Lightbulb

An incandescent lamp or filament lamp (formerly incandescent light ) is an artificial light source . Colloquially, incandescent lamps are referred to as light bulbs because of their shape . In the incandescent lamp, an electrical conductor is heated up by electrical current and thus stimulated to glow. The widespread design of the incandescent lamp with a screw base is technically referred to as a general service lamp (abbreviated to A lamp or AGL ).

It is still very often used today for living space lighting. However, because it is very inefficient (around 10–22 lm / W compared to 61–140 lm / W for white LEDs ), a number of states and confederations of states, including the European Union , Switzerland , the People's Republic of China and Australia , a ban on the manufacture and sale of incandescent lamps with low energy efficiency has been decided or has already come into force. In this way, energy efficiency should be increased and thus energy saved .

history

Even before the invention of electric light , the term incandescent lamp was used to refer to a spirit device for generating ethereal vapors, over the wick of which a spiral made of platinum wire is attached. After the flame was extinguished, the platinum catalytically oxidized the rising fuel vapor further and generated heat in the dark embers, which kept the process going.

In 1801, Louis Jacques Thénard showed that metal wires can be brought to a bright glow by the electric current from galvanic elements. The Scot James Bowman Lindsay presented an incandescent lamp in 1835. William Robert Grove published the first platinum wire incandescent lamp in 1840. The first patents were secured by Frederick de Moleyns in 1841 and John Wellington Starr in 1845.

There is evidence of an early incandescent lamp with platinum thread under an evacuated (evacuated) glass bell from around 1820. The origin and dating of the lamp known as the “De-la-Rue lamp” or “De-la-Rive lamp” are not clear. On July 25, 1835, James Bowman Lindsay from Scots demonstrated a constant electric light at a public meeting in Dundee . He stated that he could "read a book a foot and a half away." Lindsay completed the device to his own satisfaction, but then turned away from his invention and turned to the problem of wireless telegraphy . Frederick de Moleyns received the first known patent for an incandescent lamp in 1841. He used carbon powder between platinum wires under a vacuum flask. The American John Wellington Starr also received a patent for an incandescent lamp from Edward Augustin King in London in 1845. This patent mentions carbon pencils as a suitable incandescent material for bright light. Also in 1845 the Englishman William Robert Grove published the construction of an incandescent lamp with a platinum filament in a spiral shape, which he had developed in 1840.

Numerous patents for incandescent lamps were registered from the 1850s. The developers initially failed to manufacture longer-lasting incandescent lamps due to vacuum technology. After the invention and the spread of the vacuum pump, design efforts intensified in various countries in the 1870s, resulting in numerous patent applications. However, the burning time of the constructions was less than ten hours. In addition to the durability of the lamps, the problem of energy consumption became a focus of efforts. In 1874 Alexander Nikolajewitsch Lodygin received a patent in Russia for an incandescent lamp with a carbon filament or a thin carbon pencil in a glass bulb filled with nitrogen .

The British physicist and chemist Joseph Wilson Swan also developed an incandescent lamp in 1860, using charred paper as a filament in an empty glass flask. It was not until 1878 that he succeeded in producing a practically usable electric light bulb. He acquired his patent in England in 1878 two years earlier than Edison obtained his comparable patent in the USA. He equipped his incandescent lamps with a special socket, the Swan socket , which, unlike the screw threads on Edison incandescent lamps , did not loosen when shaken, for example in vehicles. After initial patent litigation, Edison and Swan came to an agreement and finally founded a jointly operated company in London in 1883.

Thomas Alva Edison , who is wrongly called the inventor of the light bulb, improved the incandescent lamp and received the basic patent number 223898 for his developments in the USA on January 27, 1880, the invention date of October 21, 1879, which is common in traditional representations, is valid according to the results of more recent source research however as a legend. His incandescent lamp consisted of an evacuated glass bulb with a charcoal filament made from charred bamboo fibers. Numerous improvements, especially in the precision manufacture of the filament, led to incandescent lamps with which Edison successfully competed against the gas lamps that were common at the time. Durability, light output and energy costs played a role. In contrast to Swan's lamps, Edison's incandescent lamps were equipped with high-resistance filaments, which were difficult to manufacture, but made their use in electrical networks much easier and cheaper. With high voltage for high-resistance loads, electrical energy could be transported more easily, and the possible smaller cable cross-sections saved considerable amounts of copper. This made a power supply network for electricity technically feasible and competitive with networks for gas lamps. In particular, Edison was able to solve the problem of the divisibility of light with his high-resistance lamps; all previous solutions required a separate power source for a few lamps. That is why the invention of the practical incandescent lamp is commonly attributed to Thomas Alva Edison. Edison's design was the first incandescent lamp that was not only manufactured in small numbers in workshops, but also went into series production in a specially built factory.

The use of carbon filament light bulbs in private households in the 1880s went hand in hand with the establishment of supply networks for electrical energy. These products therefore mark the beginning of pervasive electrification in cultural development . In Germany, the Café Bauer (Berlin) is considered to be the first building to be illuminated with incandescent lamps in 1884, which was manufactured by Emil Rathenau according to Edison patents.

The distribution of the newly emerging electronics market was fought hard in the 1880s, with numerous patent lawsuits in particular involving the key product of electrification, the incandescent lamp with a high-resistance carbon filament. Heinrich Göbel stated in patent litigation between Edison Electric Light Co. and other American light bulb manufacturers in 1893 that he had already experimented with carbon filament light bulbs from the early 1850s, but was unable to prove his claim that the Edison invention was anticipated in court. Nevertheless, he was considered to be the inventor of the carbon filament light bulb in Germany in the 20th century. The first German incandescent lamp is said to have been manufactured in Stützerbach ( Thuringia ) in 1883 . Sources in this regard, however, contradict the older incandescent lamp by C. H. F. Müller shown above .

The suitability of osmium , tantalum or tungsten for filaments was known because of the high melting point of these metals. But only technical developments in powder metallurgy such as sintering technology made it possible to process it economically. Tungsten, osmium and tantalum are rare and therefore expensive raw materials. The processing problems to be solved were greatest with the very hard and brittle tungsten. The Austrian chemist and founder of Osram , Carl Auer of Welsbach , an important contribution to the invention, the incandescent lamp by (1890 Patent), and tungsten, has developed a process for the production of wires from osmium that time as metals having the highest melting points were .

1897 invented physical chemist Walther Nernst in Göttingen named after him Nernst lamp , by the AEG and Westinghouse was produced (Nernst Lamp Company). In this incandescent lamp, a thin rod (Nernst pin) made of a solid electrolyte (mainly zirconium oxide with additives) serves as the incandescent body instead of a carbon or metal thread. The Nernststift does not require a protective gas, but can be operated in normal ambient air.

In 1903, Willis R. Whitney invented a filament that did not blacken the inside of an incandescent lamp. It was a metal-coated carbon thread. A year earlier (1902) the German chemist Werner von Bolton and the Swiss physicist Otto Feuerlein recognized the chemical element tantalum (Ta) as a suitable material for the production of metallic filaments. In 1905 the first incandescent lamps with tantalum filaments were delivered and gradually replaced the previous carbon filament lamps . The tantalum lamp was a brief episode in the history of the incandescent lamp in the run-up to the development of the tungsten lamp used today, but by the outbreak of the First World War , over 50 million tantalum lamps were manufactured and sold worldwide using the Bolton and Feuerlein process.

In 1906 the General Electric Company bought patents for tungsten filaments as a basis for their own research and further development work. Various sources name Alexander Nikolajewitsch Lodygin as the patent holder, who had already experimented with tungsten in the 1890s and presented such a lamp at the 1900 World Exhibition . At that time, many developers, including the Croatian Franjo Hannaman from Zagreb, experimented on developing a practical tungsten filament lamp. Filaments made from metal obtained by means of sintering were extremely brittle and processing into spirals or loops was impossible for mass production. In 1910, William David Coolidge , who worked for General Electric , invented a method of making mechanically stable tungsten filaments. General Electric began commercial production of the tungsten filament incandescent lamps that are still used today. This type of lamp significantly improved the ratio of light output to energy consumption. General Electric regained the dominance in the incandescent lamp sector that had been lost after the Edison patents had expired.

In 1911, Irving Langmuir discovered that using an argon-nitrogen mixture in an incandescent lamp extended the life of the tungsten filament. Krypton has been used as a filling gas since 1936, and xenon for high-performance lamps for the first time since 1958 . In 1931, the chemist Mary B. Andrews applied for a patent in the USA for an electric incandescent lamp, which was granted in 1935 with the number 2019331. An earlier patent grant to a woman in incandescent lamp technology is currently unknown.

The Berlin inventor Dieter Binninger developed a long-lasting (150,000 h) " eternity light bulb " for his Berlin clock , which was especially intended for applications that constantly incur high replacement costs, such as traffic lights or his set theory clock . His patents, filed between 1980 and 1982 for “extending the service life of general-purpose incandescent lamps”, however, are essentially based on a modified filament geometry and operation with undervoltage using an upstream diode .

Working principle

In an incandescent lamp, an electric current is made to flow through a thin thread made of a conductive material ( conductor ) (usually a metal ). Thanks to a suitably chosen material, e.g. B. tungsten , this does not melt. The metal filament has the shape of an incandescent filament (filament). If a sufficiently strong electric current flows through the thread, it is heated so much ( Joule heat ) that it glows . The temperature of the incandescent filament is, depending on design about 1500-3000 ° C , so that they according to the Planck's law of radiation electromagnetic radiation emitted , mainly in the field of infrared radiation and visible light is. The emission of photons (light particles) is caused by the relaxation of the thermally excited electrons in the filament.

However, only a very small part of the electrical power consumed is emitted in the form of visible light, since only approx. 2.2% of the electrical energy is converted into light in ordinary incandescent lamps. By far the largest part of the energy, however, is radiated in the infrared range as thermal radiation. A remainder is transferred to the filling gas and the glass bulb as well as to the supply and holding wires of the incandescent filament by means of thermal conduction and convection .

construction

The incandescent lamp consists of a base including the electrical power leads in the pinch foot and a glass bulb that shields the filament and its holder from the outside environment. The different designs and types of power are usually characterized by the ILCOS lamp designation system and are described in more detail there.

base

The base of an incandescent lamp is used to fix it in a lamp socket and to make electrical contact. The version of the socket limits the permissible power and current consumption of the incandescent lamp that can be operated in it. Light fittings for E27 Incandescent lamps are often at 60 W limited.

Socketless lamps only have connecting wires or a pinch foot without a socket for plugging in. Plug-in base lamps only have reinforced pins on the pinch foot. Traditional incandescent lamps have Edison bases made from sheet metal into which the lamp is cemented. In the case of projection lamps (except halogen), signal lamps and those for vehicle headlights, the base is precisely adjusted with respect to the filament. The exact position of the filament requires the use of bayonet sockets. In the base of general service lamps of higher power (from 40 or 60 W) there is a fuse or a suitable thin piece of wire to prevent the arc that may ignite inside the lamp when it burns out, triggering the upstream fuse or bursting the glass bulb .

Glass bulb

In normal ambient air, the filament would immediately burn to tungsten oxide due to the oxygen and the high operating temperatures , which is why it is shielded from the ambient air by the glass bulb. Since metal is constantly evaporating from the filament during operation, the size of the bulb essentially depends on the sublimation rate of the wire material. Conventional incandescent lamps or incandescent lamps with high output require a large glass bulb so that the precipitation can be distributed over a larger area and the transparency of the glass bulb is not restricted too much during the life of the lamp. The inside of the glass bulb can be partially mirrored, matted (roughened inside) or made of opaque glass ( milk glass ). Colored incandescent lamps are seldom made from colored glass, more often from lacquered bulbs.

Due to the manufacturing process, incandescent glass bulbs have a pump nozzle (pumping out the air and filling with protective gas ) that is melted off. In the case of older incandescent lamps and halogen lamps, it is at the tip of the bulb, and in the case of general service lamps, for example, it is protected in the base. Special demands are made on the type of glass only in the case of more compact designs; it is partly made of heat-resistant glass or - in the case of halogen lamps - made of quartz glass .

Protective gas

The glass flask used to be evacuated . Today the light bulbs are filled with a protective gas. This simplifies production and reduces the rate of sublimation . The heat losses caused by conduction and convection when filled with gas are limited by choosing the heaviest possible inert gas molecules or atoms. Mixtures of nitrogen and argon are a concession to manufacturing costs. Expensive incandescent lamps contain krypton or xenon , which allows them to be heated up more.

filament

history

The first patented incandescent lamps in the 1840s had platinum filaments . However, no product emerged from these developments. Only at temperatures just below the melting point of platinum of 1772 ° C was an acceptable light output achieved. Precise temperature control for durable filaments proved too difficult. Thomas Alva Edison gave up this technical approach.

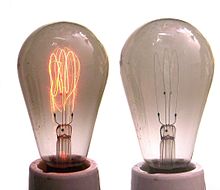

The first commercially produced incandescent lamps contained a filament made of carbon with a sublimation point of 3550 ° C. The charring of natural thin fibers from fast growing tropical plants such as bamboo was suitable. The manufacturing process is much more complex than making thin threads from platinum. Furthermore, the operation of carbon threads requires a stronger vacuum in the glass bulb. Carbon filament lamps are still available today. The slightly reddish light and the gentle increase in brightness when switched on are often perceived as pleasant.

Research into metal filaments continued, primarily in order to increase the brightness. According to Vienna's radiation law, which was already known at the time , a higher temperature of the filament is required than can be achieved with a carbon filament. An important intermediate step was osmium filaments . The high melting point made it possible to achieve a high level of brightness with relatively little heat generation. The disadvantage is that osmium is so brittle that it cannot be formed into wires at all, but has to be processed with a binding agent into a paste containing metal powder and then injected into threads. The filaments obtained in this way are even more sensitive to vibrations than carbon filaments. In addition, they are relatively thick and conduct very well, so they require very low voltages at low power levels, which were difficult to provide in the direct current networks customary at the time. Because of these disadvantages, the osmium filaments were very quickly replaced by those made of tantalum . From 1903 it was possible to produce the likewise high-melting tantalum very pure and thus malleable into fine wires. The tantalum filaments replaced the carbon filaments in most applications in the period that followed. From 1910, tungsten filaments became common after methods had been found to shape this metal, which melted even higher than osmium, into thin metal wires.

present

In addition to the possible increase in temperature and thus the light yield related to the power, the metal threads also have another advantage: They can be formed into small coils, which increases the power density - the incandescent lamp becomes smaller with the same light output. In addition to the reduced space requirement, the light can also be better bundled. In addition, a higher temperature can be achieved with the same electrical power, because the heat source has a smaller expansion and thus does not lose as much heat to the environment. In the case of high-power lamps, the wire is often twisted twice in order to limit this heat convection with a small Langmuir layer and / or to accommodate a large amount of wire in a small volume at high operating voltages.

Coils and double coils are produced by winding tungsten wire on molybdenum wire of larger diameter, this - in the case of double coils - in turn on another thicker wire. The auxiliary wires are etched away.

Long coils must be held in place with support wires. Special requirements are placed on vehicle lamps with regard to vibration sensitivity.

Electrical Properties

Due to the positive temperature coefficient ( PTC thermistor ), when a metal wire incandescent lamp is switched on, a very high inrush current (five to fifteen times the rated current) flows, which quickly heats the filament to operating temperature. As the electrical resistance increases as the temperature rises, the current drops to the nominal value. The previously used carbon filament lamps , on the other hand, showed a gentle increase in the current when switched on, as only when the temperature rises enough charge carriers are released for the current transport (carbon is a thermistor ).

The high inrush current is the cause of incandescent lamp failures immediately upon switching on (see below ). This can cause an arc (at higher operating voltages) , which can trigger the fuse and / or burst the glass bulb. Incandescent lamps for mains voltage are therefore provided with a fuse in the base in the form of a thin connecting wire.

The high inrush current of metal wire light bulbs puts a strain on the power supply system of the light source .

Optical properties

Light output

Almost all of the energy supplied to the lamp is converted into radiation, and the losses due to conduction and convection are low. But only a small wavelength range of the radiation is visible to the human eye, the main part is in the invisible infrared range and cannot be used for lighting purposes.

The wavelength distribution of the generated light corresponds to Planck's law of radiation , its spectrum is continuous like the sun . However, since the temperature of the filament is much lower, the red component by far predominates, blue is only very weakly represented. The radiation maximum of the radiation shifts with increasing temperature according to Wien's shift law to smaller wavelengths and thus to visible light, but always remains in the IR range. At the same time, the spectral radiation flux density and thus the radiation maximum increases with the fourth power of the temperature. The brightness of an incandescent lamp therefore depends to a disproportionately large extent on the temperature of the filament, with the level of the operating voltage being decisive.

In order to obtain the highest possible light yield , the radiation maximum must therefore be shifted as far as possible from the range of long-wave infrared radiation ( heat radiation ) into the range of visible light by increasing the temperature without coming too close to the melting temperature of tungsten. Because tungsten already sublimates beforehand , which reduces the service life of the incandescent lamp:

- The detached atoms condense on the cooler inner glass wall, blacken it and reduce the light output. This problem is largely eliminated in the halogen lamp.

- The filament gets thinner and hotter, accelerating its own destruction.

In some cases, attempts are made to reflect the infrared radiation component back onto the filament by means of a coating on the glass bulb ( dichroic mirror ), which reduces the power consumption at the same filament temperature (so-called IRC coating, see below for halogen light bulbs ).

The light output is about 12 lm / W at a filament temperature of about 2700 K. If the temperature is increased to 3400 K, the light yield increases to around 34 lm / W. However, the higher temperature leads to a greatly shortened service life. The luminous efficacy of typical general service incandescent lamps is given as 10–20 lm / W.

| power | Luminous flux (at 230 V) |

Light output |

base |

|---|---|---|---|

| 25 W | 230 lm | 9.2 lm / W | E27 |

| 40 W | 430 lm | 10.8 lm / W | |

| 60 W | 730 lm | 12.2 lm / W | |

| 100 W | 1380 lm | 13.8 lm / W | |

| 150 W | 2220 lm | 14.8 lm / W | |

| 200 W | 3150 lm | 15.8 lm / W | |

| 300 W | 5000 lm | 16.7 lm / W | E40 |

| 500 W | 8400 lm | 16.8 lm / W | |

| 1000 W | 18800 lm | 18.8 lm / W |

The maximum temperature is limited by the properties of the filament material. In order to enable the highest possible temperatures, the refractory metal tungsten ( melting temperature 3422 ° C) is used today for filaments , previously also osmium or carbon . However, none of these substances can achieve the color temperature of around 6200 K , which is desirable for light similar to daylight , since tungsten is even gaseous at this temperature ( boiling temperature 5660 ° C). Even if it were successful, the light yield would be a maximum of 95 lm / W (at approx. 6600 K) due to the broad emitted wavelength band.

Light spectrum and color temperature

Incandescent lamps with color temperatures of around 2300–2900 K emit a light that is significantly more yellow-red than natural daylight. Depending on the sunshine, daylight is 5000–7000 K. Other light sources with this typical color temperature of incandescent lamps ( energy-saving lamps , fluorescent lamps and LED lamps ) are offered as " warm tones ". In contrast to incandescent lamps, fluorescent lamps do not produce a continuous light spectrum, which is why the color rendering index is often poor.

The filament temperature does not correspond to the color temperature of the emitted light, since tungsten is not an ideal black body ; The color temperature is around 60–80 K higher than the filament temperature (in the temperature range of conventional incandescent lamps). The reason is the wavelength-dependent emissivity of the metallic tungsten, which increases somewhat as the wavelength decreases.

In order to achieve a higher color temperature for projection and stage lighting purposes as well as for photo work, appropriate incandescent lamps are operated with very high filament temperatures, which allow color temperatures of 3400 K. The service life drops accordingly to a few hours in some cases. Often, heat protection filters are also used, which further increase the color temperature. Compare also cold light mirror lamp .

On the other hand, incandescent lamps are often operated (dimmed) with undervoltage in order to create atmospheric light, similar to that of candles (approx. 1600 K) or fire.

Luminance

The luminance of the filament of an incandescent lamp is 5-36 M cd / m 2 . Even if this value is exceeded by other artificial light sources (e.g. high pressure gas discharge lamps , carbon arc lamps , LEDs ), incandescent lamps are therefore well suited for applications in which the light has to be bundled, such as projectors and headlights .

The effective luminance can be further increased by the design of the filament ( double helix , flat helix). In general, thick filaments (for low operating voltages) have higher effective luminance than thin filaments.

Light modulation

Due to the thermal inertia of the filament, even incandescent lamps operated with mains or low-frequency AC voltage show only slight fluctuations in brightness. The brightness modulation with twice the operating frequency is stronger, the thinner the filament is. It is therefore particularly pronounced for lamps with low power for mains voltage and is around 30% with a 15 W and 230 V incandescent lamp.

Low-voltage incandescent lamps in particular are considered to be flicker-free due to their thick, thermally inert filaments - an advantage when illuminating rotating machines. Incandescent lamps with a very thin filament for operating currents of less than 0.1 A can be modulated with frequencies of up to a few 100 Hz and were previously used in handicraft projects for optical voice transmission.

use

Possible uses

One advantage of the incandescent lamp is that it can be dimmed continuously . Many energy-saving lamps (especially compact fluorescent lamps , some LED lamps) cannot be dimmed; some are gradually dimmable; However, continuously dimmable energy-saving lamps are significantly more expensive. The disadvantage is the sharp decrease in the light output when dimming an incandescent lamp.

Another advantage is the immediate full brightness, both at low and high temperatures. In contrast, the brightness of most energy-saving lamps is temperature-dependent; compact fluorescent lamps only achieve their full brightness with a delay. LED lamps in particular do not tolerate high ambient temperatures.

Incandescent lamps work with any frequency (up to> 100 MHz) and also with direct current ( emergency power systems , automobiles).

Incandescent lamps are still used except for lighting:

- Near-infrared or heat emitters (e.g. for drying paints, keeping animals, in the fixing roller of laser printers and Xerox copiers , in thermal copiers )

- Signalization (traffic lights, continuity tester, etc.)

- PTC thermistor (overload protection, amplitude control)

- Radiation source in spectrometers

lifespan

The service life of an incandescent lamp decreases drastically as the luminous efficacy increases, due to the higher filament temperature. At 2700 K conventional incandescent lamps achieve a service life of around 1000 hours, at 3400 K (studio lamps) only a few hours. As the diagram shows, the brightness doubles when the operating voltage is increased by 20%. At the same time, the service life is reduced by 95%. Halving the operating voltage (for example by connecting two incandescent lamps of the same type in series) reduces the light output, but extends the service life by more than a thousand times.

If the costs for replacing a lamp are high (replacement, installation), a high luminous efficiency can be dispensed with in favor of a longer service life and the operating voltage can be reduced. Signal lamps are usually difficult to change or should fail as rarely as possible. Here incandescent lamps are often operated with a low light yield.

The service life of an incandescent lamp does not end when the filament material evaporates evenly, but when it burns through at one point. The reason is instability, which is related to the increase in electrical resistance with temperature: parts of the filament that are only slightly thinner and initially only heat up faster when switched on due to the higher current density, then also have a higher resistance due to their excess temperature, heat up extremely briefly and lose some material through evaporation. The next time the device is switched on, the problem worsens. When the device was switched on for the last time, an arc discharge in the filling gas can even start from the interruption point, which spreads to the connecting wires and has a high power consumption.

In order to prevent the glass bulb from bursting due to such or otherwise igniting arc discharges, some 230 volt incandescent lamps have a fuse in the base. It has the shape of a thin glass tube. High-voltage halogen lamps have an additional protective glass bulb or may only be operated with a cover.

One way to extend the life, therefore the limitation of the inrush current or the frequently used technique in the event preheating (engl. Pre Heat ) by a permanent current flow just below the luminous threshold.

The failure probability of incandescent lamps can be described by an exponential distribution or, with consideration of the history, by a Weibull distribution .

Compromise between service life and light output

The dimensioning of incandescent lamps for a given operating voltage is a compromise between service life and luminous efficacy and, according to the manufacturer, results from the intended application in addition to the technological capabilities of the various manufacturers.

By filling with the expensive noble gas krypton, the evaporation rate is reduced and in the case of the more sophisticated halogen incandescent lamps, a certain return transport of the evaporated tungsten is achieved. However, the temperature and the thickness of the filament have a decisive influence.

A standard 60 W general service incandescent lamp for 230 V with a lifespan of 1000 hours generates e.g. B. a luminous flux of 710 lm , i.e. 11.8 lm / W.

A 60 W incandescent lamp for signal applications with a service life of 8000 hours generates 420 lm (7 lm / W); one with a service life of 14,000 hours 380 lm (6 lm / W)

Low-voltage incandescent lamps do better in terms of service life and efficiency. Signal lamps (“Sig”), for example for light signals with the BA 20 d bayonet socket and operating voltages between 12 and 50 V, achieve z. B. a luminous efficacy around 13 lm / W and have an average service life of 8,000 ... 12,000 hours.

The usual service life of incandescent lamps differs considerably. In the EU, for example, lamps for 230 V have a life expectancy of 1000 hours. In the USA (mains voltage 120 V) lamps with an expected service life of up to 20,000 hours are also offered. The luminous efficiency of such a 60 watt incandescent lamp is only 9.6 lm / W.

Halogen bulbs are offered with a life expectancy of approx. 50–6,000 hours and for traffic lights with up to 15,000 hours. The light yield is correspondingly wide.

With the same output, incandescent lamps for a lower nominal voltage have a thicker filament and thus a longer service life. Conversely, a higher luminous efficiency can be achieved with low-voltage incandescent lamps with the same service life. The service life actually achieved, however, depends significantly on the usage parameters:

- Exact compliance with the nominal voltage (the possible network plus tolerance of 15% shortens the service life to less than a fifth)

- Vibrations during operation

- Ambient temperature

- Frequent switching on and off: preferably a part of the filament that has already become thin is destroyed when it is switched on due to its lower heat capacity. Due to the low resistance of the remaining, still cold filament ( PTC thermistor effect ), a particularly high current flows at first.

For applications in which replacement is time-consuming or high reliability is required, there are incandescent lamps that achieve a long service life combined with a similarly low luminous efficacy as early incandescent lamps: So-called Sig lamps achieve an average life of 14,000 h (high-voltage krypton lamps) .

On the other hand, due to the high filament temperatures (high efficiency and luminance), the service life of projector bulbs is often only 50 to a few 100 hours. Projector halogen lamps for 24 V / 250 W achieve a luminous flux of 10,000 lm (40 lm / W) with a service life of 50 hours. For taking photos and exposing photographic material, conventional, frosted special incandescent lamps with large bulbs (e.g. OSRAM Nitraphot S), which achieve a color temperature of 3400 K, which is very high for incandescent lamps. These lamps have a luminous flux of 7500 lm at 250 W, i.e. up to five times the luminous efficacy of a general-purpose incandescent lamp with a comparable output and nominal voltage, as well as double that of a halogen incandescent lamp with a service life of 2000 hours. This is paid for by a very short lifespan of just a few hours.

Motor vehicle light bulbs, on the other hand, are designed for the 14 or 28 V of the vehicle electrical system instead of their nominal voltage of 12 or 24 V. In contrast, the operating voltage of low -voltage halogen systems for halogen lamps with a nominal voltage of 12 V is often only 11.5 V.

In the documentary Buy for the Garbage Dump by Cosima Dannoritzer, the average lifespan of 1000 hours for incandescent lamps is attributed to agreements made by the global Phoebus cartel from the 1920s, under the leadership of General Electric at the time . The limit is regularly cited as an example of planned obsolescence . The cartel was officially dissolved in 1941; In 1953 the operators were legally convicted and, among other things, prohibited from reducing the service life of incandescent lamps. The usual service life of general service lamps is still 1000 h.

Examples of longer life

The Centennial Light (English centennial light ) lights since 1901 almost continuously in the fire station of Livermore in the State of California . However, it is said of this 60 watt carbon filament lamp that it “currently shines with 4 watts” .

In 1928, construction workers in a Glasgow theater found a forgotten room behind a walled-up door that contained a burning lightbulb and a calendar from 1906; so the lamp was likely to burn continuously for 22 years. Under the pseudonym Michael Gesell, Otto Ernst Hesse wrote about it in the Vossische Zeitung on June 7, 1928 :

“The consumption demand of this magic lamp does not seem to have increased particularly in these years. Otherwise - according to the theories of electrical engineers - the theater would certainly have gone bankrupt by now because of excessive electricity bills. "

Light bulb types in comparison

| Manufacturer | Type name |

technology | Operating voltage |

performance recording |

Luminous flux |

Market launch |

base | living life |

|---|---|---|---|---|---|---|---|---|

| Shelby Electrics Company |

Centennial Light |

Carbon filament lamp | 110-120V |

60 W ( 4 W now ) |

circa 1890 | 1,034,000 h (118 years) |

||

| Osram | CLAS A FR 60 | Tungsten filament lamp | 230 V | 60 W | 710 lm | E27 | ||

| Osram | 64440 | Low voltage halogen lamp | 12 V | 50 W | 910 lm | GY6.35 | 2,000 h | |

| AEG | EVZ-066 | Nernst lamp | 95 V | 47.5 W | 1900 | E27 | 700 h | |

| Osram | SIG 1541LL SIG 1543LL SIG 1546LL |

High- voltage krypton lamp | 235 V |

60 W 75 W 100 W. |

380 lm 540 lm 780 lm |

E27 | 14,000 h |

Special forms

Halogen lamps (tungsten-halogen cycle process)

By using a compact quartz glass bulb and adding the halogen iodine (formerly also bromine ), incandescent lamps can be constructed that have a service life of 2000 to 5000 h even at elevated operating temperatures of 2800 to 3100 K. These so-called halogen incandescent lamps have a whiter light and luminous efficacy of 10–19.5 lm / W (conventional incandescent lamp 12–15 lm / W, energy-saving lamp 40–60 lm / W, current LED lamps up to over 100 lm / W).

Special photo halogen lamps with up to 35 lm / W have higher values - but with 1–2 kW power consumption and a few hours of operation.

The iodine reacts (together with residual oxygen) with the tungsten atoms evaporated from the glow wire and stabilizes an atmosphere containing tungsten. The process is reversible: at high temperatures the compound breaks down again into its elements - tungsten atoms are deposited on the filament. Small temperature differences along the filament only play a subordinate role in the decomposition. The idea that tungsten is deposited only on the thin, overheated areas of the filament is wrong. In reality, however, the condensation of tungsten atoms takes place at the coldest parts of the filament - whiskers are formed . The principle is chemical transport , which is also found in a similar way in the Van-Arkel-de-Boer process .

The addition of halogen also prevents tungsten from precipitating on the glass bulb at a glass temperature of more than 250 ° C; Because the bulb is not blackened as a result, the glass bulb of a halogen lamp can be made very compact. The small volume also enables a higher operating pressure, which in turn reduces the evaporation rate of the glow wire. All of this results in the life-prolonging effect of halogen lamps. When the halogen lamp is dimmed, however, the halogen process is reduced because the temperature required for this is no longer reached, which can then lead to blackening of the glass bulb. However, the blackening can be reversed by briefly operating at full power.

The small volume enables the filling with heavy noble gases to reduce the heat conduction at a reasonable cost.

Impurities on the bulb (e.g. by touching it) can lead to clouding of the quartz glass, as remaining salts contribute to devitrification as crystallization nuclei and thus cause damage. Therefore, a halogen lamp should ideally not be touched with bare fingers or cleaned afterwards. The widespread assumption that fats from the skin burn into the glass, however, does not apply.

The high inner wall temperature of the glass bulb required for the halogen process is achieved by the small distance between the bulb and the filament - i.e. a much smaller design compared to normal incandescent lamps of the same heat output - and makes the use of silica glass ( quartz glass ) necessary. Greater wall thicknesses of around 1 mm are typical in order to offer compressive strength against gas expansion at high temperatures. As a precaution, rod-shaped halogen rods are usually operated behind protective glass, which is intended to intercept the splinters of a bursting piston. Reflectors made of pressed glass with a glued-on flat plate or blown glass can be installed around the inner bulb. Just like non-reflective over-bulbs, they all lower the surface temperature of the lamp outside and protect against fire and burning of the hand. Gas-tight current feedthroughs are implemented with the quartz glass bulbs of halogen incandescent lamps and also with quartz glass burners of gas discharge lamps by means of molybdenum foil strips.

IRC halogen incandescent lamps (IRC stands for infrared reflective coating ) have a special coating on the glass bulb that allows light to pass through but reflects the heat radiation onto the filament, a so-called heat mirror . This reduces heat loss and consequently increases the light yield. According to the manufacturer, the energy consumption, together with the use of xenon as a filling gas component, can be reduced by up to 30% compared to standard halogen lamps, but this relates to inefficient standard comparison lamps, in real terms it is around 20%. The luminous efficacy of the 12 V / 65 W Osram 64445, for example, is 26 lm / W.

Halogen lamps for 230 V in the standard design with E27 base save approx. 20% energy with this IRC technology compared to normal incandescent lamps (for example 42 W instead of 60 W, 30% power saving with about 10% less brightness) and can replace them everywhere. These lamps do not achieve the efficiency of compact fluorescent lamps and even less that of LED lamps , but by achieving energy efficiency class C they were able to replace the classic incandescent lamp after the first stage of Regulation (EC) No. 244/2009 of the European Commission of March 18, 2009 based on Directive 2005/32 / EC (Eco-Design Directive) of the European Parliament . Like conventional incandescent lamps, halogen lamps can be disposed of in the residual waste after use and achieve an equally good color rendering index .

Shockproof light bulbs

For special applications, the lighting industry produces special lamps with the same design as the general-purpose incandescent lamp with an E27 base. Impact-resistant lamps have a specially reinforced filament construction and are designed for any burning position and for a longer service life (typically 2000 hours). The impact resistance of products from well-known manufacturers is checked by independent testing institutes. The typical areas of application of such special lamps are applications with harsh operating conditions, such as in industry, shipping, mining or work lighting in maintenance areas and automotive workshops. Impact-resistant lamps are identified by the abbreviation "sp" (for the embodiment) in the lamp designation.

Due to their construction, these special lamps are less efficient than conventional incandescent lamps and are also more expensive; as “special lamps”, however, they are not affected by the EU lamp regulation. In view of the last stage of the so-called incandescent lamp ban (September 1, 2012 for the 25 W and 40 W types), they were recommended by dealers and on internet platforms as an alternative to buyers who reject compact fluorescent tubes , while industry stakeholders ( ZVEI- Fachverband ) advise against it.

Other variants

In addition to special bulb shapes, the material used (e.g. matt or made of opal glass ) and the selected colors, there are the following special shapes:

- Bilux lamps: They are used in vehicle headlights and have a free ( high beam ) and a filament with a cover ( low beam ) with a similar power consumption.

- Incandescent lamps with two filaments of different power (two-filament lamps, for example as a combination tail light / brake light or with main and replacement filament .)

- Incandescent lamps with internal reflector

- Projection lamps with filaments in the focal point of an interior mirror

- So-called dome mirror lamps or head mirror lamps (KSL) with incandescent filaments in the center of a reflective hemispherical shell

- Tungsten ribbon lamps: They have a ribbon instead of a filament; Use as radiation standard or in older pyrometers (visual comparison of luminance and color temperature with that of the measuring object)

- High-temperature radiant heater : Incandescent filament with a relatively low operating temperature, arranged in an often partially mirrored glass bulb, which primarily allows the infrared component to pass in the direction of radiation ( red light )

- Incandescent lamps for heating purposes: for example, rod-shaped halogen incandescent lamps in the fixing roller of Xerox copiers and laser printers

- Rod-shaped halogen incandescent lamps of around 70 to 300 (often 118) mm in length with terminal, trough-shaped connection contacts (cemented in a ceramic sleeve ("halogen rod")) with outputs of around 100–2000 W: an elongated single or double coil is located with spacers (made of wire or glass indentations) in a quartz glass tube, use in spotlights on construction sites or in ceiling washlights.

- Cold light mirror lamps : They have an external dichroic reflector that only reflects visible light, but allows infrared to pass through (application: low-voltage and high-voltage halogen lamps, projection lamps).

- Line lamps are in principle large festoon lamps for mains voltage made of elongated glass tubes, usually opaque, with a filament over the entire length. Line lamps are typically only 30-60 cm short and have bases protruding radially from the tube axis, either a two-pole in the middle or two single-pole near the tube ends, the contacts are slightly dome-shaped. ( Fluorescent tubes , on the other hand, are up to 150 cm long, have the axial contact, at each of the ends usually by a pair of pins that protrude axially from the sockets and can thus be easily distinguished.)

Flashing light bulbs sometimes have a bimetal switch arranged in series with the filament . This version can be found, for example, in older warning lamps or glow sticks for St. Martin's Day . This switch is closed when it is cold. As a result of the thermal action of the filament and the thermal capacity of the bimetal , the switching element bends and opens a contact point. The current flow is interrupted and the light bulb goes out. After sufficient cooling, the contact closes again, the filament lights up again and thus heats the switching element again, the process starts all over again, the lamp flashes.

Environmental aspects and prohibitions

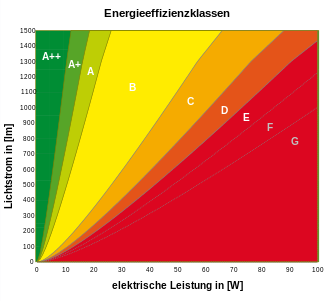

Energy efficiency classes of incandescent lamps

Household lamps are classified in energy efficiency classes in the European Union , with a scale ranging from A (very efficient) to G (less efficient). “Efficiency” is only understood to mean the luminous efficiency, a possible heating benefit is not taken into account. Conventional incandescent lamps achieve efficiency classes D, E, F and G. Low-voltage halogen lamps that are typically operated with 12 V are often in efficiency classes C, D and E, but do not have to be officially divided into efficiency classes. High-voltage halogen lamps that are operated directly with 230 V now also achieve efficiency class C and are therefore suitable as a replacement for conventional incandescent lamps in addition to energy-saving lamps after 2012. Measurements by Stiftung Warentest , however, showed that halogen lamps often do not achieve the declared energy efficiency classes.

Since around 2005, the manufacture and sale of incandescent lamps with low luminous efficacy have been banned in some countries, or such bans are planned to save energy. Incandescent lamps must be replaced by energy-saving lamps with better light output.

In practice, the energy consumption and luminous efficacy of the light sources inevitably deviate from the nominal values. The EU regulation 244/2009 tolerates average manufacturing tolerances of up to 10% in spot checks by the market surveillance authorities. There have been reports that some manufacturers are deliberately exhausting these allowable tolerances.

Regulations and developments by region

Australia

Australia became the first country to announce in February 2007 that it would ban conventional incandescent lamps from 2010. The government expects that this measure will reduce the emission of four million tons of greenhouse gases into the air each year.

European Union

In December 2008, the EU Commission announced that, on the basis of the Ecodesign Directive 2005/32 / EC, production and sales bans for lamps with low energy efficiency were being implemented in the member states. The sale of incandescent lamps that have already been placed on the market remains permitted. In mid-April 2009 the corresponding regulation (EC) No. 244/2009 came into force. In 2010 and again in 2014, mechanical engineer Siegfried Rotthäuser and his brother-in-law Rudolf Hannot sold incandescent lamps over the Internet as part of a satirical project called Heatballs . With the small heating elements they successfully tried to evade the ban on incandescent lamps. The requirements were previously discussed again due to extensive criticism; the Environment Committee of the EU Parliament decided on February 17, 2009 with 44:14 votes to adhere to it. Ireland was the first EU country to plan to ban the sale of low-energy light bulbs from January 2009.

Affected products that are already on the market may still be sold and traded after the specified dates, but prohibited products may no longer be placed on the EU market and delivered to retailers or end users. The manufacture of light bulbs without meeting the standard for export to countries outside the EU is still permitted. The Customs should since September 2009 parcels check for banned bulbs.

Lamps with frosted glass must have energy efficiency class A since the first stage of the requirements (since September 2009) ; this meant a ban on the manufacture and sale of frosted light bulbs. Since frosted lamps are not a point source of light like clear lamps, the EU Commission believes that their function can be directly replaced by available energy-saving lamps.

For lamps with clear glass , i.e. point light sources, the following minimum requirements apply depending on their power consumption:

- Since September 2009: from 100 W efficiency class C; less than 100 W efficiency class E.

- Since September 2010: from 75 W efficiency class C; less than 75 W efficiency class E.

- Since September 2011: from 60 W efficiency class C; less than 60 W efficiency class E.

- Since September 2012: efficiency class C for everyone

- Since September 2018: efficiency class B for everyone; Exception: efficiency class C for halogen lamps with G9 and R7S bases, for which there is currently no suitable replacement. (The deadline has been extended from 2016 to 2018 in accordance with the amending regulation (EU) 2015/1428.)

Conventional incandescent lamps are currently available in efficiency classes D, E and F; Halogen lamps (230 V) partially achieve efficiency class C. Low-voltage halogen lamps are not divided into energy efficiency classes. In addition to the requirements for energy efficiency, stricter quality requirements for other operating properties apply from the first stage, such as service life, decrease in luminous flux, switching resistance, start-up time (up to 60% of luminous flux is reached) and requirements for product information on packaging and catalogs .

The consumer center in Hamburg has put together questions and answers on the "light bulb exit". The European Commission has also published a guide and summary.

Special lamps, for example for use in motor vehicles, in bicycle lighting, in refrigerators, ovens or medicine, are not affected by the prohibitions; also lamps of particularly small and large output (luminous flux below 60 lm or over 12,000 lm).

Regulation (EU) No. 2012/1194 applies to reflector lamps that emit a bundled light beam. The following minimum requirements apply to incandescent lamps with bundled light and LED lamps:

- Since September 2013: efficiency class B, C or D (depending on voltage and luminous flux). LED lamps in the upper range of efficiency class B.

- Since September 2014: efficiency class B or D (depending on voltage). LED lamps in the upper range of efficiency class B.

- Since September 2016: efficiency class B. LED lamps in the upper range of efficiency class A.

For fluorescent lamps and high pressure discharge lamps , Regulation (EC) no. 245/2009.

New Zealand

In New Zealand , low energy efficiency incandescent lamps should be banned from October 2009. These plans have since been abandoned and are to be replaced by more efficient savings options.

Cuba

On November 17, 2005, Fidel Castro asked the Cubans to replace conventional incandescent lamps with energy-saving lamps. The background is the energy shortage in Cuba .

Switzerland

In Switzerland, the sale of incandescent lamps that do not meet at least energy efficiency class E has been banned since 2009.

United States of America

In the USA, the Energy Independence and Security Act passed in 2007 decided to gradually tighten the regulations on the energy efficiency of incandescent lamps between 2012 and 2014. Apart from the exceptions that have been agreed, for example for colored light bulbs, this law bans conventional light bulbs. The last major conventional incandescent lamp factory in the United States closed in September 2010.

People's Republic of China

In November 2011 it became known that light bulbs would also be banned in China in the medium term. According to this, the sale of incandescent lamps with over 100 W will be banned from October 2012, until 2016 the output of the permitted incandescent lamps will be gradually reduced, so that from October 2016 only lamps with less than 15 W output will be permitted. The incandescent lamps are to be replaced by LED technology. This should save 48 TWh of energy per year.

Criticism of bans

The bans on incandescent lamps met with criticism from the population and industry. Among other things, it was criticized that replacements for incandescent lamps such as LEDs or energy-saving lamps are more expensive to buy; however, the life cycle costs over the entire period of use are lower. In the case of fluorescent lamps , improper disposal or breakage can also lead to mercury emissions , whereas LEDs are mercury-free.

In addition, in the opinion of some critics, bans on incandescent lamps are not suitable for saving CO 2 , since only emissions trading ultimately costs carbon dioxide emissions . The amount of energy saved by the ban on incandescent lamps can therefore be sold elsewhere without having to purchase additional emission certificates. Alternatively, the certificates that are not required can be sold by the energy producers to other industries. The effect of a ban on incandescent lamps on CO 2 emissions is therefore only indirectly effective. A more sensible control instrument for achieving the controversial climate targets is therefore the direct limitation of the amount of carbon dioxide emissions.

future

Further development

Processes currently used or investigated to increase the light output of the incandescent lamp include the halogen process and the like. a. the following:

- selective increase of the emissivity of the filament in the visible spectral range by means of photonic crystal structures

- selective back reflection of undesired spectral components on the filament by means of photonic crystal structures or with interference mirrors

- Use of filling gases with a high atomic mass, resulting in lower heat transport and reduced evaporation rate of the tungsten

So far, only the infrared reflective coating of the glass bulb and the filling with krypton or xenon are practical.

Alternatives to the incandescent lamp

Electric light sources

Light sources with better efficiencies or a higher luminous efficacy are, for example, gas discharge lamps ( fluorescent lamps , mercury vapor lamps , sodium vapor lamps , metal halide lamps ). Although these also often have Edison bases, they require ballasts for operation and can therefore not be used directly in exchange for incandescent lamps. Compact fluorescent lamps with (electronic) ballasts integrated in the base are a direct replacement for (household) incandescent lamps .

Light sources with high luminous efficacy based on light-emitting diodes (LED lamps) are already available for most areas of application . They are maintenance-free, have a long service life and are low in energy consumption. White LED lamps have with 61 to 140 lm / W higher by a multiple efficiency than incandescent lamps with about 10 to 22 lm / W .

When using LEDs instead of incandescent lamps, bicycle lighting has the advantage of higher luminous flux with the same electrical output. The service life and reliability are higher. The luminous flux does not fall as steeply as with incandescent lamps when the vehicle is powered from a dynamo at lower driving speeds. The same applies to battery-powered lights, including those integrated into cell phones.

Non-electric light sources

Non-electric light sources are only an alternative to incandescent lamps if no power connection is available. Light sources with a short lifespan and brightness, but without an external energy source, are the so-called glow sticks , which are based on chemiluminescence . Tritium gas light sources have a service life of a few years and, like the glow sticks, also do not require an external energy source. They are mainly used as emergency lighting and, like fluorescent lamps, are based on fluorescence , but stimulated by the beta radiation of radioactive tritium . Due to their low light output, they are only suitable as a guide in the dark; so z. B. clockwise or pistol sights .

Gas lanterns are primarily of historical importance, although their energy efficiency is comparable to long-life incandescent lamps. As with camping gas lights , the burning of gas is used as an energy source, another example are the high-intensity lamps operated with kerosene or kerosene vapor . Compared to petroleum lamps, these achieve a significantly higher luminosity thanks to a mantle .

The light bulb in art, literature and monument design

The approximately 40 meter high Edison Tower with an oversized stylized light bulb (approximately 4.5 meters high) was built in 1937 in honor of Thomas Alva Edison in Menlo Park, today Edison (New Jersey) .

1954 built obelisk with a light bulb symbol on the Göbel Bastion on the Ebersberg above Springe in honor of Heinrich Göbel , who was believed to be the inventor of the light bulb in Germany in the 20th century.

- In his monumental painting Guernica, Pablo Picasso designed an incandescent lamp in place of the sun. It probably points to the bombs dropped by airplanes, which is also indicated by the word play "la bombilla / la bomba" ( bombilla "light bulb") , which is evident in Spanish .

- Ingo Maurer created an oversized incandescent lamp made of glass with an ordinary incandescent lamp inside called Bulb for the Museum of Modern Art in New York.

- In his multiple called Capri-Batterie, Joseph Beuys shows a yellow light bulb and its power supply from a lemon.

- Lewis Latimer , a son of American slaves and later the only African American on Thomas Alva Edison's close staff, wrote poetry and wrote about the incandescent lamp, “ Like the light of the sun, it beautifies all things on which it shines, and is no less welcome in the palace than in the humblest home. "(German:" Like the light of the sun, it makes all the things it shines on more beautiful, and is no less welcome in palaces than in the most modest house. ")

- In his novel Die Blechtrommel, Günter Grass has the main character Oskar Matzerath say the following sentence about his birth: "I saw the light of day in the shape of two sixty-watt incandescent lamps."

- Pink Floyd : Cover and poster for Delicate Sound of Thunder

- The cartoon character Daniel Düsentrieb has a partner for his inventions in his little helper , a robot he created himself in the form of a lightbulb with legs.

- Wolf Vostell stuck light bulbs on many of his canvases and assemblages. He also used them at happenings .

- James Rosenquist painted the F-111 bomber spread over four huge partial pictures combined with other subjects such as spaghetti with tomato sauce, a hairdryer, lightbulbs and a mushroom cloud. The painting is about three meters high and 26 meters wide.

- In 2004, Stefan Klein and Olaf Neumann designed a stamp on behalf of the Federal Ministry of Finance for the then believed 150th anniversary of the invention of the light bulb.

literature

- Dieter Frank: From the incandescent lamp to the light throw lamp. An evolutionary story . In: The Fourth Wall. Organ of the TheaterMuseum Berlin initiative . Edition 009. Berlin 2019, pp. 164–175 ( Online in the Internet Archive )

- Roland Heinz, Andreas Schulz (foreword): Basis of light generation. From the light bulb to the laser. 3. Edition. Highlight, Rüthen 2008, ISBN 978-3-937873-01-5 .

- Andreas Holzinger: From wax candles to light bulbs. (= German paperbacks. Volume 95). Harri Deutsch, Thun / Frankfurt am Main 1998, ISBN 3-8171-1566-0 .

- Noe Lazar Müller: The manufacture and properties of metal wire lamps . Knapp, hall a. S. 1914. ( Digitized in the Internet Archive )

- Hans Christian Rohde: The Göbel legend. The struggle for the invention of the light bulb . To Klampen, Springe 2007, ISBN 978-3-86674-006-8 . (At the same time dissertation at the University of Hanover 2006)

- Hans-Jürgen Wulf, BAG Turgi Electronics (ed.): The history of electric light bulb lighting . Marbach & Marbach, Eich, Lucerne 1998, DNB 958095167 .

Web links

- Comparison table for all common light sources

- Helmut Höge: This is the temporary caretaker speaking! taz.de about planned wear and tear on incandescent lamps

- Critical report on the EU ban on spiegel.de

- Selection tables

- Bye bye lightbulb! Farewell to the discontinued model

- Cozy warm light in the freezing cold winter , “Wiener Zeitung” from November 17, 2011, supplement “ProgrammPunkte”, p. 7, accessed on January 7, 2012

Individual evidence

- ↑ Classic Eco Superstar A. ( Memento from August 14, 2012 in the Internet Archive ) accessed on July 3, 2014.

- ↑ a b Lighting Basics. In: Energy.gov. Office of Energy Efficiency & Renewable Energy, accessed January 30, 2016 .

- ^ Incandescent lamp (encyclopedia entry). In: Pierer's Universal Lexicon of the Past and Present. 4th edition, publishing house by HA Pierer , Altenburg 1857–1865. 1865, Retrieved July 3, 2018 .

- ^ E. Covington: A lamp of unknown origin. ( Memento from February 11, 2007 in the Internet Archive ) In: frognet.net. Retrieved February 27, 2007.

- ↑ Groves Lamp of 1840 ( Memento October 22, 2010 in the Internet Archive ), accessed October 31, 2010.

- ↑ https://www.planet-wissen.de/technik/energie/electrizitaet/pwiethomasalvaedison100.html

- ↑ United States Patent and Trademark Office

- ↑ The incandescent lamp comes to Germany. In: ard.de. Retrieved August 9, 2011.

- ↑ Hans-Christian Rohde: The Göbel legend - the struggle for the invention of the light bulb . To Klampen, Springe 2007, ISBN 978-3-86674-006-8 .

- ^ The History of Electric Lighting. (English) , accessed October 28, 2010.

- ↑ Christoph Drösser ( Isn't it? ): The eternal light. In: The time . No. 33/1999.

- ↑ Patent application DE2921864A1 : Device for increasing the service life of lamps, especially incandescent lamps. Released on November 27, 1980 ( Triac ballast for voltage reduction).

- ↑ Patent application DE3001755A1 : Process for extending the service life of general service light bulbs . Published July 23, 1981 .

- ↑ Patent application DE3213333A1 : Use of general service incandescent lamps and processes to extend their service life. Registered on April 7, 1982 , published on December 23, 1982 ( upstream connection of a diode for half-wave operation, pulse switching for direct current operation).

- ^ Nicola Armaroli , Vincenzo Balzani , Towards an electricity-powered world. In: Energy and Environmental Science . 4, (2011), pp. 3193-3222, p. 3213, doi: 10.1039 / c1ee01249e .

- ↑ Examples can be found in the technical report on IEC 1231 ( memo of February 22, 2012 in the Internet Archive ) of the ZVEI

- ↑ HALOGEN ECO technology from OSRAM for improved halogen lamps. ( Memento from November 6, 2013 in the Internet Archive ) In: osram.de.

- ↑ Comparison of lamps ( Memento of May 8, 2006 in the Internet Archive )

- ↑ Häberle, Häberle, Jöckel, Krall, Schiemann, Schmitt, Tkotz: Electrical engineering table book . 25th edition. Verlag Europa-Lehrmittel, Haan-Gruiten 2013, ISBN 3-8085-3227-0 , p. 190 .

- ^ Halogen low-voltage lamps ( Memento of January 18, 2012 in the Internet Archive ) (PDF; 2.6 MB), Osram

- ↑ Light sources - applications & light measurement. ( Memento from January 19, 2012 in the Internet Archive ) (PDF; 1.2 MB), Gigahertz-Optik (Ed.), 2008, p. 4.

- ↑ https://www.emsp.tu-berlin.de/fileadmin/fg232/Lehre/MixedSignal/Dateien/High_Speed_1/04_Oszillatoren_50_140_MHz.pdf

- ↑ https://www.amazona.de/workshop-praxistipps-fuer-die-klein-pa/3/ Protection of speakers

- ↑ Böhmer, E .; Ehrhardt, D .; Oberschelp, W .: Elements of Applied Electronics - Compendium for Training and Profession; Springer-Verlag 2010; 506 pages; Page 208: stabilization of RC oscillators

- ↑ http://www.gluehbirne.de/10-x-Osram-Gluehbirne-60W-E27-klar-Gluehlampe-60-Watt-Gluehbirnen-GluehlampenAllgebrauchsgl%C3%BChlampe (link not available)

- ↑ data sheet of the OSRAM SIG 154x LL (PDF; 127 kB)

- ↑ mercateo.at ( Memento from March 4, 2016 in the Internet Archive )

- ↑ mercateo.com ( Memento from March 4, 2016 in the Internet Archive )

- ↑ aerolights.com ( Memento from March 16, 2015 in the Internet Archive )

- ↑ osram.de

- ↑ http://www.lighting.philips.com/main/prof/conventional-lamps-and-tubes/special-lamps/optical-medical-equipment/halogen/halogen-non-reflector/924006520503_EU/product Philips type 7748XHP 250Watt , accessed Jan. 4, 2018

- ↑ gluehbirne.de ( Memento from April 23, 2015 in the Internet Archive )

- ↑ kaufonline.net ( Memento from August 27, 2012 in the Internet Archive )

- ^ Documentary by Cosima Dannoritzer , Buy for the garbage dump , 75 minutes, 2010. (online)

- ↑ Webcam: Livermore's Centennial Light Live Cam

- ^ Livermore's Centennial Light Facts

- ^ "Bagatelles - The Magic Lamp" In: Vossische Zeitung, No. 265 of June 7, 1928.

- ↑ ( Page no longer available , search in web archives: Osram HALOSTAR ST 50 W 12 V GY6.35 )

- ↑ ( page no longer available , search in web archives: Osram high-voltage krypton lamps )

- ↑ Basic Physics of the Incandescent Lamp (PDF; 275 kB) accessed on October 20, 2009.

- ^ Chemistry in incandescent lamps ( Memento from June 22, 2012 in the Internet Archive ), last accessed on October 2, 2012.

- ↑ Background knowledge on the technology of lighting systems

- ↑ Robert Meinke: Right? Sensitive glass. In: The time . April 3, 2003, archived from the original on September 2, 2003 ; accessed on July 29, 2020 : “When you touch the pears, it is not the fat that is on the skin that is harmful, but the sweat, more precisely the alkali compounds that it contains - including common table salt. These substances can literally burn themselves into the glass. The result is soiling that becomes noticeable as streaks and stains. ... The fact that the halogen lamps, which can reach temperatures of up to 600 degrees on the surface and have to withstand an internal pressure of around 20 bar, burst because of the contamination, is something Rademacher describes as an 'extreme case'. "

- ↑ Regulation (EC) No. 244/2009 . In: EUR-Lex .

- ↑ Directive 2005/32 / EG In: Official Journal of the European Union .

- ↑ Special lamps, impact-resistant normal lamps. (PDF) (No longer available online.) Philips, August 12, 2012, formerly in the original ; Retrieved August 22, 2012 . ( Page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice.

- ↑ LBS lamp designation system. (PDF) Uniform system for naming electrical lamps for general lighting. (No longer available online.) In: LBS_sum_2010-07-28. ZVEI: Light, archived from the original on November 21, 2011 ; Retrieved August 22, 2012 .

- ↑ Waldorf Jürgen: Do not unsettle consumers when it comes to lamps. Press release 94/2012. ZVEI, August 12, 2008, accessed on August 22, 2012 .

- ↑ OSRAM catalog 2009 http://catalogx.myosram.com/ Halogen Energy Saver Classic, lamp power <42 W - energy efficiency class C.

- ↑ Halogen lamp test by Stiftung Warentest , in: test, issue 2/2009 (accessed online: January 2, 2013)

- ↑ Regulation (EC) No. 244/2009 , accessed on August 24, 2019 . Annex III: Review Procedures for Market Surveillance . In: Official Journal of the European Union. L 76, p. 14.

- ↑ EU tolerates cheating with lamps. In: Süddeutsche Zeitung. (accessed online: December 17, 2015)

- ↑ In Australia the light bulb is banned ( Memento of September 27, 2007 in the Internet Archive ) . On: ÖKO-TEST Online . On: February 20, 2007 (news item)

- ^ Phasing out incandescent bulbs in the EU. (PDF; 468 kB) (No longer available online.) In: ec.europe.eu. Archived from the original on April 10, 2011 ; accessed on January 14, 2017 .

- ↑ Regulation (EC) No. 244/2009 […] environmentally friendly design of household lamps with unbundled light in the consolidated version of February 27, 2016 , accessed on May 20, 2009 . In: Official Journal of the European Union. L 76, pp. 3-16.

- ↑ The light bulb goes out . In the Süddeutsche Zeitung. February 18, 2009, p. 8.

- ^ Department of the Environment, Heritage and Local Government: Gormley Outlines Position on Plan to Introduce Minimum Energy Efficiency Standards for Light Bulbs. ( Memento of August 22, 2012 in the Internet Archive ) January 10, 2008.

- ↑ After the ban: Customs should intercept lightbulbs. In: Wirtschaftswoche . May 16, 2009. Retrieved January 14, 2017 .

- ↑ What you should know about phasing out incandescent lamps. Consumer advice center Hamburg, August 30, 2012, accessed on January 14, 2017 .

- ↑ Implementation Guideline. (PDF) European Commission, July 2015, accessed on January 1, 2018 .

- ↑ Deutschlandfunk : Broadcast Marktplatz, September 9, 2010, 10:00 am - 11:30 am

- ↑ Regulation (EU) No. 1194/2012 […] environmentally friendly design of lamps with bundled light, LED lamps and associated devices

- ↑ Regulation (EC) No. 245/2009 [...] environmentally friendly design of fluorescent lamps without built-in ballast, high pressure discharge lamps as well as ballasts and luminaires for their operation [...] in the consolidated version of February 27, 2016 , accessed on January 1, 2018 . In: Official Journal of the European Union.

- ↑ New Zealand Bans Conventional Light Bulbs , Welt.de, June 17, 2008, accessed December 8, 2008.

- ↑ National ditches light bulb phase-out , Stuff.co.nz, December 17, 2008, accessed August 26, 2009.

- ^ Edison's light bulb before going out , NZZ of March 17, 2008.

- ↑ United States Government Printing Office: Public Law 110-140 - Energy Independence and Security Act of 2007

- ^ Light bulb factory closes; End of era for US means more jobs overseas. In: Washington Post. Sept 8, 2010.

- ↑ Light-emitting diodes for the Middle Kingdom. Beijing bans the light bulb . In: ntv.de. November 5, 2011. Retrieved November 6, 2011.

- ↑ China unveils plans for incandescent lamp phase-out . In: ledsmagazine.com. September 5, 2011. Retrieved September 6, 2011.

- ↑ Bodo Sturm: The ban on incandescent lamps does not help . In the Süddeutsche Zeitung. 19./20. July 2008, p. 24.

- ↑ http://www.scinexx.de/wissen-aktuell-19717-2016-01-12.html

- ↑ https://www.osram.de/osram_de/presse/pressemachrichten/_fachpresse/2007/halogen-energy-saver_weltpremiere/index.jsp?search_result=%2fosram_de%2fsuche%2fadvanced_search.jsp%3faction%3ddosearch%26inp_searchxenon_1%3dd 2birc% 26website_name% 3dosram_de IRC process and xenon filling of halogen lamps

- ^ Thomas Edison and Menlo Park. Edison Memorial Tower Corporation, accessed September 16, 2018 .

- ^ Photo of the picture Guernica by Pablo Picasso , accessed on October 25, 2009.

- ^ Museum of Modern Art, Ingo Maurer Bulb , accessed on October 25, 2009.

- ^ Photo of a variant of the Capri battery by Joseph Beuys , accessed on October 25, 2009.

- ↑ Wolf Vostell. Life = art = life, Gera art gallery. EA Seemann, 1993, ISBN 3-363-00605-5 .

- ↑ Figures F-111

- ↑ First Day Cover "150 Years Incandescent Lamp 2004"