ICE 3

| ICE 3 | |

|---|---|

|

An ICE 3 at the Oberhaider-Wald-Tunnel on the high-speed line Cologne – Rhine / Main

|

|

| Numbering: |

403 series 406 series 407 series |

| Number: | BR 403: 50 BR 406: 17 built, 16 in service BR 407: 17 |

| Manufacturer: | Siemens / Bombardier |

| Year of construction (s): | 1997-2012 |

| Axis formula : | Bo'Bo '+ 2'2' + Bo'Bo '+ 2'2' + 2'2 '+ Bo'Bo' + 2'2 '+ Bo'Bo' |

| Gauge : | 1435 mm ( standard gauge ) |

| Length over coupling: | 200.84 m end car: 25,835 mm middle car: 24,775 mm |

| Height: | 3890 mm |

| Width: | up to 2950 mm |

| Trunnion Distance: | 17,375 mm |

| Empty mass: | 409 tonnes BR 406: 463.257 t ready for operation |

| Service mass: | BR 406: 495.670 t normal payload 520.040 t maximum payload |

| Wheel set mass : | BR 406: 15.64 t ready for operation 16.80 t normal payload 17.59 t maximum payload |

| Top speed: | 330 km / h (alternating current, constructive) 220 km / h (direct current, constructive) |

| Continuous output : | 8000 kW 4300 kW (direct current) |

| Starting tractive effort: | 300 kN |

| Performance indicator: | 19.6 kW / t (ICE 3) 18.4 kW / t (ICE 3M) |

| Power system : | 15 kV 16.7 Hz ~ (ICE 3) 15 kV 16.7 Hz ~ / 25 kV 50 Hz ~ / 1.5 kV = / 3 kV = (ICE 3M) |

| Power transmission: | Overhead line |

| Number of traction motors: | 16 |

| Drive: | Axis-riding gear with curved tooth coupling between frame motor and pinion shaft |

| Brake: | Motor brake , eddy current brake , disc brake , spring brake |

| Coupling type: | Scharfenberg |

| Seats: | 1st class / 2nd Class / total BR 403 1st series: 98/356/454 BR 403 2nd series: 98/362/460 BR 406 / 406F: 91/334/425 BR 407: 111/333/460 |

| Floor height: | 1250 mm above sea level |

As ICE 3 different series of be ICE - high speed trains called. With a top speed of 330 km / h , they are the fastest passenger trains operated by Deutsche Bahn. In regular operation, they can reach speeds of up to 300 km / h in Germany and up to 320 km / h in France .

A key feature of the ICE 3 is the drive that is distributed under the floor over the entire train . Four of the eight cars of an ICE 3 multiple unit about 200 m long are powered. Compared to locomotive-hauled trains, the ICE 3 has a lower axle load and more seats for the same train length.

As of November 1, 2017, there were a total of 80 ICE 3 multiple units in the inventory of Deutsche Bahn AG and a further 3 in the inventory of Nederlandse Spoorwegen . Originally 54 multiple units were delivered in 2000 and 2001, 37 of which were single-system trains from the 403 series and 17 multi-system trains from the 406 series for traffic to Belgium and the Netherlands. In 2004 and 2005, a further 13 single-system trains from the 403 series of a second series were delivered. For traffic to France , six of the 17 multi-system trains were converted into the 406F series (also ICE 3MF ). The 17 multi-system trains of the 407 series ( Velaro D ), which were commissioned in 2008 and have been in passenger service since 2013, are also assigned to the ICE 3 family as ICE 3 MS .

Within the company, all ICE 3 trains are named ICE W . W stands for eddy current brake , a braking technology that the older ICE series trains do not have.

history

Technical concept

The concept of the ICE 3, which was developed from scratch, arose from European compatibility specifications and technical requirements. A scheduled maximum speed of 300 km / h (corresponding to an increase in drive power of around 60 percent), a maximum static axle load of 17 t and a maximum train length of 400 m with a reduced vehicle width (according to UIC 505-1) were planned.

Initial considerations, based on the ICE, to create 2 half-trains with two power cars and six intermediate cars were also discarded due to excessive technical and economic complexity, as were variants with an additional booster (a central railcar without a driver's cab). At the beginning of 1994, the decision was made for the ICE 3 to abandon the previous power head concept in favor of a multiple unit. This concept was finally offered to Deutsche Bahn by industry.

A three-system variant planned in the early planning stage, which would have been called the 405 series , was discarded, as was a two- system variant under the 404 series .

construction

The following table gives an overview of the structure of the ICE 3 multiple units:

| Serial number | [x9] | [x8] | [x7] | [x6] | [x5] | [x4] | [x3] | [x2] | [x1] |

|---|---|---|---|---|---|---|---|---|---|

| Class 403 (8 cars) | 5 403.0 | 5 403.1 | 5 403.2 | 5 403.3 | 5 403.8 | - | 5 403.7 | 5 403.6 | 5 403.5 |

| Class 406 (8 cars) | 5 406.0 | 5 406.1 | 5 406.2 | 5 406.3 | 5 406.8 | - | 5 406.7 | 5 406.6 | 5 406.5 |

| Class 407 (8 cars) | 5 407.0 | 5 407.1 | - | 5 407.2 | 5 407.3 | 5 407.8 | 5 407.7 | 5 407.6 | 5 407.5 |

Particularities:

- Highlighted units are powered

- Car 5 403.0 / 5 406.0 / 5 407.0: 1st class end car with a driver's cab

- Car 5 403.1 / 5 406.1 / 5 407.1: 1st class transformer car with pantograph

- Car 5 403.5 / 5 406.5 / 5 407.5: 2nd class end car with a driver's cab

- Car 5 403.6 / 5 406.6 / 5 407.6: 2nd class transformer car with pantograph

- Car 5 403.3 / 5 406.3 / 5 407.2: on-board bistro / on-board restaurant

design

concept

The design of the ICE-3 multiple units was to be taken over from the ICE-T, for which Deutsche Bahn announced a competition in autumn 1994. The requirement was that the drafts had to be easily adaptable to the ICE 3, so that a uniform design could be found for both vehicle series.

In a briefing to the invited designers, Deutsche Bahn emphasized that the new vehicles should "make the technical progress and the existence of a new generation of vehicles visible". It is “imperative to give the vehicles a forward-looking design. They have to exceed today's national and international standards, because the main application of these trains is in the 3rd millennium. "

Deutsche Bahn had recognized that in the competition between modes of transport it would have to orient itself more closely to the needs of customers and work out its unique selling points more clearly, both in terms of technology and design, and largely gave the designers a free hand for the design.

execution

The design offices Pininfarina (near Turin ), DesignworksUSA ( Los Angeles ) and Neumeister ( Munich ) were invited by Deutsche Bahn to participate in the design competition that opened in autumn 1994 . You should submit a draft design along with a 1:10 scale model within five weeks. The German railroad cars AG ( Görlitz ) participated on their own initiative in the competition.

After an internal assessment by Deutsche Bahn and the industry, the drafts were submitted to the board of Deutsche Bahn for decision at the beginning of December 1994.

A team led by Alexander Neumeister was awarded the contract to design both multiple unit series in 1994 . Only the driver's cab , the passenger information system ( Siemens Design & Messe , in coordination with Neumeister) and the seats (DesignworksUSA) were designed by other companies. The on-board restaurant was originally designed by Siemens Design. After their proposal was not accepted by the board of Deutsche Bahn, the Neumeister team quickly developed a new design.

The design concept of the trains ran parallel to that of the ICE T . The interior and exterior design clearly stands out from the design of the ICE 1 and ICE 2 , which went into service in the early and mid-1990s . With the continuous, mirrored window band and the characteristic paintwork (red stripes on a white background), the key design elements of the ICE family have been retained.

In the first half of 1995, Neumeister's competition design was further elaborated and refined, and a model ( two-meter model ) of the outer shape and an interior segment on a scale of 1:20 were created and presented. In the following three months, other original -size models ( mock-ups ) costing several million DM were created . Non-rollable 1: 1 models of an end car and a restaurant car were built in a Siemens Nixdorf workshop in Poing and, together with the model of an ICE T, set up on a platform in December 1995 and presented to the railroad management board. The mock-ups were in the factory near Munich for almost a year and were used, among other things, for customer surveys. In addition, several models of three and a half cars in 1:20 and 1:10 scale were created in early 1996 for technical optimization.

The interior design elements that are characteristic of the ICE 3 and ICE T include curved, sandblasted , semi-transparent, glass luggage racks, numerous cladding made of beech wood and the use of chrome , stone and leather .

Neumeister's competition design also provided for numerous other innovations in the interior that were not implemented. These include, for example, largely rotatable seats, an alternative lounge concept and interior lighting based on fiber optics with color changes between day and night. Originally it was planned to equip the train exclusively with large areas; In the course of the design development, Deutsche Bahn required the installation of compartments in 1st class. The seats of the ICE 3 largely correspond to those of the ICE 2 , with minor changes .

The design of the ICE 3 was awarded the Federal Product Design Prize. The front part of the end car mock-up is exhibited today in the DB Museum in Nuremberg .

Among the postage stamps issued in 2006 , a welfare stamp with the motif of an ICE 3 appeared on October 5th .

Orders and costs

In July 1994, Deutsche Bahn ordered a total of 50 of the new high-speed trains from the industry. 13 trains should be usable in cross-border traffic. The first four trains were to be used with the timetable change in December 1997 between Frankfurt, Cologne and Amsterdam.

The acquisition costs for the 37 ICE 3 and 13 ICE 3M were initially 1.6 billion DM and were later given as 1.9 billion DM. In addition, there was an option for 50 more multiple units. On March 16, 1999 it was decided to call up 14 trains from this option. The rest of the option lapsed.

In September 1995, the Dutch State Railways and Siemens signed a letter of intent for the purchase of six ICE high-speed trains. Production of the trains, which cost a total of 210 million euros , was to begin in January 1996 and the trains were to be handed over at the end of 1998. The letter of intent also contained an option for further trains. Four multiple units were later ordered and delivered.

In the early planning phase, up to around mid-1996, the trains were referred to as ICE 2.2 (according to one source also ICE 2/2 ) for contractual reasons . The designation ICE 2.2 was due to the fact that the ICE 3 delivery contract was based on a conversion right from the ICE 2 delivery contract for a total of 73 additional ICE 2 trains. Although the third generation of ICE was technically very different from the second generation of ICE, the connection to the ICE 2 contract should be documented with the designation ICE 2.2 .

The units were built by the manufacturer consortium known as the ICE 2 consortium under the leadership of Bombardier Transportation and Siemens Verkehrstechnik . The car bodies were manufactured by Siemens-DUEWAG (today: Siemens), Adtranz (today Bombardier), Bombardier and Alstom . Siemens and Adtranz took over the electrical equipment. Siemens' own share was around 20 to 25 percent. There was also an option for 50 additional eight- car vehicles .

At times (around 2005) the Austrian Federal Railways also considered purchasing ICE 3.

As compensation for a class 406 multiple unit that had been canceled due to an accident, the DB bought one of its multiple units from the NS. As of January 1, 2013, the DB again owned 63 multiple units, the NS now 3.

Installation

In October 1998, rolling tests were carried out on the Munich-Freimann dynamometer . For the first time, parts of a train (the three cars 406 001/201/301) were officially exhibited at the Eurailspeed in Berlin at the end of October .

From December 1998 an eight-part multiple unit was in the Wegberg-Wildenrath test center . In 1999, the trains started operating there. On February 1, 1999, multiple unit 301 completed its first journeys under its own power on the outer ring, including journeys at higher speeds. In March 1999 the first two end cars of an ICE 3M of the Dutch State Railways arrived at the test center.

The presentation of the first ICE 3 took place on July 9, 1999, also in Wildenrath . In mid-1999, a Deutsche Bahn and one of the Dutch State Railways each were on the move on the DB network. At the beginning of August 1999 a multiple unit was transferred for approval runs in the network of the Dutch railways. The first personnel training trips took place in March and April 2000, and a trial run with employees took place in May 2000.

On May 23, 2000 the first ICE 3 was presented to the trade press at the ICE plant in Berlin-Rummelsburg . Representatives of the ICE-3 working group symbolically presented the then railway boss Hartmut Mehdorn with a large key for the train (Item 303). On a subsequent presentation trip for journalists to Wolfsburg, the train with special approval reached a top speed of 307 km / h.

To start passenger service at the end of May 2000, 14 multiple units of the 403 and 406 series were available. They were initially approved for 250 km / h on new lines, 200 km / h (on LZB in the old network) or 140 km / h (without LZB). The multiple units were first used in passenger service between June 1 and October 31, 2000, as Expo-Express (EXE) for Expo 2000 . An ICE 3M ran from Amsterdam via Osnabrück to Hanover. Initially, eight ICE 3 and three ICE 3M were available. The maximum speed of the trains was initially limited to 200 km / h; higher speeds were only achieved on individual eddy current-enhanced sections.

At the beginning of October 2000, 23 trains of the 403 series and six of the 406 series were available for operation. On November 5, 2000, operations started on the Munich - Hamburg / Bremen line (with wing in Hanover ). At the same time, scheduled operation in the Netherlands was started. A two-hour cycle was set up between Cologne and Amsterdam, and a pair of trains ran from and to Frankfurt am Main; two EuroCity train pairs were initially retained. As of October 24th, a multiple unit was already in use with two pairs of EuroCity trains. In the first few months of operation, the trains ran without major disruptions; However, due to an assumed sensitivity to crosswinds , the maximum speed of the multiple units was initially limited to 200 km / h on many routes. In the first year of operation, the trains remained without major abnormalities.

In another test run in 2000, the train reached a speed of 368 km / h, setting a new world record for mass-produced rail vehicles . When the timetable changed in December 2000, around two thirds of the 54 trains ordered had been handed over. In August 2001 the delivery of the ICE 3M was completely completed.

For the approval of the ICE 3 trains for 330 km / h, an ICE 3 reached a speed of 367 km / h during an acceptance test on September 3, 2001 at Gardelegen (high-speed line Hanover – Berlin). On the basis of the measurement data obtained, the Federal Railway Authority was to make a decision by 2002 about the approval of trains for 330 km / h, while the maximum operational speed of the trains was initially limited to 230 km / h. On February 22, 2001, an ICE 3M between Berlin and Wolfsburg had reached a top speed of 355 km / h.

For the (later) approval in Switzerland, an ICE 3M multiple unit was on the road in the Alpine republic in the first week of December 2000. The use of the eddy current brake, even for rapid braking, is not intended in Switzerland. Further test runs on behalf of the ICE 3 consortium for the technical approval of the R series followed between May 1 and 15, 2001. Among other things, a train was traveling on the Gotthard southern ramp. In the gray wood tunnel , speeds of over 200 km / h were achieved. At the end of 2001, test series were carried out in Switzerland, Belgium and France for the approval of the vehicles. The approval in Switzerland was granted after six months. Since the ZUB-262 devices were not converted to the Euro-ZUB devices that are now required for cost reasons, this approval was ultimately not used.

In preparation for the commissioning of the new Cologne – Rhine / Main line, towing and coupling tests were carried out on the Erkrath – Hochdahl steep ramp with trains that had broken down on steep gradients . From January 2002, the trains were used for licensed journeys on the new Cologne – Rhine / Main line.

From October 2001, a test operation (without passengers) took place on the new high-speed route Cologne – Rhine / Main. To open the high-speed line, two ICE 3 full trains (each in double traction ) ran the line in parallel (multiple units 328/331 and 307/302). From August 1 to December 14, 2002, eight ICE 3 multiple units were used for the scheduled shuttle service between Cologne and Frankfurt. On the new high-speed line, the trains reached 300 km / h for the first time in passenger traffic, higher than the other ICE multiple units approved for up to 280 km / h.

In order to ensure that the trains run safely in strong crosswinds , underground weights of 1,550 kg per car were installed in both end cars of all single-system trains in the second half of 2002. With the start of the full operating program on the new line, the ICE 3 trains were withdrawn from the north-south route Hamburg / Bremen – Munich on December 15, 2002. Numerous technical problems arose on the new route, which led to delays and train cancellations. All traction motors supplied by Bombardier had to be overhauled (every second in total), as did the eddy current brakes, which regularly hit the rails - the insulation that was thus detached meant that water could penetrate the coils, which led to short circuits. According to the railway, up to 700 malfunction reports of the two highest categories were received in the trains' diagnostic systems every day. According to media reports, there were repeated problems with the coupling of two train parts. Problems also arose regularly with the transition to the Belgian 3 kV network. In the summer of 2003, the air conditioning systems on the trains proved to be too weak. There were numerous failures of overloaded air conditioning systems. At the end of March 2004, the conversion of the systems began; Externally, these can be recognized by roof attachments that are designed to prevent warm exhaust air from being sucked in.

With the timetable change on December 15, 2002, full operation of the new Cologne – Rhine / Main line with ICE 3 trains began. An average of 33 sets of the 403 series and eleven of the 406 series were used for 112 daily train journeys on seven lines. The average mileage of the multiple units reached around 500,000 km per year. According to the manufacturer, besides the two earlier ICE generations, it was the highest annual mileage of all high-speed trains worldwide. The manufacturer justified the sudden occurrence of a number of technical problems in 2003 largely with the high demands on the fleet. By the end of October 2003, the ICE 3 fleet had a total mileage of around 46 million kilometers.

With the timetable change on December 14, 2003, the planned annual mileage was increased to more than 550,000 train kilometers by further intensifying the operations. This was the top value in the ICE family. A further increase in mileage was planned for 2004.

On December 21, 2004, then Federal Chancellor Gerhard Schröder and Russian President Vladimir Putin drove from Dortmund to Düsseldorf in an ICE 3 . The occasion was the order for 60 Velaro RUS from the Russian State Railways . By the turn of the year 2004/2005 the ICE 3 fleet had covered around 70 million kilometers, individual multiple units up to 1.8 million kilometers.

As a result of increased damage levels and other causes, some trains on line 41 (Nuremberg – Essen) were temporarily canceled in the summer of 2005. At the end of 2005, seven ICE 3 trains were the first ICE trains to be equipped for mobile Internet access (so-called Mobility Net ). All ICE 3 trains for domestic traffic (403 series) now have this equipment, which can be used to access the Internet via WLAN on individual routes .

In 2002 and 2006, two ICE-3 multiple units each were used in double traction to open the high-speed line Cologne – Rhine / Main and the high-speed line Nuremberg – Ingolstadt – Munich .

In mid-2006, a new coupling head was tested on an ICE 3.

Reconstruction of the interior (2002)

Originally the trains consisted of four 2nd class cars and three 1st class cars, which were separated by a dining car. They offered 415 (403 series; 141 in 1st class) or 404 (406 series) seats - each including 24 seats in the restaurant.

At the beginning of 2002, the interior fittings of the trains were rebuilt in the Delitzsch and Hagen repair shops . Investigations with a view to the imminent opening of the high-speed line Cologne – Rhine / Main had shown that the number of seats in 1st class was too high, whereas in 2nd class it was too low.

The 1st class intermediate car 26/36 next to the dining car was converted into a 2nd class car; the three compartments of the car were retained - for the first time, three compartments are also available in 2nd class. As part of the retrofit, the seat spacing (large area) was reduced from 971 to 920 mm. In addition, some of the tables and cloakrooms have been removed from both classes. The measures increased the number of seats to 441 (403 series) and 431 (406 series). Another source speaks of an increase from 416 to 454 seats per train - while the number of seats in 1st class fell from 141 to 98, the number of seats in 2nd class rose from 250 to 356. This resulted in the vote of seats on the windows are given up, so that some window seats are at the level of an outside wall (so-called wall window seats ).

There was no play wall or toy motorcycle in the children's compartment; the compartment was redesignated as a multifunctional compartment. The removal of the restaurant area, which was replaced by bistro tables and twelve regular 2nd class passenger seats, met with massive criticism. As part of a new gastronomy concept, from the opening of the high-speed route Cologne – Rhine / Main, an increased at-the-seat service should be offered instead of the restaurant . Deutsche Bahn did not implement plans to expand this concept to other ICE multiple units after the line opened.

The weight per seat (in the original seating) has been reduced by ten percent compared to the ICE 2. The steps have been optimized for platform heights of 76 and 55 centimeters.

Problems with axles

On July 9, 2008 at 4:12 p.m., an ICE 3 (multiple unit 310 Wolfsburg ), which was traveling from Munich to Dortmund as ICE 518, derailed when exiting Cologne main station in front of the Hohenzollern Bridge due to a broken axle . The train was brought to a standstill by emergency braking after the wheelset rolled over the sleepers. Nobody was injured in the accident, and passengers were able to return to the platform through doors at the end of the two parts of the train. During the journey on the high-speed route from Frankfurt am Main airport long-distance train station to Cologne Hbf, passengers had informed the train attendants about abnormal driving noises. In its investigation report, the Federal Agency for Railway Accident Investigation came to the conclusion that the shaft had already broken before entering Cologne Hbf the wheelset shaft could already have broken in the approach of the train to Cologne Hbf on the new line in the northern section in the area Dierdorf - Windhagen. "

Due to imminent danger , the Federal Railway Authority issued a notice on July 10, 2008, to shut down all ICE-3 trains after the end of the journey on that day, where the ultrasonic test of the axles had been more than 60,000 kilometers ago . The regular intervals for ultrasound examinations of the wheelset shafts made of 34CrNiMo6 stainless steel have also been shortened from 300,000 to 60,000 km by an EBA order. (This was later reduced to 30,000) 61 out of 67 multiple units were initially affected. As a result, several hundred trains were canceled in whole or in part in the following days or were replaced by replacement trains.

According to an expert report by the Federal Institute for Materials Research from 2009, material contamination is the likely cause of the breakage of the wheelset shaft . Vatroslav Grubisic, a specialist in the dimensioning of vehicle parts, warned of the inadequate design of the wheelset shafts before the accident, referring to the breakage of a wheelset shaft on the ICE TD . However, his considerations on the dimensioning of the wheelset shafts are controversial in the professional world.

In October 2008, the Federal Railway Authority further reduced the test intervals for the wheelset shafts after a crack two millimeters deep had previously been discovered in a similar shaft of an ICE T. As a result, the ICE 3 was restricted in circulation, which led to the failure of train parts and entire trains. The diagnosis of all 32 axles of an ICE 3 multiple unit, which is now required every 20 days or so, takes at least 16 hours per multiple unit.

A working group from Deutsche Bahn, Siemens, Alstom and Bombardier worked on technical solutions in early 2009. A complete replacement of the wheelset shafts was initially expected to cost around ten million euros. At that time, the delivery time for new shafts was around six months, with installation taking around one to one and a half years. The axles of the ICE 3 trains of the second series were not objected to. At the beginning of 2009, Deutsche Bahn deemed it necessary to replace all wheelset shafts. From the company's point of view, the industry was asked to take care of it.

By mid-2009, Deutsche Bahn had procured eleven new ultrasound systems with a total value of three million euros in connection with the accident. At the beginning of January 2010, the company spoke of having largely reduced the restrictions that customers felt with eleven additional ultrasonic systems, 135 additional employees and the new ICE plant in Leipzig .

In mid-July 2009, the Cologne Public Prosecutor closed the investigation against Deutsche Bahn due to the lack of suspicion . DB employees are not responsible for any breaches of duty during the incoming inspection of the wheelset shaft.

On October 12, 2009, Deutsche Bahn announced an agreement with Siemens and Bombardier. Accordingly, new drive wheel set shafts made of stainless steel 25 CrMo 4 (EA4T) should be developed and tested for the trains. After the shafts were approved, all of the roughly 1,200 drive wheel set shafts on the ICE 3 trains were to be replaced. According to press reports, the manufacturers should pay for the spare parts costs (an estimated 84 million euros). Approval of the wheelset shafts was initially expected by the end of 2010, with installation in series production in 2011. In mid-2012, Deutsche Bahn expected to start converting to around 1,200 new wheelsets in the third quarter of 2012. Ten trains should have been converted by the timetable change in December 2012. The conversion should be finished at the end of 2014. The interval for the ultrasound checks should thus be increased from 30,000 to 240,000 kilometers. Due to delays in the approval process, the start of the conversion originally planned for 2011 could not be kept.

The new shafts were available in February 2012. The 1200 new axles were completely produced and stored at the beginning of 2013. The Federal Railway Authority insisted on a new registration and test drives for each individual multiple unit due to the higher weight. At the beginning of 2012, DB planned to receive approval in the first quarter of 2013 and to finish the upgrade in 2015. According to a media report from the end of 2013, the installation of the new shafts should start in early 2014 and take two and a half years.

The approval finally took place at the end of October 2014; Afterwards, the renovation began, which should be completed by 2016. For technical reasons, initially only the 50 trains of the 403 series should be converted. In March 2019, DB Fernverkehr informed the Federal Agency for Railway Accident Investigation that the replacement of the drive wheel set shafts for the 403 series had been completed.

Siemens took over the development costs of the new axles, the Deutsche Bahn the costs for approval and installation. Siemens and Deutsche Bahn agreed not to disclose the total cost of the exchange. They should be in the lower double-digit million euro range. According to a press report, Deutsche Bahn suffered damage of several hundred million euros due to the shortened inspection intervals (lost sales, additional employees, costs for maintenance and replacement of the axles). Unofficially it is 350 million euros up to and including 2009. Rail boss Rüdiger Grube had put the damage to the railroad from the problems with the axles of the ICE 3 and ICE T at 250 million euros in June 2009 and announced claims for damages against the manufacturers Siemens, Bombardier and Alstom. Before doing this, however, negotiations should take place; If necessary, discounts for new rail purchases are also a solution. Siemens sees no basis for compensation because the shafts were manufactured according to applicable standards and approved by the railway. Bombardier also sees no basis for compensation.

407 series

In 2007, the railway launched a tender for a further four-system EMUs (for Germany, France, Belgium and optionally to Switzerland) h for a maximum speed of 320 km / and at least 420 seats, from Siemens with an eight-car Velaro D trainset victorious emerged. The multiple units are included in the ICE 3 fleet, although they are a new design. However, the concept and technology of the ICE 3M is very similar. They operate to France, Belgium and within Germany.

Commissioning, initially scheduled for December 2011, was delayed by over two years. The 16 planned units were also not available as planned for the timetable change in December 2012 because the Federal Railway Authority did not issue approval. An expert complained that the braking system only responded with a delay of over a second due to problems with the control software. In addition, there were apparently other technical problems. In September 2013, Deutsche Bahn no longer expected use in domestic traffic before the first quarter of 2014 [obsolete] and full international operational readiness before the end of 2016. [obsolete] In fact, the Federal Railway Authority granted approval shortly before Christmas 2013.

Modernization of the interior

In 2016, after the ICE-T redesign, which began at the end of 2013 and was completed at the end of 2015, the 67 ICE 3 trains are to be modernized for 200 million euros in the Nuremberg repair shop. At the beginning of 2015, the board of directors of Deutsche Bahn should decide on the redesign of the 403 and 406 series. The renovation should start in the 4th quarter of 2015 at the earliest and end in the 4th quarter of 2020.

In 2016, a train was to be converted on a trial basis. The series conversion was now planned for the end of 2016, the use of the first modernized vehicles was planned for July 2017. The rest of the fleet was originally supposed to be converted by 2020. Each train was initially scheduled for twelve weeks and later eight weeks. By December 2017, eleven trains had undergone the redesign, and by the end of 2018 18 multiple units; the first multi-system multiple unit was redesigned in spring 2019. The redesign program was suspended from October 2018 to late summer 2019, so in 2020 the previous schedule was abandoned. Now all multiple units should have gone through the redesign by spring 2024. The redesign will be carried out for all trains in Nuremberg.

As part of the redesign, the trains will receive a completely new interior. The 403 series trains will have new seats. Before the renovation, from the 4th quarter of 2014 at the latest, a three to six month trial and market research should take place with a maximum of 70 places in both classes from three selected providers. The installation of new air conditioning systems is also planned. The installation of a classic on-board restaurant and the European train protection system ETCS is also planned. Findings from the ICE-T test train 1129 are to be incorporated into the ICE-3 redesign. In December 2017, twelve multiple units were equipped with ETCS ( SRS 3.4.0 ). The multiple units are among the world's first vehicles to be equipped according to Baseline 3 .

After the redesign is complete, both series of the 403 series will have a uniform 450 seats, 101 in 1st and 349 in 2nd class. The trains of the 406 series will have 444 seats, 99 of them in 1st and 345 in 2nd class. The restaurants should each have 20 seats. Due to narrower seats, the seat divider (knee depth) should be increased by a few millimeters to 82 cm (2nd class) or 90 cm (1st class). The compartments in the first class are retained.

In October 2019, DB announced that from 2020 a total of almost 60,000 seats in the ICE 3 and ICE 4 would be replaced by a new model. The seats were more comfortable and had previously been tested by 600 people in the seating laboratory and 5800 passengers.

Accidents

outlook

Since the commissioning of the last new line of the German Unity No. 8 (VDE 8) traffic project, ICE 3 trains have been running three times a day as ICE Sprinters between Berlin and Munich. The ICE sprinters have been running 5 times a day in each direction since December 2018. Most of them also run on the ICE Sprinter line 15 (Berlin-Erfurt-Frankfurt). Due to the high demand, even more ICE 3 trains are to be used on VDE 8 in the future. To this end, consideration is being given to replacing ICE 3 on line 42 (Dortmund – Stuttgart – Munich) with a thirteen-part ICE 4.

In 2019, Deutsche Bahn considered purchasing a new generation of high-speed trains based on the ICE 3. In July 2020, it was announced that Deutsche Bahn had ordered 30 new Velaro trains from Siemens for around one billion euros in order to increase the number of high-speed connections as part of the corporate strategy “Strong Rail”.

Carriage arrangement and arrangement

The 67 multiple units consist of eight cars:

- 1st class powered end car with open seating area and lounge (car 29/39, series 403.0 / 406.0)

- 1st class non-powered intermediate car with open space and three compartments (car 28/38, class 403.1 / 406.1)

- 2nd class powered intermediate car with open seating and three compartments (car 27/37, class 403.2 / 406.2) - until 2002, 1st class car. In the 13 trains that were delivered in 2005/2006, the car is designed as a continuous open-plan car.

- Non-powered dining car with seating area, galley , bistro with four standing tables as well as train attendants' compartment, telephone booth (removed later) and personal toilet (car 26/36, class 403.3 / 406.3).

- 2nd class non-powered intermediate car with barrier-free toilet (with changing table ), children's compartment and open-plan area (car 25/35, class 403.8 / 406.8)

- powered intermediate car with open space 2nd class (car 23/33, class 403.7 / 406.7)

- 2nd class non-powered intermediate car with open seating (car 22/32, class 403.6 / 406.6)

- powered end car with open plan 2nd class and lounge (car 21/31, class 403.5 / 406.5)

If the trains with a train unit run as a half train, the wagons are numbered 21 to 29.If two half trains run as a block train, the wagons of the two train units are given the numbers 21 to 29 and 31 to 39.

The vehicle gauge largely corresponds to the standard of the International Union of Railways (UIC). In principle, the vehicles can therefore be used freely in Europe. The car length of the end car is 25,675 mm, that of the middle car is 24,775 mm. With a maximum of 2,950 mm, the car body width is up to 23 mm above the specification of the relevant UIC leaflet 505. This excess of dimension was agreed with the neighboring railways. The large areas of the train are up to 2.25 m high, the vestibules 2.05 m.

The ICE 3 of the first series (also ICE 3M / MF ) had a dining car ( serial number 25/35) with a bistro and restaurant upon delivery . As part of the introduction of a new catering concept, which provided for increased service at the square, the restaurant area was replaced by twelve seats and an additional bistro area with four standing tables. The ICE 3 trains of the second series have already been delivered with this equipment.

When the first series was delivered, two out of eight cars were still intended for smokers. Since the end of 2008 the vehicles have been non-smoking trains.

technology

particularities

In addition to the ICE T , which was developed in parallel, the ICE 3 represents a technological leap in German and European high-speed traffic.

They are the first European high-speed series trains,

- in which all drive components below the floor level are distributed over several cars (without power cars ),

- those with eddy current brakes and

- which are provided with a “ lounge ” from which travelers can look “over the shoulder” of the train driver.

Distributed drive

The main innovation of the trains compared to the previous vehicles ICE 1 (from 1991) and ICE 2 (from 1996) is the distributed drive . Almost all of the electrical equipment ( traction motors , traction converters , transformers, etc.) is distributed over the entire length of the train under the passenger compartments. No power cars with their relatively high axle load were used. Eight cars, four of which are powered, form an operationally inseparable multiple unit or an ICE-3 half-train .

Two non-powered intermediate cars are located between each three cars, the two electrically inseparable traction groups . The middle car of each traction group is a non-powered transformer car (TR) with pantograph and transformer (5 MW output per car). The other two are the converter cars (SR) with two motor bogies each with two traction motors (and converters ). The two end cars of a half-train are each provided with a driver's cab . In the single-system half-train, the pantographs are attached to transformer cars 2 and 7. In the multi-system half-train, cars 3 to 6 are each equipped with a pantograph.

The driven cars are each driven by four 500 kW motors (each 750 kg mass), which reach a speed of around 4100 revolutions per minute and a planned mileage of around 2.3 million kilometers (until replacement). With a drive power of 8 MW per half-train, with a maximum service weight of 420 tons, a specific power of 19 kW / t results ; this is about twice as high as that of the ICE 1 . The ICE 3 can be accelerated from 0 to 100 km / h in 49 seconds. The ICE 3 can thus cope with greater gradients than its predecessor series in planned operation. Until the introduction of the ICE 4, it was the only passenger-transporting train that was allowed to use the high-speed Cologne – Rhine / Main line with a route of up to 40 ‰ .

By distributing the drive power to many axles, the adhesive load is reduced, and the more even distribution of the weight saves the maximum axle load to 17 tons. The former ensures that the drive axles have less tendency to skid , which means that better acceleration can be achieved under unfavorable traction conditions. Last but not least, the reduced weight should minimize the stress on the superstructure . The advantage of the underfloor technology can be seen in the better noise insulation of the units located under the passenger compartment through noise barriers. The disadvantage, however, is the inability to separate the multiple units and the greater susceptibility to crosswinds . Calculations in the early phase of development had shown that driving half of the axles would achieve an optimum of the force on the rails, number of motors, weight and recoverable braking energy. This concept gives passengers at both ends of the train a clear view of the route. From the lounge seats, separated only by a pane of glass, you can look over the driver's shoulder. At the same time, the number of seats could be increased by around 15 percent with the same train length.

To test the distributed drive , a powered intermediate car was added to a regular ICE that operated as ICE D and the new ICE S test train was purchased at the end of the 1990s .

The power requirement of an ICE 3 traveling in double traction is given as up to 18 megawatts. With an average mileage of around 500,000 kilometers, each ICE 3 consumed around 10 gigawatt hours of energy in 2009.

Eddy current brakes

The ICE 3 is the first European series train to be equipped with an eddy current brake. The system is only used as a service brake on the new lines Cologne – Rhine / Main, Nuremberg – Ingolstadt , which can be driven at 300 km / h, as well as the new VDE 8 lines . Additional stretches have also been upgraded for use when braking quickly. The maximum permissible speed of the ICE 3 is limited to 250 km / h in order to avoid excessive wear and tear on the disc brakes, which are then already active in low braking levels.

The maximum power consumption of the eddy current brakes per half-train is around 800 kW. Two magnets each 1290 mm long on each bogie generate a braking force of up to 200 kN per half- pull .

Crumple zones

The ICE 3 is also the second high-speed train in Europe after the TGV Duplex that has integrated “ crumple zones ”. In the event of a collision, the coupling and, in a further stage, deliberately deformable elements at the intercar transition absorb the kinetic energy . A three-stage system of cylindrical energy absorbers in front of the driver's cab absorbs the impact energy through controlled compression .

Other technology

Motors and power supply

The separately ventilated traction motors and eddy current brakes are on a common DC intermediate circuit supplies. The motors transmit their torque to the final drives via a curved tooth coupling; the attachment of coupling dampers is prepared. The two transformer cars are connected to one another via a high-voltage roof line so that they can be driven with just one pantograph raised. Converters in the transformer car with an output of 2 × 250 kVA feed the two train busbars of the two halves of the train with a DC voltage of 670 V. From the train busbar, converters with 70 kVA output are fed into the individual carriages. Single-phase 50 Hz consumers are fed via 10 kVA inverters, 20 kVA with 670 V are available for the main heating per car. If both converters fail in one half of the train, the busbars between neighboring traction units are coupled through. Car lighting, door and brake control, the passenger information system as well as drive and train control devices are supplied from a 110 V battery busbar. A battery charger converts 670 volts to 110 volts, supplies the busbar and charges the batteries at the same time.

Bogies

The bogies under the wagons (type SGP 500 ) are a further development of those of the ICE 2. Driven and non-driven bogies have the same structure and differ only in the traction motors attached to them (on driven axles) or eddy current brakes (non-driven axles). All wheel sets each have two (403 series) or three (406 series) brake discs.

Special absorbers reduce wheel noise by five to eight decibels . The train is made of fire retardant materials. The wheel sets must remain operational for at least 15 minutes under full fire conditions.

Brakes

The wheel sets are equipped with pneumatic high-performance brakes, with two wheel brake discs on the drive wheel sets and two (403 series) or three (406 series) shaft brake discs on the non-driven wheel sets, each with a high energy absorption capacity thanks to high-alloy cast steel paired with sintered metal linings. The traction motors on driven wheelsets act as motor brakes, eddy current brakes are attached to the non-driven wheelsets of the train.

The brake systems are controlled by a brake control computer. The majority of the service braking power is provided by engine brakes , supported in sections by eddy current brakes; the maximum braking power of the 16 motors is a total of 8.2 MW. Small and medium delays are produced by eddy current and motor brakes. A braking force of up to 300 kN is generated via disc brakes, the eddy current brakes achieve their greatest braking force with around 150 kN above 180 km / h. The disc brakes are only used in the low speed range or in the event of strong operational or rapid braking. Drivers can also turn on the disc brakes if necessary.

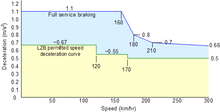

The full braking distance from 300 km / h is specified with 2800 m, that from 330 km / h with 3300 meters. The trains' brake sand containers hold a total of 440 kg of sand. The braking power of the eddy current brake exceeds that of the electromotive brake in the upper speed range. The full braking deceleration is 1.1 m / s² up to 160 km / h and falls above this to 0.6 m / s² for display-guided journeys (LZB, ETCS). Rapid braking takes place in two stages, with a switch from the lower to the higher stage at around 170 km / h. The minimum braking decelerations required in the specification sheet for the trains are between 1.00 m / s² (from 330 km / h) and 1.26 m / s² (from 140 km / h). In braking tests, instantaneous decelerations between around 1.1 m / s² (over 160 km / h) and just under 1.8 m / s² (between 60 and 160 km / h) were measured.

Couplings

The automatic Scharfenberg couplings connect the main air line and main air reservoir line as well as control and information lines. A total of twelve plug and 44 spring contacts are connected to one another. Two ICE-3 half-trains can be coupled to form one train. Coupling an ICE 3 with an ICE T and ICE TD is also possible. The trains will also be able to be coupled with trains from the 407 series using new software .

Guidance system

The train control system is based on the Train Communication Network , which was presented as a draft standard by the International Electronical Commission in 1995. The bus systems are redundant. As a higher-level system, two central control units (ZSGs) in each of the two end cars control and monitor the two traction units. Diagnostic messages are generated by these devices and forwarded to the train crew. This ZSG combines the functions of AFB , central position and speed detection (ZWG), safety driving circuit (Sifa), diagnosis system (DAVID) and the central unit for monitoring and control (ZEUS) , which were previously implemented separately .

Passenger information system and public communication

The passenger information system is controlled from a control center in the conductor's compartment. For communication, a train-wide loudspeaker system, cordless telephones and emergency intercoms (if the control center fails) were set up for the train attendants. For optical communication, displays are available at all entrance areas (inside and outside) as well as LED displays in the ceiling area at both ends of the large areas of each car. While the train's course is faded in when the train stops outside , the current speed is temporarily faded in inside, and two to three-line advertising texts are also shown on the large displays at the end of the car. An electronic reservation system with LED displays at every seat informs about reservations. Numerous other ideas for the passenger information system, for example video-on-demand , television reception, the connection of an ATM and the sale of tickets, tickets and the like, were not implemented.

Public communication, which included a fax machine in the conductor's compartment, was initially handled via the C network and later via GSM networks. There are cars with cell phone amplifiers (D and E networks) in every train . The first class area is equipped with service call buttons. The terminals for timetable information in the first series were later taken out of service.

Air conditioners and toilets

A special feature of the ICE 3 air conditioning systems is the use of air as a refrigerant . The application of the process, which had been used in aviation for a long time, was investigated for railway air conditioning systems from 1991. After the development of laboratory samples (from 1992) ICE 1 cars were finally tested in operation. In January 1996 the decision was made to equip the ICE 3 trains with air-assisted air conditioning. Compared to the ICE 1 air conditioning system with 1,1,1,2-tetrafluoroethane (R134a) as the refrigerant, around 500 kg of weight per car could be saved. This also avoids the global warming potential of R134a , which belongs to the fluorocarbon family . After numerous failures of the air conditioning systems in the summer of 2003, investigations showed that the heat exchangers were too small, and the intake and exhaust openings on the roof were unfavorably arranged. As a result, stronger devices were installed in autumn 2003, which are recognizable as striking angular boxes on the roofs at the ends of the car, while the original air conditioning systems were flush with the roof. In the second series, modified air conditioning systems were installed ex works, but their roof structures were designed to be more aerodynamic.

Between the end of 2014 and autumn 2015, new, air-assisted air conditioning systems were tested on a multiple unit of the first series.

With a water consumption per flush of 0.4 liters (other source: 1.5 liters), the toilets are considered environmentally friendly.

maintenance

After their commissioning, the trains were based at the ICE plant in Munich . The maintenance of the trains is carried out in the depots Frankfurt , Munich and Dortmund , as well as in the smaller works in Cologne and Basel. The ICE 3M trains are based at the Frankfurt-Griesheim plant. This is the only place where the train's multi-system components can be serviced. For this purpose, the four operating voltages can be fed into the plant's overhead line.

According to information from Deutsche Bahn AG, more than one million euros are spent on maintenance per year and vehicle. A major overhaul of the train, necessary every 1.65 million kilometers (originally 1.4 million), costs around 1.2 million euros. It is carried out in the DB repair shop in Krefeld.

In 2003 a small overhaul (so-called "IS 600") was necessary after 1.2 million kilometers, a major overhaul (so-called "IS 700") after 2.4 million kilometers. With the exception of these two major programs, all other maintenance work was carried out at night.

literature

- Michael Krische: ICE - Intercity Express - ICE 1 · 2 · ICE ICE 3 ICE · TD · T · ICE ICE S . GeraMond, Munich 2004, ISBN 3-7654-7110-0 .

- Heinz Kurz: InterCityExpress. The development of high-speed traffic in Germany . EK-Verlag, Freiburg 2009, ISBN 978-3-88255-228-7 .

Web links

Individual evidence

- ↑ a b c d e f g h i j k l m n o p q r s t u Dieter Eikhoff: Everything about the ICE . transpress-Verlag, Stuttgart 2006, ISBN 978-3-613-71277-5 , pp. 41-52.

- ↑ a b c d e f g h i j k l m n o p q r s Heinz Kurz: ICE 3 and ICE T - New generation of railcars for Deutsche Bahn . In: Railway technical review . 48, No. 9/1999, pp. 549-559.

- ↑ Fact sheet: Key data on the ICE family. (PDF; 364 kB) (No longer available online.) Deutsche Bahn AG Kommunikation, archived from the original on July 24, 2013 ; Retrieved on April 28, 2013 (two-page document as of August 1, 2006).

- ^ A b Ansgar Brockmeyer, Thomas Gerhard, Edzard Lübben, Manfred Reisner, Monika Bayrhof: High-speed trains: from power car to distributed traction . In: European Railway Review . Vol. 13, No. 3, 2007, ISSN 1351-1599 , pp. 67-79.

- ^ A b Frank Panier: New DB high-speed multiple units for international use . In: Eisenbahntechnische Rundschau , Issue 9/2010, September 2010, ISSN 0013-2845 , pp. 520-530.

- ↑ Deutsche Bahn AG (Ed.): Fact sheet ICE 3MF ( Memento from July 24, 2013 in the Internet Archive ) (PDF; 295 kB). Three-page document dated May 2007.

- ^ Vehicle lexicon for long-distance transport. DB, August 8, 2019, p. 91 ff. , Accessed on September 28, 2019 .

- ↑ a b c d e f g h Christian Tietze: The premiere of the ICE 3 . In: Eisenbahn Magazin , issue 12/1998, pp. 20 ff, ISSN 0342-1902 .

- ↑ a b Peter Lankes: The third generation: The ICE2.2 . In: Eisenbahn-Kurier , No. 278, November 1998, ISSN 0170-5288 , pp. 36-41.

- ↑ a b c d Alexander Neumeister: The outer face . In: DB Reise & Touristik AG, ICE T consortium (ed.): ICE T. BR 411, 415 and 605 . Hestra-Verlag, Darmstadt 2000, ISBN 3-7771-0288-1 , pp. 24-27.

- ^ The trains with tilting technology from Deutsche Bahn . In: Railway technical review . 49, No. 5/2000, pp. 295-306.

- ↑ a b c look ahead . In: Der Spiegel . Issue 7/1995, February 13, 1995, ISSN 0038-7452 , p. 92.

- ↑ a b Michael Krische: "An optimal compromise" . In: BahnExtra: 20 years of ICE . Edition 6/2004, ISBN 3-89724-175-7 , pp. 48-52.

- ↑ Alexander Neumeister: The interior design . In: DB Reise & Touristik AG, ICE T consortium (ed.): ICE T. BR 411, 415 and 605 . Hestra-Verlag, Darmstadt 2000, ISBN 3-7771-0288-1 , pp. 28-32.

- ↑ a b c d Elke Trappschuh: Faster, further, more beautiful . In: Alex Buck (Ed.): Alexander Neumeister. Designer monographs 8 . Verlag Form, Frankfurt am Main 1999, pp. 16–51.

- ↑ a b c d Armin Scharf: The ICE 3 and the German Pendolino . In: raised ground floor . 1997, No. 4, p. 36 f.

- ↑ a b c Interview with Alex Neumeister: The more complex, the better . In: Buck (1999), pp. 69-81.

- ^ Message ICE T: in schedule operation since the end of May 1999 . In: Railway technical review . 48, No. 6/1999, p. 398.

- ↑ a b c d e The new hits . In: ZUG , No. 11/1996, without ISSN, pp. 20-24.

- ↑ ICE at diving station . In: ZUG , No. 11/1995, without ISSN, p. 14 f.

- ↑ Volker Albus, Achim Heine: Die Bahn. Brand culture positions . Nicolaische Verlagsbuchhandlung, Berlin 2002, ISBN 3-87584-055-0 , p. 62 ff.

- ↑ Bahn orders new trains for three billion DM . In: Süddeutsche Zeitung , No. 196, 1996, ISSN 0174-4917 , p. 23.

- ↑ The train will soon accelerate to 330 km / h . In: Süddeutsche Zeitung , No. 296, 1994, ISSN 0174-4917 , p. 28.

- ↑ a b Deutsche Bahn orders 40 multiple units . In: Süddeutsche Zeitung , No. 189, 1994, ISSN 0174-4917 , p. 22.

- ↑ a b c d Expo premiere for the ICE 3 in Frankfurter Allgemeine Zeitung , May 30, 2000.

- ↑ a b c Konrad Koschinski: The ICE 3 rolls to the EXPO . In: Eisenbahn-Journal . Vol. 26, No. 7/2000, ISSN 0720-051X , pp. 26f.

- ↑ Message redemption of the ICE options . In: Eisenbahn-Revue International , issue 5/1999, ISSN 1421-2811 , p. 170.

- ↑ Holland orders six ICE trains from Siemens . In: Süddeutsche Zeitung , No. 219, 1995, ISSN 0174-4917 , p. 213.

- ↑ Announcement of the start of construction: NBS Cologne – Rhein / Main . In: Railway technical review . 45, No. 1/1996, p. 88.

- ↑ Announcement DB plans for trains of the future: New ICE generations with even more comfort and speed . In: Railway technical review . 45, No. 4/1996, p. 221.

- ↑ Heinz Kurz: InterCityExpress - The development of high-speed traffic in Germany . EK-Verlag, Freiburg, 2009, ISBN 978-3-88255-228-7 , p. 139.

- ↑ ICE 3 in action . In: Eisenbahn-Revue International , issue 7/2000, ISSN 1421-2811 , p. 306 f.

- ↑ a b White Train, Green Banana and Black Peter . In: Frankfurter Allgemeine Zeitung , March 4, 2003.

- ↑ Message No ICE-TD for the ÖBB . In: Eisenbahn-Revue International , issue 6/2005, ISSN 1421-2811 , p. 289.

- ↑ The new faces of the ICE family . In: ZUG , No. 11/1998, without ISSN, pp. 16-19.

- ↑ Message Impressions from InnoTrans and Eurailspeed in Berlin . In: Eisenbahn-Revue International , Issue 12/1998, ISSN 1421-2811 , pp. 518-523.

- ↑ a b ICE 3 in test operation . In: Eisenbahn-Revue International , Issue 9/1999, ISSN 1421-2811 , p. 376 f.

- ↑ Message commissioning of the ICE 3 . In: Eisenbahn-Revue International , Issue 3/1999, ISSN 1421-2811 , p. 59.

- ↑ Report of the Dutch ICE 3 in the Wildenrath test center . In: Eisenbahn-Revue International , issue 4/1999, ISSN 1421-2811 , p. 116.

- ^ Announcement ICE 3 training . In: Eisenbahn-Revue International , issue 6/2000, ISSN 1421-2811 , p. 244.

- ↑ a b Torsten Berndt: Sibling love . In: ER-Verlagsgesellschaft (ed.), Freiburg: ZÜGE . No. 5/2001, without ISSN, pp. 12-17.

- ↑ a b c d e f g h Ernst Reuss: The operational use of the ICE 3 - fleet average mileage at world record level . In: Eisenbahn-Revue International , issue 1/2004, ISSN 1421-2811 , p. 14 f.

- ↑ a b c ICE 3. Clear start for the new star . In: mobile . April 2000, pp. 12-14.

- ↑ New times, new trains . In: mobile . May 2000, p. 10.

- ↑ a b c d Georg Wagner: InterCityExpress - The star trains in long-distance transport of the DB . EK-Verlag, Freiburg 2006, ISBN 3-88255-361-8 , pp. 10-12.

- ↑ Message With the ICE 3 to the EXPO . In: Eisenbahn-Revue International , issue 4/2000, ISSN 1421-2811 , p. 147.

- ↑ ICE acceptance notification is progressing . In: Eisenbahn-Revue International , issue 12/2000, ISSN 1421-2811 , p. 530.

- ^ Message ICE to Amsterdam . In: Eisenbahn-Revue International , issue 12/2000, ISSN 1421-2811 , p. 531.

- ↑ a b c Lukas Gagel: Flagship without flaws . In: Lok Magazin , issue 7/2001, pp. 12–21.

- ↑ Report Spain: Velaro E in passenger use ( Memento from November 24, 2015 in the Internet Archive ). In: eurailpress.com from June 25, 2007.

- ↑ Notification of ICE 3 approval . In: Eisenbahn-Revue International , issue 11/2001, ISSN 1421-2811 , p. 474.

- ↑ News update shortly . In: Eisenbahn-Revue International , issue 4/2001, ISSN 1421-2811 , p. 355.

- ^ Walter von Andrian: ICE 3 high-speed train on a test drive to Switzerland . In: Eisenbahn-Revue International , Issue 2/2001, ISSN 1421-2811 , pp. 66–68.

- ^ Walter von Andrian: ICE 3, ICE-T and ICE-TD in Switzerland . In: Eisenbahn-Revue International , issue 7/2001, ISSN 1421-2811 , p. 302 f.

- ^ Walter von Andrian: ICE 3 on its final spurt to Europe . In: Eisenbahn-Revue International , issue 4/2005, ISSN 1421-2811 , p. 174 f.

- ↑ Report of coupling and towing attempts with ICE 3 . In: Eisenbahn-Revue International , issue 10/2001, ISSN 1421-2811 , p. 429.

- ↑ Wagner (2006), p. 49.

- ↑ Commissioning in two stages . In: On the subject , ZDB -ID 2115698-0 , edition 2/2002, April 2002, pp. 4-7.

- ↑ a b c Thomas Feldmann: altitude zero, the second . In: Lok-Magazin , issue 1/2003, pp. 36–51.

- ↑ Report breakdowns on the new line . In: Eisenbahn-Revue International , issue 3/2003, ISSN 1421-2811 , p. 99.

- ↑ Message ICE 3 with suction hoods . In: Eisenbahn-Revue International , issue 7/2004, ISSN 1421-2811 , p. 290.

- ↑ Eikhoff (2006), pp. 63–96.

- ↑ Electrical operation at Deutsche Bahn in 2004 . In: Elektro Bahnen , Volume 103, Issue 1–2 / 2005, p. 30.

- ↑ ICE 3 bottleneck reveals DB structural deficiency . In: Eisenbahn-Revue International , Issue 8–9 / 2005, p. 367.

- ↑ New coupling head . In: Eisenbahn-Revue International . Issue 8–9 / 2006, ISSN 1421-2811 , p. 415.

- ↑ Without author: Previous long-distance traffic in the Rhine Valley . In: Eisenbahn JOURNAL: Tempo 300 - The new Cologne – Frankfurt line . Special edition 3/2002, ISBN 3-89610-095-5 , p. 20.

- ↑ a b c Investigation report on train derailment, July 9, 2008, Cologne Central Station. Federal Agency for Railway Accident Investigation, November 8, 2019, archived from the original on November 9, 2019 ; accessed on November 8, 2019 .

- ↑ Spiegel online: ICE derailed on Hohenzollern Bridge .

- ↑ EBA notification regarding the wheelset shaft breakage on an ICE of the 403 series. (No longer available online.) In: Eisenbahn-Kurier. July 14, 2008, archived from the original on July 23, 2008 ; Retrieved June 27, 2008 .

- ↑ a b The railroad steel returns . In: Frankfurter Allgemeine Zeitung , May 9, 2010.

- ↑ a b c Deutsche Bahn AG: ICE axle break triggered by manufacturer error: Cologne public prosecutor's office closes investigations against DB . Press release from July 17, 2009.

- ↑ Dispute about ICE axles before the solution . In: Handelsblatt , October 12, 2009.

- ↑ Expert doubts the safety of ICE axles . In: Spiegel Online , July 19, 2008, accessed July 19, 2008.

- ↑ V. Grubisic, G. Fischer: Failure of wheelset shafts and their causes . In: ZEVrail , Vol. 130, 3/2006, pp. 98-106.

- ↑ Grubisic, Fischer: Notes on the dimensioning of wheelset shafts . In: ZEVrail, Volume 132, Issue 4/2008, pp. 150-154.

- ↑ Review of the ICE 3 fleet completed without abnormalities ( memento of November 24, 2015 in the Internet Archive ). Eurailpress , July 27, 2008.

- ^ Railway finds crack again in ICE axis ( memento of October 18, 2008 in the Internet Archive ). In: Financial Times Deutschland , October 16, 2008.

- ↑ Overcrowded trains due to stricter ICE controls . Press release from Westdeutscher Rundfunk from October 15, 2008.

- ^ ICE manufacturers attack Deutsche Bahn . In: Die Welt , October 27, 2008.

- ↑ Bahn accelerates inspections of the ICE axes . In: Handelsblatt , February 23, 2009.

- ↑ Bahn wants to replace ICE axles as a precaution . In: Handelsblatt , February 23, 2009.

- ↑ New axes for Mehdorn . In: Frankfurter Allgemeine Sonntagszeitung , No. 8, 2009, p. 38, February 22, 2009.

- ↑ This is how railway chief Grube drives to work . Berliner Zeitung , January 6, 2010.

- ↑ Deutsche Bahn AG: Grube: Agreement on a joint solution for ICE axes, important progress for the DB . Press release from October 12, 2009.

- ↑ Bahn wants to replace 1200 axes . In: Frankfurter Allgemeine Zeitung , October 12, 2009.

- ^ Christian Schlesinger: ICE converted . In: Wirtschaftswoche , No. 23/2012, June 4, 2012, p. 12 (similar version online ).

- ↑ There are new axles for the ICE 3, but ... ( Memento from December 12, 2013 in the Internet Archive ). Report in DMM Travel from February 13, 2012.

- ↑ Christian Siedenbiedel: The railway stroll Office . In: Frankfurter Allgemeine Sonntagszeitung . No. 7 , February 17, 2013, p. 26 ( faz.net ).

- ↑ a b Deutsche Bahn AG (Ed.): Annual Report 2012 (= Annual Report ). 2012, ZDB -ID 2117244-4 , p. 110 ( dbschenker.de [PDF]). Annual Report 2012 ( Memento of October 24, 2015 in the Internet Archive )

- ↑ International reports . In: Eisenbahn-Revue International . No. 12 , 2013, ISSN 1421-2811 , p. 634 .

- ↑ Arno Stoffels: Soon there will be more trains on the move again . In: Nürnberger Nachrichten . November 3, 2014, p. 25 (similar version among other titles online ).

- ↑ a b Nikolaus Doll: Despite ICE super axles, there is a problem with railways in the winter . Welt online , November 13, 2014.

- ^ Klaus Ott: Expensive axle break ( memento from March 9, 2010 in the Internet Archive ). In: Süddeutsche Zeitung , June 26, 2009, p. 21.

- ↑ ICE suppliers let rail come to the front . In: Capital (online edition), July 20, 2009.

- ↑ One second to stop . In: Spiegel Online . No. 48 , November 24, 2012, p. 17 ( [1] ). (Also available from the printed edition as a PDF file ).

- ↑ André Werske: ICE 3 407 (Velaro D) of Siemens series Hochgeschwindigkeitszuege.com, March 24, 2013.

- ↑ a b Rüdiger Köhn: New ICEs are now being delivered. FAZ.NET , December 20, 2013.

- ↑ Daniel Goffart, Olaf Opitz: We drive on edge . In: Helmut Markwort , Uli Baur (Ed.): Focus . No. 36 . Hubert Burda Media , September 2, 2013, ISSN 0943-7576 , p. 66-73 ( online ).

- ↑ The modernization of the ICE-T fleet has started . In: Eisenbahn-Revue International . No. 2 , 2014, ISSN 1421-2811 , p. 102 f .

- ↑ a b c d e Arno Stoffels: Bahn completes the ICE-T modernization . In: Nürnberger Nachrichten . December 12, 2015, p. 13 .

- ↑ Comfort offensive for passengers: ICE 3 gets a freshness treatment. (PDF) (No longer available online.) In: deutschebahn.com. Deutsche Bahn, March 7, 2017, archived from the original on March 12, 2017 ; accessed on May 26, 2019 .

- ↑ Germany-Berlin: Parts for locomotives or rolling stock . Document 2014 / S 160-288139 of August 22, 2014 in the supplement to the Electronic Official Journal of the European Union .

- ↑ Deutsche Bahn AG (Ed.): Interim Report January – June 2016 . Berlin July 2016, p. 27 ( online [PDF]). online ( Memento from August 17, 2016 in the Internet Archive )

- ^ Deutsche Bahn AG (Ed.): More rail for metropolises and regions ( Memento from March 20, 2015 in the Internet Archive ). Presentation from March 18, 2015, p. 16.

- ↑ ICE 3 redesign: an overview of the adjustments. Comparison: That will change for the ICE 3 by 2020. In: inside.bahn.de. Deutsche Bahn, April 11, 2017, archived from the original on July 30, 2017 .

- ↑ a b c ICE 3 redesign: an overview of the adjustments. Comparison: That will change for ICE 3 by 2024. In: inside.bahn.de. Deutsche Bahn, April 22, 2020, accessed on June 25, 2020 .

- ^ Germany-Munich: Seats for rail vehicles . Document 2013 / S 208-361156 of October 25, 2013 in the supplement to the Electronic Official Journal of the European Union .

- ↑ Germany-Munich: air conditioners . Document 2013 / S 231-401676 of November 28, 2013 in the supplement to the Electronic Official Journal of the European Union .

- ↑ Germany-Munich: air conditioners . Document 2014 / S 178-314583 of September 17, 2014 in the supplement to the Electronic Official Journal of the European Union .

- ↑ Questions to the DB . In: mobile . May 2015, ISSN 0949-586X , ZDB -ID 1221702-5 , p. 56 .

- ↑ a b DB presents the first modernized ICE 3 . In: Eisenbahn-Revue International . No. 4 , April 2017, ISSN 1421-2811 , p. 204 .

- ^ DB Mobility Logistics AG (Ed.): Deutsche Bahn starts modernizing its ICE-T trains . Press release from December 6, 2013.

- ↑ New line VDE 8.1 opened . In: Eisenbahn-Revue International . No. 2 , February 2018, ISSN 1421-2811 , p. 70-72 .

- ↑ 60,000 more comfortable seats for ICE 4 and ICE 3: the conversion will start in early 2020. In: deutschebahn.com. Deutsche Bahn, October 23, 2019, accessed on October 24, 2019 .

- ^ André Daubitz, Frank de Gavarelli, Marcus Schenkel: A major project on the home straight - the new line between Erfurt and Leipzig / Halle . In: Railway technical review . tape 64 , no. 12 , 2015, ISSN 0013-2845 , p. 33-42 .

- ^ SFS Cologne - Rhein / Main: ICE 3 withdrawal for VDE 8 route . In: Eisenbahn-Revue International . No. 4 , April 2020, ISSN 1421-2811 , p. 180 .

- ↑ Nikolaus Doll: The risky "Germany first" strategy of Deutsche Bahn. In: welt.de. June 7, 2019, accessed June 10, 2019 .

- ↑ Corporate circles - Bahn buys 30 ICE trains from Siemens . In: Reuters . July 13, 2020 ( reuters.com [accessed July 13, 2020]).

- ↑ a b Daniel Riechers: ICE. New trains for Germany's express traffic. Transpress, Stuttgart 2001, ISBN 3-613-71172-9 , p. 131.

- ↑ a b Motors completely replaced in eight hours . In: DB Welt , June 2007 edition, p. 3.

- ↑ a b Heinz Kurz: InterCityExpress - The development of high-speed traffic in Germany . EK-Verlag, Freiburg, 2009, ISBN 978-3-88255-228-7 , pp. 193, 196.

- ↑ The innovation driver. 15 years of ICE . In: bahntech - the technology magazine of Deutsche Bahn AG , issue 1/2006, p. 6, PDF ( Memento from December 6, 2008 in the Internet Archive ) (1.4 MB).

- ↑ A veteran leaves the Deutsche Bahn . In: DB Welt , July / August 2007 edition, p. 15.

- ↑ Brain and Heart from DB Energie . In: DB World . No. 6 , 2014, p. 11 .

- ^ Deutsche Bahn AG (ed.): Railway has a key function for climate protection . Press release from January 11, 2010.

- ↑ Heinz Kurz: InterCityExpress: The development of high-speed traffic in Germany . EK-Verlag, Freiburg 2009, ISBN 978-3-88255-228-7 , p. 195 .

- ↑ a b c In environmental protection, ICE 3 depends on competition in long-distance traffic . In: DB Welt , June 2007 edition, p. 6.

- ↑ Without author: The project for the new Cologne – Rhine / Main line . In: Eisenbahn JOURNAL: Tempo 300 - The new Cologne – Frankfurt line . Special edition 3/2002, ISBN 3-89610-095-5 , pp. 34–63.

- ↑ a b c Klaus Heckemanns, Jürgen Prem, Stefan Reinicke: Brake management of ICE® trains . In: Railway technical review . tape 53 , no. 4 , 2004, ISSN 0013-2845 , p. 187-197 .

- ↑ Number of tracks 440 . In: mobile . October 2010, p. 54.

- ↑ D. Jaenichen, R. Jaensch: New LZB / FZB for the new Cologne-Frankfurt / Main line . Dresden April 1997, p. 12 .

- ↑ Dieter Jaenichen, Norbert Rudolph, Thomas Weiss: LZB brake panels for inclinations up to ± 40 ‰ . Dresden 2001, p. Appendix 9.2 (brake position R + WB, 198 brake hundredths, 25% of the eddy current brakes switched off).

- ↑ BR 407 - the Velaro D for Germany (part 1) . In: ahead , Volume 62, Issue 6/2010, pp. 25-27, ISSN 1438-0099 .

- ↑ One team for 100,000 rail vehicles . In: DB Welt , May 2008 edition, p. 8 f.

- ↑ New air conditioning units tested in the ICE 3 . In: Swiss Railway Review . No. 1 , 2016, ISSN 1022-7113 , p. 34 .

- ↑ How does the ICE 3 toilet actually work . In: DB Welt , October 2007 edition, p. 15.

- ^ Message ICE castling . In: Eisenbahn-Revue International , Issue 8–9 / 2000, ISSN 1421-2811 , p. 340.

- ↑ Deutsche Bahn AG: Deutsche Bahn: The safety of the ICE axles is beyond question / allegations are unfounded . Press release from August 14, 2008.

- ↑ Maintenance calendar for every ICE . In: DB Welt , May 2007 edition, p. 6.