Traction current

Traction current refers to the energy supply for electric railways , mainly for driving traction vehicles . The electrical current is supplied via current collectors , which are connected to an overhead contact line or busbar (s). The circuit is closed again via the rails as a return conductor . For the return flow is isolated, z. B. in the London Underground , an additional busbar is used.

Historically, different electricity systems developed in different countries or at different railway companies, which are often independent of the public electricity network of a country.

history

After the introduction of the railroad in Germany in 1835, first attempts were made at the end of the century with various electrical systems and motors, with 15 kV with 16 2 ⁄ 3 Hertz prevailing in the German Reich in 1912 .

Due to the technically undemanding controllability and high standstill torque, which proved DC - series motor as the ideal drive for rail vehicles. However, such motors cannot withstand high voltages and therefore require higher currents , which in turn require large and expensive cross-sections of the overhead contact line or busbar. If the stopping points are further apart, it is therefore more economical to supply the locomotives with higher-voltage alternating current and to install a transformer . The energy required for its constant transport is less than losses in the catenary would be.

The weight of a transformer is essentially determined by its iron core. This in turn is approximately inversely proportional to the frequency of the alternating current. Due to the controllable technology in transformer construction, a frequency of 50 Hertz had established itself in European networks. However, due to the brush fires developing on the collectors , it was not possible to operate series motors in the required power range at a frequency of 50 Hertz. Therefore, traction current networks with 25 Hz and 16 2 ⁄ 3 Hertz were created. In order to be able to generate traction current from the 50 Hertz power grid with rotating synchronous converters , the division factors 2 and 3 were selected. The use of modern asynchronous converters with an integral division ratio, however, turned out to be problematic at high powers, so that the target frequency of many Networks has since been changed to 16.7 Hertz, with 16 2 ⁄ 3 Hertz being within tolerance.

The current state of the art in the field of power electronics makes the reduced frequency of the alternating current no longer mandatory. Modern vehicles are mostly equipped with direct current motors with a nominal voltage of 6 kV, with a transformer with 25 kilovolt primary voltage and a tap at 15 kilovolts, these can be equipped as multi-system vehicles. Switching the traction current to 25 kilovolts is currently not possible in the area of Deutsche Bahn, as the required increased safety distance between the overhead line and existing bridges is not given. However, larger distances are planned for new buildings. The pending Europe-wide standardization of traction current systems is a relatively minor problem in cross-border traffic, the additional costs for the transformer in multi-system vehicles are low compared to the costs for the multiple train control systems and the national approval procedures.

In addition, the timing of a possible changeover of traction current in Germany is influenced by the useful life of the older series with AC motors , which are difficult to convert. The series 103 , 141 and 150 have already been taken out of service, the series 110 , 140 , 139 and some of the younger examples of the 111 and the 151 remain among the standard locomotives . Even if the Reichsbahn series 112 , 114 , 143 and 155 are retired, only three-phase locomotives will remain in the Deutsche Bahn portfolio . A changeover is then relatively easy, in return there is no need to maintain an independent 110-kilovolt high-voltage network and the substations can be connected to the high-voltage networks of the general energy supply companies. Since the high-voltage networks have already been set up, there is no need for action and the decommissioning of the older series can take decades.

In the post-war period, the decision was made to replace large areas of steam locomotives with electric locomotives. At that time only 5% of the lines were electrified, so the choice of the electricity system was a new one. In order not to become dependent on RWE, minor technical disadvantages were accepted and an individual solution in Central Europe was set up an independent traction current network .

Power systems

DC voltage

On the vehicle side, DC voltage is the simplest solution. DC series machines have long been the best available electrical machines for vehicle propulsion. This has only changed with the gradually becoming available semiconductor power electronics since the 1970s. The power station of the Frankfurt-Offenbacher Trambahn-Gesellschaft, built in 1884, generated direct current with a voltage of 300 V for the first commercially operated electric tram line of the Frankfurt-Offenbacher Trambahn-Gesellschaft .

Since the vehicles needed direct current, it was previously obvious to supply them with direct current from the contact line . The greatest disadvantage of the direct supply of the vehicles with direct current is the low possible overhead line voltage, which increases the currents flowing with the same power and thus the losses in the contact line. Since no transformation can take place in the vehicle, the voltage is limited by the insulation properties of the insulating materials used in the motors, usually to 1500 volts or 3000 volts.

However, the lack of a main transformer in the vehicle does not have to be a disadvantage, because this means that the vehicle can be built shorter with the same output and can therefore drive through tighter curve radii. Furthermore, it is also possible to keep the clearance profile lower and to equip the traction vehicle with a continuous platform.

Where only relatively small vehicle outputs are required, for example on trams , or where large conductor cross-sections are used anyway for mechanical reasons, e.g. B. in busbar operation ( subway ), therefore mainly direct current is used. In addition, because of their proximity to the ground and the resulting small insulation clearances, busbars can only be operated with low voltages (usually 500 to 1200 volts). In trams, large insulation distances could be implemented, but a medium-voltage overhead line network in the confines of urban streets between buildings would be too dangerous. In the case of light rail vehicles, the smaller insulation distances result in a lower clearance profile and thus a considerable cost advantage when building inner-city tunnels.

Curving and the smaller clearance profile also play a role in electrified industrial railways. In Strossengleisen of opencast mines and especially in pit lanes even an often side catenary used the motive power units shall then also with extended pantographs only as high as the car. The low operating voltage is even an advantage here, since the flying construction of the stopes would make it difficult to implement expensive insulation measures.

The missing mass of the transformer, on the other hand, often has to be compensated for with ballast weights so that the vehicle does not skid when starting . The ballast weights can, however, be distributed unobtrusively on the vehicle floor.

Although these advantages of direct current operation cannot be played out on main railways , it is used in some countries, e.g. B. in Italy, Slovenia, the Netherlands, Belgium, Eastern Europe, Spain, South East England, Southern France, South Africa and Japan. This is for historical reasons, new lines for high-speed traffic were also built there with the power system 20-30 kilovolts and 50 or 60 Hertz.

In mainline railways with direct current operation, 3000 volts overhead contact line voltage is common. Only the Netherlands, Japan and France use 1500 volts, and south-east England only use 750 V (via busbars next to the tracks). Since the power of the locomotives is very high, as is typical for full railways, high currents flow in the contact line, which is why it has to be designed differently, often there are several conductor cables. The pantographs of the locomotives also have to be designed differently, since arcs do not extinguish themselves with direct current operation. Particularly powerful traction vehicles have to connect several pantographs to the contact line, which can cause problems due to contact line vibrations.

A major problem in direct current operation is the power and thus the speed control. One option that is always used in electric traction vehicles is the optional series and parallel connection of the traction motors. If there are more than two traction motors, these are usually only switched into two groups, since the insulation still only allows 3000 volts in parallel operation. With this switching option, the vehicle only offers three speed levels (only one motor / group, series connection, parallel connection). The obvious possibility of controlling the output of the motors more precisely by changing the operating voltage, as is done in AC operation by taps on the main transformer, is not possible in DC operation because the contact wire voltage is fixed.

Conventional DC vehicles therefore have at least one of the two other options for power control, sometimes both:

- On the one hand, the current can be limited by series resistors, which reduces the torque and thus the speed of the vehicle. The disadvantage is the high energy consumption in the intermediate gears, since the excess electrical energy is "burned". The advantage is that the resistors can also be used to brake the vehicle, as a result of which the mechanical braking system can be made smaller and is less subject to wear. Older tram vehicles in particular make use of this option; the resistors sit on the vehicle roof because of the waste heat.

- Alternatively or additionally, the torque and thus also the speed of the vehicle can be influenced by field weakening . The stable adjustment range is small with the series machine, more than three levels are rare.

This disadvantage of direct current operation does not apply to modern vehicles in which the direct current motors are fed with the help of power electronics via a chopper control or the direct current is converted into three-phase current with a frequency converter so that the simple and robust asynchronous motors can be used. Nevertheless, in modern multi-system traction vehicles, the power under direct current is usually lower because the disadvantage of higher currents to be transmitted relative to alternating current remains unchanged.

The power supply of direct current operated railways has been carried out since the 1920s by rectification in substations fed by the public network, with mercury vapor rectifiers being used in the past and semiconductor rectifiers today . The substations are usually fed from the medium-voltage network , even on mainline railways .

AC voltage

As for the public electricity supply, alternating voltage can be easily generated ( generator ) and converted and distributed in transformers .

The power system of the drive must be distinguished from that of the energy supply. For every application there is a suitable option for coupling any power system on the drive and network side using power electronics . In the case of electronically controlled rail vehicles with corresponding inverters , the electrical energy flow can take place in both directions, i. H. When accelerating, the vehicle draws electrical energy from the supply system and when the vehicle brakes, part of the electrical energy is fed back into the network.

Single phase systems

AC voltage with standard industrial frequency

The world's largest distribution in railways has AC voltage with the national network frequency (mostly 50 Hertz, in the USA and sometimes in Japan 60 Hertz).

The operating voltage is mostly 25 kilovolts, in the USA ( Lake Powell Railroad ) and South Africa ( ore railway Sishen – Saldanha Bay ) there are railways with 50 kilovolts.

The advantage of using the standard network frequency is that it can easily be fed from the public electricity network, at least in theory. In practice, however, there is a risk of unbalanced loads in the industrial network. To prevent it from 20 to 60 kilometer be catenary sections alternately to the three different phases of the 50 Hz network connected. In the overhead line, phase protection lines are arranged between the contact line sections , which the traction vehicles must drive with momentum and the main switch switched off. 50 Hertz railways can only be supplied from the public power grid at points with the highest network output, where the unbalanced load is insignificant in percentage terms. Otherwise, the railway's own high-voltage lines are required.

At first it was disadvantageous that the necessary motors were large and not suitable for the high frequency, so the alternating current had to be rectified and power electronics were required for this. This required power rectifiers, a technology that was only mastered in the early 1940s. In the beginning, mercury vapor rectifiers were also used; Only in the 1960s did semiconductor rectifiers gain acceptance.

The voltage was initially regulated via variable transformers, as in the case of the reduced frequency operated locomotives, later regulation via phase control, typically with thyristors, was used.

Alternating current with reduced frequency

In some European countries (Germany, Austria, Switzerland, Sweden, Norway) the railways run on single-phase alternating current at a frequency of 16 2 ⁄ 3 Hertz or 16.7 Hertz instead of 50 Hertz , which is lower than that of the public power grids . An exception is the Rübelandbahn , which operates at 50 Hertz and 25 kV and is supplied directly from the public network.

There are also traction current systems with 25 Hertz. The New York - Washington section of the east coast network in the USA and the Mariazell Railway are still operated with this frequency today .

Since AC voltage allows the contact wire voltage to be transformed to the voltage suitable for the motors, a significantly higher contact wire voltage can be selected than with direct current operation (initially around 5000 volts, now 15 kilovolts in the countries mentioned at the beginning of the section). The transformers were designed as variable transformers (see also tap changer for power transformers ) and enable voltage regulation without the use of loss-making resistors. The mass of the transformers is the power-limiting factor in electric locomotives , with the exception of modern conversion using semiconductors .

The frequency, which is lower than that of the public power grid, was chosen at the beginning of the 20th century because it was not possible to operate large single-phase electric motors at high frequencies, as the so-called transformer voltage caused excessive sparking on the commutator . For historical reasons, machine converters or generators were used whose pole division divided the network frequency of 50 Hertz into thirds, i.e. 16 2 ⁄ 3 Hertz as the frequency of the traction current. However, the actual value of the frequency fluctuated depending on the constant speed of the generator.

When converting rail energy using synchronous-synchronous converters, the frequency of the rail current is in practice exactly one third of the current network frequency of the national supply network. Such converters are in operation in Sweden and north-east Germany , among others .

Despite the greater prevalence of the 50 Hz system, not all experts today consider the 16.7 Hz system to be inferior. As already mentioned, supplying a railway line with 50 Hz from the national network is not without problems due to the risk of unbalanced loads. The reduced network frequency also has the advantage that the voltage drops caused by reactive power are only one third as large. On the other hand, the transformers have to be larger and the substations cannot be supplied directly from the public grid. For this reason, completely independent networks with traction power lines are often maintained. The traction current network also makes it possible to produce or buy electricity at the cheapest place. The masts in this network usually have two pairs of conductors (2 × single-phase lines).

A study commissioned by the Federal Network Agency showed that the traction current network is only suitable for balancing renewable energy across the region with great effort .

16 2 ⁄ 3 Hz versus 16.7 Hz

The network frequency of the traction current network, like the 50 Hertz network frequency of the European interconnected network , is kept within a certain tolerance range. The current actual network frequency depends, among other things, on the current demand and the current supply of electrical energy and therefore fluctuates. The tolerance range for 16.7 Hertz systems in the traction current network is 16.5 Hertz to 16.83 Hertz during 99.5% of a year and 15.67 Hertz to 17.33 Hertz during the remaining 0.5% of a year.

Converters, among other things, are used to balance the power between the traction current network and the European network . This is a mechanical combination of two rotating electrical machines , as shown in the adjacent figure, one of which works as a motor and one as a generator. This enables power to be transmitted between the various power grids with different grid frequencies. With the double-fed asynchronous machines used , a slip is necessary. These machines are used instead of synchronous machines in order to be able to control the power flow and its direction on the converter. The power flow is set by means of a regulator via the rotor circuit with slip rings .

Since the setpoint of the network frequency in the European interconnected network is exactly three times the value of the former setpoint 16 2 ⁄ 3 Hertz in the traction current network, at 50 Hertz, the slip required for the asynchronous machine was zero in the past, particularly at times of low load, such as at night has been. In this synchronous run, an undesired direct current component occurs on one phase in the rotor circuit, which leads to an uneven thermal load on the machine and, in extreme cases, can trigger thermal operational protection and an emergency shutdown.

By shifting the setpoint frequency of the control since 1995 from 16 2 ⁄ 3 Hertz to 16.7 Hertz now, a low slip in the asynchronous machine is guaranteed even in low-load operating times; this corresponds to a deviation of 0.2% and is within the permissible tolerance range. As a result, in this stationary case, the slowly rotating direct current component is distributed evenly over the phases of the rotor circuit and the brushes of the slip rings, which also distributes the thermal load and prevents local peaks. Even with the new setpoint frequency of 16.7 Hertz, undesired synchronous operation can briefly occur in the machine set if the frequency fluctuates, but this is only a temporary event due to the control, which cannot occur as a steady-state operating state. This keeps the thermal load on the components of the converter within permissible limits.

The fact that exactly 16.7 Hertz was chosen has no deeper meaning. If the shift was too great, however, there would have been problems with locomotives whose technology is designed for a frequency of 16 2 ⁄ 3 Hertz. The traction current networks of Germany, Austria and Switzerland switched the target frequency to 16.7 Hertz on October 16, 1995 at 12:00 . With the HVDC close couplings based on power electronics , the changeover of the rail frequency does not play a role, as does the sections that are electrically isolated from the rest of the rail network and that are operated with rotating converters from synchronous machines.

Two-phase systems

Two-phase systems are also known as "two-voltage systems" or autotransformer systems. Such systems can be found on various high-speed rail lines electrified with 50 Hertz in France as well as in Belgium, the Netherlands, Luxembourg and Italy. For the networks operated at 16.7 Hertz, only one pilot system is in operation in Germany between Stralsund and Prenzlau .

Three-phase systems (three-phase current)

Three-phase current, or more precisely three-phase alternating current , is almost predestined for railroad drives due to the good properties of the three-phase motor, because asynchronous motors are very robust and require little maintenance, because they do not need brushes and are relatively light in weight in relation to their performance.

Use of externally generated three-phase current

Most historical applications of the three-phase drive worked with a supply line via multi-pole overhead lines . The disadvantage here was that asynchronous motors can only be operated economically at certain speeds that are dependent on the frequency. Accordingly, to change the driving speed, the frequency would have to be changed on the power plant side as long as frequency conversion on the locomotive was not possible. However, this was only suitable for experiments, not for practical operation. Due to a special circuit of the motors (pole changing), they can be designed for several speeds, but a finely stepped or continuous change as with DC motors is not possible.

Another disadvantage of a three-phase railway system is the need for a three-pole power supply, which when the rails are used as one of the poles requires a two-pole overhead contact line. However, this is complicated (especially at switches and crossings) and prone to failure (risk of short circuits).

In fact, three-phase traction current networks were only used to a very limited extent: In northern Italy there was a larger three-phase system for a long time from 1912 to 1976 (3600 volts 16 2 ⁄ 3 Hertz). The Gornergratbahn (750 volts 50 Hertz) and the Jungfrau Railway (1125 volts 50 Hertz) still run on three-phase current today, as do the Chemin de Fer de la Rhune (3000 volts 50 Hertz) in the French Pyrenees and the Corcovado mountain railway (800 volts 60 Hertz).

In the years 1901 to 1903 there were test drives with three-phase high-speed railcars on a military railway between Marienfelde and Zossen near Berlin. A three-pole overhead line with wires lying one on top of the other, which were tapped at the side, was used. On October 28, 1903, a world speed record for all means of transport was set there at 210.2 km / h, which was only broken in 1931 with the rail zeppelin, which reached 230 km / h.

For the Passion Play in 1900, the Ammergau Railway was electrified with three-phase current in 1899 . After the practical operation failed, Siemens-Schuckertwerke successfully converted the power supply and the vehicles from 1904–1905 to single-phase AC voltage with 15 Hertz.

Three-phase drive with on-board three-phase conversion

By using power electronics , modern locomotives can use the advantages of three-phase current in any traction current network without having to accept its disadvantages when it is supplied to the vehicle. Voltage and frequency can be continuously regulated electronically ( frequency converter ). This type of drive has become generally accepted today. The first locomotive that converted single-phase alternating current with power electronics on board into three-phase current was the test locomotive Be 4/4 12001 of the Swiss Federal Railways in 1972 . The first units of the German Federal Railroad's 120 series followed in 1979 . There were also locomotives in which the on-board conversion was carried out with rotating converters.

Power supply

The traction current can either be provided centrally via traction power stations and large frequency converters and then distributed via a separate traction current network . This happens in countries where the frequency of the traction current differs from the public network, e.g. B. Germany, Austria, Switzerland.

In the decentralized structure, energy is drawn from the public grid. The substations at the feed-in points have static converters or rotating converters in which the voltage and frequency of the general electricity network is transformed into traction current ( decentralized converter or converter stations ). If the trains and the public network are operated at 50 Hz, one transformer is sufficient; a traction current network is then not necessary. This solution is therefore favored in Great Britain, Northern France and Southeast Europe, where the overhead line voltage is 25 kV. This solution is also favored for direct current railways with 1.5 kV (including in the Netherlands and southern France) and 3 kV (for example in Belgium, Poland and Spain).

The main difference to the centrally supplied traction current network is that the converter stations, in particular for phase synchronization, are only connected in parallel with the same converter stations via the overhead line. Separate traction power lines or traction power networks are not available here. This is practiced in Sweden, Norway, Brandenburg, Mecklenburg-Western Pomerania and parts of Saxony-Anhalt. In the past, the systems were largely controlled on site, today they are locally separated in the control centers .

Central supply

The traction current network with central supply is fed from power plants that are specially designed for traction current and in Germany, Austria and Switzerland have a frequency that differs from the rest of the electricity network.

The energy is transported via traction power lines to the substations on the railway line. In the substation, the voltage of the railway power line is transformed into contact wire voltage and fed into the overhead line . The traction current network therefore enables energy to be transported to other regions without frequency conversion. The converter or converter plants used are referred to as central converter or converter plants due to their use in the power generation network.

The switchgear was previously controlled in the respective power generator or in small remote control units and today in control centers . The disadvantage of this structure is that if a supply unit fails, the entire network can be affected.

There are traction current networks in Germany, Austria and Switzerland (16.7 Hertz), these are also connected to each other.

Electricity for auxiliary systems

For reasons of network availability and operational safety, the traction power supply for the traction and the ancillary systems are usually managed separately. In addition, the European largely uniform network with a frequency of 50 Hertz is not compatible with all traction supply networks and their various frequencies.

Application examples

The Mariazellerbahn has its own traction current network with 25 Hertz single-phase alternating voltage . On this railway, the voltage in the conductor cables of the traction power lines mounted on the overhead line masts is 27 kilovolts and in the overhead line 6.5 kilovolts.

In the USA, some lines of the former Pennsylvania Railroad between New York, Philadelphia and Washington are still operated with single-phase alternating voltage of reduced frequency (25 hertz, although the frequency of the public power grid in the USA is 60 hertz), whereby only passenger traffic runs with electric traction . These railways also have their own high-voltage network; the conductors of the traction current high-voltage lines are mostly mounted on the overhead line masts.

The Italian Railways possessed 1902-1976 for the supply of their electrified with AC lines (3600 volt 15 Hertz) in northern Italy via a powered with 60 kilovolts traction power network, which has been fed from hydropower plants and a thermal power plant. Mobile substations were also used to feed the catenary.

In the case of railways that are operated with single-phase AC voltage of mains frequency or DC voltage, the energy required for operation in the substations is obtained by linking the phases of the three-phase system (in the case of AC railways) and with rectification (in the case of DC railways). In these cases, there are only a few dedicated traction power lines.

Railway power plants

In order to provide traction current, some railway companies or electricity generators who cooperate with them operate special power plants . The traction current generators for alternating current with reduced frequency are considerably larger than those for the public power grid, the associated turbines are custom-made.

In some cases there are combined systems that can optionally also generate ordinary mains electricity. Furthermore, the DB power plants are networked with those of the Austrian and Swiss Federal Railways and can exchange traction current directly.

Converter / converter plants

As of 2018, around a third of traction current was purchased from the public 50 Hz network via the electricity exchange. The interface between the public high or extra high voltage network and the traction current high voltage network is formed by a traction current converter or traction current converter plant . While three-phase alternating current with voltages such as 220 kilovolts or 380 kilovolts and a frequency of 50 Hertz are common for the public high-voltage network, traction current high-voltage networks almost everywhere only have one alternating current phase, with a frequency of 16.7 in Germany, Austria and Switzerland Hertz and voltages of 66, 110 or 132 kilovolts are common. In addition to the converters , which are now considered to be old , in which the networks between generator and motor are mechanically coupled by rotating masses between the two power systems, systems without mechanical parts have been used in Germany since 2002, which convert the electricity solely with electronic components. In this case one speaks of converters . The converter stations are gradually being replaced by converter stations.

Railway power converter plants in Germany

Central converter / converter plants

| investment | Year of commissioning |

Applied technology | Maximum transmission capacity |

State location |

Remarks |

|---|---|---|---|---|---|

| Hamburg-Harburg | Converter |

Hamburg 53 ° 26 ′ 57 ″ N, 10 ° 0 ′ 6 ″ E |

|||

| Bremen | 1996/2012 | GTO thyristor | 100 MW / 80 MW |

Bremen 53 ° 7 ′ 48 ″ N, 8 ° 40 ′ 49 ″ E |

Mittelbüren power plant location |

| Chemnitz | 1965 | Converter | Out of service |

Saxony 50 ° 51 ′ 43 ″ N, 12 ° 56 ′ 18 ″ E |

04/05/2016: EBA plan approval for termination without replacement |

| Taught | Converter / converter | 101 MW |

Lower Saxony 52 ° 22 ′ 53 ″ N, 9 ° 57 ′ 12 ″ E |

37 MW rotating / 2 × 32 MW static |

|

| Limburg | IGCT converter | 120 MW |

Hesse 50 ° 24 ′ 20 ″ N, 8 ° 4 ′ 3 ″ E |

8 × 15 MW | |

| Bark | Converter | 25 MW |

Hesse 51 ° 3 ′ 7 ″ N, 9 ° 17 ′ 2 ″ E |

2 × 12.5 MW | |

| Jübek | Inverter (GTO) | 14 MW |

Schleswig-Holstein 54 ° 33 ′ 26 ″ N, 9 ° 24 ′ 34 ″ E |

first traction current converter | |

| Dresden - Niedersedlitz | 1977 | Converter | 120 MW |

Saxony 50 ° 59 ′ 39 ″ N, 13 ° 50 ′ 6 ″ E |

3 × 40 MW 1 × out of service |

| Cologne | 1957/2011 | Converter / converter | 75 MW / 80 MW |

North Rhine-Westphalia ? |

|

| Düsseldorf - Gerresheim | Converter |

North Rhine-Westphalia 51 ° 13 ′ 17 ″ N, 6 ° 50 ′ 12 ″ E |

|||

| To sing | Converter |

Baden-Württemberg 47 ° 45 ′ 29 ″ N, 8 ° 52 ′ 54 ″ E |

|||

| Karlsfeld | 1999 | IGCT / GTO thyristor | 232 MW |

Bavaria 48 ° 12 ′ 55 ″ N, 11 ° 26 ′ 5 ″ E |

100 MW + 132 MW, operator: E.ON |

| Saarbrücken | Converter |

Saarland 49 ° 14 ′ 38 ″ N, 6 ° 58 ′ 39 ″ E |

|||

| Nuremberg - Gebersdorf | 2011 | Converter | 60 MW |

Bavaria 49 ° 25 ′ 23 ″ N, 11 ° 0 ′ 31 ″ E |

2 × 30 MW, operator: E.ON |

| New Ulm | 1972 | Converter |

Bavaria 48 ° 23 ′ 51 ″ N, 10 ° 1 ′ 16 ″ E |

||

| Neckarwestheim | 1989 | Converter / converter | 86 MVA |

Baden-Württemberg Converter: 49 ° 2 ′ 22 ″ N, 9 ° 10 ′ 41 ″ O Converter: 49 ° 2 ′ 16 ″ N, 9 ° 10 ′ 39 ″ O |

Converter on the area of the Neckarwestheim nuclear power plant |

| Weimar | 1973 | Converter | Out of service |

Thuringia 50 ° 59 ′ 28 ″ N, 11 ° 20 ′ 37 ″ E |

used both centrally and decentrally |

| Karlsruhe | 1957 | Converter | 53 MW |

Baden-Württemberg 48 ° 58 ′ 48 ″ N, 8 ° 22 ′ 30 ″ E |

two converter sets (generator: 26.5 MVA, motor: 31.25 MVA) |

| Karlsruhe | Converter | 50 MW |

Baden-Wuerttemberg 48 ° 58 ′ 49 ″ N, 8 ° 22 ′ 33 ″ E |

2 × 25 MW (machine 2 has an additional generator for its own use) | |

| Hof (OT: Unterkotzau ) | 2013/2014 | Converter | 37 MW |

Bavaria 50 ° 20 ′ 40 ″ N, 11 ° 54 ′ 55 ″ E |

2 × 18.5 MW (from E.ON's 50 Hz network) |

Decentralized converter / converter plants

The following converter plants come from the network of the Deutsche Reichsbahn, which is largely fed directly from the 50-Hertz state network through conversion and were initially operated in three shifts with two-man staff, later one-man staff, and partly from the mid-1990s operated remotely. The converter plants come from more recent times and are increasingly replacing them or are being newly built across Germany.

| investment | Year of commissioning |

Applied technology | State location |

Remarks |

|---|---|---|---|---|

| Adamsdorf | 1984 (converter) 2011 (converter) |

Converter / converter |

Mecklenburg-Western Pomerania 53 ° 24 ′ 31 ″ N, 13 ° 2 ′ 45 ″ E |

Remote control operation |

| Anklam | Converter |

Mecklenburg-Western Pomerania 53 ° 51 ′ 4 ″ N, 13 ° 42 ′ 35 ″ E |

Commissioning on June 25, 2010 | |

| Berlin-Rummelsburg | 1984 | Converter |

Berlin 52 ° 29 ′ 12 ″ N, 13 ° 30 ′ 34 ″ E |

last constantly manned converter plant; Closed in 2011 |

| Bützow | Converter |

Mecklenburg-Western Pomerania 53 ° 49 ′ 31 ″ N, 11 ° 59 ′ 4 ″ E |

Remote control operation | |

| cottbus | 1989 (converter) 2012 (converter) |

Converter / converter |

Brandenburg 51 ° 45 ′ 0 ″ N, 14 ° 17 ′ 13 ″ E |

Remote control operation |

| Doberlug-Kirchhain | 1981 (converter) 2008 (converter) |

Converter / converter |

Brandenburg 51 ° 36 ′ 59 ″ N, 13 ° 33 ′ 25 ″ E |

The constantly manned converter plant was replaced in 2008 by a remote-controlled converter plant |

| Eberswalde | 1987 | Converter |

Brandenburg 52 ° 50 ′ 40 ″ N, 13 ° 48 ′ 1 ″ E |

by supplying the feed area from the central network, out of order |

| Falkenberg / Elster | 1987 | Converter |

Brandenburg 51 ° 34 ′ 50 ″ N, 13 ° 15 ′ 28 ″ E |

Switch to remote control, due to the supply of the feed area from the central network, out of order in 2002; Demolished in 2008 |

| Frankfurt (Oder) | 2012 (converter) | Converter | Brandenburg | Converter out of operation since 2015 |

| Halle (Saale) | Converter | Saxony-Anhalt | after the reunification (GDR) out of service; partially demolished | |

| Lalendorf | Converter |

Mecklenburg-Western Pomerania 53 ° 45 ′ 15 ″ N, 12 ° 23 ′ 55 ″ E |

tore off | |

| Löwenberg | Converter |

Brandenburg 52 ° 54 ′ 6 ″ N, 13 ° 11 ′ 18 ″ E |

out of operation due to supply of the feed area from the central network | |

| Ludwigsfelde (Genshagener Heide substation) | 1981 | Converter |

Brandenburg 52 ° 20 ′ 6 ″ N, 13 ° 16 ′ 38 ″ E |

out of operation due to the supply of the feed area from the central network; tore off |

| Lübeck-Genin | 2008 | Converter |

Schleswig-Holstein 53 ° 50 ′ 21 ″ N, 10 ° 39 ′ 14 ″ E |

|

| Magdeburg | 1974 | Converter |

Saxony-Anhalt 52 ° 9 ′ 13 ″ N, 11 ° 39 ′ 35 ″ E |

Remote control operation |

| Neustadt (Dosse) | Converter |

Brandenburg 52 ° 50 ′ 51 ″ N, 12 ° 27 ′ 25 ″ E |

Remote control operation | |

| Oberröblingen | Converter |

Saxony-Anhalt 51 ° 26 ′ 44 ″ N, 11 ° 17 ′ 44 ″ E |

Remote control operation | |

| Prenzlau | Converter |

Brandenburg 53 ° 20 ′ 0 ″ N, 13 ° 52 ′ 22 ″ E |

Remote control operation | |

| Rosslau (Elbe) | Converter |

Saxony-Anhalt 51 ° 53 ′ 52 ″ N, 12 ° 14 ′ 30 ″ E |

Remote control operation | |

| Rostock | 1985 (converter) 2011 (converter) |

Converter / converter |

Mecklenburg-Western Pomerania 54 ° 3 ′ 53 ″ N, 12 ° 8 ′ 39 ″ E |

Remote control operation |

| Schwerin | 1987 | Converter |

Mecklenburg-Western Pomerania 53 ° 35 ′ 40 ″ N, 11 ° 23 ′ 13 ″ E |

Remote control operation |

| Senftenberg | 1988 | Converter |

Brandenburg 51 ° 31 ′ 59 ″ N, 14 ° 1 ′ 15 ″ E |

as a converter plant out of operation since 2015, only 15 kV switch post |

| Stendal | Converter |

Saxony-Anhalt |

Remote control operation | |

| Stralsund | Converter |

Mecklenburg-Western Pomerania 54 ° 17 ′ 11 ″ N, 13 ° 5 ′ 25 ″ E |

Remote control operation | |

| Wittenberg | 1978 | Converter |

Saxony-Anhalt 51 ° 52 ′ 30 ″ N, 12 ° 41 ′ 20 ″ E |

Out of service |

| Weimar | 1973 | Converter |

Thuringia 50 ° 59 ′ 28 ″ N, 11 ° 20 ′ 37 ″ E |

used both centrally and decentrally; Out of service |

| Wittenberg | 1987 | Converter |

Brandenburg 52 ° 59 ′ 47 ″ N, 11 ° 46 ′ 8 ″ E |

Remote control operation |

| Wolkramshausen | 2002 (converter) | Converter / converter |

Thuringia 51 ° 26 ′ 20 ″ N, 10 ° 44 ′ 9 ″ E |

Converter plant 2002 replaced by a converter plant |

| Wünsdorf | 1982 | Converter |

Brandenburg 52 ° 10 ′ 22 ″ N, 13 ° 27 ′ 44 ″ E |

out of operation due to the supply of the feed area from the central network; Demolition from 2008 |

| Wustermark (Priort) | Converter |

Brandenburg 52 ° 32 ′ 28 ″ N, 12 ° 58 ′ 25 ″ E |

Out of service |

Railway power converter plants in Austria

A number of converter plants are operated by ÖBB Infrastruktur AG .

Auhof

In the 1950s, it was necessary to build converter plants in eastern Austria for the electrical supply of the Western Railway and later the Southern Railway . The Auhof converter plant in Vienna's 13th district began operations in 1956 with two converter sets. In 1960 it was expanded with a third set of converters. Since the machines had to run almost constantly under full load, the ÖBB recognized in the 1980s that renovation would be pending in the next few years. In 1990 the ÖBB decided to overhaul the converter plant while increasing the output from 61.5 megawatts to 90 megawatts. After construction began in September 1990, two converter sets were put into operation in 1998 and the third converter set in August 2000. The Auhof traction power converter plant is located immediately to the south of the “Umspannwerk Wien-West or Auhof” of Wiener Netze and is therefore confused with it.

Bergern

In order to cover the increased demand for electricity due to further electrification, densification of local traffic, increases in speed and improvements in comfort through the use of air-conditioned passenger coaches, it was necessary to set up an additional energy source for traction current in eastern Austria. The Bergern converter plant was built about six kilometers west of Melk between 1979 and 1983 . The location of the converter plant resulted from the feed of the Danube power plant Melk and the location of the joint facility with Energieversorgung Niederösterreich Aktiengesellschaft (EVN AG) and Verbund AG .

Kledering

The growing demand for energy in eastern Austria and the construction of the central marshalling yard in Vienna led to the decision to build another rail supply system in the Vienna area at the end of the 1980s. The Kledering converter plant was built between 1986 and 1989 and is located directly next to the central marshalling yard on the Ostbahn . After the first two machine sets were put into operation in 1989, they were completed in 1990 with the third set of converters.

Ötztal

In the municipality of Haiming , around 50 kilometers west of Innsbruck , the Ötztal converter plant was built between 1992 and 1995 . The location next to the Arlbergbahn was chosen because of the 110-kilovolt traction power line passing 600 meters away. The system comprises two sets of machines and also serves as a substation for powering the Arlbergbahn.

Saint Michael

Already during the construction of the Sankt Michael substation in 1963, consideration was given to the expansion with a converter plant. The converter station in Sankt Michael, built between 1972 and 1975, is used to supply traction power to the federal states of Styria and Carinthia . The location in Upper Styria resulted from the crossing of two routes of 110 kilovolt traction power lines and the proximity of the Hessenberg substation owned by Verbundgesellschaft.

Uttendorf / Schwarzenbach

In 2015 was at ÖBB train power plant Uttendorf of the power plant group Stubachtal im Pinzgau the frequency Uttendorf put into operation, the tethered to the 110-kilovolt underground power grid power plant group with the 380-kilovolt three-phase supply of Austrian Power Grid connects. The 50-Hertz high-voltage road is fed into the new transformer station in Schwarzenbach, around 2.8 kilometers from the power station, where the traction current system voltage is stepped up from 110 kilovolts to the overland network voltage of 380 kilovolts. The system enables the transfer of traction current generated in the Stubachtal to the eastern part of Austria via the 50 Hz network with its lower transmission losses. Although referred to as a frequency converter, it is a modern electronic converter with an output of 48 megawatts.

Railway power converter plants in Switzerland

There are 10 traction power converter plants in Switzerland. These are:

- Rupperswil

- Seebach

- Wimmis

- Kerzers

- Giubiasco

- Angles

- Massaboden (power plant with converter)

- Grafenort (e.g.)

- Bever (RhB)

- Landquart (RhB)

Substations (Uw)

AC railways

A substation corresponds roughly to a substation in the public network. A substation transforms the energy from the high-voltage network into the overhead line network.

There are AC -Unterwerke used, the voltages between three and 50 kilovolts or frequencies produce 16.7 (DB, SBB and ÖBB), 25, 50 or 60 Hertz. In Germany and Austria, substations are only responsible for changing the voltage. In parlance, converter stations are therefore often referred to as substations, but this is only a generalization.

In the case of a DB, SBB or ÖBB traction power substation, single-phase alternating voltage from the high-voltage network (see above) is transformed from 132, 110 or 66 kilovolts for feeding into the contact wire down to 15 kilovolts, the frequency of 16.7 Hz does not change.

Mobile substations (fUw) are also used in Germany, Switzerland and some other countries. They are designed in such a way that they can also be relocated to another location via the rail network without major adjustments.

In Switzerland, connections to the high-voltage network have been prepared at various points so that the mobile substations can be moved to other locations in the event of special requirements (revision of fixed substations, temporary large-scale transport). SBB currently has 18 mobile substations, consisting of a four-axle command car and an eight-axle transformer car.

DC railways

In the case of substations for DC voltage systems ( S-Bahn Berlin and Hamburg , trams , light rail vehicles , underground trains , industrial railways in mining), the electrical energy is supplied from the medium-voltage network of the distribution network operator as three-phase alternating current . The overhead line voltage is generated via converter transformers and six-pulse bridge rectifiers . Silicon diodes are used as rectifiers . In the past, rotating converters and water-cooled or air-cooled mercury vapor rectifiers were used for this purpose.

The polarity for connecting the catenary and the rails as a return line can be freely selected. Technically and economically there is no preferred variant. Most railway operators have the positive pole on the contact line. Examples of the negative pole on the catenary are the S-Bahn Berlin, as well as the trams in Darmstadt and Mainz.

To avoid stray current corrosion and premagnetization of AC systems by stray direct currents, the pole of the direct voltage connected to the track, which also serves as a return line, is galvanically isolated from the earth along the tracks and only in the substation via diodes or directly with non-system-earthed parts (e.g. water pipes ) connected. To protect people against inadmissibly high contact voltages, voltage limiting devices must be used so that the rail potential between the running rails as return line and the building ground does not exceed 120 V.

Operational management of traction power networks

As with all other electrical power supply networks, the operation of the traction current network is monitored from one or more control centers. Depending on the country and also from the history, these have different names such as load distribution, network control center, central switching center, etc. The control centers have, among other things, the task of monitoring the switching status of the networks, ensuring the supply through scheduled switching operations and switching operations in the event of a fault, and plannable switching to coordinate from the point of view of security of supply.

Germany

The main control room (HSL) of DB Energie is located at the company's headquarters in Frankfurt / Main. There are seven regional central switching points (ZES) (as of 2015) in the Deutsche Bahn network. The computer-controlled ZES are located in Berlin, Cologne, Munich, Leipzig, Lehrte, Borken (Hesse) and Karlsruhe.

Austria

Central control center Innsbruck

As early as 1925, when the Arlbergbahn began to operate electrically , the load distributor in Innsbruck was put into operation to commence the interconnected operation of the Spullersee and Schönberg power plants . This had the task of controlling electricity generation, regulating the synchronicity of the individual power stations and ensuring that the substations were supplied with the required traction current.

Since August 1998 the load distributor (central control center Innsbruck) has been housed in one of the most modern control rooms in Europe. From here, the machine use of the power and converter plants is centrally controlled according to the load situation in the rail network and optimized via online programs. The Innsbruck control center also monitors all 110 kilovolt and 55 kilovolt transmission lines of the ÖBB traction current network and makes the necessary switching. The control of work assignments or switching operations in the event of a malfunction to isolate errors and restore supplies for all Austrian transmission lines are thus in one hand. If power plants or supply lines fail due to natural events (heavy rainfall , thunderstorms , avalanches ), large-scale supply bottlenecks can be prevented by rapid intervention. In addition, necessary measures, such as troubleshooting orders to the responsible employees (outside of normal working hours to the on-call service), operational restrictions, changes to the energy schedule, can be carried out as quickly as possible.

Regional control centers

In addition to the central control center in Innsbruck, ÖBB has installed four regional control centers. These have the task of balancing the load between the 56 substations.

Switzerland

The central network control center (ZLS) of the SBB is operated by the energy division of the infrastructure division in Zollikofen . From there the power plants and almost all converter plants can be controlled remotely.

Signal power supply

In some countries, the signal boxes are also supplied by their own traction power networks. Where the trains are operated with AC voltage, a frequency that is not a harmonic of the traction frequency is often used for the signal power supply in order to avoid influencing the track circuits . For example, the signal systems on the Northwest Corridor in the USA are operated at 91⅔ Hertz , and distribution is carried out at 6.9 kilovolts . The traction frequency is 25 Hertz.

Energy consumption and origin at Deutsche Bahn

Deutsche Bahn is one of the largest consumers of electricity in Germany and in 2018 consumed around 8,200 GWh for traction electricity and 18,000 GWh for stationary energy. Since only 60% of the route is electrified, 430 million liters of diesel are also used. There are 20,000 electric trains and 7,500 diesel locomotives.

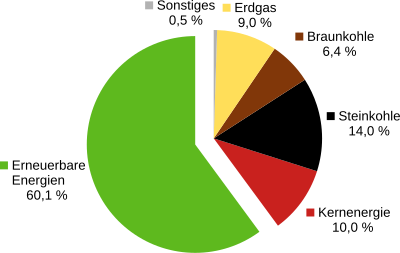

In 2017, the traction power of DB Energie GmbH consisted of 10.7% EEG surcharge-financed electricity, 32% from other renewable energies. 32% was generated from coal-based power generation and 13.4% from nuclear energy, 11.4% comes from natural gas, 0.5% from other fossil fuels.

The expenditure for energy is around 1.1 billion euros, with total expenditure of around 37 billion euros, that is almost 3% of the total expenditure of Deutsche Bahn (2012).

The costs per kilowatt hour for Deutsche Bahn AG in 2012 were 8.75 ct at 12,000 gigawatt hours. For comparison, the average price for industrial electricity in Germany in 2012 was around 13 ct / kWh.

Railway power and EEG levy

With the current EEG, Deutsche Bahn AG is largely exempt from the EEG surcharge , as electricity-intensive manufacturing companies and railways are to be protected in their international and intermodal competitiveness through a special equalization scheme. On the basis of these regulations ( § 63 with associated regulations §§ 64 - 69 EEG 2014), the EEG surcharge is only calculated in full for energy consumption up to one gigawatt hour per year. For the energy share between one and 10 gigawatt hours, 10% of the EEG surcharge has to be paid, between 10 and 100 gigawatt hours only 1% of the EEG surcharge. The railway's own facilities are generally exempt from the EEG surcharge.

According to the energy supply contracts of DB Energie , a surcharge of 1.0 cents or 0.1 cents per kilowatt hour (with an approved hardship application according to §§ 63 ff. EEG 2014) is levied as the EEG surcharge .

At the beginning of 2013, Environment Minister Altmaier proposed a change in the “energy price brake”, both regulations - ie the partial exemption from the EEG surcharge for electricity-intensive companies and the exemption for self-generation systems. Deutsche Bahn AG saw itself burdened with additional expenditure of 500 million euros annually, of which 137 million euros would result from the possible elimination of the reduced EEG surcharge and 350 million euros from the possible introduction of the EEG surcharge for self-generated electricity.

See also

- List of traction power systems

- Railway power systems:

- Traction power line

- List of formerly electrified railway lines

- Chronicles

- History of the electric drive of rail vehicles

- Chronicle of the line electrification of the Deutsche Bahn AG

- Chronicle of the route electrification of the Deutsche Bundesbahn

- Chronicle of the line electrification of the Deutsche Reichsbahn (until 1945)

- Chronicle of the route electrification of the Deutsche Reichsbahn in the GDR area

- Chronicle of the electrification of railway lines in Austria

- Chronicle of the electrification of railway lines in Switzerland

- Electric railway operation in Silesia

- trolleybus

literature

- Hartmut Biesenack: Energy supply for electric railways , Vieweg + Teubner-Verlag, 2006 ISBN 3-519-06249-6

Norms

- EN 50163: Railway applications - supply voltages of railway networks (Germany: DIN EN 50163; VDE 0115-102: 2005-07 and DIN EN 50163 / A1 VDE 0115-102 / A1: 2008-02; Austria: ÖVE / ÖNORM EN 50163 edition: 1 April 2008)

Web links

- 10 years of electrical reunification of Germany (PDF file; 322 KiB)

- Private collection on traction current

Individual evidence

- ^ A b Peter Thomas: Deutsche Bahn: 300 km / h with the flow of history . In: FAZ.NET . May 1, 2017, ISSN 0174-4909 ( faz.net [accessed February 5, 2020]).

- ↑ RAILWAY ELECTRIFICATION: The Hertz cramp. In: Der Spiegel . October 7, 1953 .

- ↑ M. Link: For the calculation of contact line vibrations with the help of frequency-dependent finite elements . In: Engineer Archive . tape 51 , no. 1-2 , 1981, pp. 45 , doi : 10.1007 / BF00535954 ( PDF ).

- ↑ Podstacja WSTOWO krótki opis. (No longer available online.) Podstacja.internet.v.pl, archived from the original on April 1, 2009 ; Retrieved June 7, 2011 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ^ A b c Walter von Andrian: The blackout at the SBB . In: Swiss Railway Review . No. 8 . Minirex, Lucerne 2005, p. 373-379 .

- ^ Walter von Andrian: Symposium "100 Years of High-Performance Traction" . In: Swiss Railway Review . No. 8 . Minirex, Lucerne 2013, p. 406 .

- ↑ Michael Bauchmüller: Railway lines as power lines. Nobody operates such a comprehensive pipeline network as the railways, but it is only of limited use as a reserve for the energy transition. Because the networks of the energy and train industry are incompatible. However, there may be another solution. In: Süddeutsche Zeitung . 2nd July 2012 .

- ↑ DIN EN 50163 / A1 (VDE 0115-102 / A1): 2008-02, section 4.2

- ↑ Conversion of the railway network frequency from 16 2 ⁄ 3 to 16.7 Hz. Accessed on December 3, 2011 .

- ^ Rolf Fischer: Electrical machines . 14th edition. Hanser, 2009, ISBN 978-3-446-41754-0 (Chapter 5).

- ↑ C. Linder: Changeover of the target frequency in the central traction current network from 16 ⅔ Hz to 16.70 Hz . In: Electric Railways . Issue 12. Oldenbourg-Industrieverlag, 2002, ISSN 0013-5437 ( online [accessed December 3, 2011]). Online ( Memento of the original from November 3, 2013 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Orbits change frequency . In: Swiss Railway Review . No. 11 . Minirex, Lucerne 1995, p. 460 .

- ↑ a b Nico Molino: Trifase in Italia 1902-1925 , ISBN 88-85361-08-0 and 1925-1976 , ISBN 88-85361-12-9

- ↑ Share of renewable energies in the DB traction power mix increases to 57 percent. 80 percent share of green electricity by 2030. In: Press release. DB Netze, November 2018, accessed on September 4, 2019 .

- ↑ Glossary of DB Energie. (No longer available online.) Archived from the original on October 27, 2007 ; Retrieved October 25, 2007 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Planning approval according to § 18 AEG in connection with § 74 Abs. 6 VwVfG for the demolition of the transformer plant in Chemnitz. (No longer available online.) Archived from the original on June 2, 2016 ; accessed on June 3, 2016 . Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ ÖBB-Infrastruktur AG: Energy distribution ( Memento of the original from September 24, 2015 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ PressReader.com - Newspapers from around the world. In: pressreader.com. Retrieved October 2, 2016 (JavaScript required).

- ↑ Construction information KW-Tauernmoos - frequency converter Uttendorf. (PDF) Info folder. ÖBB-Infra, June 2013, accessed on October 8, 2016 .

- ↑ SBB power failure of June 22, 2005 , page 24 ( Memento of July 3, 2006 in the Internet Archive ) (PDF; 3.5 MiB)

- ↑ The frequency converters of the SBB. , accessed February 7, 2016.

- ↑ ÖBB Bau AG: Central Control Center Innsbruck ( Memento of the original from March 20, 2016 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ a b Deutsche Bahn AG: Facts & Figures 2019 (PDF; 825 KiB), Berlin, accessed on May 5, 2020

- ↑ About us. DB Energie GmbH, accessed on February 5, 2020 (German).

- ↑ DB Energie GmbH: Labeling of electricity deliveries 2017 (PDF) DB Energie GmbH, October 2018, accessed on April 29, 2019 .

- ↑ a b Deutsche Bahn AG: Facts and Figures 2012 ( Memento of the original dated December 3, 2013 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. (PDF; 8.8 MiB) p. 27, Berlin 2013, accessed on July 13, 2013

- ↑ DB Energie (Ed.): Bahnstromppreise 2012 ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. (PDF; 4.6 MiB). In: EnergieNews from December 2011, p. 3, online at dbenergie.de

- ↑ Die Welt: Altmaier Plan could increase rail fares , edition March 14, 2013, accessed on July 12, 2013