Control engineering

Control engineering is an engineering science that deals with the control processes occurring in technology . Like control technology, it is a branch of automation technology .

A technical control process is a targeted influencing of physical, chemical or other variables in technical systems . The so-called controlled variables are even when disturbances acting either to keep as constant as possible ( fixed value control to affect) or so that they follow a predetermined temporal change ( sequence control ).

Well-known applications in the household are the constant temperature control for the room air ( heating control ), for the air in the refrigerator or for the iron . With the cruise control , the driving speed in the vehicle is kept constant. Follow-up control is generally more technically demanding, for example course control with an autopilot in shipping , aviation, or space travel , or target tracking of a moving object.

Regulation means measuring the variable to be influenced ( controlled variable ) and continuous comparison with the selected reference variable . The controller determines a manipulated variable from the control deviation ( control difference ) and the specified control parameters . This acts on the controlled variable via the controlled system in such a way that it minimizes the control deviation in spite of existing disturbance variables and the controlled variable assumes a desired time behavior depending on the selected quality criteria .

This article is a summary of the most important basics, the system definitions, design strategies, stability tests, system analyzes and the calculation methods of control engineering. Furthermore, the historical development of the subject is dealt with, and comparisons are made between control technology and control technology .

History of control engineering

Natural phenomenon regulation

The feedback principle on which a regulation is based is not a human invention, but a natural phenomenon .

- Example: Regulation processes in living nature

- In humans and animals : regulated body temperature, regulated blood pressure and regulated blood sugar; Pupil opening regulates incidence of light; upright gait for bipeds with balance control.

- The hare-fox population model (see predator-prey relationship and Lotka-Volterra rules ) as an example of biological equilibrium regulates a reference variable as a function of the different food offers to an approximately fixed hare-fox ratio.

- Disturbance variables: climate, vegetation, changed terrain characteristics, diseases, people .

- Example: Earth's climate

- From a geological point of view, the global average air temperature near the ground ( sea level ) has been relatively constant for many millions of years. The control principle for the narrow temperature range as a climatic requirement of the more highly developed biological life is used in nature, if z. For example, when the air temperature rises, the global water surface temperature of the world's oceans rises and solar radiation is reduced by water vapor with cloud formation. Numerous long-term and short-term disturbances affecting climate change:

- long-term disturbances:

- The distance between the earth and the moon increases ( tide change ), ocean currents change their direction, the earth's continental plates move ( continental drift ), the earth's magnetic poles move .

- Short-term disturbances in geological terms:

- Strong volcanism leads to cooling, large meteorite impacts lead to cooling or, in extreme cases, to burning of the earth's surface, periods of low solar activity ( sunspots ) cause slight cooling ( Little Ice Age controversial!).

- Biological: algae growth and iron fertilization (as a carbon bond to reduce carbon dioxide : controversial!), Deforestation, burning of fossil fuels and increased methane emissions (see alkanes ) lead to the greenhouse effect .

- Example: biological systems and geology

- The Gaia Hypothesis was developed by the microbiologist Lynn Margulis and the chemist, biophysicist, and physician James Lovelock in the mid-1960s. It says that the earth and its entire biosphere can be viewed as one living being.

Term cybernetics

The fundamental analogies between control processes in living nature and in technical systems have been described in more detail since the 1940s. In Germany, this took place through the “General Regulatory Studies ” from Hermann Schmidt , who was appointed to the first chair for control engineering at the TH Berlin-Charlottenburg in 1944 . In the USA it was Norbert Wiener who dealt with regulations for military applications during the Second World War. Both investigated the feedback mechanism in technical and biological systems. In 1947, Norbert Wiener was the creator of the well-known term cybernetics for the science of control and regulation of machines and their analogy to the behavior of living organisms (due to the feedback through sensory organs ) and social organizations (due to the feedback through communication and observation ). Hermann Schmidt later also used the term cybernetics.

Historical examples of technical regulations

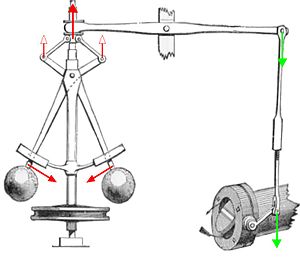

right: actuator ( throttle valve in the steam feed line)

left: measuring element and controller as a unit (centrifugal pendulum on a speed measuring shaft )

middle: negative coupling (horizontal lever and vertical rod), lower speed increases the Throttle opening

Setpoint change by changing the length of the vertical rod to the throttle valve

The principle of closed-loop control was used by mechanics in ancient times. There is evidence of devices for regulating fluid levels, which were invented by Ktesibios from Alexandria and his pupil Philon from Byzantium . Ktesibios regulated the water level in a container from which an inlet water meter was supplied with water. The flow of water from a constant height is uniform and increases the accuracy of the watch. An oil lamp from Phylon has become known in which the oil was automatically kept at the same level. The constant oil level improved the even burning of the flame, a luxury that is not available in today's oil lamps. But the effort was small, although it was a fully-fledged regulation.

After that, the principle of regulation was only taken up again in modern times. In the 17th century, the first temperature control, designed by the Dutchman Cornelis Jacobszoon Drebbel, in an incubator for chicken eggs. In 1681 the Frenchman Denis Papin invented a simple pressure control for a pressure cooker by installing a pressure relief valve .

The first regulator to be mass-produced was the centrifugal regulator , the invention of which is incorrectly attributed to James Watt (see illustration). The governor was previously used on windmills. Watt equipped the steam engine, invented by Thomas Newcomen in 1769, with such a controller in 1786.

For the emerging steam engine technology, the water level control with float known from antiquity was used by the Russian Ivan Polzunov . The float influenced the steam boiler's water inlet valve via a linkage.

The wheel set of a rail vehicle is designed in such a way that it automatically steers back into the center of the track due to the conical running surfaces of the wheels. If the wheelset, e.g. B. is shifted from the track center by lateral wind forces or unevenly laid track, the rolling radius increases on one side and decreases on the other side. Due to the rigid coupling of the two wheels, the wheelset therefore steers back into the center of the track with a dampened sinusoidal run . Contrary to popular belief, the flange is not required for tracking. If the mechanically feedback system is inadequately designed, the wheelset tends to vibrate unstable at high speeds.

The injection pump of a diesel engine contains a controller to meter the amount of fuel supplied per revolution so that the engine speed remains constant according to the position of the accelerator pedal . Without this regulation, it would tend to instability and self-destruction, since more and more fuel would be supplied at higher speed.

For a long time, the technology of automatic control has been limited to use in prime movers. A first expansion extended to the control of variables in process engineering , especially temperatures, pressures and mass flows. After the Second World War, the standardized, multi-adjustable electrical, hydraulic and pneumatic PID controllers were created .

In the recent past, the application of control engineering has expanded to all areas of technology. The expansion of automation , for example with the help of robots , and the new space technology provided impetus . Control engineering has now entered into a symbiosis with information technology (both hardware and software). The traffic control in order to avoid traffic jams is an example of a complex system when the green phases of the intersections according to the actual traffic volume as a green wave are matched to one another, is that a constant flow of traffic possible results.

Chronology of the development of control technology

| year | Researcher mathematician |

Historical events |

|---|---|---|

| 300 BC C. |

Ktesibios from Alexandria Philon of Byzantium |

Water channels, combined suction and pressure pump, water organ, water level regulator |

| 200 BC C. |

Probably Archimedes | Antikythera Mechanism : Reconstruction result (2012): A cogwheel mechanism-based calendar-astronomical simulator with 7 pointers to display the movement of the celestial bodies (sun to Saturn). |

| 1. year- hundred |

Heron of Alexandria | Heronsbrunnen level control |

| circa 1770 | Leonhard Euler | Differential and integral calculus, etc. a. with difference equations, pioneer of numerical calculation, Euler's polygon method, Euler equations. |

| circa 1780 | Pierre-Simon Laplace | System descriptions using the Laplace transformation , Laplace equation , Laplace operator . |

| 1782 | James Watt | Beginning of the industrial revolution, construction of a steam engine |

| 1788 | James Watt | Centrifugal governors transferred from windmills to use on steam engines |

| 1868 | James Clerk Maxwell | System description of various controllers using differential equations |

| 1895 | Adolf Hurwitz | Stability criterion depending on the denominator polynomial of the transfer function, Hurwitz polynomial |

| 1922 | Nicolas Minorsky | Ship control with PID regulation in the US Navy |

| 1932 | Harry Nyquist | Stability criterion based on the locus of the frequency response |

| 1938 | Hendrik Wade Bode | Frequency response analysis ( Bode diagram ) |

| 1942 | Ziegler / Nichols | Setting rules for P, PI and PID controllers |

| 1942 | Norbert Wiener | Models of prediction (prediction), models of the flight path of aircraft; Automatic destination control. |

| 1944 | Hermann Schmidt | First chair for control engineering in Germany at the TH Berlin-Charlottenburg |

| 1947 | Norbert Wiener | Creator of the term cybernetics . Among other things, the feedback mechanism in technical and biological systems is examined here. Another fundamental term for this is communication theory . |

| 1948 | Walter Richard Evans | Root locus |

| 1955 | Heinrich Kindler | First institute for control engineering in the German-speaking area at the TH Dresden |

| 1957 | Winfried Oppelt | First chair for control engineering in the Federal Republic of Germany at the TH Darmstadt |

| 1960 | Rudolf Kálmán | Kalman filter , state space representation |

| 1962 | Richard Bellman | Bellman's Optimality Principle , Dynamic Programming , Bellman Algorithm |

| 1965 | Lotfi Zadeh | Fuzzy set theory developed as fuzzy set theory (University of California, Berkeley). Used in Japan as fuzzy logic for fuzzy regulators (controllers) in industrial processes since the 1980s, and in Europe since the 1990s. |

| 1969 | Richard E. Morley | Invention: Programmable logic controller (PLC) at the US company Modicon (type Modicon 084). Based on the microprocessor (invented in 1971 in the USA), the PLC gradually developed into a universal means of automation for control, regulation and processing of measured values. |

| 1974 | Günther Schmidt | First European universal controller based on microprocessors (digital controller) at the Technical University of Munich (together with H. Birk) |

| 1976 | Aérospatiale | First analog fly-by-wire control system in the Concorde airliner to ensure flight stability at all speeds |

| 1987 | airbus | First digital fly-by-wire control system in the Airbus A320 airliner |

Definition of regulation and control

Standardization of regulation and control

In automation technology, controls also play a very important role in addition to regulation. The history of the standardization of regulation and control can be found in the article Control technology .

The standard "IEC 60050-351 International Electrotechnical Dictionary - Part 351: Control technology " defines basic terms for control technology, including process and management , and includes regulation and control. In Germany it replaces the DIN standards DIN IEC 60050-351 and DIN V 19222: 2001-09. The previously valid standard DIN 19226 for the definition of regulation and control-related terms has not been valid since 2002.

In the English-language specialist literature, the English word control (for the process) or controller (for the hardware implementation) is used in an undifferentiated manner for both regulation and control . This term is often simply translated as control . Control engineering is usually translated as control engineering . Knowledge of the context is therefore required in order to be able to translate correctly.

Principles of regulation

The DIN IEC 60050-351 standard contains the following definition of the term control :

- The regulation or regulation is a process in which one variable, the controlled variable, is continuously recorded, compared with another variable, the reference variable, and influenced in the sense of an adjustment to the reference variable.

- The control is characterized by the closed action sequence, in which the controlled variable continuously influences itself in the action path of the control loop.

This definition is based on the action plan for a single-loop single-variable control, as it occurs most frequently in practice. The individual variables such as the controlled variable, the reference variable as well as the non-mentioned measured variable (feedback), the manipulated variable and the disturbance variable are to be regarded as dynamic variables.

The time-dependent controlled variable (actual value) is measured by a measuring element and its result is compared with the reference variable (setpoint) . The control deviation as the difference between the setpoint and the actual value is fed to the controller, which uses it to create a manipulated variable based on the desired time behavior (dynamics) of the control loop . The actuator can be part of the controller, but in most cases it is a separate device. The disturbance variable affects the controlled system ; it can also only influence individual parts of the controlled system . The measuring element in the feedback can have a time delay that has to be taken into account with fast controlled systems.

For the intended minimization of the system deviation (or system deviation) , the polarity of the system deviation depends not only on the reference variable , but also on the action of the controlled system (direct or inverting).

A positive control deviation only leads to a positive increase in the controlled variable via the gain of the controller if the controlled system requires a positive control value to reduce the control deviation. If it is a controlled system z. B. a heating, a positive control value leads to a rising temperature. The opening of a window, solar radiation or cooling effects caused by wind speed are external disturbances. If the controlled system is z. B. a cooling unit, a positive control value (i.e. switching on the compression refrigeration machine ) leads to a drop in temperature. Such a case is marked in the block diagram of the control loop by a reversal of the sign of the manipulated variable.

In principle, the regulation of a controlled system as a multiple variable system is similar to the single variable system. It requires the analysis of the coupling elements and thus a higher mathematical effort for the control loop design. A characteristic of multi-variable control is that a single manipulated variable as the input variable of the controlled system always influences several output variables (controlled variables) (here via factors G21 and G12 ). If an air conditioning system is to regulate both the temperature and the relative humidity to setpoints, an intervention in the heating system leads to an increase in temperature and - for physical reasons - to a decrease in the relative humidity at the same time . Adjustment intervention in the humidification device to increase humidity also lowers the temperature in the air-conditioned room. The control intervention is optimized via the decoupling controller so that more moisture is supplied at the same time as the temperature rises (factor GR21 ).

Control principles

The DIN IEC 60050-351 standard contains the following definition of the term control :

- The controlling , the control is due to the peculiar to the system laws affect an operation in a system in which one or more variables as input variables, other variables as output or control variables.

- The characteristic for controlling is either the open path of action or a temporarily closed path of action, in which the output variables influenced by the input variables do not act continuously and do not act on themselves again via the same input variables.

With the action plan of controls, the feedback carried out via the measuring element of the controlled variable does not apply to the action plan of the regulation. The reference variable forms a manipulated variable via the control device, which directly determines the output variable via the control path.

If there are no disturbances affecting the control system, open control works without any problems if the control system is well known. If the disturbances can be measured, they can be compensated by suitable measures. For example, the energy supply for a heating device, in which the flow temperature is regulated as a reference variable as a function of the outside temperature and thus heats the room, is an open control. If a window in the room to the cold external environment is opened, a disturbance variable acts and the internal room temperature drops because the energy supply is not increased without feedback.

The action plan in the figure shows a control system that is shown as an open chain of control device and control line. In order to be able to compensate also known dominant disturbing influences by a control, an additional disturbance variable can be used (upper block in the figure), which acts as a feedback of the disturbance variable to the input of the control path and thus compensates this disturbance variable.

Advantages and disadvantages of regulations compared to controls

In principle, regulation is technically more complex and more expensive than control because it measures the control variable as a control variable and has to determine the (dynamic) manipulated variable with a suitable controller. Control is only advantageous if the effect of disturbance variables can be tolerated and there are no high demands on the accuracy and constancy of the control variable.

Advantages of regulations:

- The influence of known and unknown (i.e. non-measurable or non-measured) disturbance variables is reduced so that the controlled variable largely corresponds to the specified setpoint.

- A larger gain can make the controlled system faster as long as there are no manipulated variable limits and no instabilities occur.

- Controlled systems that tend to be unstable can be stabilized by a control system.

- Requirements for the dynamic accuracy and the energy expenditure required for this can be optimized according to specified goals (quality criteria).

Disadvantages of regulations:

- The control loop can be caused by unwanted, z. B. parameter changes caused by aging and wear become unstable.

- Accurate and quick measurements of the controlled variable can be costly.

- Heuristic optimization methods such as “ trial and error ” are not sufficient for demanding regulations. Qualified professionals are required.

The advantages and disadvantages of controls are described in the article Control technology .

technical realization

The input and output variables and their processing in a control or regulation system can be implemented using analog technology or digital technology . Today, analog systems are largely being replaced by digital systems that support automation through remote control , remote maintenance and networking in the sense of Industry 4.0 and are usually cheaper to manufacture. In special cases, pneumatic or simple mechanical controllers are used.

Depending on the structure and intended use, a distinction can be made:

- Industrial controller: machine-level individual controllers for small systems with their own microprocessor

- Process control devices: Expandable industrial controllers with an interface to a higher-level (control) system

- Universal controller: Process controller in the form of expansion cards or software control modules for programmable controls

- Industry controller: Special process controllers that are optimized for certain areas of application

Analog technology

Analog signals are continuous in value and time and therefore have a stepless and arbitrarily fine curve. The limits of the signal resolution are given by parasitic signal noise components. If shielding measures and signal filters are used, the signal resolution can be improved. The control or regulation intervention takes place continuously without delay and is therefore also suitable for highly dynamic control loops.

Analog control systems are mostly based on analog electronics with operational amplifiers and analog multipliers for the basic arithmetic operations. The specification of the reference variable and the setting values for the controller are usually implemented using potentiometers. In rare cases, pneumatic controllers are also used.

Digital technology

Digital systems have a discontinuous course with discrete values for measured values and manipulated variables that are updated with a specified sampling rate . With the technologies available today, both the resolution of the system sizes and the available computing power are so high that the performance of analog systems is exceeded in almost all applications and can even be implemented more cost-effectively in more complex systems. However, there remains the systemic risk of undetected software defects that can have improper or catastrophic effects.

Programmable logic controllers (PLC) process the binary input signals via the digital arithmetic unit into binary output signals . The arithmetic unit is controlled by a program that is stored in memories.

Programmable logic controllers have a modular structure and are offered by many manufacturers. You can use it to implement simple switching mechanisms for combinatorial and sequential behavior for successive functional sequences ( sequence controls ). The sequential process can be connected with a feedback as a completed confirmation of a control process and thus corresponds to a temporarily closed control. Digital or analog subsystems can also be integrated. Analog measured values are sampled in a time-discrete manner and converted into discrete digital values using analog- digital converters. Analog output signals can be processed with digital-to-analog converters or pulse width modulation for analog actuators. Stepper motors are controlled directly.

The control devices influence the controlled system or a technical process via operating elements such as signal transmitters (switches, buttons , keypad) with control functions such as switching, counting, time comparators and storage processes as well as time sequence functions. If physical analog quantities are monitored or regulated, the corresponding sensors are required. Emergency interventions for the automatic shutdown of the process, sometimes with an orderly shutdown, may also be necessary.

The process flow takes place within the control path or its exits. Actuators and actuators of all kinds ( motors , valves , pumps , conveyor belts , contactors ), hydraulic and pneumatic elements, power supply, controllers act on the process. Output signals relate to the monitoring of the process and are implemented using signal lamps, alphanumeric displays, error message panels, acoustic signal generators, log recorders, etc.

Applications of digital control and regulation technology are, for example, offset rotary machines for printed products, the automation of chemical production plants and nuclear power plants .

Digital technology and networking increase the risks of catastrophic program errors and uncontrollable situations, such as B. in the case of the two crashes of the Boeing 737 Max due to the weaknesses of the Maneuvering Characteristics Augmentation System (MCAS). Technical processes can be attacked by cyber attacks , such as the Stuxnet computer worm on Iranian centrifuges for uranium enrichment.

Other realizations

Very simple mechanical controllers do not require any auxiliary energy. The bimetal thermostat of an iron closes the electrical contact of the heater as long as the target temperature is not reached. Then, due to the delay in the measurement and the switching hysteresis of the contact, there is a quasi-periodic switching on and off, during which the temperature of the ironing surface fluctuates around the setpoint with a deviation of a few Kelvin.

Pneumatic regulators require compressed air as auxiliary energy. They are mainly used in applications that require explosion protection and the risk of sparks must be avoided.

- Examples of control and regulating devices (period 1788-2016)

Centrifugal governor of a Boulton & Watt steam engine (1788)

Thermostat T86 of Honeywell , designed by Henry Dreyfuss (1953)

Time-controlled room temperature controller flexostat from Sauter (1967)

Hybrid anti-lock braking system from Bosch (1978)

Digital control unit for the active joint lock in the articulated bus from MAN (1986)

Compact controller RU 5X for heating systems from R + S controllers (approx. 2005)

Modular PLC ControlLogix of Allen-Bradley (2013)

Compact PLC for small controllers Logo! from Siemens (2016)

Tools for rapid prototyping in research and development

In research and development, the problem regularly arises of testing new control concepts. The most important software tools for computer-aided analysis, design and rapid control prototyping as well as simulation of control systems are listed below.

- MATLAB and Simulink , The MathWorks

- Thanks to numerous toolboxes, a very extensive software package for numerical mathematics, suitable for simulation, system identification, controller design and rapid control prototyping (commercial)

- Scilab , Institut National de Recherche en Informatique et en Automatique (INRIA)

- Also very extensive software package for numerical mathematics with a similar concept and syntax as MATLAB, suitable for simulation, system identification and rapid control prototyping (free)

- CAMeL-View TestRig

- Development environment for modeling physical systems with a focus on controller design and rapid control prototyping as well as for connection to test stands (commercial)

- Maple

- Computer algebra system (CAS), masters numerical and symbolic mathematics, particularly suitable for some design methods of non-linear control (commercial)

- Mathematica , Wolfram Research, Inc.

- Comprehensive software package for numerical and symbolic mathematics (commercial)

- dSPACE

- Integrated hardware and software solutions for connecting MATLAB to test stands (commercial)

- LabVIEW , National Instruments (NI)

- Integrated hardware and software solutions for computer control of test stands (commercial)

- ExpertControl

- Software solutions for fully automatic system identification and fully automatic, model-based controller design for classic controller structures (PID controllers) as well as controller structures for higher-order systems (commercial)

- TPT

- Systematic test tool for control systems which, in addition to simulation, also offers results evaluation and analysis options.

All the tools listed show a high degree of flexibility with regard to the application and the controller structures that can be used.

Technical applications

- Railway technology

- A variety of control problems arise in drive control, for example torque and speed need to be controlled. Fuzzy control was successfully used on the Sendai subway .

- aviation

- Control problems occur in numerous components of aircraft, for example in the turbines, but also in relation to flight dynamics. Examples of flight dynamics control problems are the control of the roll, yaw and pitch angles, as well as the autopilot . See also flight controls .

- Energy Technology

- Position control of a control valve with an actuator within a controller cascade . In the interconnected power supply network, voltage and frequency must be maintained across the network. In every power plant, voltage and frequency are regulated locally, so that the task is solved with decentralized controllers by varying the control power (see also power plant management ). Globally, only the power setpoints of the individual power plants are specified.

- Automotive engineering

- Cruise control and anti-lock braking system (ABS), but also electronic stability program (ESP) are well-known controls in the vehicle sector, which are also referred to as driver assistance systems . Internal combustion engines also contain a variety of control loops, for example for idling speed, air ratio (see also lambda probe ), knock control (see also knocking (internal combustion engine) ). Modern automatic gearboxes require control loops for synchronization when shifting.

- Electric drive

- In vehicles with an electric drive, electric motors with greater powers are used. These are controlled via a speed and torque control, in hybrid vehicles also in connection with the combustion engine.

- pipeline

- In pipelines there are mainly meshed controls for flow , pressure control (inlet pressure, outlet pressure ) and position control including limit value control .

- robotics

- In production automation, the axes of the production robots must be positioned. A quick settling time and the slightest overshoot play a particularly important role here.

- process technology

- In process engineering, chemical and physical parameters are regulated that play a role in the process under consideration. Examples are the control of level, temperature, pH value and oxygen content of a stirred tank reactor or keeping substance or ion concentrations constant with a chemostat .

- Water management

- In order to avoid floods and secure the water supply, subordinate regulations of chains of dams are important. The filling level of an individual reservoir is specified by a higher-level management and regulated locally.

Tasks of the controller and associated design strategies

The controller's task is to approximate the controlled variable as closely as possible to the reference variable and to minimize the influence of disturbance variables. The reference variable can be designed as a fixed setpoint, as a program-controlled setpoint specification or as a continuous, time-dependent input signal with special follow-up properties for the controlled variable.

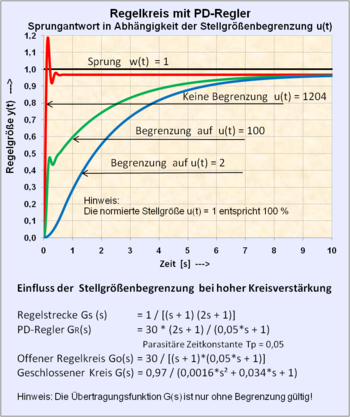

An excessively high loop gain that is not adapted to the controlled system can lead to oscillatory instability in controlled systems with several delay elements or even with dead time behavior. Due to the time delay in the controlled system, the control difference is fed to the controller with a delay via the set-actual value comparison. This lagging shift in the controlled variable can cause positive feedback instead of negative feedback at the setpoint / actual value comparison, and this makes the closed control loop unstable and builds up permanent oscillations.

Control loop design strategies for linear systems

The design strategies for control loops in linear systems relate to the optimization of the static behavior and the time behavior of the respective closed control loop. For example, the smaller the time delays in the controlled system, the higher the so-called loop gain and thus the gain of the controller can be selected, which improves the static accuracy of the control.

A high loop gain also makes the control loop dynamically fast, but it can only be implemented to a limited extent in practice because the manipulated variable cannot grow indefinitely due to technical stops or a lack of energy. A lower controller gain in connection with a temporally integral component of the controller makes the control loop for all static influences more precise and more stable, but also slower. To this end, an optimized compromise solution must be found using a suitable design strategy. To assess this, the term control quality was defined, which makes it possible to estimate the unavoidable periodically damped transient response of the controlled variable in control loops with higher-order controlled systems.

Control loop design strategy for mixed linear and nonlinear systems

The design strategy for mixed linear and nonlinear systems is more complicated and relates to models such as B. the Hammerstein model , in which a static non-linearity interacts with a dynamic linear system. The behavior of discontinuous non-linear static controllers in connection with linear controlled systems can be treated using the harmonic balance method.

Controllers in control loops with non-linear and linear components can be treated sensibly with numerical mathematics, especially with modern simulation tools such as those available for personal computers (PC).

Various theoretical and experimental analysis methods and mathematical design methods are used to determine the system behavior of the controlled system and the controller. The basics of mathematical treatment and the special procedures for control engineering follow in the following chapters.

As a simple, illustrative example of a standard control loop, room temperature control based on hot water central heating and its device components is intended to serve here.

Example of heating control in a building

Gas boilers, oil boilers and solid fuel boilers gain the thermal energy from the combustion of mostly fossil fuels and transport the thermal energy via the heat carrier water. A boiler heated by a combustion chamber is connected to a hot water circuit with radiators and / or underfloor heating with the help of a heating pump .

The heat supplied by the radiator heats the surrounding room air through convection and radiation. The thermal energy with the temperature gradient between the radiator and room temperature flows, depending on the size of the outside temperature, via the windows, doors, room walls and outside insulation to the outside weather.

Decentralized room temperature control

The amount of heat given off to the building is given by the difference between the flow and return temperatures on the boiler and the flow rate of the water. All radiators in the rooms of a building have the same flow temperature, which is usually controlled according to the outside temperature. The radiators in all rooms are equipped with thermostatic valves.

The size of the radiators is adapted to the respective room size. The flow temperature required for an existing outside temperature is recorded and controlled by an outside temperature sensor. Selectable heating characteristics from a characteristic field take into account the different heat requirements of buildings and thus the relationship between the outside temperature and the flow temperature. The aim is to automatically maintain the room temperature as a controlled variable at a desired setpoint with the help of a thermostatic valve .

With the thermostatic valve located on the radiator, the desired temperature of the room is set by turning the thermostatic cap within the range of a scale. The sensor of the thermostatic valve measures the current room temperature (theta) and changes the flow rate of the hot water through the radiator and thus the amount of heat supplied to the room via the valve position ( actuator ). The thermostatic valve has a proportional control behavior (P controller), which reacts somewhat slowly to disturbance variables when the deviation between the setpoint and actual value increases at low outside temperatures.

For the decentralized room temperature control as well as the central building temperature control with a reference living room, the use of a modulable burner with constant behavior of the heat energy generation applies to modern heating systems. This burner can, for example, continuously change its thermal energy in the range from approx. 10% to 100% depending on the requirements. The area of constant behavior of the burner is called the degree of modulation in terms of heating technology.

Condensing boilers with gas are able to extract and use almost all of the heat contained in the flue gases.

Compared to a heating system with intermittent on / off operation, the following advantages are associated with a modular burner:

- Low thermodynamic material stress in the burner chamber,

- Reduction of the burner noise and avoidance of expansion cracking noises in the pipelines,

- Fuel saving.

Below the inconsistent area of the burner, it works intermittently with a considerably reduced heat requirement.

Main controller for the reference living room

In addition to the decentralized temperature control of the living rooms with thermostatic valves, a reference living room (also pilot room, lead room, largest living room) is set up in modern heating systems, in which a central high-quality main controller via a room temperature setpoint generator and a reference room temperature sensor sets the flow temperature for the entire hot water circuit of the Centrally in the building and regulates the reference room temperature.

The temperature differences between the radiators and the cooler room air generate air movements ( convection ) and, to a lesser extent, radiant energy , which act on the sensor. The controller increases the flow temperature as required by switching on the burner or, if necessary, reduces it by switching off the burner.

For the quality of room temperature control, the structural room conditions and device arrangements such as radiators and the distance from the room temperature measurement location are also decisive. In an elongated room you cannot expect that a radiator with a thermostat at a distance of 10 cm will set a uniform room temperature over the entire room. On the other hand, a large distance between the radiator and the room temperature measurement location means that there is a longer signal delay ( dead time behavior ).

It is common practice to mount the sensor in the reference living room on the opposite wall of the radiator level. The sensor measures the air temperature, not the inner wall temperature. The radiators in the reference living room do not have thermostatic valves.

Designations for components and signals in the control loop

Annotation:

- In the German specialist literature, the control-related signal designations are not always taken from the valid DIN standards, but in some cases probably come from the representations of signal flow plans of dynamic systems in the state space. This theory, which originated in the USA by the mathematician and Stanford University professor Rudolf Kálmán , and the associated signal designations have remained unchanged since the 1960s.

- Some technical books on control engineering also show the designations X A (output variable) and X E (input variable) for the representation of signal inputs and signal outputs of transmission systems .

| designation | Signs as in state space systems | Symbol according to DIN IEC 60050-351 |

Meaning in general and in the example (room temperature control with thermostatic valve) |

|---|---|---|---|

| Controlled system | G S (s) |

|

|

| Disturbance | d | z |

|

| Controlled variable | y | x |

|

| actual value |

|

||

| Measuring element |

|

||

| Measurand | y M | y M |

|

| Reference variable | w | w |

|

| Setpoint |

|

||

| Control deviation |

e = w - y |

e = w - x |

|

| Regulator | G R (s) |

|

|

| Actuator |

|

||

| Control variable | u R | y R |

|

| Manipulated variable | u | y |

|

Definition of thermal energy

Colloquially, the thermal energy is somewhat imprecisely referred to as "heat" or "thermal energy". The thermal energy of a substance is defined as

where is the specific heat capacity , the mass and the absolute temperature . This definition assumes that the substance is within its physical state . For water, the liquid state applies in the temperature range from 0 (+) ° C to 100 (-) ° C at normal pressure at sea level .

A supply of heat increases the mean kinetic energy of the molecules and thus the thermal energy of a substance, a dissipation of heat reduces it.

If two thermal energy systems with different temperatures come together, their temperatures will equalize through heat exchange. This adjustment takes place until there is no longer a temperature difference between the systems. This process is known as heat transfer .

Without additional help ( energy ), thermal energy can never be transferred from the system of lower temperature to the system of higher temperature.

The heat flow or heat flow is a physical quantity for the quantitative description of heat transfer processes.

In physics and materials science, the interface or phase boundary is the area between two phases (here phase = spatial area of matter, composition and density of homogeneous matter). The interfaces between liquid and solid, liquid and liquid, solid and solid and solid and gaseous phases are called interfaces.

Alternative continuous and discontinuous regulation

There are two ways of regulating the reference room temperature as continuous or discontinuous regulation:

The change in the outside temperature is generally to be regarded as a static disturbance variable because the time response is very slow in relation to the change in the flow temperature. The heating controller can only react when the change in the outside temperature is noticeable through the external insulation and the mass of the building walls on the measuring sensor in the reference room.

The control of the room temperature in the reference room can usually be done conventionally using digital controllers that have to be adapted to the controlled system of the hot water circuit.

Industrially manufactured heating boilers are often designed with digital controllers using fuzzy logic . The basic idea of the fuzzy controller relates to the integration of expert knowledge with linguistic terms, through which the fuzzy controller is more or less optimally modeled using empirical methodology to a non-linear process with several input and output variables, without the mathematical model of the process (Controlled system) is present.

To put it simply, the application of fuzzy logic corresponds to the human way of thinking to recognize tendencies in the behavior of an unknown system, to anticipate and to counteract the unwanted behavior. This course of action is defined in the so-called “IF-THEN control rules” of a rule base.

Process of continuous and discontinuous regulation:

- The room temperature in the reference room can be regulated using a stepless controller that acts on a continuously operating mixing valve ( three-way mixer ) that accesses the boiler when there is a need for heat. This form of regulation is often used in apartment buildings.

- The room temperature of the reference room can be regulated using a two-point controller.

- This low-cost variant is particularly suitable for intermittent operation for cyclical switching on and off of the burner.

Discontinuous regulation

A discontinuous two-position controller without hysteresis has properties that correspond to a high loop gain . Whether it can be used to the full depends on the type of controlled system. This controller is particularly suitable for control systems that have to be controlled within wide limits for continuous power adjustment in intermittent operation (on / off operation).

The ratio of the maximum to the current heat energy requirement is given by the ratio of the switch-on / switch-off time:

The manipulated variable of the two-position controller determines the ratio of the switch-on time to the switch-off time, depending on the control deviation. The controller hysteresis and dead time behavior of the controlled system reduce the switching frequency. Special feedback from the two-position controller and the activation of a D component of the control deviation increase the switching frequency.

Calculation of the thermal energy flows

The behavior of the thermal energy flows can be calculated by using a block diagram with individual function blocks to show the dynamic time behavior of the thermal energy flows at the so-called interfaces (e.g. burner / boiler, radiator / air or interior / exterior walls / exterior weathering). The function blocks correspond to suitable mathematical models as system description functions.

Day and night reduction in room temperature

The storage behavior of the building walls and their insulation are of decisive importance for energy saving with the help of the so-called day-night lowering of the room temperature. With a constant low outside temperature and a longer-term room temperature reduction, the energy-saving potential is great. If the room temperature drops briefly, the building walls then have to be heated up again without the boundary surfaces in the masonry and the insulation becoming stationary, which would make it possible to save energy.

Externally controlled flow temperature limitation

The heat requirement in living spaces is several times higher in the very cold winter than in the transition period between autumn and spring. For this reason, the flow temperature of the heating circuit is limited by means of a precontrol via a controller depending on the outside temperature, so that large overshoots of the room temperature (controlled variable) as well as heat losses are avoided.

The radiator temperature is usually not measured, it is recorded from the mean value of the flow temperature and the return temperature at the boiler. Heat losses from the insulated pipelines are neglected.

The characteristic curve for limiting the flow temperature of the heating circuit as a function of the outside temperature can be set in commercial systems and is dependent on the climate zone . The limited flow temperature must be slightly higher than the value that is required for the heat demand of the set reference room temperature setpoint. The limitation control of the flow temperature as a function of the outside temperature can be carried out using a simple two-point controller.

Disturbance variables of the heating control circuit

Disturbance variables in room temperature control are changes in the generation of heat energy through intermittent operation. B. the effects of fluctuations in gas pressure (gas boiler) or changes in the calorific value of the heating oil (oil boiler) are negligible.

The main short-term disturbances affecting room temperature are open doors or windows and solar radiation in the window area.

The main disturbance factor in building heating is the influence of the outside temperature. The change in outside temperature and the influence of wind and precipitation are long-term disturbances due to the heat storage capacity of the building mass.

Disturbance variables can attack all part of the controlled systems. Short-term disturbance variables have a slight influence on the actual value of the controlled variable if they occur at the input of the controlled system. Disturbance variables on controlled systems have the greatest influence when they occur at the output of the controlled system.

The assessment of a linear control loop with a reference variable jump is calculated using the reference variable transfer function.

The assessment of the disturbance behavior of a linear control loop on a linear controlled system is often calculated using a disturbance jump with the disturbance variable transfer function.

Stationary or abrupt or pulse-like disturbance variables in the control loop can be taken into account positively or negatively in a graphical signal flow diagram using an addition point.

The most dominant disturbance variable in the control system of a heating system, which changes within wide limits, is the heat energy outflow from room temperature via the building walls to the outside weather. While the influence of a disturbance variable on any control loop only shows technical information or a required specific behavior of the controlled variable, the disturbance variable of the energy flow of a building temperature control to the outside weather means an energy cost factor of considerable extent.

The energy flow to the outside weather is under normal operating conditions, i. H. closed windows and doors, depending on:

- from the outside weather, such as outside temperature, sun, wind and rain,

- the quality of the building's thermal insulation .

- The better the outside insulation, the lower the radiator temperature can be for a given outside temperature.

- on the size of the reference room temperature

- Every reduced degree Celsius of an individual “feel-good room temperature” reduces the radiator temperature considerably in percentage terms.

- from the size of the dominant time constants of the three mathematical sub-models of the radiator temperature to the room temperature to the outside temperature.

- For constant outdoor weather conditions and a given target value for the reference room temperature, after a sufficiently long time, an equilibrium condition is established between the heat energy generated and the heat energy flowing off through the building.

Simulation of a heating control circuit with partial models

Task: Calculation of the temporal behavior of the mean radiator temperature and the room temperature of a reference living room for the room temperature setpoint specification from 5 ° C to 20 ° C at a stationary outside temperature of −10 ° C. Wind and precipitation should not change for this process.

The signal flow diagram of the simulation of the reference room heating control shows the relationships between the sub-models.

Data specification for the heating control circuit For a rough calculation of the control process for the room temperature in the reference room, simplifications and numerical assumptions must be made from experience. The following data are given:

- maximum flow temperature: 80 ° C

- Room temperature setpoint: 20 ° C

- stationary outside temperature: −10 ° C

- Outflow of heat energy (in ° C) is measured empirically:

- For a mean stationary radiator temperature of 60 ° C and a stationary outside temperature of −10 ° C, a room temperature of 20 ° C is reached after a sufficiently long time.

- With this information, a room temperature change of 1 ° C corresponds to the ratio of the differential values of the radiator temperature to the room temperature with reference to the outside temperature:

- Factor = [60 ° C - (−10 ° C)] / [20 ° C - (−10 ° C)] = 2.33 ° C per 1 ° C change in room temperature

- Limited mean radiator temperature at −10 ° C outside temperature: 70 ° C

- Selected stationary initial value of the room temperature in frost protection mode as setpoint: 5 ° C

- Calculated stationary initial value of the mean radiator body temperature in frost protection mode:

- For a required stationary reference room temperature of z. B. 5 ° C, d. H. Room temperature reduction of 15 ° C results in a required radiator temperature of:

- Radiator temperature = 60 ° C - 2.33 15 ° C = 25 ° C.

Definition of the partial models based on the estimated data specification

For the dynamic process of the setpoint changes with reference to the radiator temperature, the room temperature and the heat energy outflow, the initial conditions of the individual systems must be taken into account.

- Partial model 1: Heat energy generation from the burner to the radiator temperature

- The heat energy generated in the burner and boiler is pumped through all pipes and radiators as the flow temperature with the heating pump and appears again on the boiler as the return temperature. The mean radiator temperature is taken as the mean value of the flow and return temperatures.

- Data:

- Tt = 4 [minutes], T E = 60 [minutes] with an increase, T E = 100 [minutes] with a decrease in heating energy:

- Partial model 2: radiator temperature to room temperature

- The heat energy given off by the radiators heats the room air, which rises first on the windows and then up to the ceiling and cools down. This leads to air turbulence via convection and radiation , which reaches the room temperature sensor even after a dead time and settling time.

- The measured and controlled reference room temperature is not identical to the inside wall temperature, the floor and ceiling of the reference room, through which the thermal energy flows away to the outside weather (as a representative for all rooms).

- Data:

- Tt = 10 [minutes], T E = 200 [minutes] with an increase, T E = 300 [minutes] with a decrease in heating energy:

- Partial model 3: room temperature to the inside of the building wall to the outside to the outside

- The mathematical model for the dissipation of heat energy from the room air via the windows and the building walls to the exterior insulation and the exterior weathering is very complicated and is therefore simplified.

- The partial model 3 consists of a static part, which shows the relationship between radiator, room and outside temperature using a straight line equation, and a dynamic part, which takes into account the storage capacity of the building walls and insulation.

- Depending on the nature of the mass of the room walls (heat storage capacity, thermal conductivity, internal thermal insulation, proportion of internal and external walls) and the insulation material on the outside, it can be a complicated system of a higher order with a large dominant time constant. To simplify this sub-model 3, a first-order delay element (PT1 element) with a large equivalent time constant is selected as the dynamic system behavior.

- For the simulation of the energy flow, there is a static relationship with this information that can be determined by a straight line equation.

- Simplified model of the time behavior:

- Assuming a linear relationship between the radiator temperature and the selected room temperature at constant outside temperature, the value of the radiator temperature can be calculated from straight line equations for various room temperature values.

- General straight line equation with X as input variable and Y as output variable:

- Static relationship of partial model 3

- A straight line equation is used to determine which value must be subtracted from the filtered radiator temperature (= output model 2) as a function of the outside temperature so that the room temperature results as a control variable.

- For a room temperature of 20 ° C, the associated radiator temperature is given as 60 ° C. For another value of the room temperature, the associated radiator temperature can be calculated from the proportion of the temperature differences to −10 ° C:

- For static model 3, the difference [radiator temperature - room temperature] is required. This value is subtracted from the output of model 2:

- This results in the static values for the setpoint jumps in the room temperature, the associated values for the radiator temperature and all intermediate values:

-

- Setpoint room temperature 20 ° C:

- [Radiator temperature] - [Radiator temperature - room temperature] = [room temperature] = 60–40 = 20 ° C

-

- Setpoint room temperature 5 ° C:

- [Radiator temperature] - [radiator temperature - room temperature] = [room temperature] = 25–20 = 5 ° C

Graphical representation of the temperature values of the heating control

Task Based on the partial models of the controlled system, the graphical course of the radiator temperature and the room temperature from the frost protection mode to the operating status should be calculated and graphically displayed.

- Commercial computer programs are ideal for calculating transmission systems or simulating control loops. With the most popular programs such as MATLAB and Simulink, extensive instruction sets are available for the theoretical modeling of dynamic systems and many special control commands.

- Alternatively, linear systems can be calculated numerically with the help of difference equations. Non-linear systems such as the two-position controller can be easily calculated with the help of IF-THEN-ELSE instructions. A calculation sequence refers to a chain of systems connected in series, starting with the input signal and ending with the output signal. Each sequence k relates to the discrete time k · Δt.

For a better understanding, two diagrams with the static and dynamic behavior of partial model 3 are shown.

- Graphic representation of the temporal behavior of the temperature values without heat storage of the building walls (partial model 3 with T = 0).

- Graphic representation of the temporal behavior of the temperature values with heat storage of the building walls (partial model 3 with T = 500 [minutes]).

Critical assessment of the simulation results

- In principle, the calculated time curves for the radiator temperature and the room temperature correspond to realistic heating controls.

- Reliability of the mathematical models

- The simulation of a dynamic process is as good as the quality of the mathematical models of the controlled system.

- Model 1 (heat energy generation to the radiator) can largely correspond to reality.

- Model 2 (heating of the room temperature) is physically connected to model 1, but cannot guarantee that model 1 is free of interference due to the larger time constants. It acts more than a 1st order low-pass filter on the sawtooth change in radiator temperature.

- Model 3 (outflow of thermal energy to the outside weather) subtracts from the output value of model 2 the portion of the outwardly flowing thermal energy. Although Model 3 is a system with distributed energy storage, it is treated as a system with a concentrated energy storage for reasons of easier predictability. This results in the controlled variable room temperature as a function of the radiator temperature and the outside temperature.

- The time constants of all sub-models are estimated.

Graphic representations of the temperature values

For a better understanding, the control processes are shown in 2 diagrams, statically without the stored thermal energy of the walls and dynamically with the stored energy of the walls. This is the third partial model, the time constant of which is set once to a value for T = 0 and T = 500.

The following shows the simulation of the model of the building heating control loop for a jump in the setpoint from frost protection mode 5 ° C to operating mode 20 ° C.

Comment on the illustration of the simulation with the third partial model without storage capacity of the room walls The calculation of the flow of thermal energy from the initial values to the final values is carried out purely statically without stored thermal energy in the building walls.

The setpoint jump takes place after 200 minutes. The simplified static partial model 3 as a PT1 element with the behavior of the time constant T = 0 shows the steady-state conditions of the radiator temperature and the room temperature, which are established after a sufficiently long time. The transition from the lower temperature values to the upper temperature values is not real in time because the stored heat of the building walls is not taken into account for each value of the radiator temperature and the room temperature.

Comment on the illustration of the simulation with the third partial model with storage capacity of the room walls The calculation of the flow of thermal energy from the initial values to the final values takes into account the stored thermal energy of the building walls.

The setpoint jump takes place after 200 minutes. The simplified static partial model 3 as a PT1 element for the heat storage capacity of the room walls with the time constant T = 500 minutes shows the behavior of the rise in radiator temperature and room temperature. It becomes clear that the room temperature has already reached the target value of 20 ° C, while the radiator temperature is only required at 45 ° C due to the stored thermal energy of the walls. Only after approx. 2000 minutes does the radiator temperature of 60 ° C become static, assuming constant weather conditions.

Mathematical methods for describing and calculating a control loop

This chapter shows the application of the methods of control engineering and system theory for the calculation of dynamic systems and control loops. The terms of methods of system descriptions, transfer functions, linear and non-linear controlled systems, time-invariant and time-variant systems, two-point controllers, mathematical system models and numerical calculations are touched upon and help is given in detailed articles or their chapters.

A dynamic system is a functional unit with a specific time behavior and has at least one signal input and one signal output. Models ( modeling ) of a real dynamic transmission system are mathematically described by:

- Differential equations

- Transfer function and frequency response

- State space representation

- Numerical time-discrete description of linear systems ( difference equations ) and non-linear systems (logical commands, table values)

Ordinary differential equations

A differential equation (DGL for short) is an equation that contains one or more derivatives of an unknown function. Different physical problems can be represented formally identically with DGL-en.

If derivations only occur with respect to one variable, one speaks of an "ordinary differential equation", whereby the term "ordinary" means that the function under consideration only depends on one variable. Many dynamic systems from technology, nature and society can be described with ordinary DGL-s.

A linear DGL contains the function you are looking for and its derivatives only in the first power. There are no products of the function sought and its derivatives; Likewise, the function you are looking for does not appear in arguments of trigonometric functions, logarithms, etc.

Creation of a differential equation A differential equation is a determining equation for an unknown function. The solution to a DGL is not a number, but a function!

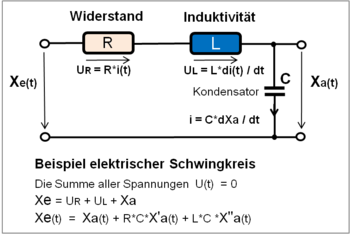

Example of an electrical oscillating circuit: Voltage balance: According to Kirchhoff's 2nd theorem, the sum of all voltages in a mesh is zero.

The voltage drop across the resistor R results from U R = i · R. According to the law of induction, the voltage across the inductance U L = L · di / dt. The charging current across the capacitor is proportional to the voltage change across the capacitor i (t) = C · dy / dt.

The application of the mesh theorem leads to a first order differential equation:

If we put in the DGL for i (t):

one, then the oscillation equation results:

Time constants such as T 1 = R * C and T 2 ² = L * C can be introduced. If you also replace the representation of the input variable and output variable that is usual in the system description , then the well-known DGL for a series resonant circuit is:

Basics of the transfer function as a system description

The most frequently presented system description of linear time-invariant systems is the transfer function with the complex frequency . It is successfully used for system analysis, system synthesis, system stability and allows the algebraic treatment of arbitrarily switched, reaction-free subsystems.

A transfer function describes the dependence of the output signal of a linear , time-invariant system ( LZI system ) on its input signal in the image area (frequency area, s-area). It is defined as the quotient of the Laplace transformed output variable to the transformed input variable :

The Laplace transformation is an integral transformation which can be used to transfer a time function into an image function with the complex frequency . The image function can again be represented as a time function using various mathematical methods.

Dynamic time-invariant systems with concentrated energy stores (e.g. spring-mass-damper systems or electrical L, C and R elements) are described by ordinary differential equations with constant coefficients. When the system is idle, the energy stores have the value zero.

To simplify the calculation and to make it easier to understand, the differential equation is subjected to a Laplace transform . According to the Laplace differentiation theorem, a 1st order derivative of the differential equation is replaced by the Laplace variable s as a complex frequency. Higher derivatives of the nth order are replaced by .

Example of an ordinary differential equation with constant coefficients:

The Laplace transform of the differential equation is:

The coefficients a and b of the differential equation are identical to those of the transfer function.

The result of the transformation is defined according to the order of the terms of the resulting polynomial as the ratio of the output variable to the input variable as a transfer function. The transfer function G (s) can always be written as a fractional-rational function . Since the transfer function is used to describe the input-output behavior , the transfer system should have an output variable equal to zero for a given input variable at a given point in time .

Factoring the transfer function in the s domain

By determining the zeros , the polynomials of the transfer function can be brought into a product form ( linear factors ) in the numerator and denominator. The poles (zeros of the denominator) or zeros (zeros of the numerator) are either zero, real or conjugate complex . The product representation in the numerator and denominator of the transfer function is mathematically identical to the polynomial representation.

The poles and zeros of the transfer function are the most important parameters of the system behavior.

Example of a transfer function of the polynomial representation and the decomposition into the pole-zero representation with real linear factors:

Linear factors:

- In the case of linear factors of the first order, the zeros or poles are real numerical values. Stable systems contain negative real parts.

- Second degree linear factors with complex conjugate zeros or poles are combined into quadratic terms for easier calculation, in which only real coefficients occur.

- Linear factors are mostly converted into the time constant representation by the reciprocal formation of the zeros and poles.

- Product term in the time constant representation with a negative value of the zero :

In linear control technology, it is a welcome fact that practically all regular (phase-minimal) transfer functions or frequency responses of control loop elements can be written or traced back to the following three basic forms ( linear factors ). They have a completely different meaning, depending on whether they are in the numerator (differentiating behavior) or in the denominator (delaying, integrating) of a transfer function.

Depending on the numerical values of the coefficients and the polynomial representation, the products can take the following three forms in the time constant representation:

Type linear factor Meaning in the counter Meaning in the denominator

(Zero position = 0)Differentiator, D-member Integrator, I-link

(Real zero)PD link Delay, PT1 element

(Zeros conjugate complex)PD2 element: for 0 < D <1 Vibration link PT2 link : for 0 < D <1

- Here, T is the time constant, s is the complex frequency, D degree of damping.

The transfer function of a dynamic transfer system can contain single and multiple linear factors in the numerator and denominator.

Definition of the variables s

- is the independent variable in the complex frequency domain (image area, s-area) with as real part and as imaginary part. It allows any algebraic operations in the s-domain, but is only a symbol for a completed Laplace transformation and does not contain a numerical value. Exponents of correspond to the degree of the derivative of the differentials .

- Numerical values are created from the coefficients and the polynomial representation in that the polynomials of the transfer function are broken down into linear factors (products) by decomposing zeros. These zeros or poles can be zero, real or complex conjugate.

- The real parts and the imaginary parts of the zeros or poles can, depending on the numerical values of the coefficients, and also have the numerical value zero. This creates the three forms of linear factors z. B. in the denominator of the transfer function with the behavior integration, delay, delay 2nd order conjugate complex.

Table of all occurring types of regular transfer functions in time constant representation:

Name → P element I-link D link PD 1 link PT 1 link PT 2 link (oscillating link ) PD 2 link Dead time element Transfer function G (s) Poles and zeros no no Transition function

(step response)

graphically not representable

Notes on the transfer function

- The great advantage of describing linear dynamic systems as transfer functions with the linear factors is that there are only six easy-to-remember basic forms of system behavior that can be combined to form larger system forms. The transcendent form of the non-linear dead time element does not belong to it, unless it is approximated to the behavior of the dead time element as a fractional rational function .

- In connection with other system descriptions such as the differential equation, difference equation, state space representation and mixed linear and nonlinear models, naming transfer systems as transfer functions is advantageous because the system function is so well known.

- The transfer functions can be combined as individual transfer systems in the series and parallel connection of a block diagram and treated algebraically.

- The gains of the -Gliedes and -Gliedes can also be written as time constants .

- The transfer functions shown with components are called "ideal". These systems cannot "real" be produced without a combination with a delay element ( element). The time constant of the delay element must be significantly smaller than that of the D component.

- Example of a real -link with T V ≫ T:

- The numerical calculation of ideal components works with the help of the difference equations without any problems. No infinitely large edges can arise during the differentiation, because calculations are made over time .

- Conclusion: In the numerical calculation, an ideal -link fully compensates for a -link with the same time constants to the factor .

- The differentiating form of the 2nd order transfer function ( -member) with conjugate complex zeros allows the compensation of the delay element 2nd order with conjugate complex poles with the same time constants and the same degree of damping.

- Application: Pre-filter in the control loop input reduces damped oscillations of the controlled variable and thus allows a higher loop gain.

- The transfer functions are always written as fractional-rational functions.

- The transcendent function of the dead time element can be multiplicatively attached to the transfer function of a system . This form of the transfer function as a complete system is only suitable for frequency response analyzes. Any algebraic operations with a dead time element are not permitted.

- Non-regular transfer functions contain a minus sign in the equation (= positive zero). They can arise through positive feedback (= positive feedback) and behave monotonically unstable. With any input excitation , the output variable of an unstable element strives for an infinitely large value up to its natural limit, depending on the time constant .

Example of the notation of a first-order delay element with the gain factor :

These kinds of equations of the transfer functions can be treated algebraically, apply to linear systems and relate to time-invariant behavior. Transfer functions can be combined algebraically with any linear factors to form controlled systems and control loops, as long as no dead time system is included. If an input signal is given as a test signal , the time behavior of the output signal can be calculated using Laplace transformation tables .

Transfer functions as a block structure in the signal flow diagram

Transmission systems can be grouped as blocks from subsystems. The superposition principle applies . The systems in the product display can be moved in any order. The system outputs must not be loaded by subsequent system inputs (freedom from feedback).

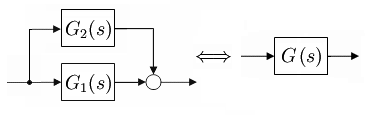

- Parallel connection:

- Equation of the transfer function of the parallel connection:

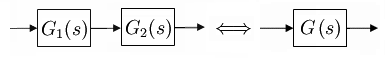

- Series connection:

- Equation of the transfer function of the series connection:

- Negative coupling or feedback:

- Equation of the transfer function of the negative feedback:

- In the case of a control loop that does not contain a static or dynamic subsystem in the negative feedback branch, the system G 2 (s) = 1.

-

- The transfer function of the closed control loop is thus:

- A positive feedback is a positive additive acting return of the signal output to the system input. Depending on the magnitude of the gain of G 1 (s), it leads to monotonous instability or a hysteresis effect.

- Equation of the transfer function of the positive feedback:

- With G 1 (s) as an open control loop, any algebraic combinations of the subsystems of the controller and the controlled system are understood.

Linear controlled systems

Linear systems are characterized in that the so-called superposition law and the reinforcement law apply. The superposition theorem states that if the system is excited with the time functions f1 (t) and f2 (t) at the same time, the system response is also formed from a superposition of the system response of f1 (t) and the system response of f2 (t).

The amplification principle means that with double the amplitude of the input function, the system response is also twice as large.

Natural linear controlled systems often contain delaying, integrating and dead time subsystems.

An electrical resistance capacitor low-pass filter of the 1st order in the reaction-free state with the time constant T = R C is described by the following transfer function:

1st order delay element (PT1 element):

To calculate the time behavior of transmission systems G (s) with the transfer function, the input signals (test signals) must be defined in the s range.

For the calculation of the step response of a system in the time domain, the standardized step 1 (t) as a Laplace-transformed test input signal is U (s) = 1 / s.

The equation for calculating the time behavior of the PT1 element can be read directly from the Laplace transformation tables:

Searched function in the s-area:

Associated function in the time domain:

The factor K is not subject to the transformation and is therefore valid in the s domain as well as in the time domain.

If the corresponding time function of a transfer function is searched for in time constants or zeros representation in the transformation tables without the Laplace-transformed input signal, the result is always the impulse response of the system.

Linear types of controlled systems

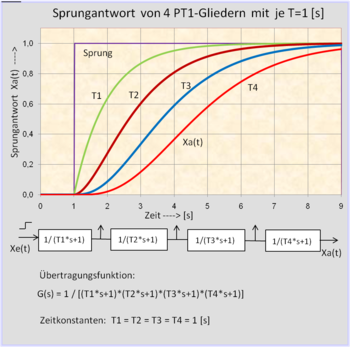

The time constant T means for a first-order delay element that an output signal has reached approx. 63% of the value of the input signal after a jump in an input signal and the signal curve asymptotically - after approx. 3 to 4 time constants - approaches the maximum value of the input signal.

- A first-order delay element ( PT1 element ) behaves invariably when the time behavior ( time constant ) does not change for a rising (jump) or falling (return) input signal u (t) . This is explained by the associated ordinary differential equation with constant coefficients.

- A 2nd order delay element with complex conjugate poles, e.g. B. a damped spring-mass system is referred to as a vibrating member. Depending on the degree of damping D, the step response approaches the maximum value of the input variable as the oscillation fades away.