Rhenish lignite district

The Rhenish lignite district , often also called Rheinisches Revier for short , is a mining district in the Cologne Bay , on the northwestern edge of the Rhenish Slate Mountains . The mining of lignite in the open-cast mining process had a major impact on the landscape and led to the formation of some important industrial sites. The district includes the Zülpicher and Jülich Börde , the Erft lowlands and the Ville , making it the largest lignite district in Europe. Clay , quartz sand and loess are mined here to a lesser extent .

The industrial use of the area with the entire value chain from coal mining to power generation is now carried out exclusively by the RWE Group (via its subsidiary RWE Power ). According to current planning, mining in the Rhenish lignite district is secured until 2030. It is difficult to make predictions about future developments, as a central pillar of the German energy transition is a coal phase-out .

Boundaries and division

Southern district

The southern area around Brühl begins south of Brühl in the Ville, there north of a line Brühl – Eckdorf / Erftstadt - Bliesheim . The southern district extends roughly to the course of Luxemburger Strasse B 265 near Hürth and Liblar and includes the former Hürtherberg mine union and the current Hürtherberg recreation area . On the south side, it encompasses the concessions of Carl Brendgen and his companies around Kierdorf . This area of small-scale pits had already been charred and recultivated by the mid-1960s . The opencast mines have given way to a wooded recreational area with a large number of small and medium-sized lakes.

Middle district

The central area comprises the Villerücken west of the Frechener Jump ( Frechen - Oberaußem - Niederaußem line ) from Luxemburger Strasse in the south to the Bergheim – Oberaußem line in the north. Today it is largely charred and recultivated, but the lignite industry with large power plants and successor industries still shapes the landscape.

Northern District

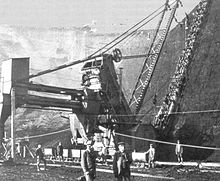

The North station joins the north of the flözfreien Kasterer Horstes and Erftstadt -Umbiegung east and reaches the mining areas Garzweiler I and II to Juechen and Erkelenz , wherein said brown coal seams located at even greater depths to below Niers and Schwalm extend. It also includes parts of the Erftscholle with the Hambach underground mine near Jülich . Here overburden and coal are conveyed with large equipment such as bucket wheel excavators , and the pits are then backfilled with large conveyor systems and skipers . The coal is brought to the plants in the south by its own rail network ( North-South Railway (Garzweiler) and Hambach Railway) . The spoil dump Sophienhöhe (290 m above sea level) towers over the Jülich Börde, visible from afar.

Western district

The western area between Düren , Weisweiler , Eschweiler , Alsdorf , Aldenhoven and Jülich with the former opencast mine Zukunft, BIAG Zukunft and the opencast mine Inden uses seams of the Rurscholle and thus supplies the Weisweiler power plant .

The mining of the less thick brown coal seams bordering this area is currently not economical. This is all the more true as this would also involve resettlement measures.

Some industrial sites on the outskirts of the area developed thanks to the lignite, for example the refinery in Wesseling, which was created in 1939 from a coal hydrogenation factory, or the RWE switchgear and substation in Brauweiler . They are commonly counted as part of the district.

Border areas

In addition to the main areas of the Rheinische Revier mentioned above, there were also deposits of lignite on the eastern and southern edges of the Cologne Bay, some of which were mined in some smaller pits until the 20th century. Geologically, these deposits are to be counted among the Rhenish lignite; Organizationally and culturally, however, the brown coal mines located in this area belong to the areas of the adjacent mountains that are characterized by other mineral resources.

The following are to be mentioned:

- Occurrences on the western edge of the Bergisches Land near Bergisch Gladbach and on the northern edge of the Siebengebirge near Troisdorf , Siegburg and Bonn , belong to the ore districts there (see Bensberger ore district )

- Occurrence on the northern edge of the Eifel near Euskirchen and Zülpich (today Neffelsee and Zülpicher See )

- Deposits in the Dutch and Belgian parts of Limburg , between Heerlen and Genk , are part of the Limburg coal district

Geological foundations

During the Tertiary , subsidence movements began in the Lower Rhine Bay 30 million years ago. A shallow sedimentation basin was created for the primary rivers Rhine , Rur , Erft , Sieg and Maas . This basin gradually subsided and formed staggered fractures , while the neighboring Rhenish Slate Mountains were raised. The original North Sea advanced into this area in several phases . Moors formed over the clay layers deposited in depressions , the vegetation of which could not be decomposed in the water. The resulting thin peat was covered with gravel , sand and clays through further changes in sea transgressions and regressions . 20 to 23 million years ago, at the beginning of the Miocene , the climatic conditions favored bog vegetation and the formation of peat. Layers of gravel were deposited on the layers of peat, sealed them airtight, and their pressure intensified the coalification process : the peat gradually turned into lignite . In the main seam group of the Ville there are brown coals up to 70 meters thick. In the last phase of the Miocene, the seams of the Inden strata formed over the Rurscholle in the western district . In the Pliocene , no seams formed, instead the area became increasingly tectonic . The basin broke into three clods along two main fracture lines (Rurrand and Erftlinie), which in turn formed smaller terrain jumps and relay fractures. These clods, sloping to the north, sank to different degrees and tilted to the east. The lignite layers of the Erftscholle are covered with sediments from 100 (Rurrand) to 400 meters (Erftsprung), in some cases even more to the north. The seams strike in the southern area near Brühl on the surface of the Ville Horstes or were cut in the impact slope by the Tertiary Rhine or the streams of the foothills .

History of the lignite industry

First uses (17th to 19th centuries)

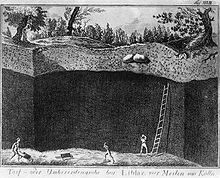

Initially, lignite was only extracted as a raw material for the color production of the Cologne umber and for the leaching of alum . Only in the late 17th century it was discovered that the wet, useless layer in the extraction of clay for ceramics - industry outsourced in Bruehl and Frechen space above the clay layer and be cleared had was combustible after drying. The landlords then had this peat-like substance ( turf ) dig up in small pits by small farmers and day laborers with hoes and spades. He was in pots to Klütten (from Low German Kluit compressed and = lumps) in the summer air-dried. The Klütten had only a low calorific value. They were used locally or sold to poor people in the nearby city. Such pits existed until the 1920s.

In the western district, lignite was found in 1819 when building a well in the village of Lucherberg near Inden . In 1826, the landlord, Karl von Goldstein, began to mine a 7.5 meter thick seam .

Beginning of the lignite industry (1850–1905)

With industrialization and railway construction (in 1859 the cathedral bridge was the first railway bridge in Cologne to connect the western Rhineland with the Ruhr area ), sales declined due to competition from cheap hard coal and reached a brief low in 1876.

At the beginning of the general upswing after the Franco-German War 1870–1871, entrepreneurs in Brühl in 1877 ( Friedrich Eduard Behrens with the Roddergrube union ) and 1878 ( Brühl union ), and in 1892 Hermann and his son Carl Gruhl with the Gruhlwerk, made coal extraction using steam-operated drainage pumps competitive and revolutionized the production of briquettes using machine presses. Such presses based on the Extersian process had been developed in 1872 in the Central German lignite mining area and were now also used in Brühl. Further briquette factories were founded in quick succession . National railway lines as well as the local railways Cologne-Frechen-Benzelrath Railway from 1893, Bergheimer Kreisbahn 1897/1899 and Hürth-Kalscheuren– Hürth-Knapsack from 1901 connected places in the Ville , opened up further coal fields or tied pits to the demand areas.

The first briquette factory in the west was built in 1888 by the Maria Theresia zu Herzogenrath union . In 1913, the Braunkohle-Industrie AG Zukunft was founded in the Westrevier as an amalgamation of various small trade unions with the aim of building a brown coal power station. In 1914, the Zukunft opencast mine and the first Weisweiler power plant went into operation.

The mechanization made further progress: 1895 was the first overburden excavator , which for the construction of the Kiel Canal had been built in the pit Donatus at Liblar used. The first cutting excavator for coal mining was used in the Gruhlwerk in Brühl in 1907 and was given the name "Iron Man". In 1909 there were four coal excavators in the 29 pits and in 1913 only three pits had no excavators. The production increased by five million tons in 1905 to 17.4 million tons in 1913. However, had sales over the traditional coal difficult. The pits competed with each other. In 1899, 19 pits merged to form a sales syndicate in order to sell briquettes as branded articles under the name Union-Brikett with uniform standards.

In the northern district between Neurath and Garzweiler, commercial mining began in 1907 with the development of the Rheingold field , initially with hoes and carts. The first scraper excavator was used a year later . Today the pit fields are grouped together in the Garzweiler opencast mine .

Start of electricity generation from lignite (1892-1918)

The first small power plant to supply the town of Frechen with electricity was built in 1892 in the Herbertskaul mine . The first power plant with an output of around one megawatt (MW) was built in 1899 in conjunction with the Brühl sugar factory at the Berggeist mine . The Berggeist power plant was taken over in 1906 by the Rheinisch-Westfälische Elektrizitätswerk (RWE) , Essen . The connection between lignite and RWE, which has now lasted more than 100 years, began at that time. In 1910, the 8 MW Fortuna power plant in the northern district was built to supply Cologne and Bergheim . In 1912–1918 the Goldenberg power plant was built by RWE in Knapsack, the first large-scale power plant based on lignite with a capacity of 90 MW in 1918 (1932: 500 MW). In addition, every briquette factory has been generating its own electricity since around 1900, which it - if not required - fed into the power grid (see also article Coal refinement ). The inexpensive energy attracted the first energy-intensive chemical plants, for example the calcium cyanamide plant in Knapsack in 1907 , which initially also generated its own electricity.

The territory between the world wars

Until the beginning of the 20th century, lignite was only of minor importance for Germany's energy and fuel supply. The higher quality hard coal was predominantly used . After the First World War, the German Reich had to cede numerous areas and lost around 40% of its best hard coal deposits. The coal mining areas that were left in place also had to pay considerable reparations . This made lignite an indispensable energy factor in all branches of industry. While before 1919 the share of lignite in electricity generation due to its low calorific value, its poor transportability and the lack of heating and transmission technology, the coal shortage associated with the assignment of territories and the self-sufficiency efforts in the Weimar Republic forced an increase a share of almost 60% of energy generation.

This resulted in a huge increase in production capacity in all German lignite regions. On this basis, Germany developed into the world's largest producer and at the same time the largest consumer of lignite in the 1920s. The statistical breakdown until 1945 distinguished the Central German Revier , the East Elbe Revier and the Rhenish Revier as the largest brown coal areas . Before the Second World War, the Central German mining district supplied around two-fifths, the East Elbe and Rhenish each around a quarter of all German lignite.

Coal production in the Rhenish lignite mining area reached 17.4 million tonnes back in 1913 as early as 1918. At the beginning of the 1920s, open-cast mining was profitable at a ratio of overburden (= overburden) to lignite of 4: 1 due to the drive for self-sufficiency and intensive mechanization become. So that could annual production to 1929 to 48.0 million tons climb. In the course of the global economic crisis , lignite production fell briefly to 39.2 million tons. Between 1933 and 1943 it rose continuously to 68.6 million tons. The focus of the funding shifted to the northern district. The first pits in the southern district closed in 1931 (Maria Glück) and 1933 (Roddergrube).

In 1920 Hugo Stinnes took over the shares in Roddergrube. This led to RWE's dominant position in lignite mining. In 1932, after taking over what was later known as Rheinbraun, the group companies provided around 60% of the workforce of a total of 12,404 workers and 70% of the 645 briquette presses in the Ville area.

The greatest increase in funding was due to the increase in electricity generation. In 1914 the two power plants at the Ville location together still had 38 MW, in 1932 the Goldenberg plant increased it to 500 MW, Fortuna to 174 MW and Frimmersdorf to 90 MW. The briquette factories generated another 11 MW of excess energy.

The chemical industry developed rapidly. In 1927 the Degussa sodium , chlorine and chlorinated lime works were built in Knapsack . The Martinswerk in Bergheim manufactured aluminum oxide and alumina hydrate.

The area under the sign of the National Socialist autarky policy

After 1933, the National Socialist self-sufficiency efforts provided further impetus for mining. The armament of the Wehrmacht and the Second World War resulted in very high energy requirements. From 1934 to 1942, the briquette production in the district increased from 9 million tons to a record number of 14.5 million tons annually. On the advice of Reich Economics Minister Hjalmar Schacht , processes for coal liquefaction were promoted and in 1937 the Union Rheinischer Braunkohlen fuel AG was founded in Wesseling.

The coal deposits of the southern district were running out, so that northern opencast mines were expanded or newly developed to meet the increased demand for coal. During the World War, coal mining and processing could only be sustained with tens of thousands of forced laborers and prisoners of war ; many Germans employed in lignite mining were called up for military service.

Union 103 civil engineering pit

During test drilling in 1927, seams north-west of Kerpen were discovered at depths of over 200 meters. Given the state of the art at the time, it was not possible to extract mining in this depth. According to the National Socialist autarky efforts, brown coal should be mined here on a trial basis. The specially founded Rheinische Braunkohlentiefbaugesellschaft began in 1939 with the sinking of two shafts between Morschenich and Elsdorf . A similar attempt by the Neu-Deutz union in Cologne-Kalk around 1850 had failed due to the high volumes of groundwater. The project initially succeeded in Morschenich: Between 1941 and 1954, seams up to 70 meters thick were mined at a depth of almost 350 meters. But the experiment was stopped as early as 1954: the geological conditions only allowed mining with extreme technical effort, which made the company uneconomical. The four main tunnels and their branch lines with a total length of eleven kilometers were reinforced with 25,000 cubic meters of concrete and 8,300 tons of steel, and the two manholes were closed. The Hambach underground mine reached these tunnels in 2014.

The area since 1945

Operational concentration

In 1960 RWE also took over BIAG of the western district. Until German reunification, the Rhenish Revier was the most important lignite region in the Federal Republic of Germany. The annual lignite production in East Germany was higher, however. Other West German lignite mining areas included the Braunschweig coal mines in Helmstedt and the Hirschberg mines near Kassel and Wackersdorf in the Upper Palatinate. In eastern Germany, lignite mining and conversion to electricity is now carried out in the Lusatian and Central German lignite districts after extensive restructuring by Vattenfall and Mibrag .

Coal refinement and power generation

The peak of briquette production was in the 1950s. At that time, more than 40 million tons of raw lignite were pressed into briquettes every year. The Carl briquette factory in Frechen alone produced around 40 million tons of briquettes from 1907 until it was closed in 1995. The use of coal in the still existing three plants of coal upgrading other hand, is low. With a capacity of 17 million tons of raw coal per year, only 10.6 million tons are currently used on average. Mainly coal dust is produced here for use in large industrial fire plants (e.g. cement works, paper mills, sugar refineries). The coal refining plant Fortuna-Nord provides plus lignite coke ago. The capacities for the production of lignite dust and coke are expanded. Due to stable lignite prices and rising oil prices , the use of lignite in industry has been economically very interesting since 2003.

The coal refining company Frechen is the only one with its 1.7 million tonnes of dry coal that still produces around half house-fire and half industrial briquettes. Nevertheless, briquette presses are still kept in the other two factories. The decline in private briquette consumption continues today. In 1990, for example, in reunified Berlin there were still almost half a million apartments with stove heating, in 2002 there were still 60,000. In 1991 1.8 million tons of brown coal briquettes were burned there, but in 2004 it was only about 25,000. In return, the share of lignite in electricity production in the district continued to increase. In 1960 it was 45 percent; in 1991, 85 percent of lignite was used to generate electricity.

Power plants

The power plants became bigger and more efficient: The Goldenberg power plant was expanded from 500 MW to 830 MW by 1950, but was replaced by a new building in 1993, the main task of which is to supply the nearby industry and the city of Hürth with process steam and district heating . Goldenberg now has an output of 171 MW. In two modern fluidized bed boilers, 1.3 billion kilowatt hours of electricity are generated annually from 1.6 million tons of coal.

In 1953/1955 the first three units of the new Weisweiler power station near Eschweiler , each with 350 MW, were built, which was expanded to 2258 MW with two units of approx. 600 MW by 1975. The use of coal in 2003 was 20.9 million tons for 18.3 billion kilowatt hours of electricity. The Inden opencast mine was opened in 1953 only to supply this power plant with coal.

The Frimmersdorf power plant near Grevenbroich was expanded from 1955 to 1970 to a total net output of 2136 MW. It has twelve blocks of 150 MW each and two blocks of 300 MW each. In 2003, its coal consumption was 22.2 million tons to generate 17.0 billion kilowatt hours of electricity.

The Neurath power plant near Grevenbroich was built from 1972 to 1976 with three blocks of 300 MW each and two blocks of 600 MW each. It consumes 18.9 million tons of coal for 16.5 billion kilowatt hours. Since January 2006, two new blocks with optimized system technology ( BoA ) with 1100 MW each have been built, which should go online in 2010. At the laying of the foundation stone on August 23, 2006, Prime Minister Jürgen Rüttgers and Chancellor Angela Merkel were also present, making the importance of the building clear. Fatal accidents on the construction site in the following years, however, set the schedule back. Both blocks had been in test operation since May and October 2011, respectively, the final commissioning with the reporting of the blocks to the EEX electricity exchange took place on July 8, 2012 (Block G) and on August 3 (Block F). On August 15, 2012, the official ceremony for the commissioning of the new units took place in the presence of North Rhine-Westphalia's Prime Minister Hannelore Kraft, Federal Environment Minister Peter Altmaier and other guests.

The Niederaußem power plant near Bergheim , planned in the 1960s as the Fortuna IV power plant , replaced the Fortuna I, II and III power plants that produced from 1912 to 1988 with two units of 150 MW each, four units of 300 MW each, and two units with 600 MW each and the 1000 MW block of a lignite power plant with optimized plant technology (BoA) set up in 2003 with currently 3864 MW gross and 3627 MW net. In 2003, coal consumption was 23.7 million tons for 24.1 billion kilowatt hours - still not taking the BoA block into account.

Large opencast mines

Raw coal production in the Rhenish Revier reached its absolute maximum in 1984 with 120.6 million tons. Annual production since 2002 has been around 100 million tons. After the expiry of the opencast mines of the Middle coalfield and their reclamation three large open pits today promote Garzweiler , Hambach and in the West area of Inden opencast mine . The connection open pit Garzweiler II was approved by the NRW Environment Minister Klaus Matthiesen in 1995 and started in 2006. All three large open-cast mines use the fan principle to mine the coal around a pivot point. The dismantling front follows the tilting front in the same direction of rotation. According to the German Brown Coal Industry Association (DEBRIV) / Federal Association of Brown Coal, coal production in the area was 99.8 million tons in 2007 . The total production in Germany was 180.4 million tons. This was 2.3% above the result of the previous year.

Germany has long been the world's largest producer of lignite: Between 1800 and 2007, 7,303 million tons were mined in the Rheinische Revier. For all German mining areas, lignite extraction amounts to 24,405 million tons during this period.

Future planning

According to the original planning, the Hambach and Garzweiler II opencast mines will be charred around 2040–2045. The Inden open-cast mine will have to stop production around ten years earlier. However, a comprehensive modernization of the Rhenish lignite power plants is currently being carried out. Due to the higher efficiency of the new power plant units, this could prolong the dismantling process. Nevertheless, it can be expected that the currently approved mining areas will be exhausted between 2050 and 2060 at the latest. In October 2013, press releases stated that the group intends to shut down eleven of its lignite-fired power plant units and to close the Garzweiler opencast mine by 2018. Obviously, the profitability of lignite-based power generation will no longer exist in the future. The group immediately denied the exit from the Garzweiler opencast mine, but the city of Erkelenz then stopped further relocation plans.

The opening up of a new opencast mine takes a relatively long time due to the lengthy approval procedures and the extensive preparatory work, including the necessary relocations, but then results in reliable electricity generation over decades.

Erp / Irresheim - Nörvenich opencast mine

Hambach II opencast mine

Furthermore, there were plans to expand the Hambach opencast mine to Hambach II, which should extend in a north-easterly direction over the communities of Elsdorf , Niederembt and Oberembt to Margaretenhöhe in an easterly direction.

To the north-east of Elsdorf-Angelsdorf , Rheinbraun (now RWE Power) began to acquire some land in the 1990s in order to build the Neu-Etzweiler relocation site there from 1994 to 2001 . A realization therefore seems unlikely.

Floating solar park

In May 2020 Meyer Burger , a manufacturer of solar cell production machines, presented an idea for a solar park in the Hambach opencast mine . This would generate electricity with an output of around ten gigawatts, which roughly corresponds to the output of the coal-fired power plants Weisweiler, Neurath, Niederaussem and Frimmersdorf, which are now dependent on the opencast mines. Considerations for a later use of the gigantic area with an area of 50 square kilometers include the flooding to the lake landscape.

The idea received support from the physicist Uwe Rau , RWE Power AG and the Minister for Economics, Innovation, Digitization and Energy of North Rhine-Westphalia, Andreas Pinkwart, among others .

Political planning and decision-making processes

The plans for lignite mining and the related questions and problems are negotiated in the lignite committee at the Cologne district government and decided by the state government as a lignite plan. The 40-strong lignite committee is made up of representatives from the municipalities, the regional councils of Cologne and Düsseldorf, and functionaries from business and employee organizations. The environmental associations repeatedly complain about the close connection between local and state politics on the one hand and RWE on the other. That makes the lignite committee a very one-sided decision-making body in the eyes of the environmental associations. The approval for the Garzweiler II opencast mine, which was granted by the SPD government shortly before the 1995 state elections, was particularly controversial. A total of 19,000 objections had been submitted to the Cologne district government. This made the subsequent formation of a red-green government coalition in NRW difficult. Compromises aimed at a review of the lignite plan, but ultimately did not call the open pit project into question. In 2004 the RWE affair again put the RWE Group's “political landscape conservation” in a negative light.

Ecological and social issues

The problem of dismantling is varied. Here are the most important problem areas:

Drainage

In order to keep the opencast mines dry, it is necessary to pump out the groundwater to depths of more than 500 meters. As a result, creeks and wetlands fall dry. T. be artificially irrigated. In addition, the structure of the soil is changing, and extensive soil subsidence occurs, sometimes at distances of 15 to 20 kilometers.

The groundwater body regenerates very slowly at great depths. Critics of the opencast mines also accuse the operators that the knowledge of the groundwater flows at greater depths is not comprehensive enough. In 1997, for example, water burst into the Hambach open-cast mine, during which water at 40 ° C flowed into the open-cast mine for several months. Experts were able to dispel fears that this water might communicate with the Aachen thermal springs .

Due to the lowering of the groundwater , trees and crops lose their connection to the groundwater. There are also negative consequences for arable farming.

Particulate matter pollution

Measurements by the State Environment Agency on the edge of the opencast mines have shown since 2004 that the fine dust caused by mining is well above the EU limit values. It remains to be seen whether the countermeasures initiated by RWE Power will be effective. The proportion of fine dust from the Hambach opencast mine is given by the State Office for Nature, Environment and Consumer Protection (LANUV) in North Rhine-Westphalia as 25%. 71% are attributed to the general background exposure. For 2004, the LANUV NRW did not list a complete measurement year for exceeding the fine dust limit value of 50 µg / m³. 35 exceedances per year are permitted. The permitted annual mean value of 40 µg / m³ is clearly undercut for 2004 with 30 µg / m³ at the Niederzier measuring station. The new limit values came into effect on January 1, 2005. Under the leadership of the Cologne District Government , an action plan to reduce particulate matter in the vicinity of the Hambach opencast mine was drawn up, which came into force on September 29, 2005. RWE Power has started implementing measures to reduce particulate matter. According to the LANUV NRW, 35 exceedances were recorded in Niederzier in 2006. This corresponded to the days allowed to exceed the limit. The annual mean value for this period has fallen to 29 µg / m³.

Measures to reduce fine dust in the opencast mines:

- Planting trees on the spoil side

- Promotion of grass growth on fallow areas (e.g. sowing)

- Fixing the driveways and the underground of the conveyor systems

- Sprinkling the upper level on the excavator side and the end slopes

- Sprinkling of the coal bunker and coal strips as well as the overburden during the removal

Mercury emissions

The operation of lignite power plants is associated with high levels of mercury . In 2011 and 2012, the Neurath and Niederaussem plants each emitted 497 kilograms of the neurotoxin into the atmosphere each year.

Climate change

Greenhouse gas emissions

The burning of lignite in the district's power plants also emits large amounts of the greenhouse gas carbon dioxide, which is the main cause of global warming . The power plant with the highest proportion of emissions in Germany is the Frimmersdorf power plant with 1270 grams of CO 2 per kilowatt hour. The Weisweiler , Neurath and Niederaussem plants occupy positions four to six after two East German plants with 1180, 1150 and 1119 grams per kilowatt hour. By way of comparison: The power plant ranked 30th among the “dirtiest” lignite power plants in Europe emitted 950 grams per kilowatt hour. The values for hard coal power plants are approx. 100 grams per kWh lower. The average value in the German electricity mix , including systems with wind, water, nuclear power and photovoltaics, was 530 grams per kilowatt hour in 2006. The total emissions in 2006 were 27.4 million tons of carbon dioxide for the Niederaussem site, 19.3 for Frimmersdorf, 18.8 for Weisweiler and 17.9 million tons for Neurath. Together, this makes up over 27% of the CO 2 emissions in North Rhine-Westphalia. The political disputes over the approval of the connection mine Garzweiler II put the RWE Group under public pressure to invest large sums in more efficient power plant technology. In the Weisweiler power plant, investments totaling 150 million euros are said to have increased efficiency from 36 to 40 percent by 2006. The BoA power plant in Neurath cost around 2.6 billion euros. The BUND described this in 2006 as a "zero-sum game in terms of climate protection policy"; A lot of coal will still be burned in the new power plant.

Residual holes

Backfilling the three large open-cast mines currently in operation is costly, but required by law. Due to the enormous volume of the lignite extracted and the overburden deposited on the outer tip, the operator no longer wants to fill it in completely. This could save RWE around EUR 250 million. At times, the Hambach opencast mine was referred to as one of the largest man-made holes on earth because of its depth of up to 470 m.

The Sophienhöhe, the largest outer dump, has a volume of around one cubic kilometer. These quantities cannot simply be dumped back into the mine holes. Therefore it is planned to fill the remaining holes with water. The dimensions of these lakes would be considerable: the lake of the Inden opencast mine would have been B. the size of the Tegernsee . The remaining lake of the Hambach opencast mine would only be exceeded in terms of water volume in Germany by Lake Constance , but would be significantly deeper than this. Since these lakes have no natural inflow and outflow, there is currently a discussion about how these large amounts of water can be channeled into the holes. It is still unclear what effects these large bodies of water will have on the Rhineland's climate. It will take some time before the lakes are completely filled, according to current estimates until the year 2090.

Some neighboring communities are hoping for an up-and-coming tourism. Experience with the Central German lignite mining area in the Halle - Leipzig area with the remaining holes already flooded shows that tourism there increased three to five years after the flooding began. Backfilling via a belt would only take 20 years and could open up new arable land. According to critics, the creation of large inland lakes brings hardly any economic or agricultural benefit compared to backfilling or at least partial filling with the construction of a few smaller lakes and deprives large areas of the design and disposal of future generations.

Flora and fauna

Due to the fertile loess soil, the area was used for arable farming in some areas before lignite mining and the natural vegetation was therefore relatively far from its natural state. The deforestation of old forests such as the Hambach Forest should, as has already happened in many areas, be compensated for by new plantings. But it takes a few decades for the young trees to grow and for a stable plant community to be established again . To assess the quality of the current plant inventory, the diversity of species, the presence of pointer species and red list species are taken into account. There was a surprising diversity of native species for the locations examined. In the case of the Sophienhöhe, which was only afforested twenty years ago, this diversity is attributed to the fact that the forest plant society is still developing. What is worrying, however, is that the mining of lignite will result in the loss of locations whose waterlogging required special growth conditions for the plants. As a result, the plant species that specialize in this and the richness of species in the region will decline. One of the endangered animal species is the Bechstein bat, which lives in the area of influence of the Hambach opencast mine . The planned relocation of the A 4 will cut through its district network and make costly “overflight aids” necessary.

Relocation

Lignite mining destroys large agricultural areas during the mining era and today requires the relocation of entire villages with a total of several thousand people. The opencast mine operators rely on German mining law . Farmers are often relocated over 30 kilometers or more in the vicinity of freshly recultivated arable land, an undertaking that is associated with many conversion difficulties and adjustments to the new agricultural conditions. Resettlement in the localities is even more complex. Since the old towns are completely leveled in one fell swoop, new residential areas have to be planned and developed in a timely manner in remote areas of the municipalities and cities, and thus entire districts have to be recreated. The innovation also creates opportunities: the infrastructure is modernized and larger settlement units can be created. By relocating grown villages, the residents not only lose their home, their social fabric is also lost. RWE is therefore endeavoring to bring the residents of one part of the community to a new settlement, for example at Berrenrath and Mödrath in the 1950s. The village community is to be preserved through the resettlement as closed as possible. Unfortunately, this does not always work satisfactorily. Commuters, for example, whose daily commute to work is much longer, prefer to settle in other locations closer to work. While only 60% of the residents of Garzweiler moved together at the end of the 1980s , when the Otzenrath district of Jüchen, which was finally demolished in 2006, was able to relocate around 80% of the old local population to the new location. The village community can live on in the new location mainly from social ties that have been saved. The clubs and the festival culture are of central importance so that those affected perceive the resettlement as "successful".

Again and again there are disputes about the compensation amounts. Since RWE Power uses the current value of the building as a basis, the compensation is often insufficient to rebuild a house of roughly comparable size, especially not if modern building standards have to be taken into account. The size of the surrounding garden land is also rarely reached again.

The relocation is often preceded by gradual desertification. Locations that are affected by the dismantling plan often record a decline in population long before that. Because of the poor business prospects, no new industries or commercial enterprises are settling here, companies that are already established no longer expand and try to relocate the company to more developable areas in advance of the official relocation. This reduces the number of jobs in the community. The young population, which is already difficult to bind to the place, is migrating to more promising business locations and residential areas with more attractive leisure activities. This development is still in that rejected the mine-planning areas new building permits because of the unfavorable prospects early and reinforced land - surveying are often frozen. These phenomena slow down the development of the places and gradually let them become deserted. However, this improves the initial situation for lignite mining: the number of households to be relocated is reduced, the compensation payments are lower and at the same time the price of land in the mining area is falling.

Loss of archaeological sites

What the excavators dig up is irretrievably destroyed. This also applies to archaeological sites. The responsible Rhenish Office for Archaeological Monument Preservation maintains a branch in Titz, where scientists, excavation technicians and excavation workers are employed for the individual opencast mines. However, only about five percent of the known sites can be systematically examined with this. The polluter pays principle otherwise applicable in North Rhine-Westphalia does not apply here. In the course of the open-cast lignite mining, numerous important archaeological researches and discoveries were made, which, however, were usually only able to tap a fraction of the actual existing sources.

Possible mountain damage

Experts from the geological service warn of possible mountain damage in the surrounding region. There is also a warning against the danger of wet cellars, as the groundwater level will rise again as soon as RWE stops operating the opencast mine. Experts suspect that in the next 40 years there will be damage amounting to 180 million euros from mountain damage caused by RWE.

External costs of lignite

The emission of carbon dioxide, nitrogen oxides , mercury , sulfur oxides , dust and noise , land consumption and the impairment of surrounding waters result in external costs in lignite extraction and electricity generation . These are estimated by the DIW at 6 to 12 ct / kWh. If these costs were included in the electricity price , according to the DIW, generating electricity from coal would be uneconomical.

Tourist and monument preservation development of the area

Similar to the recultivated lake landscape in the Ville , the high tipping areas, such as B. the Vollrather Höhe , Glessener Höhe and the Sophienhöhe opened up for leisure activities with road networks. On the Goltsteinkuppe near Lucherberg at the Inden opencast mine there is an observation building, the Indemann , which opened in August 2009 and cost more than 5 million euros . The history of the lignite mining area has so far been presented as a museum in the RWE information center in Paffendorf Castle . From here, various stations and viewpoints in the area are connected via a road of energy . The German Mining Museum in Bochum presents the Rhenish mining area in its own exhibition area. In view of the foreseeable end of lignite mining, the Rhineland Regional Council endeavors to record industrial-historical monuments, workers' settlements, the last briquette factories or large technical devices in terms of monument preservation, if necessary to preserve them and to prepare their future networked presentation in the district in the form of a lignite road .

Under the remaining industrial architecture in the district, the towering, narrow buildings of the briquette factories are particularly noticeable. But it is difficult to reconcile monument protection interests with other interests of the municipalities. In 2000, for example, the attempt to place the Carl briquette factory in Frechen under monumental protection failed in order to be able to show the production process of a historical plant as an example. The city received three gutted buildings out of ten parts of the building as part of a new district and commercial center.

Recently it has also been suggested that the artificial landscape, which the opencast mine created with enormous use of technology, be preserved (in part) and made accessible as a leisure and adventure landscape. This proposal is understood on the one hand as a strategy for use during the long operating times of the opencast mines (40 years in the Hambach opencast mine), and on the other hand as an alternative to the previous model of "natural" recultivation.

See also

- List of high tips in the Rhenish lignite district

- List of closed mines in Germany

- List of German lignite opencast mines

- List of excavated towns

- List of the demolished church buildings in the Rhenish lignite district

- Foundation to promote archeology in the Rhenish lignite mining area

literature

- Jürgen Bartel, Reinhart Zschocke: The Ville and the Cologne lignite area . In: Emil Meynen u. a. (Ed.): Kölner Bucht and adjacent areas . (Collection of Geographical Guides, Vol. 6). Bornträger Brothers, Berlin / Stuttgart 1972, ISBN 3-443-16002-6 .

- Jakob Baumann, Bernd Wiese: The Erftkreis - nature, people, economy . (Geostudies 10). Self-published, Cologne 1986, DNB 891293248 .

- Walter Buschmann , Norbert Gilson, Barbara Rinn: Brown coal mining in the Rhineland , ed. by the Landschaftsverband Rheinland and MBV-NRW , 2008, ISBN 978-3-88462-269-8 .

- Gerhard Curdes : A park landscape of the 21st century between Cologne, Aachen and Mönchengladbach: dream or chance? In: Julian Wékel (ed. On behalf of the German Academy for Urban Development and Regional Planning): New Landscapes - For the future handling of open space. Preparatory contributions to the 2004 annual conference in Münster. Berlin 2005, ISBN 3-9809331-2-1 .

- Holger Kaiser, Frederik Petersohn: Opposition in the state parliament of North Rhine-Westphalia: The CDU parliamentary group and the "Garzweiler II" open-cast lignite mine in the 12th electoral period (1995-2000). Lit, Münster / Berlin / London 2007, ISBN 978-3-8258-0167-0 .

- Arno Kleinebeckel: Lignite company. History of a raw material, a district, an industry in the Rhineland. Greven, Cologne 1986, ISBN 3-7743-0225-1 .

- Landschaftsverband Rheinland, Rheinisches Amt für Denkmalpflege (Ed.): Cöllnisch Umbra. The Rhenish lignite mining area as a landscape of monuments . Petersberg 2002, ISBN 3-935590-41-5 .

- Wolfram Pflug (Hrsg.): Brown coal mining and recultivation . Springer, Berlin / Heidelberg 1998, ISBN 3-540-60092-2 .

- Ruhrland Museum Essen (Hrsg.): Period of brown coal . Pomp, Essen 1993, ISBN 3-89355-091-7 .

- The Erdfresser - Opencast Mine - Fortuna Garsdorf . Geo (magazine) 12/1976, pages 78–96. Publisher Gruner + Jahr, Hamburg.

- Johann Paul: Risk debates about underground mining in the Rhenish lignite mining area . In: Technikgeschichte, Vol. 65 (1998), H. 2, pp. 141-161.

Web links

- Wisoveg economic, social and traffic events in the Rhineland with site and topic pages lignite, railways etc.

- RWE Power power plants and opencast mines

- Achim Schumacher, Ulf Dworschak, Jochen Weglau u. a .: Recultivation in the Rhenish lignite mining area , excursion guide II: Opencast mines (short) history + recultivation

- Project Rheinische Strasse der Lignohle (PDF file; 2.69 MB)

- critical side of the BUND on the use of lignite

- Briquette production in the Rheinische Revier

- Google Books. Heinrich von Dechen : Description of the Kuhlen- and Tummelbaues in the Brühler brown coal mining area in Archiv für Mineralogie, Berlin 1831, vol. 3, p. 413-536 (scroll or adjust above !!)

- From the Digitalis project of the Univ. to Cologne: Conrad Heusler: Description of the Brühl-Unkel mining area and the Lower Rhine lignite basin, Bonn 1897 (with numbered directory and map of the pits)

- Collection of Mining Regulations of the Arnsberg District Government, Department 6: Mining and Energy in North Rhine-Westphalia , continuously updated.

Individual evidence

- ↑ Most important domestic energy source. ( Memento from January 12, 2012 in the Internet Archive ) RWE, Presse & News, Special Brown Coal, accessed on March 27, 2010.

- ↑ WAZ, North Rhine-Westphalia dares to step out of lignite , March 29, 2014

- ↑ Garzweiler II lignite plan of the Cologne District Government - Annexes, Annex 6: System sections through the Venloer Scholle ( Memento from November 4, 2013 in the Internet Archive ) (PDF file; 1.96 MB), last accessed on February 24, 2010.

- ↑ see article in the Dutch Wikipedia

- ^ Arno Kleinebeckel: Lignite company. History of a raw material, a district, an industry in the Rhineland . Cologne 1986, p. 117 ff. And P. 155.

- ↑ Ursula Bischoff: The influence of mining traditions and large-scale industrial developments on the social structure and mobility of the lignite workers in Borna. Dissertation, Humboldt-Universität zu Berlin, 2000, p. 76. Humboldt-Universität zu Berlin, accessed on September 20, 2019.

- ↑ Georg Balzer: The European coal industry with special consideration of the international working time problem. Verlag Funk, 1934, p. 55.

- ↑ Ferdinand Friedensburg: The mountain economy of the earth. Verlag Ferdinand Enke, 1965, p. 135.

- ↑ Eckart Schmitt, Dietmar Gohl, Jürgen Hagel: Handbook of Geography. Germany. List-Verlag, 1975, p. 126.

- ↑ Erich Obst: General economic and transport geography. Walter de Gruyter, 1965, p. 78.

- ^ Arno Kleinebeckel: Lignite company. P. 155.

- ↑ Briquette production in the Rhenish lignite district .

- ↑ "Forced labor" in the Rhein-Erft-Rur region ( Memento from June 10, 2007 in the Internet Archive ).

- ^ Coenen, Manfred: Rheinische brown coal. Employment of foreigners and forced labor in the Rhenish lignite industry, in: historicum.net, URL: historicum.net ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. (Accessed Oct. 2009)

- ^ Arno Kleinebeckel: Lignite company. History of a raw material, a district, an industry in the Rhineland. Greven, Cologne 1986, p. 172 ff.

- ↑ aachener-nachrichten.de: A mine is being excavated in the open pit , accessed on January 18, 2015

- ↑ https://web.archive.org/web/20130822111537/http://www.ksta.de/region/das-brikett-mit-dem-hammer,15189102,13762018.html

- ↑ Rheinischer Merkur No. 46, 2006.

- ↑ Cöllnisch Umbra. The Rhenish lignite mining area as a landscape of monuments. ed. v. Regional Association Rhineland - Rhenish Office for Monument Preservation. Petersberg 2002, p. 85.

- ↑ DEBRIV, quoted from the Kölner Stadtanzeiger from January 11, 2007.

- ↑ Garzweiler: Erkelenz threatens RWE with stopping the resettlement

- ↑ Location of Neu-Etzweiler, Elsdorf, Nieder- and Oberembt northeast of Hambach I. OpenStreetMap , accessed on June 24, 2010 .

- ↑ Radio Rur: Mega solar park in the open pit? Retrieved May 11, 2020 .

- ↑ Hambach opencast mine: soon a 10 GW floating solar park? In: CleanThinking.de. May 6, 2020, accessed May 11, 2020 .

- ↑ a b Energy researcher Rau: Solar park can be realized in Hambach opencast mine. In: CleanThinking.de. May 11, 2020, accessed May 11, 2020 .

- ^ Jörg Abels: Hambach opencast mine: Sophienhöhe remains untouched. Retrieved May 28, 2020 .

- ↑ Radio Rur: Think of the younger generation. Retrieved May 28, 2020 .

- ↑ Brown Coal Committee .

- ↑ Eusebius Wirdeier, Johannes Nitschmann: Garzweiler or how the brown coal connection burns an entire region. Cologne 1995, p. 19

- ↑ Holger Kaiser, Frederik Petersohn: Opposition in the state parliament of North Rhine-Westphalia, the CDU parliamentary group and the open-cast lignite mine "Garzweiler II" in the 12th electoral period (1995-2000). Münster / London / Berlin 2007, p. 39 ff.

- ↑ Consequences of the lowering of the groundwater in the Moerser Land. Effects on the interaction structure of geofactors and agricultural use , Manfred Hofmann

- ↑ https://web.archive.org/web/20150923195205/http://www.bund-nrw.de/fileadmin/bundgruppen/bcmslvnrw/PDF_Dateien/Themen_und_Projekte/Braunkohle/Braunkohle_und_Umwelt/BraunkohleundKlima09_2007.paschdf (PDF) .

- ↑ fr-online.de ( Memento from October 9, 2014 in the Internet Archive ) Frankfurter Rundschau, May 2, 2014.

- ↑ The data was published by the European Commission as part of the Community Independent Transaction Log ( emissions trading ). Quoted in: Kölner Stadt-Anzeiger from April 6, 2007.

- ↑ https://web.archive.org/web/20150923195213/http://www.bund-nrw.de/fileadmin/bundgruppen/bcmslvnrw/PDF_Dateien/Themen_und_Projekte/Braunkohle/BraunkohleundKlima09_2007.pdf Brown coal and climate protection (PDF).

- ↑ www.bund-nrw.de: BoA power plant blocks climate protection (PDF; press release on the occasion of the laying of the foundation stone for the BoA power plant in Neurath)

- ↑ a b G. Kasperek: Landscape ecological aspects of lignite mining and reclamation in the Rhenish mining area. In: Geographical Rundschau. 53 (2001) H. 9.

- ^ RWE Power (ed.): Hambach opencast mine . June 2013, p. 9 ( online [PDF; 1.3 MB ; accessed on September 19, 2018]): "With 1.1 billion cubic meters of overburden, the Sophienhöhe was heaped up on former arable land from 1978 to 1991."

- ↑ https://web.archive.org/web/20131104193537/http://www.bund-nrw.de/fileadmin/bundgruppen/bcmslvnrw/PDF_Dateien/Themen_und_Projekte/Braunkohle/Inden/StellungnahmeBkPlRestsee_Mai2007.pdf Statement on the preparation process. BUND, May 2007, accessed on January 10, 2012 (PDF file; 260 kB).

- ↑ Bat should stop the Autobahn. In: Heinsberger Nachrichten. February 22, 2008.

- ↑ https://web.archive.org/web/20080222052025/http://www.uni-hamburg.de/volkskunde/Texte/Vokus/2002-2/metzger.html Dream or Trauma? On the importance of space and living space for resettlers in the Rhenish lignite district.

- ↑ https://bodendenkmalpflege.lvr.de/de/ueber_uns/aussenstellen/as_titz.html

- ↑ https://web.archive.org/web/20130419232713/http://www.bodendenkmalpflege.lvr.de/titz/ bodendenkmalpflege.lvr.de

- ↑ [1]

- ↑ F. Siegmund / D. Scherzler, Archeology and Monument Preservation in North Rhine-Westphalia 2014 - one year after the struggle against funding cuts and for a better legal basis. Archaeological Information 37, 2014, 153-180. - [2]

- ↑ 180 million euros in damage to the house every year. In: Rheinische Post. February 6, 2012, accessed December 12, 2013.

- ^ German Institute for Economic Research (DIW): Expert opinion on the necessity of updating the Nochten open-cast lignite plan in terms of the energy industry. P. 15. (PDF; 521 kB).

- ^ Regional Association Rhineland - Rhenish Office for Monument Preservation (ed.): Cöllnisch Umbra. The Rhenish lignite mining area as a landscape of monuments. Petersberg 2002.

- ↑ dubtown.de ( Memento from September 25, 2010 in the Internet Archive ) see also: Walter Buschmann: Briquette Factory Carl in Frechen. Historical use and status of conservation efforts. In: Cöllnisch Umbra. 2002, pp. 59-66.

- ↑ Thomas Knüvener: Landscape of the difference. ( Memento of the original from June 8, 2009 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. In: archimaera. Issue 2/2009.