Elevator system

An elevator system , in short elevator , elevator or elevator , is a system with which people or loads can be transported in a movable cabin , an elevator car or on a platform in a vertical or inclined direction between two or more levels. Elevators - except the Paternoster lift - count in the conveyor system to the discontinuous conveyor systems.

The actual definition of an elevator is:

- Delivery height at least 180 cm

- partially guided elevator car

- at least two permanent access points.

Definition of terms

- The word lift also refers to systems to transport winter sports enthusiasts diagonally upwards, see ski lift , drag lift and chair lift .

- A passenger cage on a crane is not a lift because it does not meet the above requirements.

- Escalators (escalators) are differentiated from elevators in that they are not subject to elevator directives, but rather to their own European directive EN 115, safety of escalators and moving walks , and do not have an elevator car.

- Shaft conveyor systems are fundamentally similar to elevator systems; in terms of technology, they are considered to be a model for elevator systems and, like these, can be assigned to discontinuous conveyor systems. There are differences to elevator systems in the dimensioning and arrangement of the essential system elements. Shaft hoisting systems are not subject to elevator regulations but to mining regulations.

- Cable cars are a separate division of transport and are subject to the relevant cable car laws.

- Funiculars are a sub-form of cable cars and are sometimes referred to as inclined lifts because of the similarity of the guidance on an inclined plane and not always easy to distinguish .

- A lifting platform consists only of a platform or even just of lifting arms in order to raise or lower goods for further transport to another level or often to make a motor vehicle accessible from below for inspection or service.

- A load lifting device with a rope hoist running freely in front of the facade of a building is also called a lotter system .

- Tail lift

- Bath lift

history

Pre-industrial era

The earliest known reference to an elevator is found in the works of the Roman architect Vitruvius, who reported that Archimedes (c. 287 BC - circa 212 BC) made his first elevator probably 236 BC. BC built. Some sources from later historical periods mention elevators as cabins on a hemp rope, powered by hand or animals. In the year 1000, a book by al-Muradi describes the use of an elevator-like hoist to raise a large battering ram that was intended to destroy a fortress.

Louis XV 1743 had a so-called "flying chair" built for one of his mistresses in the Chateau de Versailles. In ancient and medieval elevators, drive systems based on hoists or anchor winches were used. The invention of a worm gear-based system was perhaps the most important step in elevator technology since ancient times that led to the creation of modern passenger elevators. The first worm drive elevator was built by Ivan Kulibin and installed in the Winter Palace in 1793, although there may have been an earlier design by Leonardo da Vinci. A few years later, another of Kulibin's elevators was installed in Arkhangelskoye near Moscow.

Industrial age

Elevator development has been guided by the need to move raw materials such as coal and lumber off slopes. The technology developed by these industries and the introduction of steel girder construction worked together to provide the passenger and freight elevators in use today. Starting from the coal mines, elevators were operated with steam power in the middle of the 19th century and were used to move bulk goods in mines and factories. These steam-powered devices were soon used for a variety of purposes - in 1823 two London architects, Burton and Hormer, built and operated a novel tourist attraction they called the "Ascension Room". It raised paying customers to a considerable height in central London and gave them wonderful panoramic views of the city center. Small goods lifts were used early on to transport goods from the kitchen to the dining rooms. Only later were passenger lifts built. Maria Theresa had the oldest passenger elevator in Central Europe installed in the Capuchin Crypt in 1766 .

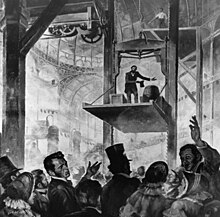

Decisive for the breakthrough was the invention of the fall-proof elevator in 1853 by the American and founder of the Otis Elevator Company , Elisha Graves Otis . During a demonstration in front of a large audience during the World's Fair in New York, Otis was in an elevator and had an assistant cut its only suspension cable. The elevator braked itself and the safety was thus impressively demonstrated. The safety system developed by Otis as early as 1852 was composed of a sawtooth ratchet and a steel spring. If the lifting cable breaks or the rope breaks, the spring loses its tension. The sawtooth ratchet is activated and the elevator is stopped. Prior to this invention, elevators were primarily used to move goods. They were considered too dangerous to transport people in apartment buildings. The first commercial elevator with the Otis security system was installed in a department store on 488 Broadway in New York City in 1857. With the now created possibility of using safe passenger elevators , the triumphant advance of the skyscrapers began , the upper floors of which could only be comfortably reached by elevators. Starting around 1891, the Leonardsatz (Ward-Leonard converter) by the US electrical engineer Harry Ward Leonard was used for speed control, especially in industrial elevator equipment. This type of motor control was only replaced with the introduction of the thyristor set, which was ready for industry.

Elevators did not gain acceptance in Europe until the 1870s, after a hydraulic elevator was presented for the first time at the World Exhibition in Paris in 1867 . In 1880 Werner von Siemens presented the first electric elevator in Mannheim . The inventor Alexander Miles developed a mechanism for automatically closing elevator doors in 1887 and filed a patent for his invention in the same year. The Otis Elevator Company supplied the first gearless elevators for the Beaver Building in New York and the Majestic Building in Chicago in 1903 .

As a result, the architectural design of large residential and office complexes changed. If more than four floors were previously considered to be downright hazardous to health, the elevator could now be used to build almost unlimited heights and the upper floors could still be comfortably reached. The value of the various levels was also reversed: “The elevator ended the era of the Bel Etage and established that of the penthouse ” (Andreas Bernard).

The previously widespread open lattice construction of the cabin in an also open shaft, mostly in the middle of a staircase surrounding it, is no longer built today for safety reasons, but such systems are still in operation outside of Germany in Europe, with the old open cabin possibly through a new closed one in the old shaft was replaced. In larger buildings such as ministries or companies, the elevator systems reserved for the management or for higher officials were mockingly and colloquially referred to as bigwigs .

The first elevator museum was founded in Mannheim-Seckenheim in 1986.

Types and shapes of elevators

Elevator systems can be subdivided depending on the design, type of system and intended use:

Types of construction according to purpose

Passenger elevator

The passenger elevator is mainly used to transport people. It is the most frequently used type of elevator. There are cable lifts but also hydraulic lifts. Whole rooms that can change floors are a special form. One of the first was Tomáš Baťa's office in the 1920s . It measured 6 mx 6 m and he could use it to drive to any of the 17 floors of the Bata company headquarters .

Freight elevator

A freight elevator is an elevator system for the priority transport of loads and, if necessary, accompanying persons. Use is only permitted for the operator of the elevator system and its employees.

For freight elevators, there were simplified designs in terms of construction, at the suggestion of the industry. Industrial buildings are often not freely accessible facilities with a fixed group of people who receive regular training. In the past, it was possible to do without the car doors . After many serious accidents, some of which were fatal, the freight elevators often had to be retrofitted with at least light curtains as safety. According to DIN EN 81, new freight elevators generally require car doors.

Freight elevator

According to the previous German Elevator Ordinance, a goods elevator is an elevator system that is intended exclusively for the transport of goods without being accompanied by people. Entering - except for loading and unloading - as well as driving along are prohibited. For this reason, the goods lifts may only be fetched and operated from outside. There must be no control panel in the cabin.

Special types of goods lifts are small goods lifts such as those used in office buildings for transporting files or as laboratory lifts, as well as dining and laundry lifts in villas or restaurants. Furniture lifts are often found in the streets, which are used to transport furniture when moving, preferably from higher floors.

Disabled lift

Elevators for the disabled with a travel height of up to three meters and a maximum speed of 0.15 meters per second are not covered by the EN81 elevator law. These elevators are "machines built into buildings". The safety is determined by the MD 2006/42. The requirements for the size of the platforms and usability are described in DIN 18040 (accessibility). For private individuals and private houses without renting, the recurring tests according to BetrSichV §§ v15 - 16 by a technical testing organization do not apply .

Car elevator

Car lifts are specially designed for the transportation of motor vehicles , especially passenger vehicles . In addition to the usual regulations, they are subject to special rules relating to the installation and operation of the systems. They are designed with a load capacity from 2000 kg.

In the Shanghai World Financial Center , a car elevator was installed to supply the exhibition hall on the 94th floor at a height of 423 meters with cars and other loads. It is designed for a load capacity of 3 tons and reaches the exhibition hall in around two minutes. It is likely to be the longest car elevator and the highest floor in the world that can be reached by a car elevator.

Elevated and underground car parks automated with conveyor technology manipulate unoccupied cars from and to handover in a drive-through cabin using vertical and horizontal processes including pallets. For example in Graz Sackstraße / Kaiser-Fraz-Josef-Kai and Rondo. Hans-Resel-Gasse.

The Austrian National Bank has organized access to the basement for cash-in-transit trucks using a lift, the gable roof of which emerges in the park in front of the building behind fences and hedges.

Construction site elevator

A construction site elevator is a type of elevator system that is installed on tall buildings to transport people and loads during the construction phase.

Until around 1970, scaffolding was built manually from long wooden ladders and connected with ropes. To this day, materials are simply lifted upwards in small quantities using a rope pull. The train is coordinated by shouting, on sight and possibly supported by a colored marking on the rope. A cross bracket or housing that surrounds the roller groove about 150 ° at the top and a knot at the free end of the rope secure the load, typically a bucket of paint, plaster or a package of thermal insulation panels.

Motorized winches for steel cables of around 4-6 mm in diameter are usually located on top of the scaffolding on a swivel arm or with rollers on a rail that extends through a building opening, in order to be able to move the winch together with the hoisted load into the interior of the building. Typical loads are 4 construction buckets on a crown-like hook frame or a disc chest , i.e. up to 100 or 200 kg. In order to properly wind and unwind the stiffer steel cable, it requires a minimum tensile force, for example through a minimum ballast weight on the hook. The electric motor of the winch is controlled by switches on a short cable, possibly on a rod protruding downwards at an angle, which is also used for manual movement.

Inclined elevators, whose dismountable rails are brought up to the eaves at a ladder angle of 75 ° to the horizontal and after a kink, continue to run on any inclined roof surface, use a support strut to open up the roof of up to 5-story houses in particular. 4 positively guided rollers in C-profiles guide a trolley with a flat loading surface parallel to the rails and a support surface protruding at right angles. Typical cargo is a stack of flat roof tiles or panels placed on edge. A bucket must be closed with a tightly fitting lid. The train is pulled by a steel cable that is guided with rollers at least at the bend in the rail and deflected at the upper end of the rail. The winch is close to the ground.

Since at least 1970 there have been construction elevators in the form of a swiveling platform with a low railing, which, pulled by a cable, moves along a lattice mast standing close to the facade and connected to it. The semi-oval loading area can accommodate 2–3 window chests, is swiveled with its straight entrance side either close to the ground or only at the target height towards the facade and locked in height, depending on the operating mode. Docking is carried out via a ramp, folded drop side or a formwork board and unloaded through a building opening. The approximately 1 cm thick rope is guided over a pulley at the top of the mast and only wound in one layer onto a drum (d = 20 cm, L = 60 cm) at the bottom by an electric motor. Early types could handle the - mostly empty - descent using a band brake on the drum purely with hand lever brakes. Passengers are prohibited for safety reasons. The 5 m high base mast, including the platform, is folded down on its carriage with the help of a rack and pinion strut and a hand crank , 4 screw supports are drawn in and a lug on the carriage or the end of the mast is coupled to a truck so that it can be pulled as a single-axle trailer.

Many construction site lifts have been working on the rack and pinion principle since the 1980s. This means that the racks are usually attached to lattice masts, which are screwed one on top of the other. The elevator cars are driven on these racks, usually with the help of electric motors, via pinions. They are therefore also referred to as climbing elevators. The conveyor speeds are very different. Depending on the transport capacity and conveying height, they are generally between 24 and 100 m per minute. Elevators in this design may only be used by specially trained persons, as they must free themselves from the cabin in the event of a malfunction.

The load-bearing capacity of construction site elevators starts at approx. 100 kg and in special cases goes up to 10,000 kg, whereby the drive version of the electric motor (s) is provided with supporting measures (hydraulic support / frequency converter), in particular to cope with the high starting currents when starting with a high load to diminish.

Delivery heights of at least 75 m are the rule, heights of up to 450 m can be achieved with special lattice masts. In the case of construction site elevators, a distinction is also made between a single car system and a double car system. This indicates the number of cars that can be raised on a mast. In the case of double car systems, racks are attached to two opposite sides of the lattice masts. These enable each car to be driven independently. This variant is mostly used to save costs in higher buildings, since only one lattice mast has to be kept and installed by an elevator fitter . Examples can be found at Enka, the Moscow City Project and the Frankfurt Trade Fair Tower .

In addition, inclined elevators are used - especially by roofers - to transport materials, from which the furniture elevators are also developed. They can be set up quickly and temporarily without major fastening measures and are designed for loads of up to 500 kg.

To work on the strongly structured facade of the church of the Barmherzigen Brüder in Graz, Annenstraße, a restorer used a minimalist elevator, which essentially consists of a bucket seat made of sheet metal with a motor that climbs up and down a finger-thick plastic rope controlled by the person sitting on it is attached to a high point of the structure.

Special form of ship lift

→ Main article: Ship lift

A special form is a ship lift with transverse conveyance and vertical conveyance , where the ship lift functions like a vertical or inclined elevator. The water trough fulfills the function of the cabin.

Designs according to the cabin system

Single cabin elevators

Elevators with one cabin for one floor have always been and still are standard.

The ever taller buildings, however, require increasingly complex elevator systems in individual shafts for the rapid coarse and fine distribution of people and loads. Cabins with more than one door are called through-loading . They allow entry and exit in different directions and thus make the room layout on the floors more flexible. Above all, through-loaders facilitate use for wheelchair users, users with prams or bicycles, which is why through-loaders are often used at public transport stations. With through-loading that opens the doors on one level on both sides, the passenger change can also be accelerated.

Double deck elevators

Double-decker elevators - also: double-decker elevators and double-decker elevators (the three terms are used equally) - have two cabins that are firmly connected to each other and thus travel to two floors at the same time. Flexible control is possible, but also grouping in pairs so that one of the elevators goes to the uneven floors and another to the even floors. At stops with a high number of passengers, such as entrance halls or sky lobbies , the floors accessed by the elevator at the same time are accessed via escalators, which make both elevator decks accessible.

In order to enable the use of double-deck elevators in buildings with different floor heights, there are constructions in which the two cabins are connected via screw spindle drives or via connecting links similar to scissors. During the journey, the control adjusts the car spacing to the respective floor distance of the two floors approached.

Double-deck elevators are increasingly being used in tall buildings. Examples:

- One of the oldest and most famous double-decker systems since it opened in 1889 has been the double-deck elevators in the pillars of the Eiffel Tower .

- In the Burj Khalifa , currently (at the beginning of 2010) the tallest structure in the world, double-deck elevators with a speed of ten meters per second were also installed.

- As a joint contract between Otis Elevator Company and ThyssenKrupp Elevator, 32 double-decker elevators were installed as high-speed elevators in the Shanghai World Financial Center . With a load capacity of 2,000 kilograms each and a top speed of ten meters per second (36 km / h), they serve the Sky Lobby at a height of 240 meters. This made these systems the fastest double-decker elevators in the world until 2010.

- In Taipei 101, they supply the visitor platforms on the 89th to 91st floors.

Double-decker elevators are also occasionally used on ships, for example on the railway ferries of Railship AG , where double-decker freight elevators (Railship I and II) and are used (Railship III) for the rapid distribution of the railway wagons. There are only two end positions there and direct transport from level 1 to level 3 is not provided.

According to this principle, systems with three or more cabins permanently connected to one another are theoretically conceivable.

Multi-car elevators (twin system)

ThyssenKrupp AG has been using elevators with otherwise conventional traction sheave technology since 2003, with two cabins operating in the same shaft. The lower cabin is carried by suspension cables that run past the upper cabin. A destination selection control means that the host computer knows the start and destination of each journey before the journey begins; Collisions are excluded in the control. Compared to two elevator systems on top of each other in the same shaft, the system has the advantage that there is no rigid border that the cars cannot cross. By moving the cabins into a deeper shaft pit or raised shaft head, it is possible that both cabs can approach all floors. This is supposed to save 65% of the time.

Theoretically, systems with three or more cabins in one shaft are also conceivable according to this principle.

Multi-car circulating elevators (multi-system)

ThyssenKrupp AG has had elevators since 2017 with several cabins operating in the same shaft system. The Multi-System is a ropeless elevator system in which the cars can move horizontally as well as vertically.

Paternoster lifts

Differentiation according to the direction of movement

Vertical elevators

The standard direction of movement of elevator systems, as can be found in buildings of all kinds, is perpendicular (vertical).

Inclined elevators

Often there are elevator systems in buildings in which the cars have to cover a distance inclined to the vertical. Sometimes combinations of inclined, vertical and arched guides are used in such systems. One of the best-known systems of inclined elevators of this type are double-deck elevators in the pillars of the Eiffel Tower.

The European standards only use the term inclined lift for lifts whose guide rails have an incline between 15 ° and 75 ° (European standard for inclined lifts - prEN 81-22). In contrast, the Lifts Directive (Directive 95/16 / EC of the European Parliament and of the Council of June 29, 1995 on the harmonization of the laws of the member states on lifts) applies to all systems with an incline of more than 15 °, without specifically delimiting the inclined lifts.

Which legal decree inclined elevators are subject to does not result from their design, but from their purpose:

- Elevators that serve buildings and structures on a permanent basis are subject to the Elevator Directive;

- Inclined elevators that are used to transport people (outside of buildings, structures, construction sites, mines or military facilities) are subject to the Cable Car Directive;

- Elevators for other purposes, especially if they are not used to transport people, are often subject to the Machinery Directive or specific regulations for the relevant sector.

→ Main article: Inclined stair elevator

Another special form of an inclined passenger elevator is the stairlift for overcoming stairs. They are designed as platform or suspension lifts for wheelchair transport or as seat and standing lifts.

Special form Schmid people mover

The Schmid people mover from ThyssenKrupp Aufzüge is a special form for bridging roads, track systems, waterways and the like. The cabin is guided in a combination in the vertical direction in two towers and in the horizontal direction over a bridge. The drive sits on the cabin roof. The cabin is attached to a carriage that takes on the guiding function on the guide rails. In the towers, the car moves vertically along the guide rails like a normal elevator. In the horizontal part of the bridge, the cabin is suspended from the carriage. The Schmid people mover is legally considered an elevator.

Elevators as a means of transport

In general, elevators are considered to be the safest and most frequently used means of transport in the world. As a statistical mean, every person uses an elevator every three days. Chance of elevators serve as transport in the public transport (public transport), they can on payment of a transportation fee or free of charge. Typically these are free-standing systems on a mountain flank, the upper level can usually be reached via a bridge:

- The Elevador Lacerda has linked the lower town with the upper town of the Brazilian city of Salvador da Bahia since 1873

- Katarinahissen in Stockholm has been connecting Slussen with Södermalm , 38 meters higher, since 1883 , and has been out of service since 2010

- On the island of Helgoland , a public transport elevator has been connecting the Unterland with the Oberland since 1885

- The Mönchsberg lift has been connecting Salzburg's old town with the Mönchsberg since 1890

- In the Swiss capital, Bern , the Mattenlift has been leading from Badgasse to the cathedral platform since 1897

- In Lisbon , the Elevador de Santa Justa has been connecting the lower town with the upper town since 1902

- The Bad Schandau elevator has been transporting people to the so-called Ostrauer Scheibe since 1904

- The Hammetschwand lift in Switzerland, completed in 1905, opens up a vantage point on the Bürgenstock

- Monaco : In Monte Carlo you can take the elevator from one part of the city to the other.

- Marburg : Four systems (one of them private, the rest public) with a total of eight elevator cars connect the upper with the lower parts of the city (see local transport in Marburg # elevators )

- In Stuttgart , a glass elevator connects the Schlossplatz with the Kleiner Schlossplatz.

- In Baden , the Limmatsteg and the promenade lift connect the community of Ennetbaden with Baden train station .

- In Luxembourg between Oberstadt and the Grund district.

- In Valletta , a 58-meter-high elevator connects Upper Barrakka Gardens with the moat and thus with the landing stages for cruise ships and ferries in Grand Harbor .

- In Genoa , the Ascensore di castelletto is operated by the local transport company Azienda Mobilità e Trasporti Genova (AMT)

- The Marienlift , built in 2003 next to the Mariensäule at the Eiserner Tor in Graz , Herrengasse raised the cabin in the shaft - both glazed - about 15 m above level against the insertion of coins and allowed a higher view of Maria and the pedestrian zone.

- The Schloßberglift from around 2010 allows driving to a little above the height of the clock tower and, with intermediate stations, opens up the cathedral in the mountain and a newer people slide.

Drive systems in elevator systems

Depending on the intended use and the state of the art, there are currently four types of power transmission systems to implement drive at delivery head. This is not to be equated with drive types for all four types of system, since there are and were different types of drives in rope elevators. Another drive system, currently known as the “rope-less elevator”, is still state of the art and still a long way from being ready for series production.

Cable lift

In the case of a cable lift, the cabin is suspended from suspension cables . The oldest form of cable lift was the drum lift , in which the ropes were wound on a drum, similar to a fishing line. One end of the ropes is firmly attached to the drum. The counterweight hangs on a second rope that is wound or unwound from a counter-rotating drum that sits on the same shaft. The first drum lifts were built in the mid- 19th century and powered by steam engines. Since the length of the ropes is limited by the size of the drum and the drum elevator is therefore not suitable for high conveying heights, it has increasingly been replaced by the traction sheave elevator. Another disadvantage is the use of only a single suspension rope, which offers less safety than the use of several ropes as in the traction sheave elevator. The lack of slip is an advantage .

Traction sheave elevator

In the traction sheave elevator , the suspension cable, which carries the car at one end and a counterweight at the other end , is guided over a driven roller, the traction sheave . The rope is not attached to the traction sheave, but is held and moved by friction . To increase the contact surface and thereby the friction, the traction sheave has grooves, e.g. B. wedge (V-shaped) or round grooves - each with or without undercut - into which the rope is pressed by the tensile stress. The traction sheave elevator has the advantage that suspension ropes of almost any length can be used (due to the dead weight of the ropes, however, above a certain rope mass, a rope weight compensation is required that compensates for the weight, regardless of the moving position) and this works more economically than a drum elevator. This type of elevator is suitable for high-rise buildings .

The traction sheave principle was invented by the German mining engineer Carl Friedrich Koepe , who first equipped a shaft hoisting system at the Hanover mine with it in 1878 .

In the beginning, steam engines were used as drive types for cable elevators , later the steam engines were replaced by electric drives. The force is transmitted to the traction sheave by electric motor gears (formerly also in drum elevators) with 0.1 m / s to 2.5 m / s or by gearless elevator machines with 0.63 m / s to over 10 m / s.

The engine room is usually located above the shaft, in the shaft head. It can also be arranged in the middle or at the lower end of the elevator shaft via pulleys. In any case, the load is absorbed by components located above. By using mostly gearless permanent magnet motors and space-saving sizes, there have also been machine room-less (MRL) cable lifts with a motor including frequency converter in the shaft and a decentralized control system since 1995 (regulated with the introduction of the EN81 1999 standard ). They are usually used up to 80 m, but not on goods lifts. Maintainability is a bit more difficult, and every manufacturer has their own patent, which is still protected. At greater heights, the drive is often gearless, but housed in an engine compartment.

There are different types of suspension:

With 1: 1 suspension , the cabin and the counterweight are each attached directly to the rope ends. With the 2: 1 suspension , the rope ends are attached to the ceiling (shaft head) of the elevator shaft, while the car and counterweight each hang from the ropes by means of pulleys. This creates a simple pulley block with which twice the payload (at half the speed) can be lifted. Other possible suspensions are 4: 1 and 6: 1 . However, they are used less often and almost exclusively in freight elevators.

Steel cables of various designs are generally used as suspension elements. For some time now , however, coated steel belts (covering made of polyurethane ), coated steel cables (covering made of polyurethane) and ropes made of plastic fibers ( aramid ) have also been used.

Hydraulic elevator

In hydraulic elevators, the car is moved by one or more hydraulic pistons , which are usually installed vertically at the bottom of the elevator shaft. If the cabin is firmly connected to the piston, it is called a direct hydraulic elevator . If the force is transmitted via suspension ropes and pulleys, it is called an indirect hydraulic elevator . The indirect hydraulic elevator is basically a reverse-operated pulley system in which the loose roller is moved by the hydraulic system. In the case of directly driven systems, the piston can be under (in-ground) or next to (free of boreholes) the cabin, in indirect systems always next to it.

In contrast to cable lifts, they are more suitable for lower conveying heights. Heights of 15 to 25 m are now possible, above which it becomes uneconomical compared to the rope. Borehole-free direct hydraulics are typically used up to a height of 10 m. The machine room is usually located next to the lowest level. If space is problematic, it can also be arranged remotely thanks to the hydraulic power transmission, usually up to 15 m away. Usually only the piston is located in and / or under the elevator shaft. There are now systems in which the drive is also installed in the elevator shaft, so-called machine room-less (MRL) systems. It also offers advantages for freight elevators, as almost only the floor and not the ceiling is loaded. This is advantageous in locations without space or sufficient stability for a shaft head and additional supports, such as old buildings that are visually preserved or cramped. The maximum speed is limited, it is a maximum of 1 m / s, usually 0.63 m / s. Hydraulic pistons also come as a 2-way telescope.

Rack and pinion elevator

With a rack and pinion elevator, the elevator car is equipped with its own drive. It can be driven by an electric motor or an internal combustion engine based on the rack and pinion principle.

Rack and pinion elevators are used, among other things, as construction hoists, crane operator hoists, rescue hoists or maintenance hoists to transport material and people. They are also installed in guyed transmission masts or similar constructions in order to be able to maintain the flight safety lights or other system parts more easily. Examples of installed rack and pinion lifts in the maintenance area are the support masts of Elbe crossing 2 or the transmission mast of the WDR in Velbert-Langenberg with a petrol engine. As crane operator lifts at the Hansaport ore handling facility in Hamburg or as rescue lifts for the fire brigade at the Zurich – Thalwil railway tunnel. Many people also know it from tours and excursions as a means of access to the roof structure of Cologne Cathedral.

Vacuum elevator

The vacuum elevator exists as an exotic special variant. The drive takes place here via a pneumatic system . A compressed air pump or turbine raises or lowers the floor pane of the lift depending on the height of the floor. In this respect, it would not be correct to speak of a vacuum, but rather of a "compressed air-powered" elevator similar to the earlier pneumatic tube . The advantages are, on the one hand, the small installation dimensions (a ring about one meter in diameter is sufficient) and, on the other hand, particularly gentle starting and stopping processes. Disadvantages are the low conveying capacity (1 to max. 2 people) and the low overall height. Modern systems reach a delivery height of up to 10 meters. The vacuum elevator, with its futuristic tubular design, finds its product niche primarily in one and two-family houses and in boat building.

Ropeless elevator

A ropeless elevator was developed and a prototype was built at the RWTH Aachen Institute for Electrical Machines. The cabin is driven by two electromagnetic synchronous linear motors and is therefore only held or moved by a vertically movable magnetic field . This work should serve the development of elevator systems for very tall buildings. One goal is the use of several cabins per shaft that can be controlled independently of one another. When the destination is selected before the start of the journey (i.e. still outside the elevator), a specific car in one of the elevator shafts is selected for the journey with which the planned transport can be carried out most quickly. The space requirement for the entire elevator system could thus be reduced by one or more shafts. Since the cabins are operated without ropes, a shaft change is also conceivable. This enables further operating strategies to be developed for the ropeless elevator system, for example a modern paternoster elevator with cabins that can move independently of one another.

As part of the research on the ropeless elevator, work is also being carried out on the development of electromagnetic linear guides in order to minimize the wear and tear of the ropeless elevator system while maintaining high ride comfort. Various research institutions around the world are working on ropeless drive solutions for elevators. Otis has been operating the Shibayama Test Tower for this purpose since 2007 . In 2017, ThyssenKrupp Elevator inaugurated a test tower in Rottweil, southern Germany , in which the technology of the ropeless elevator with synchronous linear motors is tested on a full scale. The first elevator of this type is scheduled to go into operation in Berlin in 2020.

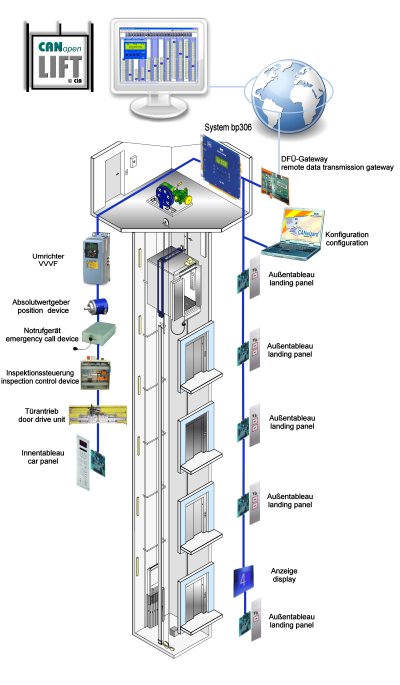

Main components of an elevator system

General components

- Impact absorbers (buffers, springs or oil dampers)

- Exterior panels

- Stand displays

- Landing door

- Direction gong

- Guide rails

- Limit switch (limit switch)

- Pit control station (including emergency call)

- Car

- Interior panel

- Inspection control

- Cabin door

- Car fan

- Light barrier or light grid

- emergency light

- Emergency call station

- Door control unit

- Engine room intercom

- Position sensor (copying)

- Shaft lighting

- Hanging cable

- Voice announcement

- control

Special components of a cable elevator

- Drive ( elevator machine ) with the components

- Service and safety brake

- possibly frequency converter

- Motor in combination with possible gearbox

- Traction sheave

- Safety gear (in both directions)

- Counterweight

- Speed limiter

- Car

Special components of a hydraulic elevator

- Drive with the components

- Lifting prevention

- Hydraulic jack

- Hydraulic block including solenoid valves

- Motor with pump

- oilcontainer

- with hydraulic rope: rope pulley

- possibly soft start (soft start) or frequency control

- Car

- possibly safety gear (only downwards and with indirect hydraulic systems)

- Pipe break protection / pipe break valve

Control concepts

Hand control

Until the middle of the 20th century, elevators were mostly hand-controlled (lever control). An elevator operator became aware of passengers with a call system, opened and closed the doors, operated a travel switch and drove to the floors upon verbal request.

Collective control

The control saves landing calls and interior commands. Provided they are in the current direction of travel of the cabin, these are processed one after the other on the way.

A distinction is made between downward or upward collection control and full collection control. The latter uses two buttons advance ( on - and from collecting). After entering a travel request via the external panel (call) or from the car panel (command), the direction selection is determined in the control (call above or below the respective cabin location). Group collective controls can be used for elevator groups, which are also designed as downward, upward or full collective controls.

Direct control

In contrast to collective control, only one command or call is saved at a time, with car commands having priority over external calls. After entering a command or call, it is saved and all further entries are blocked until the end of the journey. The direct control is found nowadays in existing systems mainly via key access for priority special trips , e.g. B. for moving furniture when moving, for patient transport in hospitals (bed elevators) or for caretakers.

Destination selection control

The destination call control was invented in 1997 by Schindler Aufzüge AG Ebikon / CH. With the destination selection control, the destination floor must already be entered when the elevator is called. This allows the control system to plan in a targeted manner and increases capacity considerably. A system with express and local elevators can thus be operated more flexibly: the passenger no longer needs to know which elevator is the express elevator, and restrictions such as “stop only on every 10th floor” are not necessary.

Destination selection controls make more sense in non-public buildings, in which several elevators are combined into a so-called "group" and the passengers are familiar with the operation, since the operation differs from the conventional type. However, you are also z. B. used in large hotels such as the Marriott Marquis in New York City .

The cabins are usually designated with letters (A, B ...). Instead of the usual call buttons, there is a terminal with a numeric keyboard or (with more modern devices) a touchscreen . The user enters the number of the desired floor or selects his destination from a list. The system then assigns him a cabin and shows the corresponding letter and an arrow in the direction of this cabin on the display. With this cabin, the user can now drive to the desired destination.

Car calls are usually not possible; the car panel only contains emergency call, door open and, if applicable, door close buttons. However, there are also hybrid systems in which car calls are partially still possible. In the cabin, all intermediate stops are shown on a separate display, often near the doors.

Smart destination selection controls have a wheelchair option. For this purpose, the outside panel contains a button with a wheelchair symbol. If this is pressed, the system takes into account the increased space required by a wheelchair. In addition, voice output as well as optical and acoustic signaling devices to locate the assigned cabin are activated. This also enables the blind and visually impaired to use it. In addition, the door hold-open time is extended when this function is used.

With multi-car elevators (two cars in one shaft), this control is a prerequisite for efficient use. There are now elevator systems with destination selection control from several manufacturers.

Sabbath control

The Sabbath lifts represent a special form of control . In Sabbath mode, they automatically and non-stop to every floor, with the doors opening and closing automatically on every floor so that no switch has to be operated when using the lift. since this is forbidden to believing Jews on the Sabbath.

Accessibility

In Europe, elevator accessibility is regulated by the DIN EN 81-70 standard, and in the USA by the Americans with Disabilities Act (ADA). The latter stipulates, among other things, that the direction gong must sound once for upwards and 2 times for downwards or a corresponding voice announcement.

Furthermore, in almost all elevators the inscription of a button is supplemented with Braille .

In many elevator cars, the main access level (i.e. usually the ground floor) is marked conspicuously, with the associated button outlined in green and sometimes protruding a few millimeters further from the control panel than the others. In the USA, instead of a green marking, you often see a star next to the floor designation.

safety

Technical rules for elevators are regulated by the European Directive 95/16 / EC . This guideline was implemented into national law in Germany by the Elevator Ordinance (12th GPSGV). In addition, elevator systems are systems that require monitoring within the meaning of the Industrial Safety Ordinance and must be checked by an approved monitoring body at least every two years . The recurring test, generally referred to as the main test, takes place every two years at the latest; However, an intermediate exam is still mandatory between two main exams. In this respect, the test cycle is around twelve months. In Austria, elevator law is not regulated by national law, but at the federal state level. Accordingly, there are nine elevator laws and regulations in Austria within the scope of building law (Vienna Elevator Act 2006, Lower Austria Elevator Ordinance 1995, Vorarlberg Elevator Ordinance, etc.). In Vienna, all elevators for passenger transport are to be checked every 12 months and those with only one carrying rope every six months.

In Vienna, the number of accidents remained the same between 1951 and 1996, with more and more existing systems, so the probability of an accident has decreased. From 1997 the trend suddenly reversed. After the evaluation, there were two explanations:

- On the one hand, more and more elevator systems are of a contemporary high standard and people are no longer familiar with the specific dangers of old elevator systems.

- On the other hand, today's society has become more complacent. People who have suffered damage are much more likely to claim damages. The insurance companies (health insurance companies) try to claim costs that arise in connection with accidents in accordance with the polluter pays principle.

security concept

Today, due to high safety requirements , elevators are equipped with a safety system that prevents deviations from normal operation, such as B. too high speeds or even a crash of the elevator car, even if all the suspension ropes should break.

In addition, the elevator cabs are suspended in rope constructions by several, usually three to ten, ropes running in parallel. The ropes are dimensioned in such a way that the breakage of one or more ropes does not lead to the breakage of the entire rope set. Up to 1999, the ropes were designed with a safety factor of 14 and since July 1, 1999 with a safety factor of 12 with at least three ropes. In an elevator with only two suspension ropes, a 16-fold rope safety is required according to EN 81-1 . This means that an elevator could easily hold the loaded car safely with just one rope. This applies to elevators in which passenger transport is permitted, i.e. only passenger and freight elevators. In the case of pure goods lifts, the required rope safety is lower. State-of-the-art passenger elevators no longer use classic ropes, but instead are moved by several (e.g. three) flat belts with many thin, parallel steel ropes inside. The control electronics constantly monitor the electrical internal resistance of each belt. If a change or greater deviation is registered here, which could indicate a damaged belt, the elevator is immediately stopped in a controlled manner at the next exit point, the doors open and an error message is automatically sent.

It is also important that the traction capability of the rope / traction sheave system is correctly designed. If the traction is too high, the ropes will wear out excessively. If the traction capacity is too low, the ropes can slip ( slip ) so that the car cannot start or brake properly or come back to its normal speed. Under certain circumstances, the car then does not come to a stop exactly at floor level, but instead comes to a stop between the floors; In the worst case, the car slowly slides up or down to the lower or upper end point, depending on whether the car or the counterweight is heavier.

A speed limiter prevents the car from traveling too quickly or up to the top or bottom of the cabin. If a limit value is exceeded, the drive is switched off electronically and the cabin is mechanically braked to a standstill. This safety device is independent of other operating parts of the elevator and works mechanically, i.e. even in the event of a power failure .

The device usually consists of a rope loop that runs between a pulley at the lower and upper shaft end, and a safety device that is attached to the elevator car. The safety gear usually consists of safety wedges that grip around the guide rails and wedge them in the event of release. With a movement of the elevator car, the pulleys at the top and bottom of the shaft are set in rotation via the rope loop. One of the deflection pulleys is provided with a centrifugal force-controlled arrangement that triggers as soon as the deflection pulley rotates too quickly. When triggered, the elevator motor is switched off. Regardless of this, the deflection pulley blocks its rotation and thus stops the rope run. If the car then moves further, the now immobile rope pulls the safety wedges together on the car until the elevator comes to a standstill. The braking of the car by the safety gear must not exceed a deceleration of 1 g (simple gravity ).

In the case of hydraulic elevators that are directly driven, which means that no ropes are required, a pipe rupture safety device is installed directly at the connection of the cylinder. With a pre-tensioned check valve, this prevents the cabin from moving down too quickly.

Emergency call

Malfunctions in passenger elevators can result in the car doors not opening, e. B. when "getting stuck" between two floors. The people trapped in the car generally have no way of freeing themselves. Therefore, there is an emergency call button in the car that is to inform the elevator attendant. In many elevators that were built before 1999, however, the emergency call button only triggers a horn or bell in or on the elevator shaft to draw attention to trapped people. It is therefore not absolutely certain whether the emergency call is actually heard, especially since passers-by may not immediately be able to correctly interpret the sound. This design is no longer permitted for newly built elevators, but existing elevators may continue to be operated unchanged within the framework of the grandfathering .

According to the Vienna Elevator Act, all elevators must be equipped with a suitable emergency call facility , depending on the year of construction up to March 2012, and no later than March 2013. The person in charge of the emergency rescue has to reach the scene of the incident within 30 minutes. If an elevator system is in operation 24 hours a day (as is common in residential buildings), there must be at least two elevator attendants. This means that older systems must be converted if it is not ensured that an elevator attendant can be reached at any time during operation. The basis is the EN 81-80 standard: Safety rules for the construction and installation of elevators - Existing elevators - Part 80: Rules for increasing the safety of existing passenger and freight elevators

Inner door and stopping accuracy

According to the EN 81 standard, new and converted elevators, with the exception of small-load elevators, now generally require cabin doors / interior doors.

In addition to pulling in limbs, one cause of many serious accidents is wedged cargo. These are rigid objects that are carried along and that arrive at the passing outer wall or fall over, get stuck, wedged and therefore take up more and more space. People can be crushed between the object and the cabin wall and / or the cabin ceiling. The object can also be, for example, a piece of furniture, a stroller, a waste paper container or a hand truck .

After many serious accidents, some of which were fatal, existing freight elevators in Germany often had to be retrofitted at least with light curtains as security. The basis is the EN 81-80 standard to increase safety. In Vienna between 1994 and 2003, the proportion of reported accidents with doorless car openings was in third place with over 19%. Depending on the year of construction, all - including existing systems and passenger lifts - had to be equipped with an interior door by 2013 at the latest, with financial support from the city. The value of the accidents concerned had decreased to 9% by 2009. (At the same time, reports of entrapment in automatic car doors have doubled and lead the statistic at 39%, but there are usually less serious injuries such as trapped fingers and bruises.) Retrofitting is also mandatory in Geneva.

About 20% of accidents are due to inaccurate stopping of the cabin, creating a step. There is a risk of falling and the possibility of broken bones or other serious injuries. This level occurs primarily in single-stage, uncontrolled drives where the brake is applied at full speed after the motor has been switched off. However, the braking effect differs depending on the load, braking status and current air temperature. With multi-stage drives, a slower speed is switched to shortly before the stopping point. Mandatory conversions of old systems are also planned here in Vienna and Geneva.

environment

Overall, the elevator systems consume more energy when standing still and waiting than when moving up and down: Almost 60% of the current is lost unused because the control and the external panels are continuously live - and also because many elevator systems are not equipped with a load measuring sensor and therefore stay lit even if no one is in it. Elevators in apartment blocks that were built around 1960/1970 typically had a ceiling light with 1–2 lightbulbs each about 40 watts electric, which only shone when a person was standing in the elevator and their body weight was pressing the floor a few millimeters down against springs and thus one Push button operated. There was a similar circuit in telephone boxes that were still wooden at the time. Later on, lift cabins with several or more extensive lights based on more efficient fluorescent tubes were mostly switched to permanent light. Because of the approval as a technical system, users cannot easily modernize the lighting system. Incandescent lamps from old lifts may be supplied with a low voltage of around 24 volts.

Record systems

The fastest and longest elevators

| Surname | speed- speed |

length | location | constructor | Construction year | comment |

|---|---|---|---|---|---|---|

| Jeddah Tower | > 10 m / s | > 1 km | Saudi Arabia , Jeddah | Cone | 2020 | Longest elevator shaft in the world, use of Kone Ultra Rope |

| Shanghai Tower | 18 m / s | 578.5 m | China , Shanghai | Mitsubishi Electric Elevator | 2014 | |

| Citic Tower | 528 m | China, Beijing | Cone | 2018 | The fast connections in the building save 320,000 working hours every day. | |

| Burj Khalifa | 10 m / s | 504 m | United Arab Emirates , Dubai | Otis Elevator Company | 2009 | Fastest double-decker elevator in the world with 10 m / s |

| Chow Tai Fook Center | 20 m / s | 440 m | China , Guangzhou | Hitachi | 2016 | Fastest single-cabin elevator in the world |

| John Hancock Center | 9 m / s | 344 m | USA , Chicago | Otis Elevator Company | 1969 | |

| Sunshine 60 Building | 10 m / s | 240 m | Japan , Tokyo | Mitsubishi Electric Elevator | 1978 | |

| Shanghai World Financial Center | 10 m / s | 492 m | China , Shanghai | ThyssenKrupp Elevator | 2008 | |

| China World Trade Center Tower III | 10 m / s | 330 m | China , Beijing | Schindler | 2009 | |

| Yokohama Landmark Tower | 12.5 m / s | 296 m | Japan , Yokohama | Mitsubishi Electric Elevator | 1993 | |

| Kollhoff Tower | 8.65 m / s | 90 m | Germany , Berlin | ThyssenKrupp Elevator | 1999 | fastest passenger elevator in Europe

|

| Olympic Tower Munich | 7.00 m / s | 182 m | Germany , Munich | Domestic cock | 1968 | Travel time to the viewing platform: 27 seconds; 0-7 m / s: 4.5 s |

| Florian Tower Dortmund | 4 m / s | 151.55 m | Germany , Dortmund | Schindler elevators | 1959 | Travel time to the viewing platform: 40 seconds |

| Augustinum Mölln | 2.5 m / s | 115 m | Germany , Mölln | Hütter elevators | 2001 | High speed inclined elevator |

| Europaturm Frankfurt | 6 m / s | 240 m | Germany , Frankfurt am Main | Schindler elevators | 1978 | Visitor platform closed since 1997 |

| Faja dos Padres (panoramic elevator) | 1 m / s | 250 m | Portugal , Madeira | ? | ? | |

| Telecommunication tower Nuremberg | 6.3 m / s | 193 m | Germany , Nuremberg | Schindler elevators | 1979 | Visitor platform closed |

| Hammetschwand lift | 3.15 m / s | 152.81 m | Switzerland , Bürgenstock | Schindler elevators | 1905/ 1990 | Highest public external elevator in Europe |

| Jin Mao Building | 9 m / s | 340 m | China , Shanghai | Mitsubishi Electric Elevator | 1997/1998 | |

| Stuttgart TV tower | 5 m / s | 150 m | Germany , Stuttgart | Domestic cock | 1956/2003 | First television tower (of its kind) in the world |

| Taipei 101 |

16.8 m / s upwards 10 m / s downwards |

448 m | Taiwan , Taipei | Cone | 2004 | Built by Toshiba |

| Post Tower | 6 m / s | 156 m | Germany , Bonn | Schindler elevators | 2001 | Destination call control Miconic 10; 20 elevators, six of them for traveling from the ground floor to the 21st floor, six for traveling from the ground floor to the 41st floor. The passenger elevators and their elevator shafts are fully glazed. |

| Danube Tower | 6.1 m / s | 213.5 m | Austria , Vienna | Cone | 1964 | Fastest express elevator in Europe in the year it opened. In strong winds and swaying of the tower, it drives at reduced speed so that the ropes don't get tangled. |

| CN Tower | 6 m / s | 351 m | Canada , Toronto | Otis Elevator Company | 1976 | Height of the tower 553 m, in 58 s to the first viewing platform at 342 m. A glass wall provides a view of the outside while driving. |

| Bailong Elevator | 326 m | China , Wulingyuan area | 1999-2002 | Outdoor elevator |

The smallest elevators

- The smallest passenger elevator in Europe is located in a private house in Copenhagen . It is a custom-made product from Hiro Lift with a cabin width of 69 cm and a depth of 61 cm. The floor space is therefore only 0.42 m². The elevator goes to stops on four floors and is approved for the transport of just one person or loads up to 150 kg.

- The narrowest passenger elevator in Germany with a width of 52 cm is in a residential building in Hamburg's St. Georg district .

The largest elevator manufacturers in the world

In 2007 the EU Commission imposed a fine of 992 million euros on five major manufacturers. The companies had agreed on prices and thus violated antitrust law. ThyssenKrupp had to pay 479.7 million euros, Otis 225 million, Kone 142 million, Schindler 143.7 million and a Mitsubishi subsidiary 1.8 million euros. This was the highest penalty that the EU Commission had imposed until then ( see also lift cartel ).

Test facilities

There are towers for research and testing of elevators and elevator components. Such test towers, like buildings (skyscrapers, towers of all kinds), are also being built higher and higher. The highest test tower is currently a test tower from Thyssenkrupp in Zhongshan, China, with a height of 248 meters; the second highest at 246 meters is the Thyssenkrupp test tower in Rottweil, Baden-Württemberg.

In the opposite vertical direction there are test shafts in abandoned mines. The longest test shaft of this kind in the world is 333 m deep and is operated by the Kone company in Finland. Among other things, tests of the world's second fastest elevators with up to 17 m / s (around 61 km / h) are carried out there.

measure up

The interlift place as the world's leading trade fair every two years for elevator technology Augsburg instead. At the interlift in 2013, a total of 515 exhibitors from 40 countries (with a foreign share of 70 percent) presented themselves to the specialist audience on a gross area of 48,000 m². 18,918 visitors with a foreign share of 54 percent set a new record for the fair.

Cabin equipment

Cabins were formerly made of wood and with vertical tension rods and horizontal beams made of steel. The interior cladding was almost always veneered wood or chipboard.

From 1950 onwards, passenger lifts were mostly provided with a 40 x 80 cm high-format mirror on the front wall so that users can check their appearance and thus make better use of the travel time. The mirror also doubles the visible size of the cramped cabin. The mirror grew larger over the decades until it covered the entire back wall. A mirroring of more than one side hardly occurs because it worsens the situation orientation of the person.

Maybe there was a horizontal handle at waist height.

Later, combustible wood was eliminated from the cabin structure and the inside was clad with sheet metal panels, steel was painted or later NiRo - also embossed. The mirror takes up the entire width of the cabin, possibly also the entire height. In department stores, glass doors and two to 3 glass walls on the sides are common. Then there is a railing all around, for stopping, stopping and also as an optical anchor for the sense of balance . Shopping carts are kept from hitting the glass here and by another rail 15 cm above the floor.

Even today, elevators for loads or in hardware stores are often completely clad in sheet metal.

Hand-opened revolving doors with spring-loaded door closers used to have a narrow 1: 6 portrait format wired glass window for visual contact with users inside and outside. These windows disappear with the use of louvre sheet metal doors.

The floor was covered with linoleum early on . The first 5 cm of the cabin floor were typically reinforced with a grooved aluminum bar, which often presented the name of the lift manufacturer, such as "Wertheim" in the oval rim, probably made of cast aluminum. Today there is typically a knobbed, hard-wearing plastic covering in the cabin.

As long as the cabins did not have internal doors, the shaft doors, the door frame and the shaft wall above and below were made as smooth as possible - the latter were bricked, plastered and plastered or plastered. The window glass was only about 3 mm thick, the screws were countersunk. On the inside of the door, an anodized aluminum plate measuring around 15 x 25 cm served as a pressure point to protect the paint. The edges of the approximately 2.5 mm thick plate were chamfered to make them easy to grip. If this panel itself did not have a large letter or number of the storey milled in and painted black, then the shaft door carried an aluminum self-adhesive label a little above the window with the same information that is required for vertical orientation in the house.

For a long time, lift shaft doors for manual opening had an L-handle made of polished cast aluminum or a vertically mounted aluminum tube that could be opened against the spring force of a door closer. Goods lifts sometimes had 2 wider door leaves and no door closer, but a latch fell into the lock and had to be opened with a twist grip.

Two plug contacts embedded in the top of the door frame are traditionally electrically connected by two brass pins on the top door to report "door closed" to the control. The door is then locked by a bolt, which must also be confirmed by an electrical contact before the elevator car can start moving.

A door bolt can be opened in an emergency, useful in the event of a power failure, malfunction or fire, after opening a small sheet metal cover on the door frame by inserting and turning a triangular key against spring force. This usually makes it possible to free people from an adjacent cabin. A door that is opened manually in this way can pose a risk of falling. The roof of a cabin sometimes has to be opened so that passengers can also use a ladder to get out via a shaft. To be on the safe side, call the fire brigade or an emergency lift service in such cases .

At the latest with the introduction of the interior doors, an elongated display bar followed on the inside above the door opening, with number fields backlit by individual light bulbs. Later, red and different colored light-emitting diode segment displays and then small graphic liquid crystal screens were used for floor displays. The floor display moved to the control panel in the cabin.

Today, lifts are no longer equipped with a stop button or toggle switch that allowed the journey to be interrupted. An alarm button has a classic effect on a doorbell in the house or today, after a certain minimum press time of typically 3 seconds, it establishes a telephone connection with an emergency service.

Projects

Elevator into space

The concept of a space elevator was already considered by Konstantin Ziolkowski (1895), Juri Arzutanow (1960) and Arthur C. Clarke (1979). Today such projects are becoming interesting again due to cost considerations. Expensive rocket launches could become superfluous. Transport costs could fall from the current tens of thousands of dollars to less than 200 dollars per kilogram of transported goods. That is why there are also competitions that are co-financed by the US space agency NASA , among others .

A rope connects a station on the earth's surface with a geostationary space station. The earth station is a huge floating pontoon on which the cargo is loaded below the surface of the water. The gondola climbs 36,000 km on a very thin but stable rope made of nanotubes . The development of this rope is currently the biggest problem in this project.

Porta Alpina

The Porta Alpina should have been the world's longest elevator in Switzerland: in the middle of the Gotthard Base Tunnel - the world's longest tunnel - the deepest train station with the world's highest and fastest elevator was to be built. Although halls were demolished, the lift was not built by the 2012 resolution.

literature

- Jürgen Dispan: Elevator and escalator industry in Germany. Development trends and challenges . Frankfurt am Main 2015 ( / Aufzugs -Branchenreport-2015- IMU-IGM.pdf Online - Industry Report 2015).

- Oliver Bachmann: Elevators and Escalators. Technology, planning, design . In: The library of technology . tape 66 . Modern industry, Landsberg 1992, ISBN 3-478-93081-2 .

- Andreas Bernard : The story of the elevator. About a moving place of modernity . Fischer Taschenbuch 17348, Frankfurt am Main 2006, ISBN 3-596-17348-5 (dissertation Bauhaus University Weimar 2005, 335 pages).

- Jürgen Dispan: Elevators and escalators - a changing industry. Investigation of the situation and development of the elevator and escalator industry . Frankfurt am Main / Eschborn 2007 ( imu-institut.de [PDF] industry report ).

- Kerstin Englert (text), Alfred Englert (photos): Elevators in Berlin. A 100 year history . Jovis, Berlin 1998, ISBN 3-931321-96-7 .

- Vittorio Magnago Lampugnani et al .: Vertical. Elevator, escalator, paternoster. A cultural history of vertical transport . Ernst, Berlin 1984, ISBN 3-433-02480-4 .

- Uwe Ruprecht: Elevator - up and down . Schack, Dortmund 1999, ISBN 3-929983-09-5 .

- Jeannot Simmen, Uwe Drepper: The elevator. The story of vertical conquest . Prestel, Munich 1984, ISBN 3-7913-0692-8 .

- Stefan Hirschauer: The practice of strangeness and the minimization of presence. An elevator ride . In: social world . tape 50 , 1999, pp. 221-246 .

- Dieter Unger: Elevators and Escalators, a user manual. 2nd, revised edition, Springer-Vieweg, Berlin / Heidelberg 2015, ISBN 978-3-662-46501-1 .

Web links

- Baunetz Infoline lifts (basic knowledge, examples)

- CANopen-Lift.org Wiki of the CANopen-Lift Community

- Online tool for risk assessment of freight elevators

- Museum for the Preservation of Elevating History (online museum for elevator history, English)

- The Vienna Elevator Museum documents a growing collection that is stored in Orth / Donau and that could be viewed on an open elevator day in August 2019. Curious hobby: time travel with historical elevators in Marchfeld

Individual evidence

- ↑ The Book of Secrets - Kitab al Asrar of al-Muradi - Part 1 of 2 on YouTube

- ^ " On the history of the elevator - from Otis to Twin ". Retrieved July 14, 2020.

- ↑ Leonardo da Vinci, Leonardo (da Vinci), Musée des Beaux-Arts (Montréal), Pierre Théberge: Leonardo Da Vinci, engineer and architect . Montreal Museum of Fine Arts. April 10, 1987.

- ↑ Hannes Etzlstorfer: Maria Theresia - Children, Church and Corset. 2008, ISBN 978-3-218-00786-3 .

- ↑ cf. z. B. Bill Bryson : Made in America: an Informal History of the English Language in the United States. Black Swan, 1998, p. 121.

- ^ Siemens Historical Institute - First electric elevator. Retrieved August 21, 2018 .

- ↑ Sayings: The big fat lifter. Retrieved January 22, 2018 .

- ^ Unterwegs-in-Teschechien.cz: An office in an elevator , from September 6, 2015, loaded on November 8, 2018

- ↑ Berliner- Mieterverein .de: The shoemaker did not stick to his last , loaded on November 8th, 2018

- ↑ The Otis Elevator Company has developed a unique elevator ... ( Memento March 4, 2016 in the Internet Archive ), dated June 23 without a year. Retrieved February 12, 2010.

- ↑ OTIS systems in the tallest building in the world - the Burj Khalifa in Dubai ( Memento from March 4, 2016 in the Internet Archive ), January 2010. Retrieved on February 12, 2010.

- ↑ Individual references in the main article Shanghai World Financial Center (section inner core of the building)

- ↑ Taipei International Financial Center (Taipei 101) , November 3, 2009. Retrieved February 13, 2010.

- ↑ MULTI - innovative ropeless elevator system , thyssenkrupp-elevator.com

- ↑ Schmid-Peoplemover® - Transfer and Revolution ( Memento of November 3, 2011 in the Internet Archive ) (PDF). Retrieved February 13, 2010.

- ↑ Vacuum Elevators , accessed July 25, 2009.

- ↑ M. Platen: Development of a synchronous linear drive for a vertical transport system. Dissertation, Institute for Electrical Machines of the RWTH Aachen, Shaker Verlag Aachen, July 2001, ISBN 978-3-8265-9011-5 .

- ↑ M. Platen, G. Henneberger: Examination of leakage and end effects in a linear synchronous motor for vertical transportation by means of finite element computation. IEEE Transactions on Magnetics, Volume 37, 2001, Number 5, pp. 3640-3643.

- ↑ B. Schmülling: Electromagnetic linear guides for elevator systems. Dissertation, Institute for Electrical Machines of the RWTH Aachen, Shaker Verlag Aachen, September 2009, ISBN 978-3-8322-8529-6 .

- ↑ HS Lim, R. Krishnan: Ropeless Elevator With Linear Switched Reluctance Motor Drive Actuation Systems. IEEE Transactions on Industrial Electronics, Volume 54, 2007, Number 4, pp. 2209-2218.

- ^ A. Onat, E. Kazan, N. Takahashi, D. Miyagi, Y. Komatsu, S. Markon: Design and Implementation of a Linear Motor for Multicar Elevators. IEEE / ASME Transactions on Mechatronics, Volume PP, 2009, Number 99, pp. 1-9.

- ↑ Helga Rietz: The elevator of the future does not need a rope | NZZ . In: Neue Zürcher Zeitung . June 23, 2017, ISSN 0376-6829 ( nzz.ch [accessed December 30, 2017]).

- ↑ Destination dispatch. Retrieved March 16, 2020 .

- ^ Aryeh Citron: Electricity on Shabbat. Retrieved July 6, 2018 .

- ↑ Standards and laws: DIN EN 81-70 for lifts. KONE GmbH, accessed January 6, 2019 .

- ^ ADA Compliance Elevators. In: ADA Compliance Directory. Retrieved on January 6, 2019 (English, “A visible and audible signal shall be provided at each hoistway entrance to indicate which car is answering a call. Audible signals shall sound once for the up direction and twice for the down direction or shall have verbal annunciators that say 'up' or 'down'. ”).

- ↑ a b c City Councilor Michael Ludwig & ZÜV Austria: Balance of the Vienna elevator retrofitting , tuev.at, July 15, 2009.

- ↑ elevator technology: evaluation , tuev.at, in 2009.

- ↑ TÜV Austria Academy: Safety Risks and Liability for Elevator Operators , ots.at, March 19, 2003.

- ↑ a b Law that enacts provisions on the construction and operation of elevators (Vienna Elevator Act 2006 - WAZG 2006) .

- ↑ Graphics: Elevator Technology : Elevator Evaluation Attachment 2 , tuev.at.

- ↑ APA / Editor: Terrible accident: Viennese woman was crushed in an elevator! , news.at, April 7, 2004.

- ↑ APA: Cruel accident in Vienna: woman was trapped in the lift cabin & bleeding to death cruelly , news.at, June 2, 2005.

- ↑ Viennese elevators only with inner door , October 12, 2006, orf.at

- ↑ Bottleneck looms : convert the lift in good time , July 15, 2009, orf.at.

- ↑ a b c Swiss Elevator Association : SNEL, EN 81-80 - Implementation in Switzerland (PDF; 34 kB), May 9, 2006, leitronic.ch.

- ↑ A lift consumes more electricity for standing still and waiting than when it is moving , http://www.energie-umwelt.ch/ , March 2011.

- ^ FAZ: At 72 km / h to the 95th floor

- ↑ a b c d e Emporis: The five highest elevator speeds in skyscrapers worldwide

- ↑ Hammetschwand Lift ( Memento from April 10, 2013 in the Internet Archive ).

- ↑ smallest passenger elevator , accessed on May 10, 2016.

- ↑ Record: Germany's narrowest elevator is in St. Georg Hamburger Abendblatt, December 23, 2016, accessed on December 25, 2016.

- ↑ Record fine against elevator constructors (tagesschau.de archive)

- ↑ interlift: Press release - interlift 2013: continuous growth through further internationalization ( memento of March 12, 2014 in the Internet Archive ), accessed on March 12, 2014.

- ↑ Holger Dambeck: Elevator is supposed to lift loads into space. Spiegel Online, October 26, 2005, loaded December 2, 2013.

- ↑ Brave idea . In: Der Spiegel . No. 10 , 1985, pp. 230–236 ( online report on the book: The Elevator. The History of Vertical Conquest ).