Lignite mining

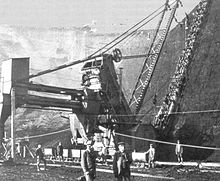

Under lignite mining refers to the mining of brown coal . It usually takes place in open-cast mining with the help of lignite excavators and conveyor bridges or conveyor belts and is associated with serious interventions in the environment.

Germany

In Germany, lignite is primarily used to generate electricity . The land use of the German Braunkohletagebauten amounted status 2006 more than 2,300 square kilometers, which is more than four times the area of Lake Constance, or nearly the area of Saarland equivalent. In addition, more than 300 settlements for lignite mining were given up and around 100,000 people were resettled . In addition to other negative influences on the water quality , there were a. also on an area of approx. 6,000 km² to lower groundwater . In 2013 around 16,410 people were employed in lignite mining across Germany, around 1.5% less than in 2012.

history

From the 16th century onwards, a lack of wood (an impending or already acute shortage of the raw material wood) was perceived as a social problem. By 1800 large parts of Europe were deforested ; many of the remaining forests were overexploited. In many places there was an acute shortage of firewood and other heating fuels every winter ; (see also history of the forest in Central Europe ).

In many places shafts were dug or drilled with the aim of finding new coal fields and other mineral resources ( "mutation bores" ).

In the late 17th century it was discovered that the wet, useless layer in the extraction of clay for ceramics - industry in the space of Brühl (between Cologne and Bonn) and Frechen -level (between Cologne and Aachen) above the clay layer and be cleared had , was flammable after being dried with the sun and air. The respective landlords had this peat-like substance ( turf ) dig up in small pits by small farmers and day laborers with hoes and spades. He was in pots to Klütten (from Low German Kluit compressed and = lumps) in the summer air-dried. The Klütten had only a low calorific value . They were used locally or sold to poor people in surrounding settlements. Such pits existed until the 1920s.

In 1698 they began to dig for lignite near Müuellen / Braunsbedra . This is considered to be the "hour of birth" of the Central German lignite mining area . The geography professor Eckhard Oelke (Martin Luther University Halle-Wittenberg), however, dated its beginnings in the year 1382, in which a kolgrube in Lieskau near Halle (Saale) is mentioned in a document.

In the later western area of the Rhenish lignite mining area ( opencast mine Zukunft and opencast mine Inden ), lignite was found in 1819 while building a well in the village of Lucherberg near Inden. In 1826, the landlord, Karl von Goldstein, began to mine a 7.5 meter thick seam.

The Astrea mine (Rhineland) was operated from 1830 to 1924 - partly open-cast and partly underground.

Lusatian lignite mining area : The 1st Lusatian seam in the Welzow area was mined from the 19th century, usually in underground construction in small pits, including unregistered pits. Grube Clara I Welzow started the brown coal mining on the Welzower plateau in the 1866th

In 1856, the mining of lignite began near Nachterstedt / Schadeleben ( Central German lignite area ) (until 1991, today Lake Concordia ).

In the course of industrialization , there was strong population growth in all European countries in the 19th century (see e.g. demography of Germany ). There was urbanization . Numerous technical inventions made innovations possible. Residential population, crafts, trade and industry all needed fuel for heating and for operating steam engines . The railway network that emerged in the 19th century and new canals ( list here ) made the transport of bulk goods over longer distances possible and affordable.

In 1859 the first railway bridge in Cologne connected the western Rhineland with the Ruhr area . Lignite sales fell temporarily due to competition from cheap hard coal from the Ruhr mining industry; In 1876 it reached a brief low.

In 1877 ( union Roddergrube ) and 1878 ( union Brühl ) entrepreneurs in Brühl made coal extraction with steam-operated bilge pumps competitive and revolutionized the production of briquettes by machine presses . Such presses were developed in 1872 in the Central German district. Further briquette factories were founded in quick succession . National railway lines as well as the local railways Cologne-Frechen-Benzelrath Railway from 1893, Bergheimer Kreisbahn 1897/1899 and Hürth-Kalscheuren– Hürth-Knapsack from 1901 connected places in the Ville , opened up further coal fields or tied pits to the demand areas.

The first briquette factory in the west was built in 1888 by the Maria Theresia zu Herzogenrath trade union (near Aachen). In 1913, the Braunkohle-Industrie AG Zukunft was founded in the Westrevier as an amalgamation of various small trade unions with the aim of building a brown coal power station. In 1914, the Zukunft opencast mine and the first Weisweiler power plant went into operation.

The mechanization made further progress: 1895 was the first overburden excavator , which for the construction of the Kiel Canal had been built in the pit Donatus at Liblar used. The first cutting excavator for coal mining was used in the Gruhlwerk in Brühl in 1907 and was given the name "Iron Man". In 1909 four coal excavators were already working in the 29 pits; In 1913 only three pits had no excavators. Production rose from five million tons in 1905 to 17.4 million tons in 1913. Sales were difficult compared to traditional hard coal. The pits competed with each other. In 1899, 19 pits merged to form a sales syndicate in order to sell briquettes as branded articles under the name Union-Brikett with uniform standards.

In the northern district between Neurath and Garzweiler, commercial mining began in 1907 with the development of the Rheingold field , initially with hoes and carts . The first scraper excavator was used a year later . Today the pit fields are grouped together in the Garzweiler opencast mine .

After the First World War, there was a huge increase in production capacity in all German lignite regions. Germany had to cede numerous areas under the Versailles Treaty and lost around 40% of its best hard coal deposits . The coal mining areas that were left in place also had to pay considerable reparations . This made lignite an indispensable energy factor in all branches of industry. While before 1919 the share of lignite in electricity generation due to its low calorific value, its poor transportability and the lack of heating and transmission technology, the coal shortage associated with the assignment of territories and the self-sufficiency efforts in the Weimar Republic forced an increase a share of almost 60% of energy generation.

The GDR mined lignite with practically no consideration for environmental concerns. Since the first oil crisis, the Soviet Union (the leading power in the Eastern Bloc or in the Council for Mutual Economic Aid ) in the GDR had raised the prices for crude oil deliveries; since then (and due to a lack of foreign currency) the GDR used lignite to an even greater extent.

Performance figures

Status 2006:

| District | Overburden movement in 1000 m 3 | Lignite extraction in 1000 t | Overburden to coal ratio (A / K) m 3 / t | Calorific value in kJ / kg |

|---|---|---|---|---|

| Rhineland | 415,798 | 96.178 | 4.3: 1 | 8,896 |

| Lausitz | 426,594 | 57,955 | 7.4: 1 | 8,638 |

| Central Germany | 73,650 | 20,353 | 3.6: 1 | 10,486 |

| Helmstedt | 13,561 | 1,804 | 7.5: 1 | 10,797 |

| All in all | 929603 | 176,321 | 5.3: 1 | 9,014 |

As of 2016:

| District | Overburden movement in 1000 m 3 | Lignite extraction in 1000 t | Overburden to coal ratio (A / K) m 3 / t | Calorific value in kJ / kg |

|---|---|---|---|---|

| Rhineland | 428.242 | 90,451 | 4.7: 1 | 9.005 |

| Lausitz | 372.712 | 62,292 | 6.0: 1 | 8,528 |

| Central Germany | 50.903 | 17,730 | 2.9: 1 | 10,669 |

| Helmstedt | 37 | 1,074 | - | 10,878 |

| All in all | 851.895 | 171,547 | 5.0: 1 | 9,030 |

Status 2019:

| District | Overburden movement in 1000 m 3 | Lignite extraction in 1000 t | Overburden to coal ratio (A / K) m 3 / t | Calorific value in kJ / kg |

|---|---|---|---|---|

| Rhineland | 355,335 | 64,806 | 5.5: 1 | 9,059 |

| Lausitz | 329,632 | 51,998 | 6.3: 1 | 8,400 |

| Central Germany | 53,810 | 14,509 | 3.7: 1 | 10,675 |

| Helmstedt | - | - | - | - |

| All in all | 738.777 | 131,313 | 5.0: 1 | 9,079 |

Territories in Germany

Lignite mining takes place in Germany or in the following coalfields in open pit instead:

- Rhenish lignite mining area in the Aachen - Ville region ( Rhineland )

- Central German lignite mining area in the Halle - Leipzig - Altenburg - Quedlinburg region

- Lusatian lignite district and Upper Lusatian lignite district in the Lausitz ( Lausitz Lake District ) around Cottbus , Hoyerswerda , Zittau

In earlier times, mining also took place in the following open-cast mining areas:

- Upper Palatinate lignite mining area in the Upper Palatinate ( Schwandorf , Upper Palatinate Lake District )

- South and east of Berlin in Brandenburg in the area Finkenheerd - Frankfurt (Oder)

- Lower Hessian lignite area : with Borkener lignite area , Hirschberg near Großalmerode , Hoher Meißner

- Westerwald lignite mining area

- in today's UNESCO World Heritage Site Messel pit near Darmstadt in Hesse , a.o. a. Lignite and oil shale mined

- Wetterau lignite mining area in Hesse

- Griese area in Mecklenburg and Prignitz in Brandenburg

- Fläming near Coswig , Saxony-Anhalt

- Oder slopes between Frankfurt (Oder) and Stettin in Neumark and Pomerania

- Weserbergland near Hameln in Lower Saxony next to hard coal : Osterwald (Salzhemmendorf)

- Helmstedt lignite mining district in Lower Saxony and Saxony-Anhalt until 2016

In later times, lignite mining also took place underground , e.g. B. in

- Union 103 mine in Morschenich

- Stolzenbach mine near Borken

- Griese area in Mecklenburg

- Altmark near Arendsee , Saxony-Anhalt

- Robertshall mine in Hamburg-Harburg

- Mittenwalde , Schenkendorf

- Region around Staßfurt and Barby ( Grube Alfred )

- Mansfeld country

Environmental impact

Groundwater lowering

Because of the age at which it was formed, lignite regularly lies under groundwater-bearing layers. For example, the seams in the Rhenish lignite mining district lie at a depth of up to 450 meters. The groundwater has to be lowered so that the opencast mine does not fill up. This is a major intervention in the water balance of the surrounding areas, rivers and stagnant water and "has devastating consequences for nature and the cities in the vicinity." () Hundreds of large pumps form several rings around the pits. The outer pumps suck off the surface water. The closer they are to the excavator, the higher they raise the water. The Garzweiler opencast mine pumps up to 230 meters; in the Hambach opencast mine up to 450 meters. The submersible pumps used there can pump 32 cubic meters of water per minute. In Garzweiler, well over 100 million cubic meters of water are pumped out every year. This corresponds to about six times the water requirement of the city of Mönchengladbach .

According to the Lausitzer und Mitteldeutschen Bergbau-Verwaltungsgesellschaft mbH (LMBV), groundwater levels are lowered up to 100 m below the opencast pits. In the Lusatian lignite mining district, active lignite mining pumped out around 230 million cubic meters of groundwater in 2009 - more than all other users put together: industry, agriculture and drinking water works together make up 160 million m³ in the state of Brandenburg .

The result of the pumping out is always a so-called sinking funnel, which influences the groundwater levels in the wide area around the opencast mine. A lowered groundwater level can cause mountain damage to buildings and damage forests during drought (especially deep-rooted trees: deep-rooted people drive their taproots towards the groundwater).

Devastation and Relocation

In addition to the ecological effects, opencast mining also has massive social consequences. As the examples of Horno and other places in the Lausitz coal area or Immerath (Erkelenz) and other places in the area of the Garzweiler opencast mine show, over three hundred settled settlements, some of which are very old, have been and will be irretrievably destroyed by (forced) relocation. In 2017, the land consumption for open- cast lignite mining in Germany was around 2.1 hectares per day. As of 2018, 372 sites in Germany were completely or partially destroyed for open-cast lignite mining. A total of around 125,000 people lost their homes; in addition, there is an unknown number of people whose places have been relocated for the construction of cooling water basins. The destruction of the Hambach Forest by the Hambach opencast mine caused massive controversy both from a cultural and ecological point of view .

Selected areas outside of Germany

Austria

- Styrian lignite mining area around Köflach - Voitsberg , Austria

- Hausruckviertel in Upper Austria in Hausruck

- Salzach lignite district in Upper Austria

- Langau-Riegersburg lignite mining area , Waldviertel in Lower Austria

- Lignite coal in the Neufeld an der Leitha area , Steinbrunn , Zillingdorf ; Industrial district of Lower Austria and neighboring northern Burgenland

Other countries in Central Europe

- Geologically connected parts of the Upper Lusatian lignite mining district are also mined in neighboring Poland ( Bogatynia ) and were mined in the Czech Republic ( Kristýna in Hrádek nad Nisou ). The Polish Turów open-cast mine supplies the Turów power plant , which went into operation in 1962 and which, with 1900 MWel, is the third largest in Poland. Huge coal finds in the Legnica area secure the existence of the facility for decades.

- North Bohemian lignite mining area in the North Bohemian Basin around Chomutov - Sokolov - Most

- Bornholm ( Denmark ), around Hasle

- Søby lignite depot (1940–1970)

- Northern Hungarian lignite mining area around Visonta and Bükkábrány

- Central Poland around Bełchatów , Konin , Gubin

- Limburg lignite district around Eygelshoven , Hoensbroek , Geleen in the Netherlands

Worldwide lignite mining

see charcoal / tables and graphics

See also

literature

- Walter Buschmann, Norbert Gilson, Barbara Rinn: Brown coal mining in the Rhineland = The architectural and art monuments of North Rhine-Westphalia 1. Wernersche Verlagsgesellschaft , Worms 2008. ISBN 978-3-88462-269-8

Web links

- Lignite mining in Lusatia

- Critical side of the Brandenburg Green League to the Lausitz area

- Lignite mining in Austria

Individual evidence

- ↑ Energy policy 20 years after Chernobyl. Documentation of the conference “Chernobyl 1986–2006: Experiences for the Future”, p. 218 . Website of the Federal Environment Ministry. Retrieved June 17, 2017.

- ↑ Germany - raw material situation 2013 . Federal Institute for Geosciences and Raw Materials . Retrieved February 6, 2015.

- ↑ Summary of Oelke's research results for Central Germany , accessed on October 17, 2015.

- ↑ Wolfgang Schossig among others: Mining in Lower Lusatia . Cottbus 2007. p. 27.

- ↑ Construction machinery - 1.) ERDBAU on ak190x.de

- ^ Arno Kleinebeckel: Lignite company. History of a raw material, a district, an industry in the Rhineland . Cologne 1986. pp. 117 ff. And P. 155.

- ↑ Ursula Bischoff: The influence of mining traditions and large-scale industrial developments on the social structure and mobility of the lignite workers in Borna. Dissertation, Humboldt-Universität zu Berlin, 2000, p. 76. Humboldt-Universität zu Berlin, accessed on September 20, 2019.

- ↑ Rolf Dieter Stoll, Christian Niemann-Delius, Carsten Drebenstedt , Klaus Müllensiefen (eds.): The brown coal open pit. Significance, planning, operation, technology, environment . 1st edition. Springer, 2009, ISBN 978-3-540-78400-5 , pp. 48 .

- ↑ https://www.braunkohle.de ›fileName = debriv_izb_20171005_web.pdf

- ↑ https://www.braunkohle.de ›fileName = 12-2019-kurz.pdf

- ↑ www.schoenfliess-nl.de ( Memento from June 17, 2010 in the Internet Archive )

- ↑ www.viademica.de

- ↑ www.alt-breitscheid.de

- ^ A b F. Plettner: The brown coal in the Mark Brandenburg: their distribution and storage. , 1852 Full text in the Google book search

- ↑ https://archive.fo/20120905123425/http://www.mz-web.de/archiv/Ehemalige-Kohlengrube-züge-jaehrlich-tausende-Gaeste-an/HC-08-04-2004-08120002613D.htm

- ↑ W. Pflug, 1998. Lignite mining and recultivation. Landscape ecology-reuse-nature protection.

- ↑ www.salzhemmendorf.de ( Memento from November 2, 2009 in the Internet Archive )

- ↑ Shots at Helmstedt . In: Der Spiegel . No. 22 , 1956 ( online - May 30, 1956 ).

- ↑ www.helmstedt.de

- ↑ www.bergamt-mv.de ( Memento from February 23, 2010 in the Internet Archive )

- ↑ www.geschichtsspuren.de

- ^ Also in the north of the district mining consequential damage ( Memento from August 4, 2012 in the Internet Archive )

- ↑ www.kanonenbahn.de ( Memento from August 15, 2002 in the Internet Archive )

- ↑ www.mansfelder-seen.de ( Memento from March 28, 2015 in the Internet Archive )

- ↑ a b WDR television (Quarks & Co.): The opencast mine damages nature and cities for decades

- ↑ Lausitzer und Mitteldeutsche Bergbau-Verwaltungsgesellschaft mbH: Annual water management report of the LMBV mbH. Period 01 January - 31 December 2017. Senftenberg.

- ↑ http://www.lausitzer-braunkohle.de/

- ^ Lignite: Germany is degrading . TIME ONLINE. August 13, 2015. Retrieved August 16, 2017.

- ↑ Land use for raw material extraction . Federal Environment Agency . Retrieved December 11, 2019.

- ↑ Many places disappeared because of lignite mining . In: Mitteldeutscher Rundfunk , October 23, 2018. Accessed October 24, 2018.

- ↑ tagesschau.de: Hambacher Forst: Between protest and violence . December 7, 2016. Retrieved August 16, 2017.

- ↑ Franziska Hein: Hambacher Forst: You must know that about the dispute . RP ONLINE. December 1, 2016. Retrieved August 16, 2017.

- ↑ Escalation in the Hambach Forest: An unequal battle comes to a head - Knowledge & Environment - 01.12.2016 . DW.COM. December 1, 2016. Retrieved August 16, 2017.

- ^ Søby Brunkulslejer. Retrieved February 9, 2019 (Danish).

- ↑ Lignite Mining ( Memento from July 30, 2012 in the Internet Archive )