Pavement (flooring)

When paving (from Old High German pflastar , Medical plasters, mortar, floor, via Latin (em) PLASTRUM , medicinal patches, adhesive plasters of Greek émplastron , Preserved Knetetes) is a covering for traffic areas in road construction and rare for floors in buildings designated. Paving stones with larger dimensions or slabs are called pavement slabs or technically as large formats . Water-permeable pavements with paving systems are among the infiltrable traffic areas .

The paving consists of the actual paving stones, which lie in a paving bed and the base layer underneath , which usually consists of compacted sieve rubble ( "mineral concrete " ) or concrete. Pavement is made from natural stone , concrete , clinker , wood or blast furnace slag . The gaps between the paving elements are usually filled with joint sand or joint mortar . As long as the elements do not crunch against each other anyway, the filler material prevents them from shifting under shear loads .

The profession that deals with laying pavers of all kinds is the paver . For the laying of larger areas, a paving plan is often drawn up by civil engineering engineers or road builders, which includes not only the type and location of the paving stones but also their height information in order to ensure orderly drainage .

Paved interiors, streets and squares of Babylonians , Egyptians and especially from the Roman Empire are known from ancient times . In the Middle Ages, paving declined, especially on country roads, and only picked up again with the increase in traffic in the 19th century, until more asphalt roads were built in the 20th century . Today, paving is used to secure inner-city streets, sidewalks and bike paths, parking lots and areas with high demands on design and quality of stay, such as pedestrian zones or public spaces.

A particular problem with paving, including particularly large-format natural stone paving with wide joint spacing, is the increased noise level that is caused by motorized vehicles when there is a corresponding traffic load. On the other hand there can be ecological advantages, because rainwater can seep through the joints, they are more breathable and advantageous for the greenery along the road . In the long term, paving is easier to repair and convert. Thus, paving is sensible to use in traffic areas up to and including load class 3.2.

In Germany, for example, the proportion of paved surfaces in the area of municipal roads is almost a quarter of the paved road surface. Use on private land is not taken into account.

history

Road or path paving has been known for a long time. Remnants of paved areas in Mesopotamia suggest that the paving technique was used around the year 4000 BC. Close. The Egyptians and Babylonians used paving stones to facilitate the transportation of goods. In Babylon, for example, the processional street from the 7th century BC Paved.

In the Roman Empire , paving technology was significantly improved. The Romans used the advantages of the paving for the construction of main roads and recognized the importance of a stable substructure. They chose between two different construction methods depending on the soil conditions. In the swampy terrain, a supporting structure made of lengthways and transverse timbers was created, on which the paving was then laid. If, on the other hand, the road ran on firm ground, the workers first piled up coarse rubble stones, then gravel or crushed stone and finally sand. The paving stones were then placed in the sand bed. The workers laid natural stones made of basalt or limestone in an irregular arrangement (so-called wild association) and built a transverse slope to drain the roadway.

“After painstakingly smoothing the stone slabs were cut into polygonal shapes and then he put them together without lime or anything else. They were fitted with such care, and the gaps were filled in so well, that the viewer thought it was a work of nature and not of man ”

In China, the use of paving, especially pebble paving, gained importance in the 11th century. In addition to being used on public roads, these pebbles were an integral part of Chinese gardens . The pebbles were sorted with great care according to color and shape and then placed in a bed of mortar, similar to the bonded construction method. The paved surfaces contained ornaments and were intended to convey stories and messages to the viewer.

After the fall of the Roman Empire, the importance of the paving declined in Europe. Only streets and squares in European cities were equipped with it, country roads remained unpaved. Only with the increase in traffic due to industrialization did paving pick up again. In the middle of the 19th century, the first guidelines for the proper installation of pavement appeared. Their basic statements are still valid today.

Initially, only stones from natural sources ( quarries , river beds , reading stones ) were available. If they were missing, for example in northern Germany or the Netherlands , stones were made from brick or clinker . These materials were replaced by concrete , which became affordable at the end of the 19th century when cement became cheaper. The exact dimensional accuracy and the variety of shapes as well as the low price ensured that concrete paving stones developed proportionately to the most commonly used paving.

The importance of pavement generally declined again in the first part of the 20th century, because the increasing vehicle traffic required flat and more stable tar and asphalt roads . With the increasing importance of city monument preservation and traffic calming since the 1970s, it is increasingly being laid out in pedestrian zones , old towns and in squares.

tasks

Appropriate requirements are sufficient load-bearing capacity and evenness with simultaneous grip . The load-bearing capacity of the paved surface is directly related to the quality of the pavement substructure, which is why particular attention must be paid to sufficient stability.

In order to be able to safely drain off surface water and to prevent it from entering the lower layers, paved surfaces must be as tight as possible (with the exception of water-permeable paved areas) and have a sufficient slope. In addition, high demands are made on durability. This means that pavements are break-proof, frost-resistant and are characterized by high abrasion resistance. In addition to being practical, paved ceilings have to be visually pleasing, which can be achieved, for example, through a beautiful shape and color or an attractive stone bond. It should be noted, however, that the axle loads have increased significantly compared to before. Furthermore, the loads from braking and starting processes have increased significantly.

“The requirements for paving have changed over time. The contact tension and the vertical load transmitted by it on the wooden wheels reinforced with steel strips was significantly higher than is the case with today's tires. For example, an iron wheel generates a contact stress between 360 and 1100 kg / cm² on a paved surface. On the other hand, a truck tire causes a contact tension of 4 kg / cm² with a permissible axle load of 5 tons. "

In addition to the increased tension, the stress from hoofbeats and the excrement of horses on the paved surfaces used to be much greater. This is still a considerable technical problem in cities with a carriage system (Vienna, Salzburg). Regardless of the type of paving, the substructure is an essential factor. This must absorb the shear forces that arise under load as well as the vertical recompaction without surface deformation.

Construction methods

In the field of paving, many different construction methods have developed and proven over time, but only a few of these construction methods are specified in standards and guidelines . Non-standardized construction methods can be found in good quality in many places.

The installation is mostly done by hand, but laying with mechanical support is possible with suitable paving formats. The installation is carried out by landscape gardeners or road builders (formerly known as stone setters).

Unbound construction

The unbound construction method is the oldest paving technique and is now part of the standard construction method. The stones are placed on a bed of chippings , sand or granules. The jointing material, which ideally should consist of the same material, is matched to this. This construction reacts to static or dynamic loads with elastic deformation. Temperature stresses are reduced by unhindered deformation, there are no constraints. The pavement basically remains permeable to water. The disadvantage is the risk that the grout is washed out of the joint or, for example, swept and vacuumed by vacuum sweepers . As a result, the stones can lose their hold. The fear is often expressed that the roots of the joint vegetation could push out the stones, but this can also have a solidifying effect on the jointing.

Bound construction

Here, the pavement bed and joints are traditionally made of cement mortar , which is sometimes improved with additives. In older books and leaflets, the bound construction method is referred to as rigid construction or Concrelith . The elongation at break for cement mortar is only 0.1–0.2 · 10–3 or 0.1–0.2 mm / m. This is less than 1/10 to 1/100 that of steel or asphalt. If the elongation at break or the (also low) tensile strength is exceeded , the grout will loosen from the stone flanks.

In the meantime, joint mortars based on reaction resin are used for bonded construction, which are much more elastic than cement mortar and adhere better to the flanks. Reaction resin joint mortars are usually drainable. Due to the pore structure, the risk of frost damage is lower than with water-repellent joint mortars. The material consists of (coarse) quartz sand and a resin that is mixed in or delivered as a ready-made mixture.

Due to the pressure-resistant jointing, the base layers underneath the paving must be made particularly resistant to deformation. High-quality bonded ceilings can only be achieved with precise planning, coordinated materials and appropriate production. The execution of this paving technique, which is considered a special construction, leads to damage relatively often. Standardization was expected for 2008.

This technique is based on the unbonded construction method, but in this case the upper part of the joint is made of bound material. The depth of the bonded joint is at least 3 cm and can assume the full height of the stone to the maximum. There are only a few binding regulations or guidelines for this type of construction, yet it is implemented in many places. Due to the bonded joint, surface water cannot seep away with all types of joint mortar, so the paved surface must always have a sufficient slope for drainage if no drainable reaction resin joint is used. Since this type of construction does not create a “rigid” structure, the joint compound must have the most elastic properties possible in order to be able to compensate for any small movements that may occur in the pavement. Bitumen joint sealants are particularly suitable for this, but cement or reaction resin- based mortars are also used. The last mentioned reaction resin joints (Romex-Drän, vdw 800 etc.) are meanwhile offered by some well-known manufacturers for different load cases. The 2-component mortars definitely achieve the strength of cement grout and are used for areas of construction class 3 to 6. A stable, solid substructure is decisive for a long service life of the grout.

With an unbound substructure, fixed joints should only be installed on traffic areas that are not subject to heavy loads (e.g. sidewalks), since the joint filling can be damaged by heavy loads.

Infiltrable construction

This construction method is a sub-area of the infiltrable traffic areas and chooses a different way in paving technology. The principle of draining surface water as quickly as possible and thus preventing it from penetrating the pavement structure is dropped with this technology. The goal of the water-permeable construction method is to infiltrate the surface water into the subsoil without detours through the pavement. Infiltration can occur either exclusively through the joints (seepage joints), but also through water-permeable paving stones. So-called joint vegetation is often desired between the stones . The successful and permanent greening of the joints, however, depends on the traffic load on the surfaces. The base layers must be matched to the seepage properties and have a filter-stable structure. The fine grain fraction ( grain size less than 0.063 mm) should not be more than 3% by mass for this purpose.

Experience has shown that the seepage capacity of this construction method decreases over the years, as the joints and stones are constantly clogged with fine particles and dust. In order to compensate for the effect of the colmation , a six to ten times higher infiltration capacity should be aimed for, depending on where the surface paving is used.

Liquid-tight construction

None of the above-mentioned paving methods can be made completely liquid-tight. Even on paved surfaces with hardened joints, liquid can penetrate into fine cracks. Based on this problem, a paving technique was developed in which neither the individual paving stones nor the joints allow contaminated water, fuel or other environmentally harmful liquids to get into the ground. This design is intended for filling systems for such liquids (e.g. for gas stations) and their suitability must be confirmed by a water law approval.

This construction method is carried out with the help of large-format concrete slabs, the joints of which are kept tight for a long time by a deep toothing and a permanently elastic seal. Only approved specialist companies are allowed to install liquid-tight pavements if they are to be produced for reasons of environmental protection.

Natural stone pavement

Manufacturing

Natural paving stones are obtained from natural stones that have sufficient strength. These particularly include granite , gneiss , basalt , greywacke and porphyry . The base material is extracted in the quarry by drilling or gentle blasting methods and then processed manually and mechanically in the factory. The rough stones are further crushed with the help of manual splitting methods using compressed air tools into manageable pieces, which are split into paving stones on the paving machine . Granite and gneiss are tweaked to shape, porphyries, basalts and sometimes marbles / limestones are hand-cut. The paving stones produced in this way are subject to natural fluctuations in terms of shape, quality and color. The permissible tolerances are specified in the relevant standards. There are also rolled (rumpled) goods, the edges of which are irregularly broken. Special qualities of stone paving are made conical and can therefore be set up without being bound with sufficient joint volume.

Natural stones from developing countries are partly obtained through child labor . An ARD report in 2008 showed that these stones are also being sold in Germany and are used for paving public spaces, whereby UNESCO certificates should guarantee goods free of child labor.

Alternatively, child labor can be effectively avoided in connection with the production of natural stone paving if Central European types of stone are used, as is consistently practiced in the Czech Republic by public and many private clients.

New paving with old Bohemian marble and limestone mosaic paving in Lomnice nad Popelkou

Relaying of paving according to monument-friendly criteria in Litomyšl

marked functional area in the parking zone with means of paving in Chrudim

Modern design of the public space with granite elements in Svitavy

New paving with old paving stones in Kutná Hora

Functional paving in Vysoké Mýto

Pavement design with a functionally oriented motif in Litomyšl

modern (approx. 2004) paving with marble in Hradec Králové

"Wild pavement" in Wiesbaden

Gray basalt, typical pavement in the Ruhr area between 1850 and 1930

Classification

The guidelines and standards applicable in Germany provide for a division of natural stones into large pavement, small pavement, mosaic pavement and natural stone slabs. The European standard EN 1342 does not recognize these distinctions. Standard 18318 also does not contain a definition of the terms large, small or mosaic paving stones. According to the TL plaster, the classification is based on the nominal thickness:

- up to 60 mm: mosaic paving stone

- over 60 mm to under 120 mm: small paving stones

- over 120 mm: large paving stone

Large stone pavement

The common sizes are 13/15, 15/17 and 17/19 cm. These are cubes with edge lengths of around 14 cm, 16 cm or 18 cm. The edge length varies by ± 1 cm, so that all more or less imprecisely broken stones between 13 and 19 cm edge length can be classified in the three grades. The term cobblestones refers to round or head-shaped stones such as the cat's head or candy pavement, which is rarely found in Germany (see under Other).

Small plaster

Small plasters are usually broken with hard metal wedges. The sizes 9/11, 8/10, 8/11, 7/9 and 7/10 cm are common. Here, too, the stones are approximately cubic, with dimensional tolerances upwards and downwards. From the 9/11 cm size range, around 100 to 110 stones per square meter are required.

Mosaic pavement

The mosaic pavement, the smallest pavement size, is now produced using a machine. The sizes 6/8, 5/7, 4/6 and 3/5 cm are common. With an edge length of 5/7 cm, there are around 270 to 290 stones per square meter.

Stone slabs

The slabs are larger than large stone paving stones, but are less thick. Their size can be in the meter range. They are suitable for covering sidewalks or large areas. The panels must have a ratio of greatest length to thickness of ≥ 3: 1. If the ratio is smaller, the norm speaks of paving slabs. Representatives of large stone formats are, for example, the “ Charlottenburger Platten ” that can be found in Berlin .

Caterpillar

In Raupflaster , outdated and rough pavement , is it is uneven set of broken paving stone, which is particularly hard and resistant. It serves to secure the river bed or the bank area and is not used as a road surface due to the rough surface.

Others

In addition to the standardized natural stone paving, there are the following non-standardized types of paving:

- Pebble paving: Pebble paving can be used to close recesses or create an ornament . Their use is particularly common today in southern Europe and Asia.

- Reading stone pavement or Wacken pavement (popularly also called cat's head pavement , trivial: candy pavement ): This old paving technique can be found in various designs according to shape and size on old traffic routes and has sometimes only survived in fragments. The round stones (also called Wacken or " stone pebbles") come from natural rubble from watercourses and ice-age debris deposits . The term wild pavement is also used for this purpose .

Plaster bandages

Natural stones are arranged in many different stone associations. The following list gives a rough overview of the most common natural stone associations. The row and diagonal pavement distinguishes the alignment and the border. The polygonal bond (also known as a net bond) is characterized by the fact that the joint is at most three stones long.

Arched pavement in Darmstadt

Concrete pavement

Manufacturing

Concrete paving stones are manufactured industrially from a mixture of cement, aggregate and water. The resulting fresh concrete can then be given in any shape. A w / c value of 0.35-0.40 should be aimed for. The cement content is 300–350 kg / m³ with a rock composition of 50–60% sand and 40–50% chippings or gravel . Furthermore, the stones must be made resistant to frost and de-icing salt damage by adding appropriate concrete. Concrete blocks consist of two types of concrete. The concrete on the underside of the stone (so-called core concrete) is supplemented with a top layer (so-called facing concrete). The surface of concrete blocks can be changed by coloring the facing concrete or adding broken natural stone.

The concrete blocks are manufactured with or without a bevel . The use of stones without a bevel is common on cycle paths and / or paths that are used, for example, by wheelchairs or shopping carts . The absence of the bevel reduces rolling resistance , increases driving comfort and reduces tire-road noise.

Classification

As an alternative to paving made of natural stone, concrete paving is often used today. This type of plaster is cheaper and more precise in its shape. Since their use in the 20th century, various combinations of shapes and colors as well as types of composite have developed. Due to their regular shape, large-area laying with mechanical support is possible. The stones have a compressive strength of about 55 N / mm² (plates have a characteristic flexural strength of 5 N / mm²) and are placed in a bedding of 30 to 60 mm. A distinction is made between the following types of concrete paving:

- Concrete block: This common stone is made in a square or rectangular shape and can be designed with or without a broken edge. To facilitate installation, spacers or knobs are provided on the sides of the stones. The usual dimensions range from 60 mm to 240 mm in width or length and 60 mm to 140 mm in depth.

- Concrete slab: By definition, concrete slabs are at least four times longer than they are thick. The susceptibility to breakage of such panels is considerably greater than that of concrete blocks, which must be compensated for by a higher material strength. They are manufactured in sizes from 200/200 mm to 500/500 mm or larger. In addition to square panels, panels in the shape of a bishop's hat or corner are also manufactured for laying diagonally.

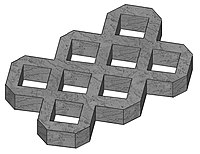

- Concrete composite stone: Concrete composite stone paving is produced in an almost unmanageable variety of shapes by the industry. The composite effect of the stones in the horizontal and vertical direction has a beneficial effect on the load-bearing capacity. The joint pattern is different depending on the stone shape. The stone shape groups include the single and double symmetrical shape, the S shape, I and H shape and the polygon shape.

-

Concrete stone: Concrete stone is characterized by a special color or surface texture. The stone color is changed with the help of white cement or pigment . The surface is changed by washing , grinding , sticking or shot peening . In order to give the pavement an antique look, the stones are rolled so that the edges are broken irregularly. In addition, the surface of the concrete block can be changed by a different composition of the facing concrete (so-called gravel or gravel attachments).

Concrete decorative stones also include paving stones, which due to their surface are suitable for the orientation of the blind and visually impaired. For example, grooves or knobs are formed on the top of the stones, which can be felt with a long stick or the soles of a shoe.

- Concrete lawn stone : Concrete stones with lawn chambers, the lawn paving stones, are suitable for use in water-permeable paved areas . This type of stone is used in many different stone formats and laying patterns.

- Pore-free concrete block : In contrast to the above-mentioned stones, the pore-free concrete blocks (also called drain stones or drainage stones ) are made of hollow- core concrete . Surface water that occurs can seep through the stone into the ground. A steady decrease in seepage is to be expected. Due to the cavities, their compressive strength is lower than that of normal concrete blocks.

Plaster bandages

The following list summarizes the large number of concrete block associations and shows the most common stone associations.

Clinker pavement

Manufacturing

Clinker bricks consist of clay or loam mixed with water . The raw mass is brought into the desired shape using an extrusion press and then dried for several days. Then the blanks can be fired at 1200 ° C until sintering . The color depends on the iron or manganese content of the starting material, but can also be changed by other additives. Due to the sintering, the clinker has a low water absorption capacity and is therefore frost-resistant .

Classification

Clinker paving consists of various formats of clinker that are mentioned in the standards. The use of clinker paving has a long tradition, especially in northern Germany and the Netherlands, as the occurrence of natural stone here is lower than in other parts of Germany. A distinction is made between paving clinker and clinker slabs. Both types have a maximum compressive strength of 80 N / mm² and, in the highest case, may absorb six mass% water. The thickness of the pavement bedding should be between three and five centimeters.

The Dresden soap stone is an example of historical clinker paving for sidewalks .

Wooden pavement

A marginal phenomenon in Pflasterbau takes the wood block or cross-grained wood parquet or forehead wood parquet , bair.-Austrian. Heeled floor a.

In contrast to parquet , the wood fibers of wooden paving are vertical, they are placed on end- grain wood , i.e. with visible annual rings . Wooden paving is composed of wooden blocks, typically often with dimensions of 6 cm × 8 cm, which are glued to the supporting sub-floor and sanded in unbound or bound with asphalt. The thickness of wooden paving is usually 2–6 cm, in addition to a square format - especially in horticulture - round wood is also common. In Graz and Linz, house passages - they are protected from rain by gates - were equipped with high-heeled pavement around 1850–1920. Horse hooves and iron-tyred wooden wheels of wagons move significantly more quietly than on stone, the underlying brick cellar vault is less stressed, the cubic format is 8–12 cm in size, only has a bevel of about 5 mm all around on the useful side The cubes become significantly thinner over time, they can develop radial cracks.

The most common types of wood are oak, as well as pine , larch and fir , which are particularly resistant in a damp environment. In the open air, the service life of the wood plaster decreases due to the swelling behavior of the wood when exposed to moisture and therefore proves to be relatively inadequate. In interiors, however, it is often valued for its pleasing appearance and its robust surface that is warm to the feet. In the past, the wood was soaked in pitch to improve its resistance. However, this type of wood protection is banned today due to the harmful effects of tar.

The typical area of application for wooden paving are workshops . Since wood is many times more resistant perpendicular to the grain, its mechanical robustness can be optimally used as a floor. Historically, end grain floors were important in all metalworking companies ( forging , scythe factories ) because the elastic, earth-moist wood tolerates glowing metal and thus alleviates the enormous risk of injury that comes from splintering iron on brittle ground. In agricultural buildings, as well as in inner courtyards and doorways, coarse paving was also moved, with logs > 30 cm standing in half-meter pieces. Such floors were suitable for metal-shod hooves and wheel rims and can also be used for extremely acidic floors in the stables area . The service life given was the same as for wooden roofs, i.e. 20 to 40 years.

Historically, in the mid-19th century, wooden pavers were also used for paving roads, especially in cities in the United States and England .

Cinder blocks

Manufacturing

Slag bricks are made of copper or blast furnace slag . Therefore, the term copper slag stone is rarely used. For the production, glowing slag is poured into the desired shape and the stone is then allowed to cool. They get their characteristic rough surface by sprinkling with grit. However, their production has ceased in Germany since the end of the 20th century.

Classification

Cinder blocks have a dark gray to almost black color and achieve high strength values. They exist in the dimensions 160/160/160 mm and 240/160/160 mm. Due to their strength, they were installed on traffic areas with high wheel loads, such as bus lanes and bus bays, as well as paving tram tracks and parking lots.

Noise development

Driving on paved surfaces with motor vehicles causes more road noise than driving on asphalt. Depending on the speed driven and the surface properties of the pavement, different level increases occur. Rough stone surfaces with a wide joint spacing (greater than 5 mm) and bevelled or broken stone edges have a noise-reducing effect . A noise reduction , on the other hand, can be achieved with the smoothest possible paving surface with small joint spacing and large stone formats.

In order to counteract the problem of tire-road noise when driving on paved surfaces with wide vehicle tires, the pavement described above should only be applied in areas with low driving speed. Alternatively, asphalt lanes can be formed.

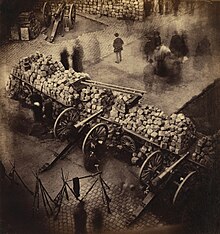

Paving stones as a barricade and weapon

Paving stones were used as a means of building barricades as early as the 19th century revolutions . The offensive of the opponent, often the counter-revolution , was to be thwarted by the rapid erection of an obstacle and protective wall . Barricades were built up by misappropriating various everyday objects. The stones of the street paving offered the advantage of being available as building material directly on site, if necessary also in combat. They were about using crowbars pulled out of the paving and temporarily piled up.

Today, paving stones are often used as projectiles in demonstrations and street battles by violent participants in clashes with the police or for property damage, which can lead to life-threatening injuries. While hard objects such as glass bottles are usually not allowed to be carried during a demonstration and are usually rejected during security checks before the event, paving stones can usually be collected on site, which makes it much more difficult for the police to completely prevent the use of projectiles.

Sports

The annual one-day cycle races Paris – Roubaix and Tour of Flanders are known as the “cobblestone races ”, as large parts of the route lead over sometimes very unevenly paved paths and streets and are therefore a great challenge for the participants. The old town criterion , which also takes place annually in Ravensburg, places the same demands on the racing drivers. The race held on the Aachen cobblestones is called the cycle race around the cathedral and town hall .

The trophy of the Paris-Roubaix cycling race is a paving stone attached to a base. For the 100th edition of the race in 2002, an oversized paving stone was also placed on a plinth in front of the Vélodrome in Roubaix .

jobs

- Steinhauer - production

- Paver - laying

- Gardening and landscaping - laying

See also

- Road surface

- Road superstructure

- Curb

- Spitstone

- Parquet - mathematical description of regular paving

- Stumbling blocks - memorial stones placed in the pavement of public sidewalks to commemorate Nazi victims

literature

- S. Borgwardt, A. Gerlach, M. Köhler: Infiltration areas. Requirements, use and dimensioning . Springer-Verlag, Berlin 2000, ISBN 3-540-66048-8 .

- Horst Mentlein: Pavement Atlas . Rudolf-Müller-Verlag, Cologne 2007, ISBN 978-3-481-02347-8 .

- Brian Shackel: Concrete Block Paving Manual . Beton Verlag, Düsseldorf 1996, ISBN 3-7640-0344-8 .

- Volker Friedrich: Paving with natural stone . Ulmer Verlag, Stuttgart 1999, ISBN 3-8001-5078-6 .

- Siegfried Vogel: The art of paving with natural stones . 8th edition. Tusa natural stones, Freudenstadt 2003, DNB 986961337 .

- 2. plaster . In: JG Krünitz (Ed.): Economic Encyclopedia . ( uni-trier.de - 1773–1858; historical aspects: history, building tradition of the 18th and 19th centuries).

- Road construction . In: Meyers Konversations-Lexikon . 4th edition. Volume 15, Verlag des Bibliographisches Institut, Leipzig / Vienna 1885–1892, pp. 374–376.

- NS Documentation Center of the City of Cologne (Ed.): Stolpersteine. Gunter Demnig and his project . Emons, Cologne 2007, ISBN 978-3-89705-546-9 .

Standards and guidelines

European standards

- EN 1338 Concrete paving stones - Requirements and test methods

- EN 1339 Concrete slabs - Requirements and test methods

- EN 1341 natural stone paving slabs for outdoor areas - requirements and test methods

- EN 1342 Natural stone paving stones for outdoor areas - Requirements and test methods

- EN 1344 paving bricks - Requirements and test methods

Germany

- DIN 18158 floor clinker plates

- DIN 18318 traffic route construction work - paving slabs and slab coverings in unbound execution, edging

- DIN 18503 paving clinker - requirements and test methods

- DIN 68702 wooden plaster

- Leaflet for water-permeable paving of traffic areas

- Additional technical contract conditions and guidelines for the production of paving slabs, paving slabs and edging (ZTV Pflaster-StB 06)

- Technical delivery conditions for construction products for the production of paving slabs, paving slabs and edging (TL Pflaster – StB 06)

- Guidelines for the standardization of the superstructure of traffic areas (RStO 01)

- FGSV 618/2 working paper - surface pavements with paving slabs and paving slabs in bonded design

- WTA Merkblatt E-5–21–07 / D Bound construction - historical pavement

- DNV - Leaflet 10/2002.

Austria

- ÖNORM B 3108 Natural stones - edging and paving stones - dimensions

- ÖNORM B 3118: 2005 Natural stones - edging stones, paving stones and paving slabs - requirements for the stone properties (national adoption of EN 1341–43)

- ÖNORM B 2214: 2005 paving work - service contract standard (procedural and contractual provisions for the execution of paving)

- RVS 8S.06.4 Technical contractual conditions for road construction; Ceiling work; Paving stone and paving slab ceilings, edging

- See also: Standards for natural stone , concrete stone

Web links

Individual evidence

- ^ Friedrich Kluge , Alfred Götze : Etymological dictionary of the German language . 20th ed., Ed. by Walther Mitzka , De Gruyter, Berlin / New York 1967; Reprint (“21st unchanged edition”) ibid 1975, ISBN 3-11-005709-3 , p. 544.

- ^ Research Society for Roads and Transport: Guidelines for noise protection on roads . FGSV-Verlag, Cologne 1990.

- ↑ D. Richter, M. Heindel: Roads and civil engineering . Teubner Verlag, Wiesbaden 2004, ISBN 3-519-35621-X , p. 11 .

- ↑ Horst Mentlein: Patch Atlas . Rudolf Müller Verlag, Cologne 2007, ISBN 978-3-481-02347-8 , p. 9 .

- ↑ Eduard Zirklerin: asphalt, a material through the millennia . Giesel Verlag, Isernhagen 2001, ISBN 3-87852-010-7 , p. 82 .

- ↑ Chris Scarre : The Seventy Wonders of the World . Frederking & Thaler Verlag, Munich 2004, ISBN 3-89405-524-3 , p. 240 .

- ^ Microsoft Corporation: Microsoft Encarta Professional 2003. Article: Roman roads

- ↑ From the work “Historiai” (War History), V.147

- ↑ Volker Friedrich: Paving with natural stone . Ulmer Verlag, Stuttgart 1999, ISBN 3-8001-5078-6 , p. 12 .

- ↑ J. Eisenmann, G. Leykauf: Betonfahrbahnen . Ernst & Sohn Verlag, Berlin 2003, ISBN 3-433-01341-1 , p. 187 .

- ↑ D. Richter, M. Heindel: Roads and civil engineering . Teubner-Verlag, Wiesbaden 2004, ISBN 3-519-35621-X , p. 249 .

- ^ Siegfried Vogel: Street and Autobahn. Comparative consideration of the construction methods according to RStO, table 1, asphalt pavements: to table 3, pavement pavements, May 2005.

- ↑ KH Hülbusch, B. Sauerwein, P. Fahrmeier: The spontaneous vegetation in the mosaic pavement of the street 'Am Weinberg' . Notebooks from the Kassel School, Kassel 1986.

- ↑ ARD-exclusive: Kindersklaven (WDR) ( Memento from November 22, 2009 in the Internet Archive ). Broadcast date Wednesday, July 30, 2008, 9:45 p.m.

- ↑ Selina Engels: Photo of the month - March 2004 - candy plasters. In: District of Stade - marketplace for the district of Stade. Krause newspaper publisher, archived from the original on March 14, 2014 ; Retrieved December 6, 2011 .

- ↑ Heidi Howcroft: Pavement for the garden, courtyard and squares. Planning, laying and preserving . Callwey , Munich 1991, ISBN 3-7667-1005-2 , p. 22

- ↑ Horst Mentlein: Patch Atlas . Rudolf-Müller-Verlag, Cologne 2007, ISBN 978-3-481-02347-8 , p. 9 ff .

- ^ Joachim Lorenz: Handbook of road construction . Fraunhofer IRB Verlag, Stuttgart 2006, ISBN 3-8167-7083-5 , p. 195 .

- ↑ About wooden paving. In: Allgemeine Bauzeitung , year 1842, p. 368 (online at ANNO ). Retrieved November 10, 2012.

- ^ Günter Wolf: Road planning . Werner Verlag, Munich 2005, ISBN 3-8041-5003-9 , pp. 327 .