehicle is below that of a pure battery electric vehicle. While battery-electric vehicles can achieve efficiencies of up to 70–80% according to assumptions made in 2014, it is around 40–50% for fuel cell vehicles tank-to-wheel ; in addition, there are further losses during hydrogen production ( see below ).

In contrast, the CO 2 balance for the manufacture of the fuel cell system is more favorable . While the production of the battery of an electric car with a large 75 kWh battery and a range of 500 km with the current energy mix and state of the art produces around 7 tons of CO 2 , a fuel cell vehicle with the same range produces around 3.3 tons, the emissions for building the hydrogen infrastructure are not taken into account. In the overall balance, which takes into account both the manufacturing effort and the operating phase, a fuel cell vehicle has a poorer CO 2 balance than a comparable battery vehicle because of the lower efficiency and thus the significantly higher energy consumption . This applies to both the current and a purely renewable electricity mix.

Emissions

While the electric drive in purely electric cars produces practically no noise emissions apart from the tire rolling noise, in fuel cell vehicles there are little additional noises, mainly due to fans that supply the air and additional units such as pumps. The operating noise of fuel cell vehicles is significantly lower than that of vehicles powered by combustion engines. With pure hydrogen operation, the direct exhaust vehicle emissions mainly consist of water vapor or water. Thus, the vehicles contribute to improving the air quality of congested areas.

Processes in the fuel cell

At the anode hydrogen is oxidized , that is, it will be electrons withdrawn. The protons penetrate the electrolyte membrane and flow to the cathode . The electrolyte membrane is only permeable for the protons, which means that the electrons are “forced” to pass through the external circuit (with the backup battery or the electric motor). There are different membrane systems for the fuel cell with different efficiency and working temperature range. At the cathode, the oxygen carried down by the air flow is reduced, i.e. electrons (which were previously removed from the hydrogen) are added. Then the negatively charged oxygen ions meet the protons and react to form water. This completes the circuit. At the same time, heat is released that z. B. can be used for heating purposes in winter, but must be removed by a fan in summer.

Fuel and tank

Pressure tanks made of carbon fiber reinforced plastic (350-800 bar) are now used for fuel cell cars , since the storage density that can be achieved with this is sufficient to achieve ranges of more than 500 km. At 700 bar, the density of compressed gas comes close to 56% of the density of liquid hydrogen.

Cryogenic liquid hydrogen (−253 ° C, liquid H 2 ) is only used when larger quantities are required, e.g. B. in fuel cell buses . About 12% of the energy bound in the hydrogen must be used for compression to 700 bar. This must be included in the energy balance as a conversion loss. For liquefaction, 28-46% is required. Refueling is similar to refueling with LPG or natural gas . Additional losses occur if hydrogen is not regularly taken from the vehicle or the storage tank at the filling station. Despite high-quality insulation, the liquid hydrogen heats up and gasses out via drain valves.

It is possible to use various energy-containing substances as fuel. For use in the fuel cell, these must first be chemically converted into gaseous hydrogen in a reformer . Direct methanol fuel cells (DMFC) use the liquid fuel methanol directly, but they are not very efficient.

Hydrogen generation and energy chain

Hydrogen gas is not an energy resource like coal , crude oil or natural gas . Hydrogen (H) consists of a proton and an electron . It is a colorless, tasteless and odorless, non-toxic gas molecule made up of two atoms (H 2 ). In nature it is practically not found in free form. It is there exclusively in bound form, e.g. B. as water (H 2 O), in hydrocarbons - also in petroleum, natural gas, coal and biomass - or in other organic compounds. Hydrogen is released using energy. Until 2012 it was obtained almost exclusively from fossil fuels .

However, the production of hydrogen from fossil sources creates CO 2 and various pollutants as by-products. For the purposes of the climate protection target, hydrogen is quite possible, without CO 2 - emission manufacture. The more climate-friendly variant is to produce hydrogen through the electrolysis of water using green electricity or as bio-hydrogen from renewable raw materials. Electrolysis is the breakdown of a chemical compound under the action of electrical energy. Hydrogen is a carbon-free fuel and can thus help reduce CO 2 . However, this potential of hydrogen can only be fully exploited if the electricity comes from renewable energy sources . The electricity required for electrolysis can be obtained from energy sources such as sun , wind and water , but this type of hydrogen production is currently not economical. Over 90% of the hydrogen currently in use is therefore generated by steam reforming from fossil sources using the conventional energy mix .

If the required hydrogen were produced from electricity by electrolysis , the overall efficiency of fuel cell vehicles would be less than 30%, while it would be at least 65% for battery electric vehicles. Fuel cell vehicles that are operated with regenerative electrolysis hydrogen therefore consume less primary energy than conventional vehicles with internal combustion engines, but also more than twice as much as battery-electric vehicles. A review carried out in 2013 showed that the consumption of hydrogen cars is around 130% higher than that of electric vehicles.

In addition, a hydrogen infrastructure would make sense as an energy storage medium that could serve as a supplement to the discontinuously produced, renewable energies.

Storage of hydrogen

Compressed hydrogen storage

The problems of storage in pressure vessels are now considered to have been solved. By using new materials, the effective shrinkage through diffusion is greatly reduced. While pressure tanks with 200 to 350 bar were still common in the automotive sector around the year 2000, 700 and 800 bar tanks with higher capacities are already in use in 2011. The complete hydrogen pressure tank system for a car weighs approx. 125 kg.

Metal hydride storage

One technology that is currently being tested is the use of metal hydrides. It relies on the fact that certain metal alloys can absorb and release hydrogen through thermal treatment. Hydrogen is stored in metal powder by pressure and released again by the supply of heat. This method offers advantages in terms of volume-related storage density. The disadvantage, however, are the high material costs and the fact that hydride storage systems only absorb approx. 2% of their own weight in hydrogen and are therefore very heavy for passenger cars, because these units weigh around 300 kg. However, they are used in class 212 A submarines, for example . The aim of research is to increase the weight-related storage densities through the use of new alloys.

Storage in nanotubes

The storage of hydrogen in carbon nano-fibers promised new perspectives . It was hoped that weight-related storage densities of 8–20% would be achieved. In reality, however, values around 2% could only be achieved. The wrong prognoses were due, among other things, to contamination of titanium in the first experiments.

N-ethyl carbazole

Another storage option that has only recently been explored is the use of N-ethylcarbazole as a storage medium. N-Ethylcarbazole can chemically store large amounts of hydrogen and later release it again. The hydrogen stored in N-ethylcarbazole could be used to operate a fuel cell in cars to generate electricity. Instead of gasoline or electricity, the driver would simply fill up with “charged”, high-energy N-ethylcarbazole (perhydro-N-ethylcarbazole or also perhydro-carbazole) at the gas station and at the same time let out “discharged”, low-energy N-ethylcarbazole. The low-energy N-ethylcarbazole could be enriched with energy in a decentralized manner; From an ecological point of view, it would make the most sense to do this directly in places where electricity is produced, for example in wind farms in the North Sea. N-Ethylcarbazole can be transported safely and without losses over long distances in pipelines or stored under pressure in tanks . Another advantage is the low impact on the environment and atmosphere.

A disadvantage is the duplication of supply and disposal. There must be two tanks in the vehicle: one for high-energy perhydro-N-ethylcarbazole and one for discharged. This can e.g. B. be a double tank with a separating membrane ( LOHC tanks, LOHC means "Liquid Organic Hydrogen Carriers"). The duplication of supply and disposal spreads through the petrol station to the entire logistics .

Another problem is that the release of hydrogen from the N-ethylcarbazole usually requires operating temperatures of between 100 and 200 degrees Celsius. This would require temperature management to control the temperature of individual functional units in the system, as the fuel cells work at around 80 degrees Celsius. In addition, the chemical release of hydrogen from the N-ethylcarbazole takes place comparatively slowly without further aids, which prevents the vehicle from being accelerated, as is expected in automobile construction. This circumstance would require the additional installation of intermediate storage, such as accumulators or supercapacitors and the corresponding power electronics.

Chemically bound hydrogen

Another option is to use bioethanol for transportation. The ethanol is catalytically separated into hydrogen and carbon dioxide and the hydrogen is transferred to a fuel cell . There are some problems with this method, such as: B. the formation of toxic carbon monoxide when converting ethanol to hydrogen. This process is no longer used in fuel cell cars.

outlook

In 2011, the Ministry for the Environment, Nature Conservation and Transport of the State of Baden-Württemberg declared that it wanted to support the expansion of a hydrogen infrastructure for future-oriented energy use and sustainable mobility.

The vehicle manufacturers Toyota , Nissan and Honda have now significantly reduced production costs for hydrogen-powered vehicles and are planning to introduce large-scale production in Japan from 2015 in connection with the construction of 100 hydrogen filling stations in the Japanese metropolitan regions. Toyota presented the world's first production car with fuel cell drive on June 25, 2014 under the name FCV in Tokyo. At the end of 2017, Toyota was producing around 3,000 fuel cell cars a year.

Daimler wanted to start series production of hydrogen vehicles by 2015 at the latest. In order to demonstrate the suitability for everyday use of the hydrogen drive, Mercedes-Benz carried out a circumnavigation of the world with several B-Class fuel cell vehicles. The tank systems required to compress the hydrogen supplied by Linde AG to 700 bar were carried as mobile units. In 2013, Daimler stated that, contrary to the original plan, series production of fuel cell vehicles would not begin until 2017, as a competitive price for the vehicles cannot currently be achieved. Other car manufacturers are also repeatedly postponing the start of series production.

However, the establishment of an infrastructure for hydrogen production , hydrogen storage and refueling is still open. In addition to the pollutant-free operation of the vehicle ( tank-to-wheel ), as in the case of purely battery-operated electric cars, the generation of the necessary hydrogen ( well-to-tank ) must also be considered under ecological aspects . Hydrogen is currently (2012) primarily produced by steam reforming using fossil primary energies, primarily natural gas. The H2 Mobility Initiative (Air Liquide, Daimler, Linde, OMV, Shell and Total) is planning a network of 400 stations by the end of 2023 .

In February 2020 there were 87 hydrogen filling stations in Germany; According to the Federal Ministry of Transport, the number should rise to 130 by 2021. Around 1,000 filling stations are required for a comprehensive network. There were 177 ready-to-use hydrogen filling stations across Europe in February 2020.

Since fuel cell vehicles are subject to the regulations of the German Electromobility Act, an e-license plate can be applied for to distinguish them from other vehicles since October 2015 and the vehicles can use the discounts for electric drives specified there.

criticism

There are critical opinions in the automotive industry about the future of hydrogen technology in this area. VW boss Herbert Diess spoke out against fuel cell technology in 2019. This is not environmentally friendly. He describes the i Hydrogen Next project by competitor BMW as "nonsense". In an interview, Professor Martin Doppelbauer from the Karlsruhe Institute of Technology (KIT) explained that the more electromobility begins to establish itself, the stronger there would be a campaign for hydrogen. The hydrogen discussion is a fairly German phenomenon. For example, there would be a single hydrogen filling station in all of Italy (as of December 2019). In France there are five as of December 2019. In Spain there are two and in Portugal none. Doppelbauer sees a need for use in the area of grid stabilization. But in the mass market of cars with millions of vehicles, it is unsuitable.

Available fuel cell vehicles and concept vehicles

Passenger cars

Honda showed the FCX Clarity 2007, a fuel cell car ready for series production. The first examples were leased to selected customers in California.

On June 3, 2008, the first Toyota FCHV-adv was approved for road use in Japan. On September 1, 2008, the Japanese Ministry of the Environment leased the first Toyota FCHV-adv prototypes for commercial testing.

The Hyundai ix35 FCEV has been manufactured in small series since 2013 and delivered to customers, it was replaced by the Nexo in 2018 .

In 2014 Toyota presented the "FCV", which has been produced since autumn 2015 under the name Toyota Mirai . The first test drives took place in Germany in November 2015. One tank of fuel is enough for up to 500 kilometers at around 90 km / h. Refueling takes 5 to 15 minutes.

For more information, see the list of fuel cell cars in series production .

Some manufacturers have already presented several generations or several different concept vehicles:

| Manufacturer | Type | year |

|---|---|---|

| Audi | Audi A2H2 | 2004 |

| Audi | Audi A7 h-tron | 2014 |

| BMW | 5 series GT test vehicles | 2015 (1) |

| BMW i | i Hydrogen Next | 2019 |

| Daimler | Mercedes-Benz NECAR | 1994-2002 |

| Daimler | Mercedes-Benz F-Cell (A-Class) | 2003-2007 |

| Daimler | Mercedes-Benz F-Cell (B-Class) | since 2007 |

| Daimler | Mercedes-Benz BlueZero F-Cell | 2008 |

| Daimler | Mercedes-Benz F600 Hygenius | 2005 |

| Daimler | Mercedes-Benz Vision Tokyo Concept | 2015 |

| Daimler | Mercedes-Benz GLC F-Cell | 2018 |

| Chrysler | Chrysler Sodium | 2001 |

| Chrysler | Jeep Commander II | 2000 |

| Chrysler | Jeep Treo | 2003 |

| FIAT | Seicento Elettra H2 Fuel Cell | 2001 |

| FIAT | Seicento Hydrogen | 2003 |

| FIAT | Fiat Panda Hydrogen | 2005 |

| ford | Ford Focus FCV Hybrid | 2002-2005 |

| ford | Ford Explorer FCV Hybrid | 2006 |

| ford | Morgan LifeCar | |

| General Motors | GM Electrovan | 1966 |

| General Motors | GM HydroGen3 | 2001-2006 |

| General Motors | GM HydroGen4 | since 2004 |

| General Motors | GM HyWire | |

| General Motors | GM sequel | since 2005 |

| Honda | Honda Clarity | since 2016 |

| Honda | Honda FCX Clarity | 2008-2014 |

| Hyundai | Santa Fe FCEV | |

| Hyundai | Tucson FCEV | |

| Hyundai | Hyundai ix35 FCEV | 2013-2018 |

| Hyundai | Hyundai Nexo | since 2018 |

| Nissan | Nissan X-Trail FCHV | |

| Peugeot | Peugeot Quark | 2004 |

| Renault | Renault Kangoo ZE H2 | 2015 |

| Toyota | Toyota FCHV | 2001 |

| Toyota | Toyota Fine-N | 2003 |

| Toyota | Toyota Mirai | since 2014 |

| Volkswagen | VW Bora Hy-motion | 2000 |

| Volkswagen | VW Bora Hy-power | 2002 |

| Volkswagen | VW Touran Hy-motion | 2004 |

commercial vehicles

buses

- DaimlerChrysler developed a drive for the Sprinter , as well as the NeBus ( O 405 N2 with fuel cell) in 1997 , the Mercedes-Benz Citaro BZ in 2002 and presented the third generation of a hybrid bus with storage battery at the UITP Congress in Vienna in 2009 with the Citaro FuelCELL-Hybrid . The Concept Sprinter F-Cell was presented in 2018 . The test operation at the Hamburger Hochbahn since 2010 was terminated at the beginning of 2019 after great ambitions. The reasons are delivery difficulties on the part of Mercedes and unsolved problems with the storage of explosive hydrogen stocks in residential areas. Newer models are manufactured as Mercedes-Benz FuelCell hybrid buses .

- Van Hool and UTC-Fuel Cell , ISE Corporation jointly presented the Van Hool new A330 Fuel Cell in 2005 . The Cologne regional traffic and the Wuppertaler Stadtwerke have firmly ordered 40 hydrogen buses from Van Hool, which are to be delivered from spring 2019.

- In 2019, 12 Urbino 12 hydrogen vehicles were ordered from the Polish manufacturer Solaris for the city of Bolzano in South Tyrol . Ballard Power Systems supplies the fuel cells for these buses .

- Hydrogenics built several midibuses with fuel cell drives on the Gulliver 520ESP from Tecnobus (Italy) .

- The Yutong ZK6125FCEVG1 Fuel Cell Bus from the Chinese bus manufacturer Yutong received market approval for China in summer 2015. This 12 m bus is equipped with eight 120 l tanks, which are located in the front part of the roof. The bus has a range of 300 km. Refueling only takes ten minutes. The fuel cell has an output of 50 kW, the drive motor has an output of 120 kW.

- Toyota developed a fuel cell bus together with its subsidiary Hino , which has been marketed in Japan since December 2014. This 10.5 m long vehicle uses the same technology as the Toyota Mirai , but has two fuel cell stacks and eight hydrogen tanks. These each supply two 110 kW (150 PS) electric motors with energy. The bus offers 26 seats and 50 standing places and has been in regular service in Toyota City since January 9, 2015 .

Trucks

Due to the requirements from Brussels: ( Regulation (EU) 2019/1242 ), truck and commercial vehicle manufacturers are forced to look for alternative drive concepts. That is why Daimler and Volvo are jointly investing in fuel cell drives. Toyota has already built a number of models together with Kenworth and is developing a new truck in collaboration with Hino Jidōsha . Iveco intends to establish a truck production facility in Ulm together with Nikola Motor Company . Hyundai is already testing corresponding trucks and a. in Switzerland .

See also:

Others

- As early as 1959, the Allis Chalmers fuel cell tractor was presented and a field test was shown. It was given to the museum after several presentations.

- From 2008 to 2010, a forklift truck from Still (R 60-25) with fuel cell drive was operated at HHLA in the Port of Hamburg as part of a project.

- CNH Global presented the "NH²" tractor based on the New Holland "T6000" model at the Sima 2009 agricultural exhibition in Paris . The tractor was brought to 120 hp in 2011.

Rail vehicles

Ships / boats

- The first fuel cell ship in the world with passenger approval was the Hydra . It was built by Christian Machens in 2000 and had an alkaline fuel cell system (AFC).

- Passenger ship: Hamburg passenger ship Alsterwasser, Zemships project . See also → H2Yacht

- Submarine: Submarine class 212 A , submarine class 214 , DeepC

- Ro-ro ship : Undine , fuel cell unit WFC20 from Wärtsilä as auxiliary drive (20 kW) with methanol insert

- The research ship Solgenia is also powered by a fuel cell.

- The Norwegian Viking Lady is a supply ship that was equipped with a fuel cell in addition to diesel-electric propulsion .

- Nemo H2 canal boat in Amsterdam

In 2011, the economic use of fuel cells to provide energy in ships was questioned in some cases.

Planes

- 2009: The first pilot-controlled aircraft that was powered exclusively by fuel cell propulsion was the Antares DLR-H2 motor glider. The first public flight started from Fuhlsbüttel Airport in Hamburg and lasted ten minutes.

- 2016: The first flight of the four-seat HY4 passenger aircraft took place on September 29, 2016.

literature

- Sven Geitmann: Hydrogen Cars - What will move us in the future. Hydrogeit Verlag, 2006, ISBN 978-3-937863-07-8 .

- Helmut Eichlseder, Manfred Klell: Hydrogen in vehicle technology: generation, storage, application. 2nd edition, Vieweg + Teubner, 2010, ISBN 3-8348-1027-4 .

- GL publishes fuel cell study. In: Schiff & Hafen, Heft 11/2010, p. 58, Seehafen-Verlag, Hamburg 2010, ISSN 0938-1643 ( Germanischer Lloyd examines the use of fuel cells in seagoing ships)

- Fuel cell drive proven in practice. In: Schiff & Hafen Heft 3/2011, pp. 46–48, Seehafen-Verlag, Hamburg 2011, ISSN 0938-1643

- Nora Luttmer: Fuel cells - soon! In: Deutsche Seeschifffahrt Heft 01/2011, pp. 48–49, Association of German Shipowners , Hamburg 2011, ISSN 0948-9002 .

Web links

- Hydrogen filling stations in Germany

- Current list of fuel cell vehicles (on the Internet)

- Current list of fuel cell vehicles (PDF file; 894 kB; 25 September 2019 not available)

- Overview of current fuel cell vehicles

- New infrastructure for future-oriented forklift drives (maschinenmarkt.vogel.de of September 19, 2008)

- NH2 hydrogen tractor

- Current market overview of fuel cell vehicles (FCEV) available on the German market as of 2019

Individual evidence

- ↑ Honda FCX Clarity: Beauty for beauty's sake, Los Angeles Times, February 13, 2009

- ↑ Tom Grünweg: Honda Clarity with fuel cell in the test - mobility. In: Spiegel Online . April 18, 2016, accessed April 12, 2020 .

- ↑ t3n.de of September 29, 2019, fuel cell: New generation of the Toyota Mirai is coming in 2020 , accessed on October 6, 2019

- ↑ Daimler hands over first fuel cell car from series production ( Memento from August 3, 2012 in the web archive archive.today ) Status: December 1, 2010

- ↑ https://h2.live/ Hydrogen filling stations in Germany

- ↑ Test drive in the Toyota FCHV adv (source: Heise as of July 29, 2011)

- ↑ DLR lecture: Battery or fuel cell - what will move us in the future? K. Andreas Friedrich; Institute for Technical Thermodynamics; Pfaffenwaldring 38-40, Stuttgart; Chart 11 dlr.de (PDF)

- ↑ Martin Doppelbauer: Strategy paper electric cars - current status and future development (V1.5) . Karlsruhe Institute of Technology . Retrieved November 7, 2019.

- ↑ U. Bossel, Theory and Practice, April 2006: Hydrogen does not solve energy problems PDF, accessed September 23, 2014

- ↑ Hydrogeit: production of hydrogen , added 5 February 2012 found.

- ↑ Dominic A. Notter, Katerina Kouravelou, Theodoros Karachalios, Maria K. Daletou and Nara Tudela Haberlandad: Life cycle assessment of PEM FC applications: electric mobility and μ-CHP. In: Energy and Environmental Science 8, (2015), 1969–1985, doi: 10.1039 / C5EE01082A .

- ↑ Viktor Wesselak , Thomas Schabbach , Thomas Link, Joachim Fischer, Regenerative Energietechnik, Berlin / Heidelberg 2013, p. 739.

- ↑ Valentin Crastan , Electrical Energy Supply 2, Berlin - Heidelberg 2012, p. 57.

- ^ Mark Z. Jacobson et al., 100% clean and renewable wind, water, and sunlight (WWS) all-sector energy roadmaps for the 50 United States. In: Energy and Environmental Science 7, (2015), 2093-2117, p. 2095, doi: 10.1039 / c5ee01283j .

- ↑ Siang Fui Tie, Chee Wei Tan, A review of energy sources and energy management system in electric vehicles. In: Renewable and Sustainable Energy Reviews 20, (2013), 82-102, pp. 89f, doi: 10.1016 / j.rser.2012.11.077 .

- ↑ Opel relies on hydrogen (as of April 6, 2011) ( Memento from February 22, 2012 in the Internet Archive )

- ↑ Tim Schröder: The space miracle in the tank. In: MaxPlanckResearch. Number 10, 2009, p. 45.

- ↑ Automobilproduktion Online from June 30, 2011, Electric gasoline Carbazole raises hopes ( Memento from July 5, 2011 in the Internet Archive )

- ↑ Bernd Otterbach: Carbazole miracle drug: The long way to the automotive industry series online, July 7, 2011.

- ↑ A hydrogen infrastructure is to be built in Baden-Württemberg ( Memento from January 23, 2011 in the Internet Archive ) (status: January 19, 2011).

- ↑ Mass market for fuel cells starts in Japan in 2015 (as of January 14, 2011).

- ↑ Jürgen Pander: Toyota with hydrogen drive: FCV drives with fuel cells - mobility. In: Spiegel Online . June 25, 2014, accessed April 12, 2020 .

- ↑ Michael Specht: Fuel cells as a drive: Why Toyota is switching to hydrogen . In: Spiegel Online . November 19, 2017 ( spiegel.de [accessed November 19, 2017]).

- ↑ Mercedes hydrogen car as a hybrid competitor ( Memento from October 22, 2012 in the Internet Archive ) (Status: January 24, 2011)

- ↑ Mercedes B-Class F-Cell on a world tour (status: January 31, 2011)

- ↑ auto-clever, March 16, 2011: Mercedes Sprinter and Viano support B-Class F-Cell on world tour , accessed August 7, 2012

- ↑ Daimler postpones fuel cells to 2017 (as of January 20, 2013)

- ↑ Nikolaus Doll: Drives: Bad prospects for the fuel cell car. In: welt.de . January 12, 2014, accessed April 12, 2020 .

- ↑ Final report on behalf of the BM VBS 2009: Where will hydrogen come from in Germany by 2050? , inserted February 5, 2012.

- ↑ Website of H2 MOBILITY Deutschland GmbH & Co. KG, Berlin , founded in 2015 as part of the Clean Energy Partnership , accessed on March 10, 2018

- ↑ This year the 100th hydrogen filling station opens . In: auto motor und sport , February 20, 2020. Accessed June 14, 2020.

- ^ Heidenheimer Zeitung GmbH & Co KG: Hydrogen: The power that comes from water. December 7, 2019, accessed December 19, 2019 .

- ↑ H2.LIVE: hydrogen filling stations in Germany & Europe. Retrieved December 20, 2019 .

- ↑ "Hydrogen is unsuitable in the mass market of cars" | bizz-energy.com. Retrieved December 20, 2019 .

- ↑ Welt online, June 16, 2008: Only water vapor comes out of this car , accessed May 6, 2012

- ↑ Toyota FCHV-adv ( Memento of August 10, 2009 in the Internet Archive )

- ↑ Japanese Ministry of the Environment leases FCHV-adv ( Memento from September 16, 2009 in the Internet Archive )

- ↑ manager-magazin, November 5, 2015: The whole tour in the Toyota Mirai for reading ( memento from August 13, 2016 in the Internet Archive ), accessed August 13, 2016

- ↑ Jens Stratmann: Concept Cars: Mercedes-Benz Vision Tokyo 2015 - The Automobile Future? www.mobilegeeks.de Internet portal, October 28, 2015

- ↑ welt.de

- ↑ Informationsdienst Wissenschaft from June 19, 2015, HyWay: Commissioning of the largest fleet of hydrogen cars in Europe , accessed on September 28, 2019.

- ↑ Boris Schmidt: With the fuel cell against the range problem. In: FAZ.net . Retrieved July 15, 2018 .

- ↑ cfr: Hamburg: Hochbahn abolishes hydrogen buses again - mobility. In: Spiegel Online . February 13, 2019, accessed April 12, 2020 .

- ↑ Boris Schmidt: From waiting for the electric bus. In: Frankfurter Allgemeine Zeitung. Technology and engine department. Tuesday 3rd April 2018

- ↑ Bozen buys twelve hydrogen buses from Solaris. IWR, June 3, 2019, accessed February 9, 2020 .

- ↑ Yutong ZK6125FCEVG1 Fuel cell city bus (# 285) Made In China. Retrieved October 12, 2017 (UK English).

- ↑ Yutong ZK6125FCEVG1 Fuel Cell Bus Passes Homologation in China (on the homepage of chinabuses.org (English)), accessed on August 16, 2015

- ↑ Toyota tests fuel cell bus in: Busdriver Magazine from January 9, 2015; accessed on August 17, 2017

- ↑ Iveco press information

- ↑ tagesschau.de

- ^ Hessian Ministry for the Environment, Climate Protection, Agriculture and Consumer Protection, May 2013: Industrial trucks with fuel cells. PDF, accessed October 6, 2017

- ^ New Holland NH2 hydrogen tractor

- ↑ New Holland presents hydrogen tractor

- ↑ Fuel cell drive under test. In: Schiff & Hafen, issue 9/2010, p. 17; Seehafen-Verlag, Hamburg 2010, ISSN 0938-1643

- ↑ Hans-Jürgen Reuß: Fuel cells on the verge of the end? In: Hansa , Heft 2/2011, p. 22, Schiffahrts-Verlag Hansa, Hamburg 2011, ISSN 0017-7504

- ↑ message on Stern.de from July 7, 2009; Retrieved August 20, 2015

- ↑ DLR: Emission-free propulsion for aviation: first flight of the four-seat HY4 passenger aircraft. In: www.dlr.de. September 29, 2016, accessed September 26, 2019 .