Double clutch

A dual clutch transmission is an automated manual transmission that enables fully automatic gear changes without interruption of tractive power by means of two sub-transmissions . The transmission control selects the gears automatically or as requested by the driver ( rocker switch / selector lever ) within the permitted speed ranges. Unlike automatic transmission with a hydraulic torque converter , the transmission takes place of the torque on one of two couplings connect the two partial transmission with the drive. As with the automatic transmission with hydraulic torque converter, this principle also enables gear changes without interrupting the tractive effort - here, in that one clutch closes while the other opens.

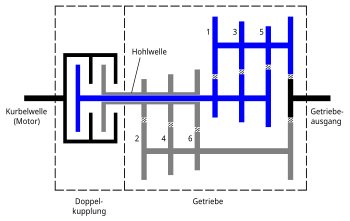

Gearbox structure

As the schematic diagram on the right shows, the dual clutch transmission consists of two automated sub-transmissions, each with a clutch. One sub-transmission carries the even gears (shown in gray) , the other the odd gears (shown in blue) . The reverse gear (not shown here) can be assigned to the even or odd partial transmission depending on the transmission concept. In terms of the wheelset principle, the partial transmissions correspond to a manual vehicle transmission , which is why they are not described in more detail here. The gear output is a special feature. The two sub-transmissions work on a common transmission output.

Sequence of switching processes

An electronic transmission control decides on the gear selection according to the shift programs, (above all) the engine speed or speed and the demands of the driver (accelerator pedal, selector lever ) and controls the shift processes. The integrated actuators operate the sub-transmissions and the clutches electromechanically or hydraulically.

Before shifting, the gear to be shifted is first engaged in the no-load branch (preselection). Then the clutch of the preselected gear is closed and that of the previously loaded gear is opened at the same time (torque transfer). In this phase, the engine speed is adapted to the new gear ratio by means of electronically coordinated "grinding" of the two clutches. It is switched without interruption of the tractive effort. The duration of this phase is made dependent on the speed difference in order to avoid a significant jolt and is a few hundredths to tenths of a second.

Without interrupting the tractive effort, it is only possible to shift from an even to an odd gear and vice versa. For this reason, the control system selects a temporary support gear from the other sub-transmission depending on the situation. If, for example, the second gear is mechanically engaged when driving in third gear at a relatively low speed and a relatively high load, then only the double clutch has to be actuated to actually transfer the torque via the preselected support gear (in this case the second) and its ratio to take effect. However, if first gear is requested in the example situation manually or by kick-down (depressing the accelerator pedal), the transmission nevertheless briefly shifts to second and only then to first.

service

The dual clutch transmission is an automatic transmission. The operation of the transmission largely corresponds to the handling of other fully automatic transmissions . Interventions by the driver are only required in the form of actuation of the selector lever when starting a journey, for reversing and parking, or in special situations, if z. B. a low gear on steep slopes is recommended. If the driver wishes to select a manual gear, this can be triggered, for example, using the paddle shifters on the steering wheel or by tapping (forwards or backwards) the selector lever of a second gate.

Coupling variants

Two wet-running multi - plate clutches or dry single- disk clutches are generally used in double clutch transmissions .

Single-disc dry clutches in double clutch transmissions are only used as standard in the compact class with motors up to around 250 Nm torque , since the dissipation of the greater heat loss is difficult to achieve at higher powers.

Wet-running clutches allow higher torques and vehicle masses with the same size. The heat loss that occurs during switching and start-up is dissipated via a flow of cooling oil. The transmission itself is usually used as the oil sump . The oil thus serves both to cool the clutch and to lubricate the wheelset. A wet double clutch always has a certain drag torque when it is open, which leads to higher idling losses, which results in a reduction in efficiency . In addition, the operation of the oil pump (output approx. 500 watts) reduces the overall efficiency by a total of 3-4%.

In addition, double clutch transmissions also differ in the arrangement of the clutches. In addition to the arrangement of two clutches of the same diameter one behind the other (see schematic diagram), designs in which a different disk diameter enables the two clutches to be nested ( see Figure VW-DSG ) are common. The advantage of this arrangement is a shorter overall length of the transmission.

Variants of the actuator system

As with the automated manual transmission, there are various concepts with the use of different actuators to carry out the shifting process and to actuate the clutch: hydraulic actuators or electromechanical actuators. Both principles have both advantages and disadvantages. So is the hydraulic actuator, which works with integrated hydraulic cylinders, z. B. faster, while the electromechanical actuator, which works with integrated electric motors, is more energy-efficient.

In 2014 Honda launched an 8-speed version with an additional torque converter, initially in the Acura ILX based on the Honda Civic for the US market. In this 8 DCT transmission , a torque converter is used for the smoothest possible starting process, which is also used to adapt the speed if necessary before gear changes.

Hybrid drive via partial transmission

If a starter generator is mounted on the input shaft of one of the two sub-transmissions , a hybrid drive can be implemented which, in addition to the operating modes of the parallel hybrid , allows additional operating modes that would otherwise require an additional clutch, which is already integrated in the dual clutch transmission. A starter generator arranged in this way cannot, however, replace the flywheel, as parallel hybrids and crankshaft start generators allow. If the starter generator is separated from the stationary internal combustion engine, i.e. the combustion engine without drag loss, by the disengaged clutch, this enables an electric vehicle drive, brake energy recovery and electrical operation of the air conditioning system. If the starter generator is connected to the running internal combustion engine via the closed clutch of the partial transmission, it can be supported by an electric motor or charged to charge the battery and its operating point can be influenced. If the other sub-transmission is also connected to the engine due to the gear selection, the first sub-transmission must be in neutral. In addition to the two existing clutches, the two existing partial transmissions and the possibility of operating the partial transmission in neutral, the battery and starter generator must have sufficient properties for the respective function.

History and brand names

The British Morgan three-wheelers had a two-speed dual clutch transmission with two drive chains on the rear wheel until 1931. In 1939 the French inventor Adolphe Kégresse and in 1940 the Darmstadt professor Rudolf Franke registered the first patents for a type of dual clutch transmission. However, it was only introduced by Porsche in the 1980s under the name PDK (Porsche Doppelkupplungsgetriebe). The first studies on the PDK go back to 1969, when the engineer Imre Szodfridt, who works for Porsche, suggested the PDK. This resulted in the Porsche type 919 transmission, the development of which was supported by the then Porsche technical director Ferdinand Piëch , but which did not go into series production due to too rough gear changes. In the course of the development of the Porsche 956/962 , the PDK was used again and repeatedly by Porsche in racing.

A double clutch transmission was first introduced in large-scale production by VW in 2003 under the designation direct shift transmission ( DSG ) . The manufacturer of the wet double clutch is the supplier BorgWarner Transmission Systems . Since 2008 VW has also been using 7-speed direct shift transmissions with dry clutch for smaller engines up to 132 kW and torques up to 250 Nm. Another model followed in 2009 with the DQ500, which is offered in larger vehicles up to 600 Nm.

Names or brands of vehicle manufacturers (sometimes not in-house developments, but from suppliers):

- Audi quattro S1 (rally sport touring car). With the Audi Quattro S1, the dual clutch transmission has become much more important

-

Fiat Powertrain Technologies - DDCT

- Alfa Romeo - TCT (Twin Clutch Transmission) 6-speed in the MiTo , Giulietta and 4C

- Fiat - DCT 6-speed in the Fiat 500X and Fiat Tipo (type 356)

- Jeep - 6-speed in the Jeep Renegade on the 1.4 MultiAir (like Fiat 500X) and 1.6 MultiJet

- Suzuki - TCSS (Twin Clutch System by Suzuki) (6-speed) in the Suzuki SX4 S-Cross and Suzuki Vitara (2015) on a Fiat 1.6-l turbodiesel

-

Getrag - Getrag PowerShift or DCT (Dual Clutch Transmission)

- for transverse engines

- Alpine - 7-speed in the Alpine A110 (2017)

- BMW - 7-speed Steptronic (double clutch) in the BMW X1 (F48) from 07/2017, BMW X2 (F39) from 03/2018

- Mini - 7-speed Steptronic (double clutch) in the Mini 3-door, 5-door, convertible from 03/2018

- Chrysler - PowerShift (presented at the IAA 2007 in the Dodge Journey in combination with a 2.0-liter turbodiesel)

- Ford - Powershift (market launch spring 2008)

- Mitsubishi - Twin Clutch SST (Sport Shift Transmission, presented November 2007 in the Lancer Evolution X ), Mitsubishi Outlander

- PSA - DCS - Dual Clutch System Peugeot 4007 , Citroën C-Crosser (like Mitsubishi Outlander)

- Renault - EDC (Efficient Dual Clutch) gradually by 2016 in all Twingo, Clio, Captur, Megane, Scenic, Kadjar, Talisman, Espace series

- Dacia - EDC (Efficient Dual Clutch) in the Duster 110 dCi

- Mercedes-Benz - 7G-DCT - 7DCT300 - A-Class W177 on the A200 (250 Nm) and A180d (260 Nm) from 04/2018, the higher-torque engines see Mercedes-Benz Powertrain

- Smart - Twinamic in the Smart 453 series from 2015

- Volvo - Powershift (May 2008 to May 2010 in the C 30 , S 40 and V 50 and later in the C 70 in combination with the 2.0-l turbodiesel; other applications: XC60 in combination with the 2.0T gasoline engine; V70 , S80 , S60 in combination with the T4 and T5 petrol engines)

- for longitudinal engines, gears on the engine

- BMW - 7-speed M DKG Drivelogic (since March 2008 in the M3 , since September 2008 in the 335i Coupé / Cabrio and in the Z4 sDrive35i , since March 2010 in the 135i Coupé / Cabrio , since September 2011 in the BMW M5 and since the beginning of 2012 in the BMW M6 available, since 06/2014 in the BMW M4 , since 04/2016 in the BMW M2 ),

- for longitudinal motors, gears in transaxle design

- Mercedes-Benz - Speedshift DCT (7-speed dual clutch transmission in the SLS AMG ) and Mercedes-AMG GT

- Ferrari - (since January 2009, 7-speed dual clutch transmission in the California , 458 Italia and F12berlinetta ; in the Ferrari FF with all-wheel drive 4RM ), then in all series

- for transverse engines

-

Hyundai Kia Automotive Group - DCT (Dual-Clutch Transmission)

-

Hyundai Motor Company

- 6-speed in the Hyundai Veloster , in a hybrid application in the Hyundai Ioniq Hybrid and Plug-In Hybrid (2016)

- 7-speed in the Hyundai i30 (GD) (from 2015), Hyundai Veloster (from 2015), Hyundai Tucson (from 2015), Hyundai i40 (from 2015), Hyundai i30 (PD) , Hyundai Kona

-

Kia Motors

- 6-speed Kia cee'd (JD) from 2012, in a hybrid application in the Kia Niro from 2016

- 7-speed in the Kia cee'd (JD) , Soul (from 2014), Optima (from 2015), Sportage (from 2015), Kia Carens (RP)

-

Hyundai Motor Company

- LuK - PSG (parallel gearbox)

-

Mercedes-Benz Powertrain

- Mercedes-Benz - 7G-DCT - 7-speed for front / all-wheel drive vehicles of the A-Class (except W177 A200 and A180d), B-Class , CLA-Class , GLA-Class

- Mercedes-Benz - 8G-DCT - 8-speed (F-DCT 400) for front / all-wheel drive vehicles based on the MFA2 platform, which among other things serves as the basis for the A-Class of the 177 series . This transmission is currently (as of 06/2020) only available in connection with all power levels of the engines OM654q (200d, 220d) and M139 (45, 45s) as well as the plug-in hybrid model A250e with M282 engine .

- Infiniti - DCT 7-speed for Infiniti Q30 and Infiniti QX30

-

Nissan / Aichi Kikai Kōgyō

- 6-speed in the GT-R (in transaxle design )

- Porsche - PDK (1984 in racing Porsche 956/962 )

- Ricardo Engineering

-

Volkswagen AG

- Artega - DSG (presented in the Artega GT , 6-speed DSG from VW)

-

Audi - S tronic (until mid-2005 under the name DSG )

- for longitudinally installed engines: 7-speed DSG (DL501, first and only DSG for differential-controlled all-wheel drive) up to 550 Nm for front longitudinal engines in the A4 , A5 , A6 , A7 and Q5

- For longitudinally installed engines, front-wheel drive: 7-speed DSG DL382 since 2014 on engines of the appropriate torque in A4 , A5 , A6 , A7 , Q5

- for longitudinally installed engines, all-wheel drive: 7-speed DSG DL382 since 2015 on engines of the appropriate torque in A4, A5, A6, A7, Q5 (from the use of the new models, DL501 is no longer used there)

- for transversely installed engines in A1, A3, Q2, Q3, TT see Volkswagen

- for Audi R8 from 2015 see Lamborghini

-

Lamborghini

- 7-speed in the Lamborghini Huracan LDF (Lamborghini Doppia Frizione) from 2014, in the Audi R8 under the name S tronic (internal Audi name DL 800 ) from 2015

- Porsche - PDK - Porsche double clutch transmission (variant of the DL501, from 2014 in the Porsche Macan with adaptations to software and all-wheel drive)

-

Seat - DSG

- 6-speed DSG in Altea since 2004, in Leon and Ibiza (from 2006), Seat Alhambra (from 2015), Seat Ateca (from 2016)

- 7-speed DSG in the Leon, Altea, Altea XL since 2009, Seat Toledo (from 2015), Seat Alhambra (from 2017), Seat Ateca (from 2017), Seat Ibiza (from 2017), Seat Arona (from 2017)

- Škoda - DSG (6-speed DSG since 2004, 7-speed DSG since February 2009, available in the model series Octavia II, Octavia III, Superb II, Fabia II, Fabia III, Rapid, Roomster, Yeti, Karoq, Kodiaq)

-

Volkswagen - DSG (direct shift gearbox) (or under S tronic at Audi) for transversely installed engines

- 6-speed DSG (DQ250 approx. 80 kg) up to 380 Nm (wet clutch) since 2003 - 2017

- 7-speed DSG (DQ380 (China market only) / DQ381 (CO2 optimized)) up to 380 Nm (wet clutch) since 2014

- 6-speed DSG (DQ400e) up to 400 Nm (wet clutch) in hybrid applications (Golf GTE, Passat GTE, Tiguan PHEV (only China) since the end of 2014)

- 7-speed DSG (DQ500 approx. 94 kg) up to 600 Nm (wet clutch) available since 2009 and a. in T5 ; Audi RS3 and Audi RS Q3

- 7-speed DSG (DQ200 approx. 73 kg) up to 250 Nm (dry clutch) available in various models since 2007; as a hybrid application in the VW Jetta Hybrid 1.4 TSI DSG

-

Volkswagen commercial vehicles

- DSG VW Caddy III - like Volkswagen

- DSG 7-speed DSG DQ500 (wet double clutch) has been available since September 2009 in the T5GP with 2.0 l TDI and then in the VW T6

-

ZF Friedrichshafen AG

- Porsche - PDK

- ZF 7DT45HL since July 2008 in the Porsche 911 , from February 2009 in the Cayman and Boxster , from October 2009 also in the Panamera as well as the 911 Turbo and Turbo Cabrio

- ZF 8DT from 2016 as 8-speed PDK in the Porsche Panamera; Bentley Continental GT from 03/2018

- Porsche - PDK

- Oerlikon Graziano

-

Honda

- First dual clutch transmission (DCT) for motorcycles in 2010 in the new Honda VFR1200F

- (DCT) as an option for the NC 700S (RC61), the Maxi Scooter NC 700D Integra (RC62), the Honda NC700X (RC63) and the Honda Africa Twin .

Recalls and known problems in series use

Dual clutch transmissions from the Volkswagen Group, more precisely the DQ200, have been the subject of product recalls in some countries around the world due to technical problems. In 2009, for example, 13,500 vehicles with DSG were recalled to the workshops due to problems.

In 2013, Volkswagen had to recall around 384,000 vehicles in China because of problems with the DQ200 dual clutch transmission. According to Volkswagen, these problems are related to extreme weather conditions (heat and cold) and heavy traffic (stop-and-go traffic).

In Japan, around 91,000 vehicles were recalled in 2013, only vehicles with the dry 7-speed DSG (DQ200).

In November 2013, the Volkswagen Group recalled 1.6 million vehicles with dry-running 7-speed dual clutch transmissions, type DQ200, 257,000 of them in Germany. Volkswagen, Audi, Seat and Škoda vehicles were affected. Even later there were complaints about quickly worn out clutches and sensor problems that make it necessary to replace the switching unit.

In Sweden, the sale of VW Passat taxis with DSG was discontinued in 2012 because there were repeated problems with taxi operations.

Advantages and disadvantages compared to conventional automatic transmissions

Dual clutch transmissions do not consume any energy between gear changes, as they shift without interrupting tractive power. The disadvantages of the type of transmission have been greatly reduced in recent years. At German automobile manufacturers, double clutch transmissions are z. B. from the company Getrag ( e.g. at BMW and Mercedes ) or in-house developments (e.g. at Volkswagen AG with the DSG and at Mercedes with the 724 gearbox series ).

literature

- Karl Ludvigsen: Porsche - Excellence Was Expected. Bentley Publishers, Cambridge / Massachusetts 2003, p. 917 ff.

Web links

- kfztech.de, section through a direct shift transmission

- Press release from Volkswagen AG: The world's first transmission with double clutch in a production car (2002)

- Audi efficiency technologies - S tronic animation

- kfz-tech.de, animated transmission diagram

- kfz-tech.de, DSG

- Hybrid drive through combination with starter generator

- VDC (Variable Double Clutch) - dual clutch transmission for off-highway

- Double clutch: transmission revolution from Wolfsburg

- Motorcycle DKG

Individual evidence

- ↑ Article on PM about the new 7-speed DSG from VW ( Memento from January 30, 2008 in the Internet Archive )

- ↑ press release . Volkswagen Media Service. Archived from the original on July 5, 2011. Retrieved March 28, 2013.

- ↑ press release . Volkswagen AG. January 21, 2010. Archived from the original on August 31, 2016. Retrieved on September 7, 2016.

- ↑ Volkswagen "autograph". January 30, 2007, accessed March 6, 2017 .

- ↑ AUTOMOBIL-PRODUKTION - Verlag modern industry: Porsche Development Board Member Wolfgang Hatz: "We will certainly make a four-cylinder for the Macan" . In: automobil-produktion.de . Archived from the original on September 19, 2014. Retrieved May 11, 2014.

- ↑ Our Products | Volkswagen Automatic Transmission Tianjin. Retrieved April 21, 2019 .

- ↑ Location symposium of the Volkswagen Group Components in Kassel: With innovative processes and products on the way to transformation. Retrieved August 25, 2019 .

- ↑ Mihnea Radu: Volkswagen Tiguan PHEV Launched in China. June 30, 2019, accessed September 21, 2019 .

- ↑ 15 years of Volkswagen double clutch transmission: DSG initiated the triumphal march of the automatic in Europe. Retrieved August 25, 2019 .

- ↑ FOCUS Online: Cars: US recall at VW . In: FOCUS Online . 18th July 2013.

- ↑ Volkswagen recalls over 384,000 vehicles in China | tagesschau.de. (No longer available online.) March 23, 2013, archived from the original on March 23, 2013 ; accessed on March 6, 2017 .

- ↑ Automobilwoche March 25, 2013: German car manufacturers are facing difficulties in China - is that a coincidence or the government's intention?

- ↑ Volkswagen recalls 91,000 cars in Japan due to DSG problems . In: autozeitung.de .

- ↑ Andre Tauber: Recall: Volkswagen suffers serious transmission damage - DIE WELT . In: THE WORLD . November 14, 2013.

- ↑ Recall: What affected VW customers now need to know. In: Spiegel Online . November 14, 2013, accessed September 22, 2019 .

- ^ Mikael Stjerna: Volkswagen Passat slut som taxi. In: Teknikens Värld. December 29, 2012, Retrieved September 22, 2019 (Swedish).

- ↑ Advantage of double clutch transmission - drive technology. In: Welt Online . October 21, 2016, accessed September 22, 2019 .