K + S

| K + S AG

|

|

|---|---|

| legal form | Corporation |

| ISIN | DE000KSAG888 |

| founding | October 3, 1889 |

| Seat |

Kassel , Germany |

| management |

|

| Number of employees | 14,868 (2019) |

| sales | 4.07 billion euros (2019) |

| Branch | Fertilizers and salts |

| Website | www.kpluss.com |

| As of December 31, 2019 | |

The K + S AG , formerly Kali und Salz AG , based in Kassel is a publicly traded German mining company with a focus on potash and salt promotion. K + S is the largest salt producer in the world and belongs to the top group of international suppliers of potash and magnesium-containing products for agricultural and industrial applications. K + S is mainly active in Europe, North and South America and employs more than 14,800 people worldwide (2019).

Since the 1890s, K + S and its predecessor companies have integrated the entire German potash industry through mergers and takeovers. Between 1971 and 1993 the company was majority owned by the BASF Group, which held a stake in the company until 2011. The subsidiaries of K + S are primarily involved in the marketing of their own products, but are also active in the service sector, particularly in the waste disposal and recycling business areas.

history

Salzdetfurth AG (1889 to 1971)

On October 3, 1889, the joint stock company for mining and deep drilling was founded in Goslar . The Silesian industrialist Guido Henckel von Donnersmarck was one of the founders . The foundation fell in a phase of new beginnings in the north German potash district. The German chemist and founder of agricultural chemistry , Justus von Liebig , had already discovered the importance of mineral fertilizers for agriculture in the middle of the 19th century , whereupon a boom in mineral fertilizers began in the following decades. The three basic components of the mineral fertilizer were potash , phosphate and nitrogen . In addition to its use as a fertilizer, the areas of application for potash salts in industry also grew. Potash mining in Germany began in the Staßfurt potash district, in the Salzlandkreis in Saxony-Anhalt , where the pioneer of the German potash industry, Hermann Grüneberg , was active. In the course of the general economic upswing in the early days , a large number of new state-run potash mines and factories were founded to meet the enormous demand. From 1865 on, the liberalization of Prussian mining law enabled private pits to be built; By 1883, the salt trade, which had previously been state-controlled, was released throughout the German Empire. When the mining sites in the Staßfurt Revier could no longer meet the increasing demand, the search for new deposits began. These were found in the then Prussian province of Hanover around the cities of Hanover , Braunschweig and Hildesheim, between the rivers Weser , Aller and Bode . Henceforth this area was called the North German potash district.

In the years that followed, the company carried out test drilling in the northern German potash district until it finally came across a deposit of the potash salt sylvinite in Salzdetfurth near Hildesheim in 1892 . Then the construction work began on the pits in order to be able to mine the salt rock at a depth of 700 meters. When this was completed in 1899, the company headquarters was relocated to Salzdetfurth and the company was renamed Kaliwerke Salzdetfurth AG . The establishment of the company coincided with a phase of rapid growth in the potash industry. From the 1880s on, private unions were increasingly established alongside state mines . At around the same time as Salzdetfurth AG, other companies were established that were later incorporated into K + S. For example Wintershall in Heringen an der Werra and the Burbach union in Walbeck . Through agreements and cartels , they were able to rapidly expand their market position. In the course of this development, the potash indicator was founded in 1888 as the central institution of the German potash industry in order to stabilize the crisis-prone and volatile market, which was repeatedly exposed to speculation and was determined by cyclical overproduction and a fight for repression by the unions. Price fixing and sales volume restrictions should calm the potash economy. For this purpose, the companies involved agreed on seven conventions, whereupon their association was also called the syndicate of seven individual contracts . This first syndicate, which existed until 1898, gradually integrated the largest producers and dominated the potash market.

Initially the focus was on the development of rock salt deposits , but soon the focus of the group turned to the mining of potash , in which the German Reich held a monopoly on the world market until the First World War . The successful funding of Salzdetfurth AG aroused the interest of established potash plants that participated in the emerging company. In 1901 Salzdetfurth AG joined the German potash cartel, in which most of the German potash mining companies were united after the end of the potash syndicate (1888–1898). The aim of the cartel was to secure the dominant position on the world market. After the first loose associations and declarations of intent since the 1870s and the establishment of the potash syndicate, the twelve leading potash mining companies came together in 1899. Up until the end of the First World War, the cartel was organizationally strengthened through agreements on volumes of production, price fixing and a joint global sales organization. With the addition of further mining companies, it continuously secured its dominant position. From 1901 the company ran its own potash factory and expanded by taking over mining fields in the area. Before the war, the development of potash deposits began in Alsace-Lorraine , with the local production being dominated by Deutsche Kaliwerke AG.

During the First World War , the German potash producers were included in the war economy. Agricultural productivity had to be ensured in view of the lack of imports. The ammonia synthesis based on the Haber-Bosch process , which is important for fertilizer production and also developed at BASF, played an important role . It represented an inexpensive substitute for the elimination of nitre, which was mainly imported from Chile before the war, by combining nitrogen with hydrogen on an industrial scale and thus making it available as a fertilizer. In accordance with the law of the minimum , successful fertilization can only be achieved if all the necessary components are sufficiently available. With this development, the later major shareholder of Salzdetfurth AG entered the fertilizer business. It was also potassium chloride required for the manufacture of explosives. Despite the loss of its export markets, which made up three quarters of the sales volume before the First World War, the German potash industry was able to maintain its production volumes due to the increased domestic demand caused by the war. Because of the drafting of labor into the war service, there soon came personnel shortages, which were compensated for with the use of forced labor and an increase in productivity.

After the First World War, the company lost its mining areas in Alsace-Lorraine. The importance of the mines in Alsace-Lorraine was only a result of the amount extracted there - this only contributed three percent to the extraction rate of the German Empire (1913) - but rather when the German potash monopoly broke through for the first time. Soon the German potash producers had to face global competition, mainly from the United States , Canada and the Soviet Union as well as from southern Europe and South America, especially Chile and Brazil . Nevertheless, in the 1920s, around 70 percent of global potash production came from Germany; in 1935 it was 62 percent. After the First World War, a process of concentration began in the potash industry that led to the formation of larger corporations with the aim of surviving the intensified competition. During the difficult economic times of inflation , Deutsche Bank , Commerzbank , Dresdner Bank and Deutsche Solvay -Werke joined the company as major shareholders. The banks involved controlled other potash groups, which they merged in 1922 to form the Salzdetfurth-Aschersleben-Westeregeln plant group through mutual holdings of the Consolidirten Alkaliwerke Westeregeln AG , the Kaliwerke Aschersleben AG and the Salzdetfurth AG . The Salzdetfurth AG held about 40 percent of the capital and took the lead within the corporate group. Together, the group of companies accounted for around 20 percent of German potash production and caught up with the dominant Wintershall Group, which at that time was able to book a share of almost 40 percent for itself. In the 1920s, the company acquired a stake in Mansfeld AG for mining and smelting operations in Eisleben . In order to prevent further expansion of the dominant Wintershall Group, most of the remaining potash groups, including Salzdetfurth AG , Burbach-Kaliwerke AG , Kali-Chemie AG and Deutsche Solvay-Werke , merged to form the potash block in 1926. An interest group that mainly cooperated in purchasing and sales. Together these companies had a market share of more than 50 percent.

During the Nazi era, the potash companies benefited from the National Socialists' self-sufficiency policy, which led to a significant increase in the demand for potash. At the urging of those in power, the Salzdetfurth-Aschersleben-Westeregeln group was merged on December 22, 1937 under the leadership of Salzdetfurth, and an extraordinary general meeting decided to change the company name to Salzdetfurth AG and to relocate the company headquarters to Berlin . In the course of the aryanization of Jewish assets, Wintershall AG acquired the shares held by the Petschek family in Salzdetfurth AG , thereby participating in their biggest competitor. During the Second World War , forced labor was used , whose share of the total workforce was more than a third in 1944. During the last years of the war, war-essential goods, art and cultural treasures were hidden in the tunnels of the potash mines. Armaments factories were built in some of the tunnels to protect them from the increasing bombing of the Allies. Numerous slave laborers were also used there.

After the war, the production facilities in the Soviet occupation zone were expropriated, as a result of which around 60 percent of the company's property was lost. Like other corporations, the company relocated its headquarters to West Germany and returned to its origins in Bad Salzdetfurth. Soon after the end of the war, production was resumed in the remaining plants, as the Allied occupying powers saw the supply of potash as a necessary basic supply. In 1948, Salzdetfurth AG was one of the largest German potash producers alongside Wintershall, Burbach-Kaliwerke AG , Kali-Chemie AG and Preussag . In the 1950s, production was rapidly expanded and, with modernized production technology, it soon returned to the pre-war level. In addition, the company expanded with sales companies in other European countries. In 1952, Salzdetfurth AG took over 25 percent of the Cologne chemical factory , in 1957 the stake was increased to 75 percent, and in 1960 the company was completely taken over. As a supplier of complex fertilizers, Chemische Fabrik Kalk had been one of Salzdetfurth AG's most important customers since the 1940s , after potash salt was added to the nitrogen-phosphate fertilizer KAMP in 1948 and sold as KAMPKA. As a result of the takeover, Salzdetfurth AG expanded its range of fertilizers, and later products for the Compo sales line were also produced in the Lime Chemical Factory . However, the company taken over resulted mainly in losses. In 1988 the production of fertilizers was stopped, after BASF withdrew from K + S in 1993 chemical production was also stopped. Since then, Chemische Fabrik Kalk has only existed as a sales company of K + S for fertilizers. In the 1960s, competition on the world market increased, in particular from companies that were active in the former African colonies that were rich in resources and striving for independent branches of the economy, as a result of which Salzdetfurth AG increasingly ran into economic difficulties. In this situation, the company sought to approach its domestic German competitor Wintershall, which already held 15 percent of the shares. Wintershall was owned by the Rosterg and Quandt families until 1968 , when it was taken over by BASF in 1968. In addition to potash mining, the company also operated a petroleum and natural gas division , which continued to exist as a BASF subsidiary of the same name after the merger in 1971.

Kali und Salz GmbH (1971 to 1993)

In 1971, Salzdetfurth AG was merged with the potash division of the BASF subsidiary Wintershall AG and Burbach-Kaliwerke AG and merged into the new Kali und Salz GmbH based in Kassel. The Burbach-Kaliwerke AG were tied to Wintershall since 1934th At that time, Wintershall became a major shareholder with 45.5 percent of the shares in the company, whose shares were traditionally widely dispersed and which at that time had got into a crisis due to over-indebtedness. In 1955, Wintershall took over the company's bank debt and in return the majority of the shares. So BASF became the majority shareholder in the new company. Securing access to the raw materials used in its production was the top priority for BASF. The corporate and acquisition policy of this time was aimed at securing the supply of crude oil, natural gas, petrochemicals and salts. For this purpose, BASF had already taken over Wintershall in 1968. With Salzdetfurth AG , the main competitor in the field of nitrogen fertilizers was brought into its own warehouse, and the desired monopoly position in Germany was expanded. As a result of the break-up of IG Farben after the Second World War, the three large successor companies Bayer , BASF and Hoechst tried to regain their old monopoly in the form of an oligopoly through company acquisitions and investments . In the 1970s, their share in West German chemical production was already over 90 percent. In 1972 Kali und Salz GmbH was converted into a stock corporation and merged with the old Salzdetfurth AG . BASF later took over the remaining shares in the company, which now dominated the potash market in western Germany. The company headquarters remained in Bad Salzdetfurth. Subsequently, the company continued to struggle with declining demand for potash. There was a cut in funding and massive rationalization measures, combined with the loss of several thousand jobs.

Kali und Salz AG (1993 to 1999)

After the reunification of Germany , the potash and rock salt activities of Kali und Salz AG and those of Mitteldeutsche Kali AG , which formerly bundled state-owned companies of the GDR and were now managed by the Treuhandanstalt , became Kali und Salz GmbH in Kassel , which was newly founded in 1993 merged. Kali und Salz AG held 51% of this company and the Treuhandanstalt 49%. Previously, in 1992, Kali und Salz Disposal GmbH was founded in Kassel, where the disposal activities of Kali und Salz AG are managed and which, alongside Kali und Salz GmbH, represents the company's second major investment. In 1994 Kali und Salz AG was renamed Kali und Salz Beteiligungs AG and in 1998 took over the 49 percent share of the Treuhandanstalt in Kali und Salz GmbH . In 1998, the shares of Kali und Salz Beteiligungs AG were included in the MDAX by Deutsche Börse after BASF, as a major shareholder, had reduced its stake in the company to 25 percent in several steps. K + S was now the dominant and only large remaining German potash and salt mining group. As the company had retracted on sales of 1.48 billion euros a loss of 300 million euros in 1993, it reached the 1997 break-even point and generated at a rise to 2.024 billion euros turnover a profit of 60 million euros.

K + S Aktiengesellschaft (since 1999)

On July 6, 1999, Kali und Salz Beteiligungs AG was renamed K + S Aktiengesellschaft . The logistics division was restructured and renamed Kali-Transport-Gesellschaft based in Hamburg , and in 2011 it was renamed K + S Transport GmbH . With 3.5 to 4.5 million tons per year, K + S Transport GmbH accounts for a good tenth of the export volume in bulk cargo handling in the Port of Hamburg , which in 2014 was 43 million tons. In addition, in 1999 the fertilizer producer Compo, including the fertilizer production and logistics site in Krefeld , was taken over by BASF in December 1999 . As a result, K + S rose to become the second largest European fertilizer producer and achieved market leadership in the end consumer market. As early as 1967 the then Salzdetfurth AG founded the joint venture Compo together with Sprenger & Todenhagen KG and in 1971 took over the entire shares. In the course of the merger with Wintershall , Salzdetfurth AG ceded 50% of its Compo shares to its main shareholder BASF, which took over Compo completely in 1986 as part of its diversification strategy. In 1999, K + S Compo bought it back from BASF for DM 420 million, which was now concentrating on its core business. Fertiva GmbH , based in Limburgerhof (now Mannheim ), was founded to control the field fertilizer activities . In return, BASF reduced its stake in K + S to 15%. Aside from its core business, K + S founded data process GmbH in Kassel as an IT service provider, which was now called K + S IT Services GmbH and has since been dissolved.

In 2002, K + S and Solvay founded the joint venture esco ( European Salt Company ) based in Hanover, in which they merged their European salt activities. Initially, K + S 62 and Solvay held 38% of the company. In 2003, BASF reduced its stake in K + S to 10%. In 2004, K + S acquired the esco shares from Solvay and in 2004 generated sales of 2.54 billion euros. K + S became active in the Netherlands and Scandinavia through esco Nordic AB , based in Gothenburg , and took over the French Societé Commerciale des Potasses d 'Alsace (SCPA) based in Mulhouse . In April 2006, K + S acquired the largest South American salt manufacturer Sociedad Punta de Lobos SA (SPL) from Chile for 480 million US dollars, which was renamed K + S Chile in 2013 . In 2009, K + S acquired the American salt manufacturer Morton Salt for 1.6 billion dollars from the chemical company Rohm and Haas , making it the world's leading salt supplier.

The business activities of fertiva and parts of the Compo professional business were merged on July 1, 2009 in the new company K + S Nitrogen . Compo was sold to the financial investor Triton on March 1, 2011 for 205 million euros. On June 25, 2012, the sales company K + S Nitrogen was sold to the fertilizer group EuroChem .

In 2012, construction work began on the new potash site in the Canadian province of Saskatchewan , in which K + S is investing around three billion euros. The Bethune plant was officially opened on May 2, 2017 and has a planned final capacity of almost three million tons per year.

A planned takeover by competitor Potash failed in 2015.

In 2020, K + S Entsorgung (Schweiz) AG , based in Delémont , was sold to the Thommen-Furler Group, based in Switzerland.

Group structure

Business areas and organizational structure

The K + S Group is divided into three business areas that are strategically, technically and economically closely linked. They are supported by the service units and the holding functions of K + S AG :

- Potash and Magnesium Products

- salt

- complementary business areas

Products

- Potash and Magnesium Products

- salt

Holdings

- K + S Minerals and Agriculture GmbH (merger of K + S KALI GmbH and esco - european salt company GmbH & Co.KG)

- Chemische Fabrik Kalk GmbH (CFK), based in Cologne

- Ickenroth GmbH, based in Staudt

- K + S Baustoffrecycling GmbH, based in Sehnde

- K + S Consulting GmbH, seat in Kassel

- K + S Potash Canada GP, based in Saskatoon, Canada

- Morton Salt, based in Chicago, USA

- K + S Chile SA, based in Santiago, Chile

Share data and shareholder structure

After the former parent company BASF had sold its ten percent stake in K + S in March 2011, the EuroChem group controlled by Andrei Melnitschenko acquired 10.43% in the company in June 2008. EuroChem has meanwhile reduced its share to below five percent. The largest single shareholder is the finance company DWS Investment with a stake of 5.69%.

The employees of K + S hold around one percent of the shares. The remaining shares are in free float. About 50 percent of the shares are held in Germany. The share had been part of the DAX since September 22, 2008 . K + S replaced the TUI AG share with the Deutsche Börse's fast entry rule . The ticker symbol SDF still comes from Salzdetfurth AG .

At the end of July 2013, the K + S share price plummeted by around 30 percent: on August 1, 2013 it was 16.91 euros, the lowest level since October 2006. Investors worried about further falling potash prices. The German Federal Financial Supervisory Authority (BaFin) initiated an investigation on August 5, 2013 to uncover possible insider trading or market manipulation. The price decline was triggered by the Russian competitor Uralkali , who terminated its sales alliance with the Belarusian Belaruskali and announced falling potash prices to the press. As a result, the shares of K + S also fell by up to 44 percent, reducing the company's value by around two billion euros.

The Deutsche Börse Group announced on March 3, 2016 that K + S will be removed from the DAX from March 21, 2016, as its market capitalization has fallen sharply. ProSiebenSat.1 Media SE was added as a replacement .

Corporate governance

Burkhard Lohr has been the CEO of K + S AG since May 12, 2017. Thomas Nöcker, Mark Roberts ( COO ), Otto Lose and Thorsten Boeckers were appointed as further members of the company management . Otto Lose left the board after only eleven months, with the press discussing the amount of his severance payment, after Andreas Radmacher, who had left the company prematurely, received 1.6 million last year. The chairman of the supervisory board is Andreas Kreimeyer.

Locations

The K + S Group with its corporate headquarters in Kassel has production sites in Europe, North America and Central and South America. The company is also represented in Africa and Asia with sales offices.

Locations in Germany

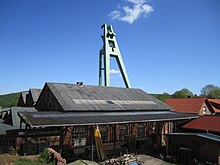

The Werra Verbund plant with locations in Wintershall ( Heringen ), Hattorf ( Philippsthal ) and Unterbreizbach on the Hesse - Thuringia border belongs to the subsidiary K + S KALI GmbH . The Zielitz potash mine in Saxony-Anhalt is the largest potash mine in Germany with an annual production of around 12 million tons of crude salt. Around 30 percent of K + S's annual production is funded here. The Werra plant also includes the Merkers site , where there is a publicly accessible adventure mine . It is one of the largest potash mining areas in the world and is roughly the size of the city of Munich . Other potash plants are Neuhof-Ellers (near Fulda) and the Bergmannssegen-Hugo plants in Sehnde and Sigmundshall near Bokeloh , both near Hanover.

In the salt division, esco - european salt company GmbH & Co. KG operates the plants in Bernburg (Saxony-Anhalt), Borth (near Rheinberg, North Rhine-Westphalia) and Braunschweig-Lüneburg at the Grasleben site (near Helmstedt, Lower Saxony).

Public perception and controversy

Brine discharge into the Werra

Annually conducts K + S by pressing up to seven million cubic meters of salt lye , which is mainly produced in the processing of potash, in the underground. Injection areas are near Kleinensee and Philippsthal in Hesse. Critics see the grouting as one of the reasons for the salinisation of the Werra. With the approval of the Kassel regional council, saline wastewater is also discharged into the river. Since October 2013, an average of 700,000 cubic meters of this has come from the Neuhof-Ellers plant via a newly built, 63-kilometer pipeline . Some civil associations and various political groups protested against the construction of the pipeline, which raised more than 2,000 objections to the project. They feared a disruption of the ecological balance of the Werra and resulting consequential damage for agriculture and tourism. At the end of 2012, the Kassel regional council approved the pipeline, the existence of which was confirmed by the court in 2014. K + S intends to manufacture around 260,000 tonnes of sales products such as potassium chloride and magnesium sulphate from the previously unused salt solutions that previously had to be disposed of . At the same time, the amount of wastewater from the Werra plant will be reduced by 1.5 million to 5.5 million cubic meters. In 2007 it was 14 million cubic meters. Since the wastewater cannot be discharged into the Werra when the water is low , production had to be temporarily stopped, which is why a new intermediate storage facility in a disused mine field was approved. A total of around one million cubic meters of production wastewater could now be temporarily stored.

Four-phase plan

In September 2014, K + S presented a concept together with the Hessian Ministry of the Environment to further reduce the amount of saline wastewater discharged and to limit it to an ecologically acceptable level after potash production has ended. According to the four-phase plan, the Werra and Oberweser should have fresh water quality by 2075 at the latest. At the same time, K + S abandoned plans for a pipeline approximately 450 kilometers long from the potash district on the Werra to the North Sea.

Spoil heaps: "Kaliberge"

There are large spoil heaps in Neuhof-Ellers, Zielitz , Heringen, Bokeloh and Philippsthal-Röhrigshof . The Heringer Halde is also called Monte Kali , the Zielitzer Halde is known regionally as Kalimanjaro . The area around Heringen and Philippsthal is jokingly referred to as the land of the white mountains .

At the former potash salt mine in Buggingen in Markgräflerland ( southern Baden ), the eroding dump is also called Monte Kalino .

Accidents

A serious mine accident occurred on April 5, 2012 in the Sigmundshall potash plant. One miner was killed and several injured. At the Unterbreizbach site of the Werra potash plant, a carbon dioxide eruption occurred on October 1, 2013 after a blast , in which three miners were killed.

Others

In the area of Philippsthal K + S maintains to supply to its own mines 60 kilovolts - power lines . The following connections exist:

- Heimboldshausen substation - Hattorf potash plant

- Heimboldshausen substation - Hera mine

- Potash plant Hattorf - Werra plant

Almost all of these lines are built on tubular steel masts in weather fir design to accommodate a circuit. In the northern area of the line to the Werra plant, some pylons are designed as weather fir pylons in steel framework construction and the two lines going out from the Heimboldshausen substation are laid together on the first four pylons, which were realized as lattice pylons in Danube design for two circuits.

See also

literature

- Dirk Reder, Severin Roeseling, Thomas Prüfer: Experience growth: The history of the K + S Group . 1st edition, Kassel 2006, online full text . ISBN 978-3-9809738-1-6 .

Note: This publication was commissioned and edited by the K + S Group. - Hermann-Josef Hohmann & Dagmar Mehnert (eds.): Colorful salts, white mountains. Growth and change in the potash industry between the Thuringian Forest, Rhön and Vogelsberg . Hünfeld 2004, ISBN 3-9809738-0-8 .

Web links

- Website of the K + S

- Early documents and newspaper articles about K + S in the 20th century press kit of the ZBW - Leibniz Information Center for Economics .

Individual evidence

- ↑ a b c d e Annual Report 2019 , accessed on July 11, 2020

- ↑ Global capacities of the largest salt suppliers in 2011, Statista

- ↑ World potash market - market share of the largest potash producers in 2013. Statista , accessed on November 13, 2014 .

- ↑ BASF separates from K + S. In: manager magazin . BASF SE, March 11, 2011, accessed on August 11, 2015 .

- ↑ Reder u. a. 2006, p. 46.

- ↑ See Reder u. a. 2006, p. 48 ff.

- ↑ See Reder u. a. 2006, p. 41 f.

- ↑ Reder u. a. 2006, p. 75.

- ↑ Reder u. a. 2006, p. 55.

- ↑ Reder u. a. 2006, p. 101.

- ↑ Reder u. a. 2006, p. 86.

- ↑ Reder u. a. 2006, p. 109. In 2000, K + S took part in the German business foundation's initiative to equip the “Remembrance, Responsibility and Future” foundation , which is intended to compensate former forced laborers of the Nazi regime ( as a participant, the then Kali and Salz Beteiligungs AG listed ( memento from March 19, 2007 in the Internet Archive ))

- ↑ Reder u. a. 2006, p. 110.

- ↑ See Reder u. a. 2006, p. 135.

- ^ Rauschel, Jürgen : The BASF. On the anatomy of a multinational corporation. Cologne 1975 (p. 28); Schreiber, Peter Wolfram: IG Farben, the innocent war planners. Profit from crises, wars and concentration camps. History of a German monopoly. Stuttgart 1978 (p. 176f).

- ↑ See Schreiber, Peter Wolfram: IG Farben, the innocent war planners. Profit from crises, wars and concentration camps. History of a German monopoly. Stuttgart 1978 (p. 176).

- ↑ Reder u. a. 2006, p. 260.

- ↑ Image brochure K + S Transport GmbH (pdf)

- ↑ Bulk cargo handling in the Port of Hamburg from 1990 to 2014 (in millions of tons), Statista

- ↑ Compo. Kali und Salz takes over BASF subsidiary. Manager-Magazin, December 22, 1999, accessed January 3, 2013 .

- ^ History of K + S AG. Retrieved January 3, 2013 .

- ↑ Klaus Max Smolka, Tim Bartz, Matthias Brügge: K + S buys US salt manufacturer Morton Salt. (No longer available online.) Financial Times Deutschland, April 2, 2009, archived from the original on April 3, 2009 ; Retrieved January 3, 2013 .

- ^ K + S sues Dow Chemical - Morton Salt is too expensive. Retrieved January 3, 2013 .

- ↑ Focus on the core business. K + S sells COMPO to the holding company Triton. (No longer available online.) K + S AG, June 20, 2010, archived from the original on June 9, 2015 ; Retrieved April 21, 2012 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ K + S share: Sale of K + S Nitrogen to EuroChem successfully completed. K + S AG, June 25, 2012, accessed on January 3, 2013 .

- ↑ Bethune Potash Works. K + S AG, accessed on September 20, 2017 .

- ↑ Die Welt: K + S is planning new mining projects after "Legacy".

- ↑ Georg Meck: Millions for the Kali mercenaries. In: faz.net. Frankfurter Allgemeine Zeitung, October 10, 2015, accessed on October 10, 2015 .

- ^ K + S Disposal (Switzerland) AG. Entry in Zefix , accessed January 17, 2020 .

- ↑ K + S sells waste disposal subsidiary in Switzerland. In: osthessen-news.de. January 17, 2020, accessed January 17, 2020 .

- ↑ Business areas of the K + S Group

- ↑ Areas of application potash and magnesium products

- ↑ Areas of application salt

- ↑ K + S bundles business in K + S Minerals and Agriculture GmbH. K + S Aktiengesellschaft, November 4, 2019, accessed on February 21, 2020 .

- ↑ Chemical Factory Kalk GmbH (CFK)

- ^ Ickenroth GmbH

- ↑ K + S Baustoffrecycling GmbH

- ↑ K + S Consulting GmbH ( Memento of the original dated November 21, 2008 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ^ K + S Potash Canada

- ↑ Morton Salt

- ^ K + S Chile SA

- ↑ BASF separates from K + S. Manager Magazin, March 11, 2011, accessed April 19, 2012 .

- ↑ Corporate and Sustainability Report 2008: Corporate and Sustainability Report 2008: Shareholder structure with high free float, page 43.

- ↑ Financial Report 2014, page 163

- ↑ Shareholder structure

- ↑ Entire paragraph: Information on the shareholder structure at www.k-plus-s.com

- ↑ Annina Reimann: Suspicion of insider trading: BaFin investigates price slide at K + S. Wirtschaftswoche , August 10, 2013, accessed on August 31, 2013 .

- ^ Daniel Mohr: Kali shares. Uralkali creates turbulence. In: faz.net. Frankfurter Allgemeine Zeitung , July 30, 2013, accessed on August 18, 2013 .

- ↑ n-tv news television: K + S goes down: ProSiebenSat.1 in the Dax from March. In: n-tv.de. Retrieved March 4, 2016 .

- ^ Klaus Max Smolka: How K + S and its Supervisory Board are wasting the money. In: www.faz.net. December 9, 2017. Retrieved April 15, 2018 .

- ↑ Klaus Max Smolka: Again, a board of directors has a goodbye. In: www.faz.net. April 14, 2018, accessed April 15, 2018 .

- ↑ FAZ.net

- ↑ Locations of the K + S Group at www.k-plus-s.com

- ↑ The Zielitz potash plant - Glückauf! . Accessed February 8, 2016.

- ↑ a b K + S puts water treatment plant in Hattorf into operation In: finanzen.ch , January 17, 2018, accessed on January 18, 2018.

- ↑ K + S in the state parliament: Sinking safely and responsibly , Focus from April 16, 2015

- ^ A b Compression dispute also in Hesse. In: Südthüringer Zeitung, October 1, 2008.

- ↑ Brussels wants a clean Weser , TAZ

- ↑ Pipeline for brine in operation from today , Fuldaer Zeitung of October 4, 2013

- ↑ a b When the Weser is salted to death. In: TAZ of February 5, 2007.

- ↑ Original protest against potash wastewater in the Werra. Thüringer Allgemeine, May 3, 2012, accessed on May 3, 2012 .

- ↑ Municipalities fail again in the fight against K + S , MDR ( Memento from January 23, 2014 in the Internet Archive )

- ↑ Michael Barck: K + S: New intermediate storage facility to alleviate wastewater problems. In: 4investors.de. August 13, 2019, accessed August 13, 2019 .

- ↑ Werra and Oberweser should achieve freshwater quality by 2075 , HNA of September 29, 2014

- ↑ Report by Michael Reinhardt (University of Trier) on the four-phase plan (PDF)

- ↑ North Sea pipeline as a solution to the disposal issue? on www.k-plus-s.com

- ^ A dead person in a mine accident in the salt mine near Hanover . Stern , April 5, 2012.

- ↑ Three dead after a mine accident. Gas explosion in Thuringia. Rheinische Post, October 1, 2013, accessed on October 1, 2013 .

Coordinates: 51 ° 18 ′ 35 " N , 9 ° 26 ′ 48" E