Construction techniques in ancient Egypt

| Build in hieroglyphics | |||||

|---|---|---|---|---|---|

qed qd build |

|||||

| Making of adobe bricks, tomb of Rechmire ( TT100 ) | |||||

With the building techniques in ancient Egypt are meant the technical aspects of building in ancient Egyptian architecture . Basically, three different construction methods can be distinguished: constructions made of plant material , adobe construction and stone construction.

In prehistoric times , wood and palm trunks hung with reeds or papyrus mats were used as skeletons for residential buildings. Since only very sparse archaeological remains of this type of construction are available, conclusions must be drawn from precipitation in later types of construction, the reproduction in early characters and the buildings that are partly still in use today as simple types of construction (e.g. for temporary shelters and stables).

In addition, a construction method developed from the air-dried mud brick that decisively determined the development of Egyptian living culture. The Egyptian mud bricks were made from the clayey Nile mud . This has been the most important building material since the Naqada-I period . This " economical " and climatically advantageous construction method made up the main part of residential buildings and at times also of sacred buildings . Although only the stone buildings of many ancient Egyptian cities are still preserved, there are also numerous archaeological remains of this type of construction, which provide a good picture.

In contrast, stone construction remained a luxury for buildings with eternal claims such as graves and temples , with the intention of "ensuring the continued existence of the divine kingdom and the divine powers". Stone construction was introduced in Egypt around the 1st dynasty . The highlights of the stone construction were the Djoser district in Saqqara at the beginning of the 3rd dynasty , the pyramids of Giza from the 4th dynasty and the stone temples in Luxor from the New Kingdom .

In the last few decades, new analytical methods in the natural sciences have led to a renewed interest in Egyptian materials engineering and technology. Completely different technological and socio-economic questions are asked for the archaeological sources . For example, new petrographic methods made it possible to determine the origin of the rocks that were used for the respective buildings much more precisely, which also provides new information on the organization and technology of the building. In spite of this, the numerous archaeological sources in particular are often not yet fully evaluated with regard to individual aspects. For example, the Egyptian door is very well documented both archaeologically and literarily, but there is still no newer publication on it that includes all excavation reports and temple and grave publications.

Wood mat construction

Origin and development

Even if only very sparse archaeological remains of the earliest forms of construction are available, conclusions can be drawn from precipitation in later forms of construction, the reproduction in early characters and the buildings that are partly still in use today as simple forms of construction.

The most original form of construction are probably round buildings, both as residential buildings and as temples, although rectangular buildings have been in use since the pre-dynastic period. Prehistoric round and oval buildings in Merimde , Omari and Maadi were wooden post constructions that were covered with reed mats. In addition, there were also found silos that were half sunk into the ground and provided with clay walls. According to Manfred Bietak , it was only the introduction of the cuboid clay brick and the more sophisticated architecture of the dynastic period that led to the replacement of the round buildings by the rectangular shape. The oval and rectangular-oval floor plan should be viewed as a transition form.

The development from wood mat construction (skeleton construction) to brick construction (solid construction) is related to the need for permanent residences of the settling nomads. One can initially assume a mixing process and the coexistence of essentially different designs. For example, wooden mat structures were also provided with mud patches. One will have to reckon with comparable building techniques and forms until the assumed split into brick or wood mat construction has taken place.

The old construction was never completely abandoned. In historical times it was partly found in the cabins on ships and was still used by shepherds for temporary shelters and stables.

Construction

The load-bearing frame of the wooden mat construction consisted of thin poles stuck vertically into the earth, which were connected to one another by cross bars. Such rods appear z. B. on representations of chapels of the gods. The shape of the "tent poles" in Thutmose III's permanent structure. in Karnak ( Ach-menu ) there should be a transfer of similar poles, namely tent poles, in stone and their striking shape could say something about the type of poles used in mat construction: “The tent pole column tapers downwards, the peculiarly shaped capital is with leaves painted, the tips of which point downwards. It is therefore a matter of plant stems that are buried with their upper end in the earth and their root knot (capital) turns upwards because it is so strong that tenon connections with cross bars are possible. ”The archaeological evidence of round post holes also matches this prehistoric buildings for example in Maadi and Merimde.

For the wall, the round huts mainly used vertical and horizontal plant stems that were tied up. In the simplest version, it was oval windshields that were open on the leeward side and at the top. Palm branch ribs or cane stalks were certainly particularly suitable as a lattice framework due to their natural curvature. A basket-like dome could be placed over the former as roofing, while mats or a grass or straw cover could be placed over the latter. In the early representations, a vertical or rectangular line pattern seems to represent the pipe or braided mat walls, while a diamond-shaped pattern probably indicates the supporting grid of the curved roof structures.

The wooden mat structures probably had a flat or curved roof. Both forms were imitated in rock tombs, which have both flat and curved ceilings and are painted with mat patterns and seem to be supported by painted strips or sculptured beams . This roof structure appears in the pole frame of the cabins of ship models, which were probably erected in the same way as the mat huts on land.

Monumental copies of this type of construction are z. B. in the Djoser complex in Saqqara implemented in stone. In the blue chambers, the mats are clearly represented by faience tiles and the entrances to the mat structures made of rolled up or rolled down mats are also shown in this form. We also have representations of such buildings on cylinder seal impressions of the 1st Dynasty. It is the oldest recognizable form of the Upper Egyptian palace or, more precisely, its original form, which Ricke, in contrast to the Mattenpalast, calls the "royal tent".

The form of the sanctuary of the Upper Egyptian heraldic goddess Nechbet , of which remains were probably found in Hierakonpolis , can be derived from the hieroglyphic depiction as Per-wer (i.e. “sacred building / residence of the great”) . According to Dieter Arnold, it is perhaps a "replica of an elephant or rhinoceros embodied in the king, constructed of wood and matting." There are at least three to four tusks on the front, a curved roof, a tail hanging down at the back and several on the front Façade towering masts typical. Perhaps the Per-wer is also shown in the “maison du sud” of the Djoser district. The lower Egyptian counterpart to the Per-wer (as a symbolic representation as a sanctuary in general) is the Per-nu, the sanctuary of the goddess Wadjit . Hieroglyphically, the sanctuary is depicted as a construction made of wood, a thatched roof and mat hangings, and the granite sarcophagi of the Middle Kingdom also reproduce a per-nu by representing a vaulted lid and raised walls with a longitudinal barrel and a side collecting wall. Until the late period, it symbolically represented Lower Egyptian sanctuaries in general in large Theban tombs. It may have been depicted in the “maison du nord” in the Djoser district.

Individual shapes such as door roll, coving and round bar, cheker frieze , round beam ceiling and shapes of various plant pillars also have their origin in wooden mat construction.

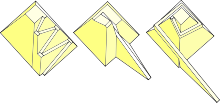

Sed festival chapels in stone in the Djoser district ( Seh-netjer type (see God's shadow ) on the left and Per-wer type on the right)

Brick construction

Composition of the building material

The Egyptian mud bricks are made up of a brown or black-gray mixture of Nile mud, sand , plant fibers or small stones and broken bricks; occasionally there are also yellowish bricks with a strong admixture of clay . According to Spencer, the most common type of brick is made from mud , chopped up straw, and a small addition of sand. But there are big differences, up to sand with gravelly earth. Regarding the optimal composition, Spencer notes: “Experiments with brick making today have shown that the best mix of the ingredients is one cubic meter of mud with a third of that amount of sand, plus 20 kg of straw. Bricks with fine sand, if they are well dried, can withstand a pressure of the order of 52 kg / cm², while bricks with the same amount of sand but also with straw are less strong. "

The fertile Nile mud from the volcanic areas of Ethiopia , which was washed ashore during the Nile floods in Egypt, contains a high proportion of clay and clay. Loam and clay act as binders to hold the other portions of the bricks together. Since the Nile mud shrinks by about 30% as it dries, sand and straw in the brick prevent the formation from breaking. Structures with a high proportion of aggregates (sand, straw) are stronger when dried, but more susceptible to erosion from the rain. Those with a high clay content are more resistant to water and erosion, but less stable. There was no standard composition for the clay bricks, but rather strong regional differences. One can also assume that no special building material compositions were used for special projects or uses, but that the material directly adjacent to the respective building site was used. Nevertheless, the workers are likely to have developed an intuitive feeling for which soil was particularly suitable and what the corresponding composition had to be.

development

Perhaps through the new, sedentary way of life, a new building material, the Nile mud, was decisive, which decisively determined the development of Egyptian living culture. The path from mat construction to brick construction possibly led through various intermediate stages, some of which can still be recognized in the simple construction designs of today's Fellach, or there was a mixing process of the various types of construction from the beginning. Instead of the mats in the walls, increasingly buried pipe or straw walls were built, which were thickly coated with mud on both sides to protect against heat and cold.

The forerunner or subsidiary form of the air-dry brick is the so-called loam patze. The walls, which were coated with Nile mud, were replaced by free-hand shaped, irregular mud patches, to which cut straw was added for better cohesion. The walls built from it were slightly sloped for structural reasons, which has been preserved in architecture, for example, on the walls of the pylons and mastabas , although this type of wall was no longer necessary in the actual brick building. When the clay paws were given regular, angular shapes, the clay brick was invented. Presumably, the first bricks were made in a manner comparable to today's peat cutting , by cutting them out of an even layer of mud.

In one of the predynastic tombs in el-Amrah , about 10 km southeast of the royal tombs of Abydos , a clay model was found that represents a house, the walls of which are apparently layered from clay sparrows. No roof has been preserved for this, but it was certainly covered with branches on which layers of thin twigs and rubbed mud were laid.

It is difficult to determine when exactly the brick began to be used in Egypt. For the 1st dynasty, the mastabas of Saqqara and Naqada have already been proven to be a highly developed adobe architecture, which certainly required good knowledge and a certain amount of experience with the building material. However, there is little evidence of the time before that. Perhaps influences from Mesopotamia also helped to promote the new building method in the first dynasties. From the representations on pallets, ivory tablets and clay closures, it can be concluded that the Egyptians used bricks on a large scale as building material as early as the Nazada II period. Representations of walls that could only be built from bricks and had to be of a certain size and thickness show, for example, the Tehenu palette and the Narmer palette, which presumably date from the Naqada III period.

Archaeological evidence of brick buildings from predynastic times was only in Naqada, where Petrie discovered a town from the Naqada I-II period. At that time people were already familiar with the construction of adobe buildings and the graves were occasionally lined with bricks, albeit with a certain degree of negligence. The size and quality of the bricks differed greatly: from poorly manufactured shapes measuring around 28 × 11.5 × 7.6 cm to more regular shapes around 28 × 15.2 × 10.2 cm. A thick wall in the northern part of the city was probably part of a fortification. Unfortunately, no specific architectural details of this city are available, but Petrie's description suggests that the ruins were of considerable size.

From the first dynasty, the monumental brick architecture flourished: Palaces, fortresses of the gods and valley districts in Abydos, Hierakonpolis, Memphis and in the Delta and Mastabas with complicated niches in Naqada, Abydos, Bet Challaf and Sakkara. As early as the 1st Dynasty, and especially the 12th Dynasty , huge brick fortresses were built in Egypt and Nubia. From the Middle Kingdom onwards, the temples of the gods were increasingly built in stone or converted, but brick temples continued to exist or ancillary facilities such as walls and magazines were still built in bricks. Particularly in the late period, temple walls were built with enormous dimensions with wall thicknesses of up to 30 m and side lengths of 600 m. From Sesostris II onwards, the cores of pyramids were piled up with clay bricks.

Fired clay bricks were rather uncommon until Roman times, but the manufacturing technique and effect of such bricks must have been known very early on. Long bars of baked clay were already used for baking ovens in the predynastic Abydos and Mahana. While these cannot be called bricks, they show that people were already aware of the fact that mud bricks could be hardened by firing. This effect could certainly also be observed with (intentional or unintentional) fires in houses. Fired bricks were first used as paving in the Middle Kingdom in the Nubian fortresses of Buhen and Schalfak. These 30 × 30 × 5 cm large, fired paving bricks were more durable and weather resistant. Baked brick pavements were also found in Al-Lahun . However, they were only increasingly used from the 21st dynasty and were only used from the 2nd half of the 1st century BC. Commonly used in BC and have only been replaced by artificial stone and concrete in the present.

The format of the tiles varied both temporally and locally, which makes dating difficult due to the size. Nevertheless, according to Spencer, it can be used for dating under certain conditions, but it should be noted that the same size could occur at different times. Spencer distinguishes two groups in terms of size: large bricks for important public buildings and small bricks for houses and smaller private graves. The formats occasionally overlapped. Large “official” bricks have already been found in houses - mostly as re-use from official buildings. It is more difficult to assess small bricks in official buildings. Even so, the separation remains pretty straightforward. Spencer notes the following basic tendency in the development of brick size: in the archaic period all bricks were small, then there was an increase in size up to the Middle Kingdom, which was followed by fluctuation until the 26th dynasty and finally a decrease until the modern time.

Both tile formats are also used in Al-Lahun. Felix Arnold states that the large bricks were used in the first construction period, as Al-Lahun was originally a state construction project. The smaller format was later used: "After the residential buildings were then transferred to private ownership, all the necessary building measures were largely the responsibility of private builders and were carried out using the construction methods customary for settlements."

Manufacture and Association

The bricks were made in ancient Egypt with wooden molds, which is evident from representations and archaeological finds and as is partly the case today, except that the connections are held together with nails instead of tenon joints in the forms. A handle protrudes on one side for better handling. The manufacturing method can still be found in Sudan today and the Nile mud was also the building material in the rural architecture of Egypt until recently for millennia. The Aswan Dam now prevents the annual Nile flood and thus also the replenishment of the suspended sediments that are now being deposited in the large dam. Rural architecture is thus a victim of the new dam. In addition, the Egyptian authorities have banned the use of the Nile mud in order to preserve the existing arable land. However, in the absence of flooding, the settlements enlarge even more at the expense of arable land.

For production, the moist Nile mud is mixed with the chopped up straw and sand, pressed into a wooden mold and smoothed by hand. The maker then loosens the mold from the brick, leaving the wet brick on the floor. This process is repeated until the whole area is filled with wet bricks, with only the thickness of the wooden shape as the space between them. The bricks are left to dry in this state for three days, then turned and after about a week they are hard enough to be stacked in a pile.

In the interior of the wall, since the 1st dynasty, layers of mats have occasionally been found at regular intervals, which are intended to prevent a brick block from tearing during drying and setting. To protect against the weather, the brick walls are plastered or chiseled with Nile mud. According to Arnold's estimates, four workers are now able to produce 3000 bricks of today's (smaller) format every day. The specific weight of a brick is estimated at 1250–1650 kg / m 3 , which means that a brick, which is usually large, weighs around 5 kg.

The most informative representations of brick production come from the grave of Rechmire ( TT100 ) in Thebes. It is clear from them how the rows of bricks are made with wooden molds. The inscription describes the scene as follows: "Brick-making to build a new warehouse for the Karnak Temple."

The bricks were laid in Nile mud or just dry sand, the use of mortar was rare. More or less the same material served as the binder that was used to make the bricks. Most of the time, the Egyptians contented themselves with a few brick associations , in which the regular alternation of stretcher and binder layers predominated. This bandage has been used at all times, especially for thin walls, sometimes also for thick walls such as enclosing walls. Trusses were regularly placed inside the walls. A herringbone bond could also be used inside the wall to shorten the wall thickness. The wall foundation often rested on a roll layer.

From the 13th dynasty and from King Nectanebo I , temple enclosures with upward and downward swiveling bed joints were also built in residential construction, presumably to prevent the corners from breaking out at greater heights. The so-called wave walls each have convex and concave bed joints and thus appear wave-shaped. The bricks are held in place by the side pressure created by the wave construction. A representation of the primordial ocean has already been assumed as a secondary interpretation of the "waves" .

Stone construction

development

Until the Ptolemaic-Roman times, the most important building technique was mud-brick construction, whereas stone construction remained a luxury for all time for buildings with claims to eternity, such as tombs and temples, with the intention of "securing the continued existence of the divine kingdom and the divine powers".

The Egyptian stone architecture does not go back to the Neolithic as in other cultures . The oldest known stone mountain temple is located in Göbekli Tepe (present-day Turkey) and is over 12,500 years old.

Stone construction was introduced in Egypt around the 1st dynasty. The floor of the tomb of King Den (Tomb T) in the Umm el-Qaab necropolis was already covered with red Aswan granite. Another important station in the early development of the monumental stone construction are the graves in the necropolis of Helwan from the 2nd dynasty , the walls of the substructure were in a few cases already clad with monolithic stone slabs, which may indicate a greater need for security for the burial and The owner's additions. In the royal area, according to the Annals of the Old Kingdom ( Palermostein ), a stone structure called Men-Netjeret was built in the 13th year of Chasechemui . In the Abydos tomb of this king there was a burial chamber paved with limestone slabs, walls clad with block masonry and in Heliopolis granite door frames. Huge stone valley districts and tombs of the kings in Saqqara also date from the second dynasty. The highlight of the early stone construction was the Djoser district at the beginning of the 3rd dynasty. Here an unprecedented monumentality of stone construction appears like a meteor. Almost all of the architectural features of this new building method were a transfer of the previously existing building forms with other materials in stone, for example enclosing walls , false doors and various column shapes. The construction methods were also initially based on adobe construction, for example small, regular blocks in the manner of adobe bricks were laid in the Djoser pyramid. But just a few generations later, in the time of Snefru , Cheops and Chephren , the pyramids and pyramid temples assumed gigantic dimensions and were built with blocks weighing up to 200 tons.

Since Djoser, all royal burial precincts have been made of stone, with the temples of the gods this remained the exception at first. It was only from the Middle Kingdom onwards that god temples were mainly made of stone. From the end of the 3rd dynasty onwards, limestone was also increasingly used in private scale construction, initially as a cladding for cult chapels, and later also as scale tobacco. From the 3rd to the 12th dynasty, granite was the preferred building material for royal burial chambers and their entrances, for example as a cladding of pyramids and temple walls.

Stone processing

Investigations of ancient Egyptian tools, the traces of which left marks on the stone surfaces of unfinished monuments and tests of the hardness of Egyptian tools have shown that Egyptian stonemasons were able to cut softer stones with copper tools, but had to cut harder stones with stone tools . According to Dieter Arnold, limestone, sandstone and alabaster were worked with copper tools, while stone tools were necessary for granite, quartzite and basalt .

Investigations of Denys Stocks in experimental archeology showed a much lower limit (in terms of hardness) for the use of copper tools. He made copper tools using the old methods and tested them on nine different rocks, from soft sandstone to hard diorite . His results were that these tools could machine red sandstone with ease, soft limestone with relatively infrequent re-sharpening of the tools, and alabaster with frequent re-sharpening. The harder sandstones and limestones (not to speak of the even harder rocks) could hardly be worked with his tools. Stocks concluded that these rocks could only be worked with stone tools and the use of metal tools (at least until the introduction of iron ) was much less common than previously assumed.

According to Arnold, however, contradict two other sources for stone processing this assumption: The stonemasons represented in grave Rekhmire, obviously used copper chisels , with a wooden Knüpfel were defeated. The machining marks on numerous unfinished or unsmoothed limestone blocks from the Old and Middle Kingdom have such pronounced rectangular shapes with sharp inner corners that can only come from copper tools. In addition, there is the archaeological find, which has handed down far more copper chisels, while stone chisels with a cutting edge are rarer. There is also evidence that the capstones of the boat pits of the Great Pyramid of Cheops were smoothed with copper tools. Small fragments of corroded copper were stuck in various places in the blocks, which are obviously broken edges of the tools used to work the rocks.

From the beginning, the production of different granite blocks radically: instead of metal chisel used to sharp hard rocks (usually made of dolerite ), with which one splinter struck off from the rock. These stone hammers gradually rounded off and became unusable as tools or had to be sharpened. These stone hammers were used to hammer gullies into the bedrock to loosen the block. The stone hammers were originally pear-shaped hammer stones, but they became more and more rounded the more often the stonemason used them to use a new corner. Since they weighed about four to seven kilograms, both hands had to be used. Completely rounded, they could no longer be used as tools, but since some of them were found under sarcophagi, it can be assumed that they were still used as primitive ball bearings. Certainly, the stonemasons faced many technical difficulties when working the hard rock, which is why they were only used extremely sparingly and were often only worked on the visible sides.

The Egyptians used the building block sparingly - despite its easy availability - and preferred "to fit complicated, inclined joint surfaces into one another in a tedious process instead of working off protruding stone into a rectangular shape". A block was not made as a prefabricated cube for the masonry, but individually cut for the specific place in the association. The blocks were delivered raw from the quarry , first of all the two sides that came into contact with the existing masonry during laying (bottom and narrow side) were smoothed, the second narrow side was only processed when the following block was fitted laterally, the top, when the following stone layer has been placed. The back was often not smoothed at all, the front only after a building was completed. The processing of hard stone was avoided on the construction site. For example, blocks of stone , architraves and obelisks were already made in the quarry.

One of the most confusing technical questions is how the Egyptians could drill and saw stone that was as hard as basalt and granite, since they had to be machined with a material at least as hard as quartz, the hardest of the minerals that make up Composed of granite. Presumably a copper drill or a copper saw was used in connection with a grinding mixture of water, plaster of paris and quartz sand. The copper blade only served as a guide, the actual cutting was done by the quartz sand. For example, in the mortuary temple of the Great Pyramid of Cheops, a mixture colored green by copper can still be seen in the deep cuts in the basalt blocks.

Quarry

The identification and determination of the origin of the stones used in ancient Egypt was carried out in particular by Rosemarie and Dietrich Klemm. Earlier data related largely to quarries in which there are inscribed or other iconographic findings. Most of the pharaonic quarries remained without inscriptions. Rosemarie and Dietrich Klemm examined the quarries far more extensively with petrographic methods. They worked out further dating criteria based on the chisel marks on the quarry walls and on the rough surfaces of the monuments in order to derive correlations. In some cases, this scheme could also be used for calcite-alabaster quarries .

Limestone and sandstone quarries can be found on both sides of the Nile Valley, and rose granite emerges in Aswan , which enabled relatively easy transport by ship. Other quarries required an appropriate infrastructure and could only be reached by land expeditions, such as the alabaster quarries of Hatnub (17 km east of Amarna ), the basalt quarries of Gebel Qatrani (10 km west of Lake Faijum), the hard rock quarries of Wadi Hammamat (to to 100 km east of Qena ) and the gneiss quarries of Toschke (80 km from the Nile). During the pyramid era there were important quarries near Tura and Ma'sara, southeast of Cairo and in Middle Egypt, the large sandstone quarries of the New Kingdom at Gebel Silsila , north of Aswan.

Most of the material for building the pyramids was broken directly at the construction site. The location and type of local rock may have been an important consideration for the pyramid builders. The main quarry area of the Cheops pyramid was about 300 m south of it. A geochemical analysis of rock samples has shown that stone material also came from a mining area on the edge of the rock east of the pyramid, from a mining area in the southeastern area of the plateau and a small part from an undefined mining area.

The quarrying technique for both soft and hard rock consisted of isolating the blocks from the surrounding rock by means of shot trenches, blasting them from the ground and then pulling them out of their bed. In ancient Egypt, this required extremely wide and deep channels around the blocks. Since the ancient stone cutters only had stone, wood and copper tools, they had to loosen the blocks with large wooden levers and needed a lot of leeway. The loss of material when the stones are broken is estimated at up to 30 to 50 percent. The triangular rock area between the main quarry of Cheops and the Sphinx in Giza, where blocks left by the quarry workers of the 4th dynasty can still be found: "The large broken blocks were divided by narrower channels that were just as wide that a worker who made a path with the pick could stand in it. In some places blocks of the kind used for the core walls of the Chephren temple have remained almost detached from the rock. "

First of all, the mining took place in the open pit , if the good material was exhausted, it had to be extracted underground . In Tura, Middle Egypt and on the Gebel Silsila, kilometer-by-miles quarry fronts with gates to impressive underground halls supported by mighty pillars were built. Underground, a corridor had to be carved out under the ceiling in order to get behind the stones to be removed. Only in this way could they be separated from the wall. In the demolition-ready stage, a quarry wall was almost vertical with slightly protruding steps. So it could be dismantled like a staircase to facilitate access and removal.

In the early days and in the Old Kingdom, hard stones were mainly extracted by collecting exposed blocks. It was only in the New Kingdom that they were actually dismantled over the course of the day, and they could only be laboriously carved out with stone tools (dolerite balls). They were used to cut gutters in the bedrock until the block came off. Mark Lehner notes that in an experiment he was able to create a 30 × 30 cm and 2 cm deep dent in the granite during five hours of hammering.

Lifting and moving heavy loads

Heavy loads were lifted using inclined surfaces, construction ramps , rope pulls and leverage . The building ramp is attested in various variants from the pyramids of the 3rd and 4th dynasties to the pyramids of the Middle Kingdom to the temples of the New Kingdom and is shown in the tomb of Rechmire. The construction ramps were usually bordered on both sides by retaining walls made of quarry stone or bricks, the interior was reinforced with heavy beams and the actual surface was a cement-hard layer of mortar or gravel. According to Arnold, the ramp width measured an average of 10 cubits (5.25 m), the angle of inclination was between 10 ° and 17 °. The Anastasi I papyrus describes a theoretical ramp made of bricks 400 m long and 30 m high.

The following selection from the Old Kingdom should give an impression of the function and construction of these ramps:

- Near the northwest corner of the unfinished pyramid of the Sechemchet in Saqqara, Zakaria Goneim was able to partially excavate a huge construction ramp.

- To the small, unfinished step pyramid from the 3rd dynasty in Sinki , four ramps led from all sides against the sloping side walls. Each of these ramps is 12 m long and has an angle of 12 ° to 15 °. If these ramps had been completed, they would have reached a height of only 6 m. In order to haul the material up to the top of the pyramid at a planned height of 12 m, additional measures would have been necessary.

- From the quarries of the northern pyramid of Sneferu in Dahshur , two huge, parallel transport roads lead up to the pyramid plateau.

- The remains of two construction ramps could be found near the Meidum pyramid .

- A huge, 5.4-5.7 m wide ramp was excavated near the Great Pyramid, which led from the quarries west of the Sphinx to the pyramid plateau east of the Queen's Pyramids .

- A 1.2 m high and 8 m long loading ramp and traces of other ramps have been documented in the diorite quarries of Abu Simbel since the time of Cheops.

- Under the pavement of the sun temple of Niuserre in Abu Ghurab , Ludwig Borchardt was able to locate five 2.5–5 m thick brick ramps east of the obelisk.

- At the Mastabat al-Firʿaun des Schepseskaf , two 1000 m long transport ramps have been preserved.

The stones were probably pulled with the help of sledges on the specially prepared ramps and roads, which had to be hard and stable (in contrast to the soft sand). The well-preserved ramps of the pyramids of Amenemhet I and Sesostris I in Lisht make this clear. They consist of a limestone quarry and mortar filling in which wooden beams are inserted to consolidate the foundation. The surface forms a layer of limestone quarry and gypsum, and Nile mud may have served as a lubricant over it. Depictions of the transport of stone statues on sledges show a worker on the front runners who pours a liquid (presumably water) as an additional lubricant in front of the sledge. The most famous representation comes from the tomb of the noble Djehutihotep from the 12th dynasty and shows 172 men pulling a statue. The discovery of carcasses of draft animals in the rubble of the mortuary temple of Mentuhotep II in Deir el-Bahari and several representations show that the Egyptians also used cattle as draft animals.

Another method of lifting loads is the rope pull. From the 4th dynasty, stone channels and pulleys for deflecting ropes are documented, but little is known about lifting with the help of ropes. From the Middle Kingdom onwards, wooden wheels for simple cable pulls have also been preserved. Two column-like edge bases flanked one of the ramps in Lischt, which could have come from a pulling or lifting device.

Lever holes on building blocks show that lifting with the help of wooden levers was also used, for example to insert a block precisely into the masonry. After the blocks were moved, the lever holes were closed with patch stones or mortar. According to investigations in experimental archeology, 150 men can lift a 180 t obelisk with levers, and 60–70 men can lift the 50–60 t granite blocks of the burial chamber of Cheops with levers and step-by-step underpinning.

Talatat

The Talatat (also called Telatat) are the typical small stone blocks from which Akhenaten's temples were built in the Amarna period . The name comes from the Arabic talatât , which means “three” and is either due to the fact that the blocks are three handspans wide or, according to another tradition, because they were piled up in groups of three.

The talatat were specific building material for the Amarna period. They have a standardized size of about 27 × 27 × 54 cm (i.e. ½ × ½ × 1 Egyptian cubit). The comparatively small size facilitated the quick construction of temples, but also the later demolition of these buildings. The talatat were later a sought-after building material, especially for foundations and fillings of double-shell walls and temple pylons .

The largest find complexes of this Talatat originally come from the Aton temples of Karnak (sandstone) and Amarna (limestone). The blocks were laid in very thin-walled walls in alternating rows of stretcher and trusses.

Construction planning

The technical problems described in the Papyrus Anastasi I (14.2-17.2) show, for example, that the construction planning was of considerable importance . Several texts from the Old Kingdom seem to show that the “masters” responsible for the technical execution “comparable to the foremen of medieval construction companies were identical to creatively designing architects ”. Imhotep is considered to be the first great builder of the Old Kingdom in Egypt and was probably responsible for the construction of the Djoser pyramid and the Sechemchet pyramid in Saqqara. In the centuries after his death, reference is made to Imhotep again and again, whereby the scope of the works ascribed to him continues to grow and the legends about Imhotep are expanded and his veneration as a sage and magician increases. In the Aegyptiaca of the Egyptian historian Manetho (3rd century BC) Imhotep is named as the "inventor of the art of building with hewn stones".

Although the Egyptian artists were able to make architectural drawings, it is questionable whether building plans in the modern sense (for the use of the architect or craftsman) existed. The approximately 25 drawings on stone, wood or papyrus that have survived are mostly hand-sized, rough sketches that only give an overview of the arrangement of the parts of the room and were occasionally provided with dimensions as a reminder for the craftsman. If necessary, simplified craft sketches on ostracas or precise work drawings of components, some with a grid, could be made from this. Important construction plans are:

- The ostracon fragment MMA 22.3.30, which was found in the rubble of the mortuary temple of Mentuhotep II in Deir el-Bahari, shows a red sketch on sandstone. Herbert Winlock saw it as an architectural representation of the garden of the temple. Dieter Arnold interpreted it as a representation of the hypostyle in the area of the sanctuary.

- In the winter of 1913, Norman de Garis Davies bought a plot of an estate from a dealer in Dra Abu el-Naga , which was drawn on a wooden board in red and black ink.

- The largest surviving construction plan is the 1.6 m long sketch of an unknown temple in the quarries of Sheikh Said.

- There is a carefully constructed and detailed plan of the grave of Ramses IV ( KV2 ) in the Valley of the Kings on the Turin papyrus in 1885.

- On the ostracon CG 25184 of the Egyptian Museum in Cairo is a plan of the tomb of Ramses IX. ( KV6 ). The two grave plans probably served as illustrative material.

- Another architectural sketch shows part of the grave of Senenmut ( TT71 ).

- A simplified representation of a shrine is on an 18th dynasty ostracon .

According to Dieter Arnold, instead of building plans, you have to count on building descriptions with dimensions. Such building descriptions with details of the individual rooms, the dimensions including building materials and the use can only be found in the late period. Particularly in the Ptolemaic period, such information was passed down through "holy books" in temple inscriptions. Architectural books of this kind were also common in classical antiquity.

The stonemasons probably drew the actual construction plan 1: 1 on the slab foundation of the building and repeated this on the stone layers erected on top. Possibly these plans were developed using an Ellen grid system, similar to how they were used to transfer wall decorations. Apparently the architects preferred cubit numbers for the overall and detailed dimensions. In addition, the buildings were often the product of countless plan changes and expansions resulting from new requirements by the client.

Measurement techniques

Distances

The fact that measuring units and instruments already existed in the 1st dynasty can be deduced from the proportions of the Narmer range and a mastaba from the 1st dynasty in Naqada (“Tomb of Menes”) was demonstrably laid out with straight cubits. All later buildings testify to the use of an exact measuring system, but elliptical bars have only been handed down from the New Kingdom, most of them as votive or grave goods. Apart from possible discrepancies and inaccuracies, Dieter Arnold calculated a length of 52.5 cm for an Egyptian cubit . The elliptical bars are also pretty much this length. The cubit was divided into 7 hand widths of 7.5 cm by 4 fingers of 1.875 cm each.

For practical reasons, rods two cubits and even longer were used for the measurement. The use of measuring ropes to measure fields has also been handed down. The exact measurement of buildings required a clear marking of measuring points. These were carved as crosses in stone slabs and have been preserved in large numbers. Nevertheless, their regular use is documented by depictions of “rope tensioning” in the founding rituals of temples. Round holes chiseled into the bedrock in the vicinity of large buildings could have been used to hold wooden measuring stakes.

Inclination angle

The ancient Egyptian builders had evidently developed a simple and exact method to calculate the angle of inclination (ancient Egyptian sqd ) without knowing our system of 90-degree division of a quarter circle. It played an important role, especially in the construction of the sloping outer walls of mastabas and in building pyramids.

We know from the mathematical Papyrus Rhind and from follow-up measurements on buildings that the angle of inclination was defined and constructed by the ratio of setback to height: “According to this, a setback from 7 hand's breadth to a height of 7 hand's breadth corresponds to an inclination angle of 45 °, one of 5: 7 hand width 54 °. "

It is more difficult to assess how the angle of inclination was constructed on the building. Most likely, wooden frames with the appropriate inclination were placed in the corners and in some places in between, from which a rope was stretched. A system of measuring lines has been preserved on the opposite wall surface of the foundation pit of Mastaba 17 by Meidum . Their insides are plastered in white and provided with horizontal auxiliary lines at cubit intervals. The slope of the foundation is drawn in this system. In the case of a pyramid by Meroe , the elevation of the pyramid slope is also drawn on an opposite wall.

Leveling

For leveling the base, the Egyptians used, among other things, an angle plumb line, some of which are still preserved and which was in use until the Middle Ages. This consisted of an equilateral triangle, which stood on a cross-beam with markings, from the tip of which a plumb bob hung down. If the angle plumb bob was on a horizontal plane, the plumb bob pointed to the marking in the middle of the crossbar. If there was an unevenness, the plumb bob was pointing to the left or right of the center mark. To level shorter distances, the Egyptians may have placed these scales on long wooden boards and repeated the measurements on the horizontal surface. This achieved a reading accuracy of ± 1 cm at a distance of 47 m. In the case of the Cheops pyramid, the deviations in the base heights of the north and south sides, which are 230 m apart, are as much as 2 cm. Horizontal height horizons are still drawn in on several unfinished walls from the Old Kingdom, with the help of which the height horizons were moved upwards. For easier orientation, the contour lines are provided with the corresponding ellipses as control marks. On the way to the mortuary temple of Mentuhotep II and in the corridor of the Sesostris I pyramid, the elevation marks were also marked by series of limestone slabs.

Orientation according to the cardinal points

Since the compass was unknown, the building line had to be aligned with the cardinal points according to the position of the stars or the sun's shadow. Often one was satisfied with approximate values, the pyramids of the 4th Dynasty, however, show a high degree of accuracy in their alignment. For example, in the Great Pyramid of Cheops, the azimuth , the deviation from the north, is only 3'6 "to the west.

Ludwig Borchardt assumed that the alignment of the north-south axis was based on the determination of the center between the point of rise and fall of a star in the northern sky. Building on this, IES Edwards proposed a measuring method in which the person standing in the construction of a circular wall selects a star and noted its rising and falling points on the wall. These were then extended to the base of the wall using a plumb bob and connected to the center of the circle. North was exactly in the middle of the angle these two lines made. However, the necessary framework conditions make this method quite impractical. So "the stars in Egyptian latitudes do not rise and fall vertically". Due to the unequal contour lines of the east and west horizons, a star appears offset to the south above the horizon (or disappears again), so that "due to these different horizon profiles, the bisector would point east to north".

Josef Dorner proposed another astronomical method based on the observation of the circumpolar stars . Since these neither rise nor set, they are visible to the observer all year round. By Dorner the Egyptians determined by flight bars the greatest digression of a Zirkumpolarsterns. According to Rolf Krauss, the eastern and western standstills of a circumpolar star are fairly easy to target. The positions of the standstills were marked by the alignment poles on the ground, the marking points were connected to the observation point and the bisector was determined from this in order to find the north direction.

Martin Isler assumes that the Egyptians determined the north direction by observing the shadow line of a staff or gnomon during the daily course of the sun. A north-facing semicircle was constructed: The length of the rod now gives the radius of a circle. As the sun rises, the shadow becomes shorter, and in the afternoon it becomes longer again. When you reach the circle again, it forms an angle with the morning line. The bisector of this angle indicates geographical north.

Ceiling and roof structures

Flat ceiling

According to Albrecht Endruweit, all Egyptian residential buildings (of the New Kingdom) made of adobe bricks had flat roofs that could also be used as living space. None of them have survived in their entirety, but there are finds in the form of fallen roof fragments that allow statements about the structural properties of the upper room closures, so that one does not have to rely entirely on assumptions, reconstructions and pictorial representations.

The main beams were laid close to one another or at intervals that could be bridged with mats, palm leaf ribs, adobe bricks or boards. After Endruweit, the main beams could have a distance of up to 70 cm. The first layer of joists was often followed by branches and a layer of bast mat for leveling. A rammed earth layer or mud brick was applied as the actual roof surface. A simpler construction was to lay the mats directly on top of the wood layers. In the case of larger spans, palm wood pillars, which rested on stone bases, were used for support.

According to Gerhard Haeny, the search for a roof structure that allowed the room to be covered with the same brick material as the rest of the house could be due to a shortage of wood or its susceptibility to termite damage or rot. As the find situation in Amarna shows, acacia wood was used as the main beam and tamarisk was used as the transverse layers.

The first flat ceiling made of limestone is known to us from the entrance hall of the Djoser district and it remained the only known ceiling construction in stone construction until the end of the 3rd dynasty. The width of the room was widened by pillars at Djoser, and the architraves extended to the center with a span of 1.3 m. In the 1.65 m wide coffin chamber of the king, the strength of the ceiling was increased by placing the 1.1 m high granite beams upright over the room.

The coffin chamber of the Cheops pyramid was already covered with 2 m thick granite beams with a span of 5.25 m. Perhaps worried by cracks in the ceiling, the builders erected five relief chambers above it and a gable roof structure above so that "it could fulfill its force-diverting function in an area that had no effect on the chamber system".

Spans of over 6 m were only achieved in the New Reich. The deck beams of the Hypostyle Hall in the Karnak Temple were 9 m long and 1.25 m thick and spanned a free-standing area of 6.7 m.

Cantilever vault

A cantilever vault consists of overhanging binder layers that gradually come closer together so that the distance between the two longitudinal walls is so small that it can easily be bridged with a single block. It also has a stabilizing function, as the pressure of the stone mass above is deflected sideways into the core masonry.

The earliest example is the burial chamber of the Meidum pyramid. Since the 2.65 m wide and 5.05 m high chamber could easily have been covered with a flat ceiling, the cantilever vault had more of a static function to divert the pressure of the pyramid, but a religious significance cannot be ruled out.

After this cautious beginning, the cantilever vaults of the subsequent pyramids in Dahshur and Giza are quite impressive. In the Great Gallery of the Great Pyramid of Cheops, its function could actually be due to the width of the corridor. In the over 46 m long and 8.5 m high gallery, the side layers of the walls shift inwards by around 8 cm from a height of 1.80 m to seven layers each.

Bent pyramid : Detailed view of the burial chamber of the upper corridor system and the connecting corridor to the lower main chamber with cantilever vaults

Meidum pyramid : corbelled vault of the central chamber

Gable roof

The gable roof consists of clamping plates, which lie in pairs at the top and lead diagonally down into the side walls. The earliest examples of this are private graves from the time of Snefru. For example, the mastaba of the Iinefer in Dahshur has such a ceiling with a span of 2.6 m. However, it was not until the Great Pyramid of Cheops that they were used on a larger scale. The ceiling of the uppermost relief chamber above the king chamber consists of eleven pairs of clamping plates, each 7-8 m long and weighing up to 36 t. The ceiling of the queen's chamber consists of six clamping plates set up at an angle of 30 °. The flat ceiling of the entrance corridor is statically relieved by a double layer of stone blocks arranged like a gable roof, which are 3 m long, have an angle of 40 ° and probably extend along the entire corridor. These are the first examples of a construction that was used in all pyramids of the 5th and 6th dynasties and reached gigantic proportions there (beams weighing 90 t at Niuserre).

Vault

The vault (arched vault ) is a ceiling construction with curved layers arranged in a curved structure with continuous radial bed joints and vertical butt joints, in which the forces from the top brick or stone are directed downwards at an angle until they hit the walls perpendicularly on which the Vault stands. It is self-supporting and more durable than, for example, a horizontal beam made of wood or stone. In contrast to the arched vault, the arches in the inclined arched vault are not free and centered above the ground, but the first arch is leaned against a retaining wall. In addition to the vertical contact pressure and horizontal transverse shear, the inclination also creates horizontal longitudinal forces on the retaining wall. Both vaults were constructed with the help of scaffolding on shuttering boards.

In brick architecture, the vault could have been constructed in the lower Egyptian imperial sanctuary in the early days, if the depictions are of a brick building and not a mat hut. For the first time it is reliably documented in grave 3500 in Saqqara from the 1st dynasty from the time of Qaa : The deceased was placed in a rectangular pit that was covered with wood and bricks and covered with two vaults. Since the 3rd dynasty at the latest, inclined arched vaults were nothing unusual in grave construction. This roof construction was also adopted in the residential architecture, but it remained rather the exception until the Ramesside period - which is perhaps also due to the traditional situation. From the late New Kingdom onwards, there was a clear increase in all types of architecture. A good example of this are the huge brick vaults of the storage rooms that surround the Ramesseum .

One of the most interesting observations made by Ludwig Borchardt in al-Lahun are arches that span door openings, as wall openings in Egyptian architecture were usually spanned by horizontal lintels made of wood or stone. The door arches were constructed from ordinary masonry bricks and only appear inside residential buildings - i.e. with doors that did not have to be closed with door leaves. It remains uncertain whether house doors were also spanned with arches - at least the installation of a door leaf without a horizontal lintel would have caused problems.

Flinders Petrie already observed barrel vaults in the residential buildings of al-Lahun . It can be assumed that the barrel vault was a common ceiling construction form in the Middle Kingdom and, in contrast to the New Kingdom, was just as common as the wooden beam ceiling. In total, Borchardt was able to determine three barrel vaults in al-Lahun in the form of a sloping arch vault, which were inclined against one of the narrow walls of the room at an angle of 7 °.

The vault construction has never really caught on in stone construction. Dieter Arnold attributes this to the fact that different versions of ceiling structures already existed and that there was not enough wood for scaffolding that this structure required. This construction was only used in emergencies, for example when there was a lack of bricks. The Djedkare pyramid is a strange exception . The passage from the antechamber to the coffin chamber was relieved by an arch above it, which consists of three wedged blocks, between which a 5 m long keystone was hung in the middle. If the construction weren't hidden below by masonry, you would be dealing with a real stone vault. Few other examples are known from the 6th dynasty from Saqqara (for example from the grave of the vizier Hebsed-Neferkara), which were also constructed to relieve doorways and to create an arch of only about one meter in diameter from roughly hewn stones. Stone vaults were only used on a larger scale from the 25th dynasty . From the Middle Kingdom and especially in the New Kingdom, mostly flat vaulted ceilings were reproduced in the rock in rock graves under the influence of temple sanctuaries and palace halls.

dome

The dome was used in Egypt as a special vault construction in residential, sacral and grave construction as a full-circle or semicircular dome.

Rod-girder domes (reed domes) were probably used for roofing round buildings in prehistoric times. They are shown on the lion-hunt palette , the Tehenu palette from late prehistoric times and on an ivory tablet from the 1st Dynasty from Abydos and on the Aha tablet from the 1st Dynasty from Naqada. From the 1st dynasty onwards, they were often used for circular granaries , which in the New Kingdom had a diameter of up to 8 m. They consisted of a diagonal mesh structure made of curved or tensioned rods with a roof skin on top.

Since the Old Kingdom at the latest, floor domes have been built from adobe bricks, especially for silos . These do not have an actual floor plan, but a circular or parabolic cross-section. Remnants of such silos have been found in Medinet Habu and Amarna , for example .

One of the few almost completely preserved dome domes from the Old Kingdom is in the mastaba of the short court official Seneb . The grave (S 4516/4524) in the necropolis of Gizeh was excavated and researched by Hermann Junker in 1927 . The dome, made of air-dried bricks, rests on a base square with an inscribed base circle, which seamlessly merges into the curvature of the gussets .

In the Pendentif dome , a triangular component forms the transition between the circular floor plan and the square floor plan of its base. The resulting triangular gussets are called pendentifs (from French pendre , to hang), hence the term hanging gusset . Such were discovered from unfired adobe bricks in a grave of the New Kingdom in Dra Abu el-Naga and in a bathing complex of the Greco-Roman period in Karanis.

The cantilever dome, which consists of cantilevered ring layers of horizontal cantilever plates above the circular base as a false vault, is also made of clay bricks, for example in the grave pyramids of the Middle Kingdom from Abydos.

Door construction

The normal form of the Egyptian door consists of a threshold, frame (post) and lintel, into which the door leaves were fastened in pivot pins. Numerous archaeological and literary sources are available for knowledge about doors and gates, but these have not yet been fully and coherently evaluated. In adobe houses, the direct attachment of door leaves was not possible for static reasons, so that a door frame made of stone or wood had to be used. Stone door posts have been preserved in many ways.

The threshold is, if possible, a stone slab made of hard stone protruding above the floor, side doors are often without threshold, on continuous paving. It carries the two posts, mostly protruding in front of the wall surface, which in the normal form are vertically positioned stone posts made of one piece. Forerunners are posts made of wood and a mixed construction of mud brick and wood, of which the house stone posts have retained their independence (in their outer shape) from the rest of the wall, which they also retain where they are made of the same material. A further development is the layering of the post from individual blocks. The lintel of smaller gates consists of a one-stone architrave , a kind of house beam above the doorway. The precursor is the wooden beam. It is characterized by the low use of the bow, although the technical ability to do so would have been there. In the case of larger doors, the architrave consists of several upright beams. The door frames of sacred buildings are regularly crowned by covings, which reach enormous dimensions in the case of large temple gates and which had to be specially fastened because of their top-heaviness. Monumental temple doors are regularly flanked by pylons, but not integrated into them.

The door leaves were usually composed of vertical boards, which were held together by attached strips. The forerunner is the tubular door made of vertical reed rods, which are held together by tied cross rods. Here with the door leaf we have one of the rare cases in which a forerunner possibly existed in the roll-up mat closure that was technically fundamentally different. The door leaves were fastened with pivot pins that protruded from the top and bottom of the door leaf and were fitted with bronze fittings. The edges or the entire surface of the door leaves of important temple gates were also occasionally covered with sheet bronze and even decorated with electrons, gold and silver.

The door leaves sat with the pivot pin down in a swivel pan. On the first pylon of the Karnak Temple, these have a diameter of 50 cm! This is either sunk into the threshold in the form of a quarter circle or as a separate stone set into a depression in the threshold. The upper pivot turned in a wooden or stone pivot bearing set in a recess in the architrave . In order to be able to insert the wing into a door that had already been walled up, the lower pivot was inserted through a corresponding channel in the threshold and the channel was then closed with stone wedges. In the Middle Kingdom the channel ran across the door axis, in the Old and New Kingdom.

In the case of double doors, a wooden or bronze sliding bolt was used as a door lock on one door leaf in two hooks (eyelets), which overlapped the other, which also had two hooks. With single-leaf doors, the bolt was in a drill hole in the door frame. Wall bars have a round or square cross-section. The front part is occasionally decorated with a lying guardian lion. If this was pulled out from the wall channel, the door could be prevented from opening.

literature

Architecture and building techniques in general

- Dieter Arnold : Lexicon of Egyptian architecture. Artemis, Zurich 1994, ISBN 3-7608-1099-3 .

- Dieter Arnold: The temples of Egypt. Apartments for gods, places of worship, architectural monuments. Zurich 1992.

- Alexander Badawy : A history of Egyptian Architecture. From the earliest times to the end of the Old Kingdom. Cairo 1954.

- Alexander Badawy: A history of Egyptian Architecture. The First Intermediate Period, the Middle Kingdom, and the Second Intermediate Period. Berkeley 1966.

- Alexander Badawy: A history of Egyptian Architecture. The Empire (the New Kingdom). Berkeley / Los Angeles 1968.

- Somers Clarke, Reginald Engelbach : Ancient Egyptian Construction and Architecture , Dover Publications, New York 1990, ISBN 0-486-26485-8 .

- Ulrike Fauerbach: Building Knowledge in Ancient Egypt. In: Jürgen Renn , Wilhelm Osthues, Hermann Schlimme (ed.): History of knowledge of architecture. Volume 2: From Ancient Egypt to Ancient Rome. Edition Open Access. Max Planck Research Library for the History and Development of Knowledge, Studies 4, 2014.

- Jean-Claude Goyon, Jean-Claude Golvin, Claire Simon-Boidot, Gilles Martinet: La construction Pharaonique du Moyen Empire à l'époque gréco-romaine. Contexte et principles technologiques. Paris 2004.

- Peter Jánosi (Ed.): Structure and Significance. Thoughts on Ancient Egyptian Architecture. Vienna 2005.

- Alfred Lucas: Ancient Egyptian Materials and Industries. London, 1948 (3rd edition), especially pp. 61-98 ( online ).

- Miron Mislin : History of Building Construction and Engineering. From antiquity to modern times. An introduction. Düsseldorf 1988.

- WM Flinders Petrie : Egyptian Architecture. London 1938.

- E. Baldwin Smith: Egyptian architecture as cultural expression. New York 1938.

- Hans Straub: The history of civil engineering. An overview from antiquity to modern times. Basel / Boston / Berlin 1992.

- Corinna Rossi: Architecture and Mathematics in Ancient Egypt. Cambridge 2004.

Wood mat construction

- Alexandre Badawy: La première architecture en Égypte. In: Annales du service des antiquités de l'Égypte '.' (ASAE) Vol. 51, 1951, pp. 1-23.

- Alexandre Badawy: Le dessin architectural chez les anciens Egyptiens. Cairo 1948.

- IES Edwards : Some Early Dynastic Contributions to Egyptian Architecture. In: Journal of Egyptian Archeology. (JEA) Vol. 35, 1949, pp. 123-128.

- Henri Frankfort: Kingship and the Gods. Chicago 1948.

- Klaus Kuhlmann: Article Rohrbau. In: Wolfgang Helck . Wolfhart Westendorf (Ed.): Lexicon of Egyptology. Volume 5, Wiesbaden 1984, columns 288-294.

- Herbert Ricke : Comments on Egyptian architecture in the Old Kingdom. Volume I, Cairo 1944.

- Herbert Ricke: Comments on Egyptian architecture in the Old Kingdom. Volume II, Cairo 1950.

Adobe construction

- Felix Arnold: Building construction in the city of Kahun. To the notes of Ludwig Borchardt. In: Peter Jánosi (Ed.): Structure and Significance. Thoughts on Ancient Egyptian Architecture. Vienna 2005, pp. 77-103.

- Diethelm Eigner: Rural architecture and settlement forms in Egypt today. Vienna 1984.

- Albrecht Endruweit: Urban Housing in Egypt. Climate-friendly clay architecture in Amarna. Berlin 1994.

- Annemarie Fiedermutz-Laun u. a .: Formed from earth. Mainz 1990.

- J.-C. Golvin et al. a .: Essai d'explication des murs “a assis courbes”. In: Comptes rendues de l'Academie des Inscriptions. Volume 58, 1990, pp. 905-946.

- Barry Kemp : Soil (including mud-brick architecture). In: Paul T. Nicholson, Ian Shaw (Eds.): Ancient Egyptian Materials and Technology. Cambridge 2000.

- PG McHenry: Adobe and Rammed Earth Buildings. Design and Construction. New York 1984.

- Andrew Plumridge, Wim Meulenkamp: Brickwork. New York 1993.

- Herbert Ricke: The floor plan of the Amarna house. Leipzig 1932.

- AJ Spencer: Brick Architecture in Ancient Egypt. Westminster 1979.

Stone construction

- Dieter Arnold: Building in Egypt: pharaonic stone masonry. Oxford University Press, New York 1990, ISBN 0-19-506350-3 .

- Somers Clarke, Reginald Engelbach: Ancient Egyptian Masonery: The Building Craft . Oxford University Press, Oxford 1930; New York 2009 ( online )

- Hans Goedicke : Some Remarcks on Stone Quarrying in the Egyptian Middle Kingdom. In: Journal of the American Research Center in Egypt. (JARCE) Vol. 3, 1964, pp. 43-50.

- Michael Haase : A place for eternity. The pyramid complex of Cheops. Mainz 2004.

- Rosemarie Klemm , Dietrich Klemm : Stones and Quarries in Ancient Egypt. Berlin u. a. 1993.

- Rosemarie Klemm, Dietrich Klemm: The Stones of the Pyramids. Provenance of the Building Stones of the Old Kingdom Pyramids of Egypt. Berlin / New York 2010.

- Mark Lehner : Secret of the Pyramids. Munich 1997.

- Vito Maragioglio , Celeste Rinaldi : L'Architettura delle Piramidi Menfite. Volumes II-VIII, Torino 1963–1977.

- George Andrew Reisner : Mycerinus. The Temples of the Third Pyramid at Giza. 1931.

- Rainer Stadelmann : The Egyptian pyramids. From brick construction to the wonder of the world (= cultural history of the ancient world . Volume 30). 2nd, revised and expanded edition. von Zabern, Mainz 1991, ISBN 3-8053-1142-7 .

- DA Stocks: Sticks and stones of Egyptian technology. In: Popular Archeology. Volume 7, 1986, pp. 24-29.

Architectural and structural questions

- Alexandre Badawy: Brick Vaults and Domes in the Giza Necropolis. In: Abdel-Moneim Abu-Bakr: Excavations at Giza, 1949–1950. Cairo 1953, pp. 129-143.

- J. Brinks: vault. In: Wolfgang Helck, Wolfhart Westendorf: Lexicon of Egyptology. Volume II, Wiesbaden 1977, columns 589-594.

- Hellmut Brunner : Article Tür und Tor. In: Wolfgang Helck, Wolfhart Westendorf: Lexicon of Egyptology. Volume VI, Wiesbaden 1986, columns 778-787.

- Joachim P. Heisel: Ancient architectural drawings. Darmstadt 1993.

- Otto Koenigsberger: The construction of the Egyptian door. Glückstadt 1936.

- Saleh El-Naggar: Les voûtes dans l'architecture de l'Égypte ancienne (= Bibliothèque d'Étude de l'Institut Français d'Archéologie Orientale du Caire. Volume 128). Caire 1999.

- Paul T. Nicholson , Ian Shaw (Eds.): Ancient Egyptian Materials and Technology. Cambridge 2000.

- WM Flinders Petrie: Tools and Weapons. London 1917.

- Serge Sauneron, Sylvie Cauville, F. Laroche-Traunecker: La porte ptolémaïque de l'enceinte de Mout à Karnak. Caire 1983.

Web links

- German Archaeological Institute: AEGARON - Ancient Egyptian Architecture Online architectural plans of buildings from Ancient Egypt

Individual evidence

- ↑ A work by AJ Spencer from 1979 Standard: AJ Spencer: Brick Architecture in Ancient Egypt is about mud brick construction, which has so far received less attention in research than stone construction . Westminster 1979.

- ^ A b c d D. Arnold: Lexicon of Egyptian architecture. P. 246.

- ↑ Paul T. Nicholson, Ian Shaw (Ed.): Ancient Egyptian Materials and Technology. Cambridge 2000, p. 1.

- ↑ Rosemarie Klemm, Dietrich D. Klemm: stones and quarries in ancient Egypt. Berlin u. a. 1993.

- ↑ Hellmut Brunner: Article Tür und Tor. In: Wolfgang Helck, Wolfhart Westendorf: Lexicon of Egyptology. Volume VI, p. 778. The only comprehensive publication on this comes from 1936: Otto Koenigsberger: The construction of the Egyptian door. Glückstadt 1936.

- ↑ Herbert Ricke: The floor plan of the Amarna house. Leipzig 1932, p. 6 f.

- ↑ Manfred Bietak: Article round buildings. In: Wolfgang Helck, Wolfhart Westendorf (Hrsg.): Lexikon der Ägyptologie. Volume V. Wiesbaden 1984, Col. 318-320.

- ↑ Herbert Ricke: Comments on Egyptian architecture of the Old Kingdom. Volume 1, Cairo 1944, p. 21.

- ↑ a b Kuhlmann: Rohrbau. In: LÄ V , Sp. 289.

- ↑ Klaus Kuhlmann: Article pipe construction. In: Wolfgang Helck, Wolfhart Westendorf (Hrsg.): Lexikon der Ägyptologie. (LÄ) Volume V, Wiesbaden, 1984, Sp. 288.

- ↑ Its full name is Men-cheper-Ra-ach-menu, which means something like "Glorious about monuments is Men-cheper-Ra (Thutmose III.)" Or "Sublime is the memory of Men-cheper-Ra" . See Thomas Kühn: In honor of Amun - Thutmose III's building projects. in Karnak. In: Kemet 3/2001, p. 34.

- ^ Ricke: Amarna house. P. 7.

- ^ Oswald Menghin, Mustafa Amer: The Excavations of the Egyptian University in the Neolithic Site at Maadi. First Preliminary Report (1930-31). Cairo 1932, p. 16 f.

- ^ Hermann Müller-Karpe: Handbook of Prehistory. Volume 2: Neolithic. Munich 1998, p. 405.

- ↑ Kuhlmann: Rohrbau. In: LÄ V , col. 292 note 11; Badawy: Design architectural. P. 47 ff.

- ↑ a b Ricke: The floor plan of the Amarna house. P. 8 f.

- ↑ Ricke: Comments. I, p. 27 ff.

- ↑ Ludwig D. Morenz: picture letters and symbolic signs. The development of writing in the high culture of ancient Egypt. (= Orbis Biblicus et Orientalis 205) Göttingen 2004, p. 91.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 190; Ricke: Comments. I, p. 27 ff .; Henri Frankfort: Kingship and the Gods. Chicago 1948, pp. 95 f.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 189; Frankfort: Kingship and the Gods. P. 95 f .; Ricke: Comments. I, p. 36 f .; Jan Assmann: The grave of Basa (No. 389) in the Theban necropolis. Mainz 1973, p. 32 ff.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 110.

- ^ A b c d e D. Arnold: Lexicon of Egyptian architecture. P. 282 f.

- ^ A b A. J. Spencer: Brick Architecture in Ancient Egypt. P. 3.

- ^ PG McHenry: Adobe and Rammed Earth Buildings: Design and Construction. New York 1984, p. 84; AJ Spencer: Brick Architecture in Ancient Egypt. P. 3; Barry Kemp: Soil (including mud-brick architecture). In: Paul T. Nicholson, Ian Shaw (Eds.): Ancient Egyptian Materials and Technology. Cambridge 2000, p. 79 f.

- ↑ McHenry: Adobe and Rammed Earth Buildings. P. 84.

- ↑ Kemp: Soil. P. 80.

- ^ Ricke: floor plan of the Amarna house. P. 9 f .; Ricke: Investigations. I, p. 21 f.

- ^ Ricke: floor plan of the Amarna house. P. 9.

- ↑ D. Randall-Maciver, AC Mace: El Amrah and Abydos. London 1902, p. 42 and plate 10 fig. 1 and 2.

- ^ A b A. J. Spencer: Brick Architecture in Ancient Egypt. P. 5.

- ^ WM Flinders Petrie, JE Quibell: Naqada and Ballas. London 1896.

- ↑ Clarke: Ancient Egyptian Frontier Fortress. In: JEA 3, 1916, pp. 176-179.

- ^ A b A. J. Spencer: Brick Architecture in Ancient Egypt. P. 140 f.

- ^ F. Arnold: Building construction in the city of Kahun. To the notes of Ludwig Borchardt. In: Peter Jánosi (Ed.): Structure and Significance. Thoughts on Ancient Egyptian Architecture. Vienna 2005, p. 83.

- ^ AJ Spencer: Brick Architecture in Ancient Egypt. P. 5 ff .; Fig.Petrie: Tools and Weapons. Plate XLVIII, 55.

- ↑ Diethelm Eigner: Rural architecture and settlement forms in Egypt today. Michigan 1984.

- ↑ Lothar Talner: Blog Sudan 1996-2011. v. a. Bau, 2007 and Ziegelformen, 2009 (accessed April 29, 2012); AJ Spencer: Brick Architecture in Ancient Egypt. P. 5 ff.

- ^ AJ Spencer: Brick Architecture in Ancient Egypt. P. 3 f.

- ^ Arnold: Lexicon of Egyptian architecture. P. 282 f .; AJ Spencer: Brick Architecture in Ancient Egypt. P. 112 ff.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 278f. and also J.-C. Golvin et al. a .: Essai d'explication des murs “a assis courbes”. In: Comptes rendues de l'Academie des Inscriptions 58, 1990, pp. 905-946.

- ^ D. Arnold: Building in Egypt. S. 3. Also G. Daniel: Megalithic Monuments. In: J. Sabloff (Ed.): Archeology. Myth and Reality. Readings from Scientific American. San Francisco 1980, pp. 56-66; J. Sabloff: Introduction. In: Archeology. Myth and Reality. Readings from Scientific American. San Francisco 1982, pp. 1-24; Roger Joussaume: Dolmens for the Dead. Ithaca / New York 1988, pp. 23, 129.

- ↑ Klaus Schmidt: You built the first temple. The enigmatic sanctuary of the Stone Age hunters. Munich 2006; Klaus Schmidt: Early Neolithic temples. A research report on the pre-ceramic Neolithic Upper Mesopotamia. In: Mitteilungen der deutschen Orient-Gesellschaft , 1998, pp. 17–49.

- ^ Homepage of the University of Vienna: The Helwan Project. (accessed April 20, 2012); E. Christina Köhler, J. Jones: Helwan II. The Early Dynastic and Old Kingdom Funerary Relief Slabs. Rahden 2009.

- ^ Siegfried Schott: Ancient Egyptian festival dates. Publishing house of the Academy of Sciences and Literature. Harrassowitz, Mainz / Wiesbaden 1950, p. 59.

- ^ D. Arnold: Building in Egypt. P. 3.

- ^ D. Arnold: Building in Egypt. P. 41.

- ^ DA Stocks: Sticks and stones of Egyptian technology. In: Popular Archeology 7, 1986, pp. 24-29.

- ^ D. Arnold: Building in Egypt. P. 42.

- ^ Zaki Nour: Cheops Boats. Pp. 34-39.

- ↑ Mark Lehner: Secret of the pyramids. Munich 1997, p. 209 ff.

- ^ D. Arnold: Building in Egypt. P. 47 f.

- ^ A b D. Arnold: Lexicon of Egyptian architecture. P. 247.

- ↑ Lehner: Secret of the pyramids. P. 210.

- ↑ Rosemarie Klemm, Dietrich D. Klemm: stones and quarries in ancient Egypt. Berlin u. a. 1993, p. VII ff., 45.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 248.

- ^ Dietrich Klemm, Rosemarie Klemm: The Stones of the Pyramids. Provenance of the Building Stones of the Old Kingdom Pyramids of Egypt. Berlin / New York 2010, p. 82 ff.

- ↑ Mark Lehner: Secret of the pyramids. Munich 1997, p. 206.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 249; D. Arnold: Building in Egypt. P. 27 ff.

- ^ D. Arnold: Building in Egypt.

- ↑ Lehner: Secret of the pyramids. P. 207.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 37 f .; D. Arnold: Building in Egypt. P. 79 ff.

- ↑ For a more detailed presentation see D. Arnold: Building in Egypt. P. 79 ff.

- ↑ Zakaria Goneim: Horus Sekhem-khet. The unfinished Step Pyramid. Volume 1 Le Caire 1957, plate XV.

- ^ D. Arnold: Building in Egypt. P. 81; Günter Dreyer, Nabil Swelim: The small step pyramid of Abydos-Süd (Sinki). In: Communications of the German Archaeological Institute, Department Kairo 38, Mainz, 1982, pp. 83–93.

- ^ D. Arnold: Building in Egypt. P. 85 ff .; Lehner: Secret of the pyramids. P. 202 f.

- ↑ Lehner: Secret of the pyramids. P. 203.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 103 .; D. Arnold: Building in Egypt. P. 71 f.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 103; D. Arnold: Building in Egypt. P. 71 f., 270 f.

- ↑ Wolfgang Helck, Wolfhart Westendorf: Article Talatat. In: Lexikon der Ägyptologie Volume VI, Wiesbaden, 1986, Sp. 186 f.

- ^ Arnold: Lexicon of Egyptian architecture. P. 259; Rainer Hanke: Amarna reliefs from Hermopolis. New publications and studies. (= Hildesheim Egyptological Contributions (HÄB) 2) Hildesheim, 1978.

- ↑ Sergio Donadoni: Article Plan. In: Wolfgang Helck, Wolfhart Westendorf (Hrsg.): Lexikon der Ägyptologie. Volume IV, Wiesbaden 1982, column 1058 and note 1.

- ^ Arnold: Lexicon of Egyptian architecture. P. 27.

- ^ Friedhelm Hoffmann : Egypt, culture and life in Greco-Roman times. A representation based on the demotic sources. Akademie-Verlag, Berlin 2000, p. 206.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 36 f .; D. Arnold: Article blueprints. In: Wolfgang Helck, Eberhard Otto (Hrsg.): Lexikon der Ägyptologie. Volume I, Wiesbaden 1975, Col. 661 f. See also: Ludwig Borchardt: Ancient Egyptian work drawings. In: Zeitschrift für ägyptische Sprache und Altertumskunde 34, 1896, pp. 69–90 ( online ).

- ^ Herbert E. Winlock: The Egyptian Expedition 1921-1922. In: BMMA II 17/1922, pp. 26-27; Dieter Arnold: The temple of King Mentuhotep from Deir el-Bahari. Volume I. Architecture and Interpretation. Mainz 1974, p. 42 and pl. 33; Dieter Arnold: The temple of King Mentuhotep from Deir el-Bahari. Volume II. The wall reliefs of the sanctuary. Mainz 1974, Fig. 6; Dieter Arnold: The Temple of Mentuhotep at Deir el-Bahari. From the Notes of Herbert Winlock. New York 1979.

- ↑ Norman de Garis Davies: An Architect's Plan from Thebes. In: Journal of Egyptian Archeology 4, 1917, pp. 194-199.

- ↑ Norman de Garis Davies: An Architectural Sketch at Sheikh Said. In: Ancient Egypt. 1917, pp. 21-25.

- ^ Howard Carter, Alan H. Gardiner: The Tomb of Ramses IV and the Turin Plan of a Royal Tomb. In: Journal of Egyptian Archeology 4, 1917, pp. 130 ff .; Carl Richard Lepsius: Basic plan of the tomb of King Ramses IV in a Turin papyrus. (Treatises of the Royal Academy of Sciences in Berlin.) Berlin 1867.

- ^ Arnold: Lexicon of Egyptian architecture. P. 37.

- ^ William C. Hayes: Ostraka and name stones from the tomb of Sen-Mūt (no. 71) at Thebes. New York 1942, p. 15.

- ^ SRK Glanville: Working Plan for a Shrine. In: Journal of Egyptian Archeology 16, 1930, pp. 237-239; Charles C. Van Siclen III .: Ostracon BM41228: A Sketch Plan of a Shrine Reconsidered. In: Göttinger Miszellen 90, 1986, pp. 71-77.

- ^ D. Arnold: Lexicon of Egyptian architecture. P. 37.