Colliery mallets & irons

| Colliery mallets & irons | |||

|---|---|---|---|

| General information about the mine | |||

| Shaft 3/4/7 seen from the south (Jan. 2011) | |||

| Information about the mining company | |||

| Operating company | Ruhrkohle AG | ||

| Start of operation | 1873 | ||

| End of operation | 2000 | ||

| Funded raw materials | |||

| Degradation of | Hard coal | ||

| Geographical location | |||

| Coordinates | 51 ° 36 '29 " N , 7 ° 7' 2" E | ||

|

|||

| local community | Herten | ||

| District ( NUTS3 ) | Recklinghausen district | ||

| country | State of North Rhine-Westphalia | ||

| Country | Germany | ||

The Schlägel & Eisen colliery , along with the Ewald colliery, is one of two now closed mines in Herten / Westphalia , in which hard coal was mined and processed.

Geographical location

The Berechtsame the mine is located mostly in the northern city of Herten in the neighborhoods thistles , Langenbochum and Scherlebeck . In the south-eastern and eastern part it extends in Stuckenbusch and Hochlar up to the present-day urban area of Recklinghausen . In addition, the northern part in the Drewer area extends to the urban area of Marl . The Westerholt district of Herten is touched on the western Markscheide , as is the former Ebbelich farmers.

Pit field

The original entitlement came from the award on August 18, 1873 and consisted of the individual fields Schlägel & Eisen , Schlägel & Eisen XI-XIII , Queen Luise and Adolf Dach . The consolidation of all fields to the Schlägel & Eisen mine field took place on November 12 of the same year. On October 20, 1876, the Kaiser Wilhelm III field was acquired and incorporated. The rights of authority experienced an expansion when in 1890 the fields Consolidated Kaiser Wilhelm , Kaiser Wilhelm V , pleats of the fields Kaiser Wilhelm I, II and IV , a field part exchanged with the field Germany and two further pleats were added. With the acquisition of the United Germany , Imperial Chancellor and German Crown Prince fields and their affiliation in 1900, the mine field was expanded to the north. A field swap with the Prussian mining treasury took place on June 12, 1911.

The mine field, the total size of which was put at more than 29 km² in 1965, was surrounded by several other mines. The Ewald colliery was on the southern marrow, while the General Blumenthal colliery was to the east. Most of the northern divide was shared with the Auguste Victoria colliery . The pit field bordered the Brassert colliery only in the northeast . To the west was the Westerholt colliery, and the Hugo colliery in the extreme southwest of the mine had a small piece of its marrow in common with the Schlägel & Eisen colliery.

Company history

Schlägel & Eisen union: first steps of a new company

The exploration for hard coal , which expanded rapidly during the founding period , had also reached today's urban areas of Recklinghausen and Herten in the early 1870s. Numerous Bohrgesellschaften brought down their exploratory drilling, always in the hope of productive resources, which overlooks yield could break down. The first drilling near Schloss Herten was found on January 5, 1873. The drilling company mallets & iron based in Essen was mentioned a few days later in the local press as if on the road to Gelsenkirchen-Buer in 1214 foot depth anbohrte a first coal seam. The seam was 5 ½ feet thick and of good quality coal. Other drilling companies were successful with their wells in the areas of Stuckenbusch, Backum and Curig, so that on the basis of these positive signs on August 25, 1873, the hammer and iron union was formed at its founding meeting. The first trades were Joseph Rive, general director from Borbeck and from January 1874 first chairman of the trade union, and Ernst Nedelmann from Mülheim ad Ruhr . In addition to Rive, the mine management committee also included the mine directors Dach, Menzel (both from Bochum ) and August Randebrock ( Dortmund ) as well as the businessman Gustav Adolph Waldthausen from Essen. The positive signs for the young union continued, because in the same year the Kaiser Wilhelm drilling company in the Scherlebeck farmers found a coal seam in the gas coal section at a depth of 1508 feet. In a list of participants for the assembly of the trades on October 15, 1875, five members of the Duisburg entrepreneurial family Haniel were listed, which may be an indication that great expectations were set for the future of the new mining company. However, additional fines had to be estimated in the first few years . For example, at the trade union meeting in July 1883, the amount of the loss was given as 200,000 Reichsmarks. The colliery hit the headlines when, on November 22, 1889, the northern conveyor cage of shaft 1 got out of the guide rails . For the promotion, this meant a temporary total failure. In addition, 224 miners were prevented from leaving for 30 hours. The local population took a large part in this mishap and the access to the colliery area was at times like a castle gate threatened by siege.

Mining company Hibernia, or Hibernia AG: the colliery under the sign of the Irish shamrock

In 1898 the trade union Schlägel & Eisen dissolved and it was taken over by the mining company Hibernia (from 1935 Hibernia AG ). From 1903 on, the colliery was able to process the extracted coal directly and on site in the 3/4 pit by means of a new coking plant . With the help of now three production sites, coal production rose rapidly until the beginning of the First World War . In 1900, raw coal production was just under 700,000 tons, but in the first year of the war in 1913 it was estimated at 1,343,222 tons. Production had almost doubled in just 13 years. The consequences of the war years and their aftermath caused production to collapse and the production figures only rose gradually. At the beginning of the looming global economic crisis , the number of production sites was reduced with the discontinuation of production on shaft 5/6. The conversion of the pit 3/4 to the central production location began in 1937 and in 1941 the plan with the production setting on the pit 1/2 was implemented. As early as 1940, there was an acute shortage of workers. An attempt was made to counteract this situation with the use of women and forced laborers . East of pit 3/4 in Lyckstraße in Langenbochum was one of a total of three camps in what is now the city of Herten, in which forced laborers were housed. However, the forced implementation of these could not prevent the funding figures from falling continuously. The coking plant and its ancillary facilities were dismantled in 1943. However, in this case the sources contradict each other. While A. Drissen expressly confirms this point in time in his work, J. Huske states in his book the year 1945 when the coking plant ceased operations. After the war had ended and the damage had been repaired, it was possible to guarantee regular production. In the course of the alignment of the northern pit field towards the end of the 1950s, an additional shaft was sunk in Marl-Drewer near the northern mine sheath. With its commissioning, the coal deposits in the north field could be mined. The funding was steadily intensified in the following years.

Ruhrkohle AG: from expansion to high-performance operation to cessation of subsidies

In 1969, Hibernia AG brought its mine property into the newly founded Ruhrkohle AG , so Schlägel & Eisen colliery became part of this new mining company. In 1972 the breakthrough with the mine workings of the Westerholt colliery was made via a conveyor mountain, via which coal could be transported for processing there from the following year. In 1975 a total production of 2,030,346 tons of coal was achieved. To date, this result was the highest output in the history of the Schlägel & Eisen colliery, and this figure was not to be reached again until the production was discontinued. From 1986, the entire output was processed again by the colliery's own processing facility, so that external processing at the Westerholt colliery was discontinued. The underground transport of coal there was then ended. At the end of the 1980s, preparations began to cease mining in the northern field. On January 1, 1990, it was merged with the Ewald colliery to form the Ewald / Schlägel & Eisen composite mine , during which the mining in the northern pit was stopped. At the end of June, coal mining on the 3/4/7 shaft also ended, so that the coal mined was subsequently transported underground to the Ewald colliery and lifted there to the surface. From July 1, 1997, the remaining facilities were part of the Ewald / Hugo composite mine. When it was shut down on April 30, 2000, all mining activities also ended at the Schlägel & Eisen colliery.

The pits in detail

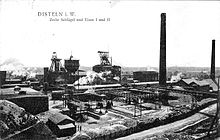

Shaft system 1/2

The area of the former shaft system 1/2 is located in the Disteln district of Herten north of today's Kaiserstraße. The groundbreaking ceremony for the sinking of shaft 1 was scheduled for June 1, 1874. In the following period, the sinking work proceeded quickly and without major operational disruptions, so that a depth of 180 feet was reached in November of the same year. About six months later, in May 1875, the shaft was already more than 580 feet deep and in November it reached a depth of 342 m, the rock layers that were formed in the geological age of the Carboniferous and are thus accompanied by coal seams. In June 1876 the ingress of water, after not being a major hindrance during the entire previous devastation, occurred steadily and in increased proportions. However, they could be mastered with the existing pump technology, so that no devil interruptions were necessary. About 25 m below the marl boundary , the shaft reached the first coal seam, which was 5 feet thick. The coals extracted from this point on were then used for their own use. In 1877, the excavation work had progressed so far that a second seam was reached and another operating point could be set up there for mining. Regular funding for sales on the coal market was thus ensured in the same year. The ventilation of the newly created mine workings became more and more difficult with the further penetration into the coal mountains, because the shaft had reached a depth of 600 m in 1882. In order to reduce the increasing risk of firedamp explosions , the sinking work for shaft 2, the starting point of which was to the east next to that of shaft 1, began on March 1, 1890 . He went in 1890 as a ventilation shaft in operation after the third floor had been reached. On April 1, 1940, pit 1/2 ceased coal production after pit 3/4/7 in Langenbochum started operating as a central production location. In 1971, shaft 1 was abandoned and subsequently backfilled, while shaft 2 remained open. In 1998 it was shut down so that the shaft could subsequently be kept by backfilling the shaft column.

Geographic coordinates of the manhole starting points:

Pit 3/4/7

The sinking work for shaft 3 began on July 1, 1895. The shaft starting point was in the south-western part of the authorized person north of today's Westerholter Strasse in the Herten district of Langenbochum. Joachim Huske reports in his work that the coal mountains were reached in a depth of 388 m in 1896, while the information given by A. Drissen deviates slightly. Coal mining was started in 1897, which meant that two mining pits could be brought into the Hibernia mining company in the following year . The second level had been driven in advance from shaft 1/2 and when shaft 3 reached it in the same year, a breakthrough between the two shafts could be made. The groundbreaking ceremony for the sinking work for shaft 4, the starting point of which was not far to the west of shaft 3, was scheduled for November 6, 1900. This shaft went into operation two years later as a weather shaft from the 2nd level. A coking plant, including ancillary extraction systems, went into operation in 1903. After the mine was continuously expanded in the following years, it was connected to the railway station in Westerholt in 1908. The beginning of the sinking of shaft 7, which was northeast of shafts 3 and 4, began on September 1, 1937. At the same time as the sinking work, the daytime facilities were rebuilt and partially expanded by the office of architects Fritz Schupp and Martin Kremmer , including the machine house , the screening plant and the shaft hall, the boiler house , the coal washing plant and the buildings for the administration and the laundry . Coal extraction through shaft 7 as the main shaft of the entire mine began in early 1941. In 1981, shaft 4 was filled and the old headframe was demolished. It was sunk again with a larger cross-section and received a new headframe. In 1986 the shaft went back into operation. After the cessation of production in 1990, the shaft system was partially demolished in the following year, while shaft 3 was filled. In 1997, shaft 7 was incorporated into the newly created composite mine Ewald / Hugo by merging the two mines Ewald / Schlägel & Eisen and Hugo / Consolidation, while shaft 4 had already been abandoned. Shaft 7 was backfilled after Ewald / Hugo was shut down in 2000. From 1990 to 2008, the shaft system was the seat of the "Technology and Logistics Service" division of RAG and DSK. Further premises were rented in 1999 from a division of the Siemens group, which was based on the mine until 2007. During the renovation of the Herten town hall, the former office buildings of the mine were used by the outsourced authorities as alternative quarters.

Geographic coordinates of the manhole starting points:

- Bay 3: 51 ° 36 ′ 29.6 ″ N , 7 ° 7 ′ 3.9 ″ E

- Bay 4: 51 ° 36 '29.4 " N , 7 ° 7' 1.8" E

- Bay 7: 51 ° 36 ′ 33.4 " N , 7 ° 7 ′ 7.2" E

Shaft system 5/6

After the mine was taken over by the mining company Hibernia , the sinking of shaft 5 began in 1898. The starting point of the shaft was east of today's Scherlebecker Strasse in the Herten district of Scherlebeck. In the following year, the hard coal mountains could be reached at a depth of almost 400 m. For weather management, the sinking of shaft 6 was started in the same year, which could be put into operation a year later. Regular funding was achieved from 1901. In 1926 the mine was connected to the Rhine-Herne Canal with the completion of the port railway . But just two years later, the decision was made to shut down the mine as a production site. The implementation of this decision took place on April 1, 1929. The coal from the construction field of the pit 5/6 was from then on lifted to the surface in the neighboring pits 1/2 in Disteln and 3/4 in Langenbochum. The two shafts, however, remained open for cable travel and weather management. Subsequently, parts of the above-ground buildings were converted and used to train the next generation of miners. The last local mining vocational school closed its service in 1989.

Geographic coordinates of the manhole starting points:

Shaft 8

For the exploration in the north of the authorized person, it became necessary to sink another shaft for ventilation and for the logistics of people and materials. In 1957, the sinking work began on shaft 8, the starting point of which was in the Drewer district of Marl, east of Loemühlenweg. It was put into operation just two years later after the breakthrough had been made with the 3/4/7 shaft . Until the end of coal mining in the north field, it served primarily as a shaft for weather management and for the cable car . The shaft was backfilled in 1989.

Geographic coordinates of the manhole starting point:

- Shaft 8: 51 ° 38 ′ 17.4 ″ N , 7 ° 7 ′ 20 ″ E

Current condition and use of the facilities

Shaft system 1/2

The area is completely leveled. The remaining daily facilities were removed. The resulting ballast material was crushed, temporarily stored and later transported away on the site. A Protego hood was installed over the filled shaft 2 during the securing work , but it is no longer available; there are no traces of shaft 1 visible. Some time ago trading companies set up shop on the site, including the branch of a large grocery discounter and that of a large hardware store company.

Pit 3/4/7

The existing building of the mine has been largely preserved after the closure. The headframe above shaft 3 with the associated hoisting machine house including the steam hoisting machine are now under the care of the Foundation for the Preservation of Industrial Monuments and Historical Culture . The ensemble is an integral part of the route of industrial culture. In 2015 the foundation also took over the headframe shaft 4 and the associated pit ventilator shaft 3/4 in its care.

As part of the SchachtZeichen project during the events for the European Capital of Culture RUHR.2010 , Schlägel und Eisen 3/4/7 was one of the many selected locations where an abandoned yellow balloon, visible from afar, marked a former mining site.

In the area of the former administration there is a school for apprenticeships in the areas of care for the elderly and health services. In the course of the redesign of the extensive colliery site, work for the demolition of large parts of the building and the renovation of the surface of the site has been in progress since the beginning of October 2012. This primarily affects the eastern part of the site in the area of the shaft hall of shaft 7 and the associated headframe, which was blown up on October 30, 2013. The renovation work was completed in 2017 and the area was recultivated into a park and the headframes were repainted. There has been a light installation at shaft 4 since 2019.

Shaft system 5/6

A small ensemble of former daytime facilities has been preserved on Scherlebecker Strasse , which today (as of December 2012), like the pit 3/4/7, represents a starting point on the industrial heritage route . In addition to the hoisting machine house of shaft 5 and the former mining vocational school with brand control in the entrance area, a workshop building, which is not visible from Scherlebecker Strasse, was placed under monument protection in 1987 . The last-named building became the headquarters of an employment and qualification company in 2005, after the former vocational school had been converted into a day care center for the elderly and a kindergarten between 1993 and 1996. The hoisting machine house has now become a versatile building. In the actual machine hall, it houses the tandem steam hoisting machine , which is operated by the Förderverein Maschinenhaus Schacht V e. V. was restored in cooperation with the state of North Rhine-Westphalia, including a small mining museum. In the neighboring so-called district meeting place, rooms can be rented for private and business events. In addition, exhibitions from various cultural areas take place there several times a year. As part of the SchachtZeichen project during the events for the European Capital of Culture RUHR.2010 , Schlägel und Eisen 5/6 was another selected location for one of the yellow balloons.

The southern part of the former area is primarily occupied by businesses from the retail and commercial sectors. To the north of the listed building there is a development area that has been built on since 1996, in addition to an office and commercial building, as well as an old people's center with adjoining apartments for assisted living, old people's apartments and apartments for families with or without children. The last undeveloped section of the site in the area of the former shafts could be given a new purpose in 2009, as a further branch of the grocery discounter mentioned in the discussion of the shaft system 1/2 was subsequently built there.

Shaft 8

Since August 1, 2008, the processing and management of the area has been in the hands of Werkstatt Brassert , a non-profit organization that supports long-term unemployed men and women with their integration into the labor market. So far (as of December 2012) the outdoor facilities as well as the building stock have been renovated and maintained with the help of these people. For some time now, the location has also been used for a broad cultural program, which the Brassert workshop is responsible for putting together. Exhibitions, concerts and other events take place on the site.

Misfortunes

The Schlägel & Eisen colliery has been plagued by major accidents several times in its 126-year history, from the start of the sinking work in 1874 to its final closure in 2000 as part of the Ewald / Hugo composite mine. The first death of an employee who fell into the shaft during the work was already being lamented during the excavation work for shaft 1. Representing all accidents that happened during the operation of the colliery, two incidents should be discussed at this point, which may make it clear that a colliery operation in its entirety, underground as well as above ground, was a dangerous workplace.

The surface steam boiler explosion on shaft 5/6 on November 17, 1922

On Saturday, November 18, 1922, the local press reported on an accident that had occurred the day before at around 9:00 a.m. on mine 5/6 in Scherlebeck. In the explosion of a steam boiler above ground, three employees were killed and, as the responsible district office announced in the same newspaper report, three employees were seriously injured. Two other employees suffered minor injuries. In the immediate vicinity of the boiler house on Scherlebecker Strasse, which itself showed considerable damage, residential and commercial buildings were damaged by fragments flying around and also by the pressure wave of the explosion. The roofs of some neighboring houses were not insignificantly damaged and almost all of the windows in these buildings were broken. The interiors of some houses were also damaged by debris entering through the windows. Some telephone lines were interrupted and the power line of the small train passing across from the accident site was slightly damaged.

The pit fire on shaft 3/4/7 on October 27, 1977

Another serious accident was reported on October 28, 1977. On Thursday, October 27, 1977 around 7:00 a.m. , a fire broke out on shaft 3/4/7 in Langenbochum in a conveyor mountain that was about 1000 m underground. One miner was trapped in the fire, while the rest of the approximately 500-strong workforce who were working underground during the outbreak of the fire were able to drive out unmolested. A rescue team, which consisted of six members of the mine rescue service, was surprised by the effects of the mine fire while attempting to locate and rescue the miner who had previously been missing . Four of the soldiers were found dead by another search party on the same day. After the news of the outbreak of the fire had spread quickly, around 200 people, employees of the colliery, as well as relatives and friends of the missing people, gathered in front of the colliery gate.

Although nitrogen , which was approached by tanker trucks, was introduced into the affected mine buildings early on to reduce the oxygen content at the source of the fire , it was initially not possible to bring the fire completely under control. A search for the three still missing people was therefore next to impossible at the beginning of the disaster. On October 29, the miner, who had been trapped in the fire, was found dead by the search parties while the search for the two missing men of the mine rescue team continued. The nitrogen, which has now been introduced for several days, had cooled the ambient temperature in the mine structures affected so far that the mine rescue team could continue to work its way towards the source of the fire. Finally, on October 31, she managed to rescue the two missing colleagues. They too did not survive the fire disaster. Thus the accident claimed a total of seven lives, six of which were from the mine rescue team.

The fire was brought under control by building dams to cut off the source of the fire from any oxygen supply. During the catastrophe, all underground operations came to a standstill and the output fell briefly from 7000 tons per day to 4600 tons per day of coal.

More mining accidents

In addition to the two accidents described above, other notable events occurred, which are mentioned below:

On April 14, 1892, three miners were killed in a firedamp explosion. Three people were also fell victim to a rock fall on May 27, 1919. A mine fire on June 17, 1940 claimed five lives; and the crash of a hoist cage on March 4, 1950 killed three miners . There were also three deaths after the break in a face on April 11, 1951.

Web links

Individual evidence

- ↑ a b c d e f g h i j k l m n o Alfred Drissen: Alt Schlägel & Eisen 1874–1949 , published by Hibernia AG 1949

- ↑ a b c d e f g h i j k l m n Joachim Huske: Die Steinkohlenzechen im Ruhrrevier , 3rd expanded and revised edition, self-published by the German Mining Museum, Bochum 2006, ISBN 3-937203-24-9

- ^ Wilhelm and Gertrude Hermann: Die alten Zechen an der Ruhr , 4th edition, edited by Karl Robert Langewische successor Hans Köster, Königstein im Taunus 1994, ISBN 3-78456992-7

- ↑ The mines and salt pans in the Lower Rhine-Westphalian mining district 1919 , Verlag Glückauf mbH, Essen 1920

- ↑ Friedhelm Glinka: War, end of war and new beginning 1940–1950 , documentation for the exhibition in the community center in Herten-Süd from 23 November to 23 November. Dec. 1992, published by the city of Herten 1992

- ↑ www.albert-gieseler.de Timetable of Hibernia AG (last accessed on December 29, 2012)

- ↑ a b c d e f g h i j k www.zechenkarte.de ( Memento from May 17, 2012 in the Internet Archive ) Shaft coordinates of the mining shafts in the Ruhr area (last accessed on December 29, 2012)

- ↑ www.gelsenkirchener-geschichten.de List of Fritz Schupp's building projects (last accessed on December 29, 2012)

- ↑ a b http://archiv.westline.de/mono.php?file_name=20080407124005_210_001_643862&jahrgang=2008&stichwort=schl%EF%BF%BDgel+&+eisen&&start=0&order=relevanz&ort=ht (link not available)

- ↑ archiv.westline.de ( Memento from November 5, 2013 in the Internet Archive ) Message in the Hertener Allgemeine from May 24, 2001 (last accessed on December 29, 2012)

- ↑ www.hertener-allgemeine.de News from October 1, 2010 (last accessed on December 29, 2012)

- ↑ www.hertener-allgemeine.de News from February 22, 2012 (last accessed on December 29, 2012)

- ↑ a b Zeche Scherlebeck - historical data ( Memento from February 17, 2013 in the web archive archive.today ) Historical time table of the Schlägel & Eisen 5/6 colliery (last accessed on December 29, 2012)

- ^ Förderverein Maschinenhaus Schacht V ( Memento from February 17, 2013 in the web archive archive.today ) Förderverein Maschinenhaus Schacht V e. V. (last accessed on December 29, 2012)

- ↑ www.industriedenkmal-stiftung.de Website of the Industrial Monument Foundation (last accessed on December 29, 2012)

- ↑ www.route-industriekultur.de Schachtanlage 3/4/7 in theme route 16 (last accessed on December 29, 2012)

- ↑ Headframes. Industrial monuments in the Ruhr area in FAZ from November 21, 12015, page 13

- ↑ a b www.schachtzeichen.de ( Memento from May 17, 2010 in the Internet Archive ) The locations of the balloons on the official website of the Schachtzeichen project (last accessed on December 29, 2012)

- ↑ www.die-schule.de Website of the practice network Watanabe (last accessed on December 29, 2012)

- ↑ www.rag-montan-immobilien.de Website of RAG Montan Immobilien (last accessed on December 29, 2012)

- ↑ www.recklinghausen.de Project plan for the pit 3/4/7 (last accessed on December 29, 2012)

- ↑ www.hertener-allgemeine.de News from September 26, 2012 (last accessed on December 29, 2012)

- ↑ www.derwesten.de News from October 30, 2013 (last accessed on November 3, 2013)

- ^ [1] Video of the demolition on October 30, 2013

- ↑ www.route-industriekultur.de ( Memento from August 5, 2014 in the Internet Archive ) Shaft 5/6 in theme route 16 (last accessed on December 29, 2012)

- ↑ www.pflegeeinrichtungen-kirsch.de Website of the care facilities Kirsch (last accessed on October 29, 2017)

- ↑ www.rag.de Website of RAG Aktiengesellschaft, notification from March 17, 2009 (last accessed on December 29, 2012)

- ↑ www.werkstatt-brassert.de ( Memento from November 8, 2012 in the Internet Archive ) Website of the Brassert workshop (last accessed on December 29, 2012)

- ↑ www.marler-zeitung.de Online edition of the Marler Zeitung from September 1, 2012 (last accessed on December 29, 2012)

- ↑ Recklinghäuser Zeitung of November 18, 1922, Volume 92, No. 286, Archive Medienhaus Bauer, Marl

- ↑ Hertener Allgemeine of October 28, 1977, Volume 145, No. 251, Archive Medienhaus Bauer, Marl

- ↑ a b Hertener Allgemeine from 29./30. October 1977, Volume 145, No. 252, Archive Medienhaus Bauer, Marl

- ↑ a b c Hertener Allgemeine from October 31, 1977, Volume 145, No. 253, Archive Medienhaus Bauer, Marl