Nordex SE

| Nordex SE

|

|

|---|---|

| legal form | Societas Europaea |

| ISIN | DE000A0D6554 |

| founding | 1985 |

| Seat |

Rostock , Germany |

| management |

|

| Number of employees | 6,880 |

| sales | 3,284 million euros (2019) |

| Branch | Plant construction |

| Website | www.nordex-online.com/de |

| As of December 31, 2019 | |

The Nordex SE , based in Rostock and administration langenhorn is a listed manufacturer of wind turbines . The company's core business is the manufacture, construction and maintenance of wind turbines; In some markets, Nordex is also active in the planning of wind farms through to their turnkey construction. The company only builds wind turbines for onshore sites, but does not operate in the offshore sector. The main product is “light wind turbines”, which are specially designed for the development of locations with comparatively low average wind speeds inland.

The main production facility is located at the headquarters in Rostock, where the company is also entered in the commercial register; further locations are in the People's Republic of China and in Jonesboro (Arkansas) in the USA, which mainly serve as service locations . Nordex has branches and subsidiaries in 19 countries. By July 2018, the company said it had installed systems with a total output of more than 23 GW worldwide . In 2017, Nordex was the company with the highest sales in the state of Mecklenburg-Western Pomerania and the company with the second-most employees.

history

Nordex A / S emerged in May 1985 from the Brande Kedel og Beholderfabrik in Svindbæk near Give in Denmark, a boiler factory founded by Flemming Pedersen and his sons Carsten and Jens. Denmark is both the pioneering country of the energy transition and the (modern) use of wind energy . Since the end of the 19th century, research into wind turbines and small systems was built in Denmark. Important pioneers here were, for example, Poul la Cour and Johannes Juul , the designer of the Gedser wind turbine . A basic technical concept for the construction of wind turbines had been tested in Denmark since the 1940s. When the country, which was almost completely dependent on oil as its primary energy source , got into a severe energy crisis as a result of the 1973 oil crisis , a wind power tradition was already in place that could be used when building new plants. Building on this, in the 1970s, companies from the plant engineering and agricultural engineering sectors began building small wind turbines that were bought by both private individuals and consumer communities for self-sufficiency.

This development was supported by the politics that drove the Danish energy transition. In 1979 the Jørgensen government introduced an investment grant of 30% for the construction of wind turbines and in 1981 a statutory feed-in tariff for wind power, which obliged Danish energy companies to purchase electricity from renewable sources at a set price above the market price for electricity.

In the 1980s there was a boom in Danish manufacturers after wind energy was subsidized by state aid in the USA, especially California, and Danish manufacturers achieved large market shares there with their reliability superior to American systems. In 1985 the Danish wind industry manufactured more than 3,000 turbines, most of them for the Californian market. This resulted in new business models for Danish companies in related sectors such as the metal industry , which increased the number of manufacturers. Among other things, Nordex also entered the wind energy industry and in 1985 had engineers Kim Andersen and Knud Buhl develop a first type of turbine, which was launched in the same year.

Activities in Germany began in 1991 with sales by Nordex Energieanlagen GmbH, founded by Volker König, Werner Napp and Günter Schmidt . In the following year, this company set up its own development and production in Rerik , which was later reintegrated into the overall company. The world's first series wind power plant in the megawatt class was built here in 1995.

In 1996, the acquired Babcock Borsig Corporation belonging Balcke-Dürr 51% of Nordex. Another 26% was acquired in 1998. In 1999, as the existing plant in Rerik proved to be increasingly too small, the former Rostock diesel engine plant was taken over, which from now on formed the main plant. At that time, Nordex was one of the 10 most successful wind energy companies in the world. In 2001 Babcock-Borsig prepared the IPO of its profitable wind energy business due to financial problems. In addition to Nordex, these included, for example, the sales company NPV, the previously acquired insolvent wind turbine manufacturer Südwind and Borsig Rotor, which was founded in 1999. The transition company, which traded under the name Taifun AG , was owned 80.5% by Borsig Energy GmbH and 19.5% by the Nordex founding family Petersen. In April 2001, Nordex shares were first listed on the stock exchange ( Neuer Markt market segment ). On October 1, 2001, Babcock-Borsig sold its remaining 29.8% stake in Nordex to Westdeutsche Landesbank for around 140 million euros . The Petersen family held a 7% stake in what was then Nordex AG. In the same year the German manufacturer Südwind was taken over.

In 2003 Nordex ran into a crisis. In addition to a general economic slowdown with a decline in demand for wind turbines and the resulting sharp decline in incoming orders, Nordex v. a. the large product portfolio with a large number of different types of systems problems, which resulted in high losses for the company. A restructuring followed by 2005, in which the variety of products was reduced and production in the main plant in Give was closed; In addition, 150 jobs were cut in Germany. In addition, the Nordex subsidiaries Südwind Energy GmbH and Nordex Energy GmbH were merged. In 2005 there was a capital reduction in the ratio of 10: 1 followed by a comprehensive refinancing of the company. In this context, the shareholders CMP Management , Goldman Sachs (indirectly via a fund) and Momentum ( Klatten ) got involved.

From 2005 onwards there was a renewed upswing of the company. In 2006 Germany's first offshore plant was built in Breitling and the Chinese production facility for large turbines was put into operation. In 2003, an offshore test facility in the Kattegat was set up in front of the Danish port city of Frederikshavn . A rotor blade production facility was opened in China in January 2007 . At the beginning of 2008, Nordex moved back to the former location in Rerik for the purpose of training. In October 2008, Nordex announced the investment in a new production facility in Jonesboro , Arkansas , USA . The approximately 40 million US dollar plant was officially opened in October 2010.

Nordex has had the legal form of a European company (SE) since March 2010 . It has been trading as Nordex SE ever since .

At the beginning of 2011, Nordex relocated its headquarters to Hamburg-Langenhorn, where the new head office in the Nordex Forum was established. In the same year, Nordex converted its main plant in Rostock, one of the first companies in the wind energy sector, to series production . Instead of the previously used dock assembly there are now three assembly lines for power house , drive train and hub, which are supplied by three pre-assembly. This enabled the production time per turbine to be reduced by 30%; at the same time, the maximum annual capacity of the plant rose to 1,000 systems.

In December 2012, Nordex closed its rotor blade production in China due to insufficient capacity utilization in the highly isolated market there. In addition, restructuring measures were also announced at the Jonesboro plant due to insufficient capacity utilization. Also in 2012, Nordex ended the development of the N150 / 6000 turbine, which was intended exclusively for offshore wind farms , due to the uncertain development in this market area and also aimed to sell the shares in the Arcadis Ost 1 offshore wind farm . In June 2013, Nordex announced that it would cease nacelle production in the USA due to low capacity utilization and cut 40 jobs. Sales, service and project management were retained on site.

At the same time, Nordex expanded rotor blade production at its main plant in Rostock to 400 blades NR 58.5, according to its own information, in order to increase the vertical range of manufacture and to reduce costs. In addition, Nordex purchases the NR 58.5 blades, some of which are made of carbon fiber reinforced plastic (CFRP), from the rotor blade manufacturer SGL Rotec and, since February 2014, from the US manufacturer TPI Composites , whose plant is located in Turkey . In March 2014, Nordex exceeded the threshold of 10,000 MW of installed capacity.

In October 2015, Nordex announced the takeover of the wind energy division of the Spanish infrastructure group Acciona . The purchase price was 785 million euros, almost half of which had to be paid in cash and the remainder with newly issued Nordex shares. Acciona thus became Nordex's largest single shareholder with a stake of 29.9%, while the previous main shareholder, the Klatten family, reduced their stake to 5.7%. The takeover was completed in early April 2016.

At the beginning of 2017, Nordex took over the Danish rotor blade developer SSP Technology with around 70 employees. In the past, SSP Technology has developed various rotor blades for wind turbines with outputs from 1.5 to 8 MW and has also produced prototypes of these blades in its own factory in Kirkeby . The aim of the takeover, which, according to Nordex, cost a low single-digit million amount, was mainly to acquire technical expertise in rotor blade construction for future turbines and the patents held by SSP Technology. Among other things, the company constructed rotor blades up to a length of 83.5 meters and also has experience in the construction of split rotor blades. However, the production of new blades will continue to take place in the Nordex plant in Rostock. In October 2019, the company's management decided on a capital increase. By way of a private placement, around 9.7 million new shares were issued to Acciona for EUR 99 million; Acciona increased its stake in Nordex to over 30% and was obliged to make a takeover offer for all outstanding shares under the Securities Acquisition and Takeover Act. After the offer expired in January 2020, Acciona held 36.4% of the capital and voting rights.

organization

Company headquarters

The headquarters of the headquarters and other group companies of Nordex SE are located in the Nordex Forum in Hamburg-Langenhorn, which the company moved into at the beginning of 2011 . The building was constructed by Hochtief and is owned by Swiss Life . The gross floor area of around 15,000 m² offers space for up to 700 workplaces; a further expansion to up to 1,200 jobs was taken into account in the construction planning. At the inauguration at the beginning of 2011 (for which the then Hamburg Mayor Christoph Ahlhaus appeared) around 500 people were employed. Particular emphasis was placed on good environmental friendliness and low energy consumption. The latter is 20% below the value of conventional office buildings. The comparatively good ecological balance was confirmed by the German Sustainable Building Council, which awarded the Nordex Forum the gold certificate.

Shareholder structure

The company's share capital is divided into around 107 million ordinary shares. The company's voting rights are distributed as follows:

| proportion of | Shareholders |

|---|---|

| 63.6% | Free float |

| 36.4% | Acciona |

Status: January 2020

Corporate management

In the case of the European company legal form, you can basically choose between the monistic and the dualistic model of management. Nordex SE has opted for the dualistic model; the company management therefore consists of the executive board and the supervisory board .

Board

- Jose Luis Blanco Diéguez, (* 1970, since April 2016, (CEO since March 17, 2017, Chief Operating Officer))

- Christoph Burkhard (* 1964, CFO)

- Patxi Landa, (* 1972, Chief Sales Officer since April 2016),

Supervisory board

The supervisory board has six members (as of 2017):

- Wolfgang Ziebart , chairman since 2012

- Juan Muro-Lara Girod, Vice Chairman

- Rafael Mateo Alcalá

- Connie Hedegaard

- Jan Klatten

- Martin Rey

| Fiscal year | Sales in million euros |

Employee 1 * | Production output in MW |

Installed capacity in MW |

|---|---|---|---|---|

| 2000/2001 | 347 | 651 | n / a | |

| 2001/2002 | 439 | 791 | n / a | |

| 2002/2003 | 196 | 867 | n / a | |

| 2003/2004 | 222 | 726 | n / a | |

| 2005 | 309 | 721 | 321 | |

| 2006 | 514 | 814 | 584 | |

| 2007 | 747 | 1,304 | 800 | |

| 2008 | 1,136 | 1,885 | 1,128 | |

| 2009 | 1,183 | 2,207 | 983 | |

| 2010 | 972 | 2,379 | 1,032 | |

| 2011 | 921 | 2,643 | 779 | 970 |

| 2012 | 1,075 | 2,536 | 909 | 919 |

| 2013 | 1,429 | 2,543 | 1,342 | 1,254 |

| 2014 | 1,734 | 2,800 | 1,417 | 1,489 |

| 2015 | 2,430 | 3,148 | 1,899 | 1,697 |

| 2016 | 3,395 | 5,129 | 2,726 | 2,622 |

| 2017 | 3,078 | 5,260 | 3.152 | 2,699 |

| 2018 | 2,459 | 5,676 | 2,278 | 2,522 |

| 2019 | 3,284 | 6,880 | 4,677 | 3,090 |

Nordex in the international market

Nordex has been active in various markets since the company was founded in 1985 . Initially the home market in Denmark was the most important sales market, but in the 1990s the company's focus shifted to Germany, where production was gradually shifted. A market share of 16% was achieved there in 1998, making Nordex the company with the second highest sales. To this end, Nordex exported systems early on to third markets such as India and later China , where production was set up in 1998 as a joint venture. In 2002 Nordex already carried out almost half of its production; In the following years exports increased significantly, while Germany played only a minor role as a sales market.

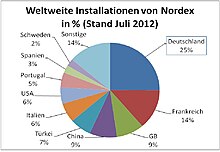

From around 2010, Nordex changed its strategy so that Germany was once again more important. This went hand in hand with a focus on inland locations, for which new systems were developed starting with the N100 / 2500, but especially with the N117 / 2400 and the N131 / 3000. In 2015, the export share was almost 70%, which corresponds roughly to the long-term average for the entire German wind industry. The market share in Germany, which in 2012 and 2013 was 3.9 and 3.5% respectively, increased significantly from 2013, despite strong market growth, and in 2014 was 8.7% in the onshore segment. This put Nordex in fourth place among manufacturers after Enercon , Vestas and Senvion . In contrast, Nordex is not active in offshore wind energy. From a historical point of view, Germany is the most important single market for Nordex: by July 2012, the company installed almost 2 GW there, which corresponds to a market share of 6.5% with the installed capacity of around 31 GW at the time.

Plant types

Previously manufactured systems

In the late 1980s and early 1990s, Nordex offered the two turbine types N27 / 250 and N27 / 150, the latter being a further development for locations with less wind. The system type was finally extended to the N29 / 250. The product portfolio was significantly expanded in 1995 when Nordex entered the megawatt class with the prototypes of the N52 / 800 and N52 / 1000 turbines developed in Germany, which were later developed into the N54 / 1000. In Denmark, the N43 / 600 went into series production in the same year, with which Nordex is now producing systems in three different performance classes. The N50 / 800 formed the technical basis for the later developed N60 / 1300 or N62 / 1300.

Technically, all these types of systems belonged to the Danish concept . This means that the rotor acted on the generators via a gearbox, which were connected directly to the power grid without an intermediate converter. The systems therefore had to be operated synchronously with the mains at a constant rotor speed. By changing the pole , one speed for low and one speed for high power was available. The output was limited by barn regulation; The rotor blades were aerodynamically designed by folding blade tips in such a way that the flow would stall if the wind speed was too high and the system was thus protected from overload. This concept was easy and inexpensive to implement, which is why it was used by many manufacturers in the 1980s and early 1990s, but the efficiency and efficiency, especially due to the rigid rotor speeds, which were often far below the aerodynamic optimum, were significantly lower than they were later developed regulatory mechanisms. As a result, this concept became increasingly obsolete.

Nordex then developed a completely new wind turbine with the N80 / 2500, the prototype of which was erected in February 2000 in the presence of Federal Chancellor Gerhard Schröder and Wolfgang Clement , then Prime Minister of North Rhine-Westphalia , in the Grevenbroich wind test field . This type was the first series wind turbine with a nominal output of 2.5 MW in 2000. 2003 followed with the N90 / 2300, a further development of this system designed for weaker winds. In 2007 the product family, which also includes the N90 / 2500, which was added in 2005, was fundamentally revised. From now on, the new systems were known as Generation Beta. In 2008 the first N100 / 2500 was installed.

At the same time, the previously insolvent manufacturer Südwind , which was taken over by Nordex, began producing 1.5 MW class systems (ProTec MD 1,500 kW) from 2001 - originally from "pro + pro Energiesysteme" (a subsidiary of aerodyn Energiesysteme and Denker & Wulf ) developed the S70 and later the S77 - under license. These systems had a pitch control and fed into the grid via converters, which enabled them to be operated at variable speeds.

| Type | Nominal power (in kW ) |

Publishing year | Remarks | piece |

|---|---|---|---|---|

| N27 / 150 | 150 | 1988 | for weaker locations than N27 / 250 | 1425 |

| N27 / 250 | 250 | 1987 | largest series system in the world | |

| N29 | 250 | N27 / 250 with enlarged rotor | ||

| N43 | 600 | 1994 | Mk1, Mk2 and Mk3 | |

| S46 | 600 | 1996 | License construction, former production of Südwind | |

| N50 | 800 | Basis for N52 / 1000 | ||

| N52 | 800 / 1,000 | 1995 | ||

| N54 | 1,000 | 1996 | Mk1, Mk2, Mk3 (first series system with one megawatt output) |

|

| N60, N62 | 1,300 | 1998 | Further development of the N54 / 1000 | 745 |

| S70 / S77 | 1,500 | 2001 | Licensed buildings | 899 |

| S82 | 1,500 | Further development of the S70, S77 (especially for light wind areas), Asia / Pacific only | ||

| N80 | 2,500 | 2000 | active sales stopped in 2012 | 267 |

| N90 | 2,300 | 2003 | for weaker winds, based on N80 / 2500 | 461 |

| N90 offshore | 2,500 | 2003 | Germany's first nearshore installation in Breitling , Rostock |

2 |

N27 (front) and N43 wind farm Asseln

1 MW system Nordex N54 Mk2 in the Rebgeshain wind farm , Hesse

Nacelle and rotor of a Nordex N62 in the "Goldner Steinrück" wind farm , Hesse

Nordex (Südwind) S77 with 111.5 m high steel lattice tower near Hilgershausen , Hesse

Nordex N80 (Beta) at Scout Moor wind farm , England

Current products

In April 2016, Nordex's product portfolio consisted of four different platforms, two platforms each from Nordex and the acquired wind power division from Acciona. All platforms are pitch-regulated and have a conventional system layout with an asynchronous generator ; The wind energy absorbed by the rotor is translated via a three-stage mechanical gearbox and drives a high- speed , double-fed asynchronous generator , which uses a frequency converter to produce electricity at a mains frequency of either 50 or 60 Hertz. Thanks to this design, the systems can largely operate at variable speeds and thus with a high degree of aerodynamic efficiency. In addition, only about a third of the generator power has to flow through the frequency converter, which means that the power electronics can be dimensioned smaller than systems with synchronous generators and full converters. As with these, however, active and reactive power control is possible. As with most modern systems, the bearing is designed as a three-point bearing.

The main product is the 2.5 MW gamma platform with the N90 / 2500, N100 / 2500 and N117 / 2400 systems. In February 2013, the Delta generation, a 3 MW platform, was presented, the first two turbine types (the N100 / 3300 and the N117 / 3000) went into series production in 2014, followed by the N131 / 3000 in 2015. It is unknown whether the delta class should only complement the gamma class or completely replace it in the long term. With the acquisition of Acciona, their AW1500 and AW3000 platforms were also taken over. The AW1500 platform consists of three series with a nominal power of 1.5 MW each and rotor diameters of 70, 77 and 82 meters. The AW3000 platform consists of four different turbines with rotor diameters of 100, 116, 126 and 132 meters, all of which have a nominal output of 3 MW.

| Type | Nominal power (in kW ) |

Remarks |

|---|---|---|

| AW 70/1500 | 1,500 | Strong wind turbine (formerly Acciona) |

| AW 77/1500 | 1,500 | Medium wind turbine (formerly Acciona) |

| AW 82/1500 | 1,500 | Medium to low wind turbine (formerly Acciona) |

| N90 / 2500 | 2,500 | Strong wind turbine |

| N100 | 2,500 | Specially designed for moderate and weak inland winds, series production since 2009 |

| N117 | 2,400 | Especially for low wind areas (inland), series production since July 2012 |

| N100 | 3,300 | Strong wind turbine, prototypes erected in summer 2013, series production started in early 2014 |

| N117 | 3,000 | Medium-wind turbine, prototype erected in summer 2013, series production started in early 2014 |

| N131 | 3,000 | Low wind turbine, series production since the 2nd quarter of 2015 |

| N131 | 3,300 | Light wind turbine, series production from the 4th quarter of 2016 |

| N131 | 3,600 | Medium to low wind system |

| N131 | 3,900 | Medium to low wind system |

| N133 | 4,800 | Strong wind turbine |

| N149 | 4,000-4,500 | Medium to low wind turbine, prototype built in 2018, series production from the 1st quarter of 2019 |

| AW 100/3000 | 3,000 | Strong wind turbine, (formerly Acciona) |

| AW 116/3000 | 3,000 | Medium wind turbine, (formerly Acciona) |

| AW 126/3000 | 3,000 | Light wind turbine, (formerly Acciona) |

| AW 132/3000 | 3,000 | Light wind turbine, (formerly Acciona) |

| AW 140/3000 | 3,000 | Low wind turbine, prototype built in 2018 |

Nordex gamma class

The Gamma class is the third evolutionary stage of the 2.5 MW class manufactured since 2000 and replaced the previous Beta generation in 2010. The type classes of the existing turbines have also been raised, making the N90 / 2500 suitable for strong wind situations and the N100 / 2500 not only for low wind locations but also for moderate wind locations. A new addition to the Gamma class was the N117 / 2400, specially designed for low wind locations, which went into series production in July 2012. The N80 / 2500 (Gamma) also belonged to this platform, but is no longer offered after the wind class increase of the N90 / 2500. The certification of the generating units according to the 4th amendment to the medium-voltage directive valid since the beginning of 2014 by FGH GmbH (since May 2015: FGH Certification Society mbH ) was completed in March 2014, according to the company.

The platform is based on a uniform modular concept. It has been improved compared to the Beta generation, is suitable for higher wind speeds and, above all, more maintenance-friendly. The platform is equipped with a rear entry into the rotor hub and an internal crane with which components up to a weight of one ton can be serviced and exchanged. In addition, most of the work can be carried out without opening the nacelle roof and thus protected from the weather.

| Type | N90 / 2500 | N100 / 2500 | N117 / 2400 |

|---|---|---|---|

| Nominal power (kW) | 2,500 | 2,500 | 2,400 |

| Rotor diameter (m) | 90 | 100 | 117 |

| swept area (m²) | 6,362 | 7,823 | 10,715 |

| Area per power (m² / MW) | 2,548 | 3.129 | 4,480 |

| Speed per minute | 10.3-18.1 | 9.6-16.8 | 7.5-13.2 |

| transmission | Yes | Yes | Yes |

| generator | double fed asynchronous generator | double fed asynchronous generator | double fed asynchronous generator |

| Hub height (m) | 65/80 | 75/80/100, (140) | 91/120/141 |

| Total height, rounded up (m) | 110/125 | 125/130/150 (190) | 150/180/200 |

Nordex N90 / 2500

The N90 / 2500 is the strong wind turbine in the gamma class. While the N90 / 2300 from which it was developed was originally designed for medium to weak inland locations, the gamma class system has now been approved for IEC 1a class locations since the wind class was increased in 2011. This replaced the N80 / 2500, which was initially offered for locations with a height limit of 100 meters, but was ultimately no longer actively marketed. The turbine is available on towers with a height of 65 or 80 meters, the total height is then 110 or 125 meters.

At certain locations with low turbulence , the output can be increased to 2.65 MW. Mass production of this enhanced version is not planned.

Nordex N100 / 2500

Nordex presented the N100 / 2500 to the public in August 2007. The system was developed on the basis of the existing N80 / 2500 and N90 / 2500 and has a newly developed rotor with a diameter of 100 meters. The increased rotor area of 7823 m² with the same output (3.13 m² / kW compared with 2.55 m² / kW for the N90 / 2500) should increase the yield on inland locations. The turbine was initially marketed as a dedicated low-wind system with average wind speeds of up to 7.5 m / s (IEC 3). The first pre-series machines were delivered in 2008 and series production began in 2009. The first project with these systems was the construction of the Germinon wind farm (see picture on the right), where 30 wind turbines of this type were installed. At the same time, these were the first series systems in the Gamma class. The operator is GDF Suez .

In the course of the market launch of the N117 / 2400 in 2011, which now replaced the N100 / 2500 as a low-wind system, the wind class of the N100 / 2500 was raised to IEC2 (mean wind conditions up to 8.5 m / s) by reinforcing highly stressed parts; In addition, the cut-off wind speed was increased from 20 m / s to 25 m / s. The basic specifications of the system were retained, which increased the yield on locations with medium wind conditions compared to the N90 / 2500 previously used here. The N100 / 2500 was initially erected on tubular steel towers with a hub height of 100 meters, followed by additional tubular steel towers with 75 or 80 meters, especially for locations with moderate wind conditions. For low wind locations, a 140-meter hybrid tower was developed together with the Max Bögl company , which went into series production at the beginning of 2012 and is also used for the N117 / 2400. It consists of a pre-stressed concrete base poured on site with a steel pipe attached. Because the lower part does not have to be transported as a whole, larger diameters are possible at the bottom of the tower and the system achieves the required higher natural frequency .

Nordex N117 / 2400

The N117 / 2400 is a "weak wind system", ie a system that has been specially designed for weaker wind locations (up to 7.5 m / s average annual wind speed). A particularly large rotor area per kW of installed power (4.48 m² / kW for the N117 / 2400) is characteristic of such wind turbines in order to generate relatively high yields even at low wind speeds, as well as a high tower to withstand the stronger and less turbulent winds in to be able to better develop higher altitudes.

The N117 / 2400 is therefore particularly suitable for inland locations. Technically, the system is based on the 2.5 MW gamma class, which also includes the current systems N80, N90 and N100, each with a nominal output of 2.5 MW. Like this, the system has a gearbox that converts the rotor speed to the higher speed required for the double-fed asynchronous generator. Partial converters generate an excitation field that rotates slowly and at a controllable speed, which enables the rotor to operate at variable speeds close to its aerodynamic optimum. The electricity produced has a network frequency of either 50 or 60 Hertz and is fed into the medium-voltage network via a transformer .

The system is certified for locations in wind class IEC 3a, i.e. H. for locations with an average wind speed of 7.5 m / s with high turbulence intensity of up to 18%. If the turbulence intensity is lower, the systems can also be used at locations with higher wind speeds. An example of this is the Pampa wind farm in Uruguay , where there is only a low degree of turbulence of 14%, but the average wind speed is 7.9 m / s. A capacity factor of 51% is to be achieved at this location . This is an exceptionally high value for an onshore wind farm and is usually only achieved by offshore wind farms .

The manufacturer offers the N117 / 2400 in three different tower versions, which allow total heights up to the blade tip in the 12 o'clock position of around 149, 179 or 199 meters. In addition to two 91-meter or 120-meter-high steel towers, a 141-meter-high precast concrete-steel hybrid tower is available, which consists of precast concrete parts up to a height of 91 meters in the lower area and steel at the top. The area of the foundation of the reinforced concrete hybrid tower is around 400 m² with a diameter of 22.5 meters, around 93 tons of reinforcing steel and 670 m³ of in-situ concrete will be installed . The mass of the nacelle, including the drive train and generator, is 106 tons. The rotor including the hub weighs 58.7 tons, a single rotor blade 10.4 tons. This means that the 58.5 meter long rotor blades of the N117 / 2400 are somewhat lighter than the almost 50 meter long blades of the N100, despite their greater length. This is made possible, for example, by the fact that highly stressed parts of the blades are made of CFRP instead of GRP .

The prototype of the N117 / 2400 was erected in December 2011 in the Stadum community wind farm, where the system is expected to generate 9.9 GWh per year at an average wind speed of 7.4 m / s . In 2012, in the first full year of operation, the plant achieved a production of around 7.8 GWh, corresponding to around 3,250 full load hours, despite being switched off temporarily for tests and certification measures . Under reference conditions, the N117 / 2400 with a hub height of 141 meters achieves around 3,960 full load hours.

The N117 / 2400 has been in high demand since it went on sale in 2011. At the end of June 2013, one year after the start of series production, 188 systems of this type were installed, and in January 2015 601 systems were installed. In 2014 this model accounted for around 39% of all new orders received by Nordex, with 186 turbines of this type being sold in Germany alone. In 2013, the N117 / 2400 was named wind turbine of the year by the industry magazine Windpower Monthly .

Nordex Delta class

At the beginning of February 2013, Nordex presented the new Generation Delta product platform, which is an evolutionary step in the Gamma class. Generation Delta consists of three turbines in the 3 MW class, the N100 / 3300, the N117 / 3000 and the N131 / 3000, the latter only being officially presented in November 2013.

One prototype each of the N100 / 3300 and the N117 / 3000 were installed in the Janneby community wind farm in summer 2013 , and another N100 / 3300 in the Danish test field for strong wind conditions in Risø . In addition, a few other pre-series machines with different tower heights were built. The certification of the two types of systems according to IEC and DIBt by TÜV Nord was completed in August 2013, according to the company. At the beginning of 2014, the N100 / 3300 and the N117 / 3000 went into series production, with the N131 / 3000 this was targeted for the second quarter of 2015.

Technically, the systems are based on the previous generation: They still have a double-fed asynchronous generator with partial converter and a three-stage transmission gear that converts the rotor speed to the required generator speed. However, according to Nordex , the nacelle has been designed to be more spacious and more maintenance-friendly and, for example, a weather-protected, direct access through the nacelle to the hub has been created. All systems can be equipped with a rotor blade de-icing system, which enables an increase in yield in cold climates in winter compared to unheated blades.

| Type | N100 / 3300 | N117 / 3000 | N131 / 3000 | N131 / 3300 |

|---|---|---|---|---|

| Nominal power (kW) | 3,300 | 3,000 | 3,000 | 3,300 |

| Rotor diameter (m) | 100 | 117 | 131 | 131 |

| swept area (m²) | 7,823 | 10,715 | 13,478 | 13,478 |

| Area (m²) per MW | 2,370 | 3,571 | 4,492 | 4,084 |

| Speed per minute | 9.0-16.1 | 7.9-14.1 | 6.5-11.6 | 6.8-12.4 |

| transmission | Yes | Yes | Yes | Yes |

| generator | double fed asynchronous generator | double fed asynchronous generator | double fed asynchronous generator | double fed asynchronous generator |

| Hub height (m) | 75/100 | 91/120, 141 | 99, 115, 144 | 144, 164 |

| Total height, rounded up (m) | 125/150 | 150/180, 200 | 165/180, 200 | 200, 230 |

N100 / 3300

The N100 / 3300 is a strong wind system that is approved for wind conditions of class IEC 1a. It complements the N90 / 2500. The same rotor blades are used as with the N100 / 2500. The N100 / 3300 can be erected on towers 75 and 100 meters high, resulting in a total height of 125 or 150 meters.

N117

N117 / 3000

The N117 / 3000 is designed for medium wind conditions. It has the same rotor blade profile as the N117 / 2400, but the rotor blades have been reinforced with additional layers of CFRP in order to be able to withstand the higher loads on the N117 / 3000. The tower variants are also based on the predecessor: The 120-meter tower of the N117 / 3000 is now also suitable for IEC 2a locations. In addition, the N117 / 3000 can also be erected on a 141-meter hybrid tower, as is already used for the N117 / 2400, but only on locations with wind class IEC 3a. This enables total heights of 150, 180 and 200 meters.

N117 / 3600

On August 3, 2016, Nordex announced an increase in the output of the N117 to 3,600 kW. The first turbine of this series was installed in November 2016 in the municipality of Admannshagen-Bargeshagen ( Rostock district ).

N131

N131 / 3000

The N131 / 3000 was presented in November 2013. It is a low-wind power plant that should achieve high yields, especially at locations with low wind speeds (up to 7.5 m / s average annual wind speed). It follows the concept of the N117 / 2400, although both the nominal power and the rotor diameter have been increased by around 25%. According to Nordex, this enabled the electricity production costs at low wind locations to be reduced by more than 5% compared to the previous system. The sound power level has also been reduced compared to its predecessor, making the system particularly quiet compared to certain competing systems. Measurements on the prototype indicate that the guaranteed sound power level is undercut in practice by around 1.5 dB (A).

Technically, the system belongs to the Delta platform, with which it shares many components. On the other hand, the 64.4-meter-long rotor blades were newly developed, which, like the N117, are reinforced with CFRP in highly stressed areas. While the basic structure of the blades remained the same, the shape was changed and the blade was significantly slimmer towards the blade tip in order to cope with the higher loads and at the same time to make the system quieter. The gearbox was also designed for lower rotor speeds and higher torque. The generator is still a double-fed asynchronous generator. The N131 / 3000 was offered with steel towers of 99 and 114 meters, plus a hybrid tower of 134 meters is available in Germany. With these towers, the system reaches total heights of around 165, 180 and 200 meters. For certain Scandinavian locations, total heights of 210 meters are also planned. The prototype of the N131 / 3000 was installed in the Janneby community wind farm in the first quarter of 2015.

In September 2014, Nordex presented a rotor blade from this turbine that had been transported to the Hamburg Messe site on a rotor blade adapter, i.e. a flange mounted pivotably on a heavy transport vehicle , during the WindEnergy Hamburg wind energy trade fair . Nordex received the first order for this system even before the prototype was commissioned.

In December 2014, the N131 / 3000 was recognized by the specialist magazine Windpower Monthly as Wind Power Plant of the Year 2014 in the class of onshore turbines from 3 MW nominal output.

N131 / 3300

In September 2015, Nordex will be presenting a 10% more powerful version of the N131 turbine with a nominal output of 3.3 MW at HUSUM WindEnergy . It is designed for German low wind locations and is therefore available on a particularly high 164 m tower, which is intended to increase yields, especially inland. The prototype was erected in Brandenburg in December 2015. In June 2016 the first N131 / 3300 was erected on a hybrid tower with a hub height of 164 meters in Hausbay and at that time it was the highest wind turbine in the world. In the first year of operation, the system achieved an energy yield of over 9 million kWh at an average wind speed of 6.1 m / s, although it was switched off in phases as planned in order to take measurements.

N131 / 3600

On August 3, 2016, Nordex announced an increase in output of the N131 turbine by a further 10% to 3,600 kW. The tower heights for this type of turbine are 84 and 112 meters, and in Scandinavia a tower with a height of 134 meters is also available. The prototype was erected in the north wind test field near Husum on a tubular steel tower with a height of 106 meters and went into operation in January 2017. The standard energy capacity of the system is around 12.9 million kWh per year under the local conditions, the capacity factor is a good 40%. The N131 / 3600 is approved for locations with medium-strong winds (IEC 2). The possible energy yield under these conditions is up to 14.4 million kWh per year.

N131 / 3900

In April 2017, a fourth sub-series of the N131 with a rated output of 3,900 kW was presented. As with the N131 / 3000 and the N131 / 3300, this type is a low-wind turbine that is especially tailored for countries with sparsely populated areas in Europe and North America. The first two prototypes in Germany were installed in Groß Pankow and Dummerstorf at the beginning of 2018 . Series production is to start in the same year.

Delta4000 platform

In September 2017, Nordex presented a new product platform called Delta4000. The platform is based on the previous Delta platform, with which it shares many basic concepts, but is designed, for example, for higher performance and can be used more flexibly from a technical perspective. A first type of system is the N149 with an output between 4.0 and 4.5 megawatts. Other types of systems followed.

| Type | N133 / 4.8 | N149 / 4000-4500 |

|---|---|---|

| Nominal power (kW) | 4,800 | 4,000-4,500 (according to customer requirements) |

| Rotor diameter (m) | 133.2 | 149.1 |

| swept area (m²) | 13,935 | 17,460 |

| Area (m²) per MW | 2,903 | 4,365-3,880 |

| Speed per minute | 6.9-13.9 | 6.4-12.3 |

| transmission | Yes | |

| generator | double fed asynchronous generator | |

| Hub height (m) | 78, 83, 110 | 105, 125, 145, 164 |

| Total height (m) | 145, 140, 177 | 180, 200, 220, 240 |

N149 / 4000-4500

The N149 / 4000-4500 was presented in September 2017. It has a rotor diameter of 149 meters and various technically different power options that enable a nominal power between 4 and 4.5 MW depending on the location. It is designed for weak to medium wind locations (wind class IEC S) and 20 years of regular operating time, whereby it can also be designed for 25 years of operating time depending on the location-specific loads. Technically, the system largely follows the Delta platform: the rotor blades are 74.5 meters long and made in one piece, the load-bearing parts are made of CFRP to save weight. The rotor torque is transmitted to a double-fed asynchronous generator via a three-stage gearbox with two planetary stages and a spur gear stage. However, the position of converters and power transformers has been changed. In the case of the Delta class, they were in the base of the tower; in the case of the Delta4000 platform, they are located directly in the machine house. This is intended to reduce transmission losses in the tower, and it can also be used to completely prefabricate the machine house in the factory hall. The system is offered in four tower heights from 105 to 164 meters. There are two tubular steel towers with heights of 105 and 125 meters, which result in total heights of 180 or 200 meters, and two hybrid towers with 145 and 164 meters, which then lead to a total height of 220 and 240 meters. For large projects, other hub heights are available upon customer request, and concrete towers can also be used. Series production of the system type started in the first quarter of 2019.

The location of the two prototypes is Wennerstorf in Lower Saxony , where the turbines are replacing four AN Bonus 1.3 MW / 62 turbines from 2003 in a repowering project commissioned by ABO Wind . The first N149, which is also the first Delta4000 system, was built in August 2018. With a hub height of 125 meters and configured with a nominal output of 4.5 MW, each of the two systems should deliver around 15 million kWh per year, corresponding to around 3,330 full load hours. These turbines were the first installed systems in a newly developed generation of onshore series from various manufacturers with rotor diameters of around 150 meters and rated outputs of 4 to 5 MW. As of December 2018, Nordex had already received 150 orders. The series was named wind power plant of the year 2018 by the trade magazine Windpower Monthly in the category of onshore plants from 3 MW nominal output .

N149 / 5.x

At the end of March 2019, Nordex announced a new turbine with an output of 5 megawatts. It is to go into series production from 2021.

N133 / 4800

The N133 / 4800 was presented in April 2018 as the second system type of the Delta4000 platform. With a nominal output of 4.8 MW and a rotor diameter of 133 meters, the system is specially designed for locations with strong winds. An adapted version of the NR 65.5 rotor blade, which is already used in the N131 turbines, is used; the rotor diameter which is 2 meters larger is the result of using a different rotor hub. The system is available with three different hub heights of 78, 83 and 110 meters. Series production is scheduled to start in 2019. A prototype with a hub height of 125 m was put into operation in Carinerland in September 2019 .

N155 / 4.5

In May 2019, Nordex announced the N155 / 4.5. It is designed for medium wind conditions and specifically intended for markets such as the USA, Latin America, Africa and Southeast Asia. Series production is scheduled to start at the end of 2020.

N163 / 5.X

The N163 / 5.X was presented in August 2019. The turbine has a rotor diameter of 163 meters, the rotor blades are one-piece and in some cases use the same internal shapes as the NR74.5 blades used on the N149. The performance of the system is not fixed, but can be selected variably within a certain range depending on the location. Nordex did not initially specify the maximum possible output, but there should be variants with at least 5.5 MW. The hub height of the system should be between 118 and 164 m; a prototype will be built in Beckum in 2020 . Series production is targeted for 2021.

AW3000 platform

The AW3000 platform consists of six different system types. The prototype of the AW 100 was erected in 2008, later further systems for weaker wind conditions were added successively. With the takeover of Acciona Windpower by Nordex in April 2016, AW3000 turbines are now being marketed by Nordex. The construction of the platform is based on a drive train with a gearbox and a double-fed asynchronous generator .

In October 2017, Nordex presented a new low-wind turbine from the AW3000 platform. The plant also has a nominal output of 3 MW, but the rotor diameter has been increased to 140 meters. Series production should start at the end of 2018. The prototype was put into operation in Spain in July 2018.

| Type | AW 100 | AW 116 | AW 125 | AW 132 | AW 140 |

|---|---|---|---|---|---|

| IEC wind class | IA | IIA | IIB | IIB / S | S. |

| Nominal power (kW) | 3,000 | 3,000 | 3,000-3,300 | 3,000-3,465 | 3000 |

| Rotor diameter (m) | 100 | 116 | 125 | 132 | 140 |

| swept area (m²) | 7,854 | 10,568 | 12.305 | 13,720 | 15,431 |

| Hub height (m) | 100 | 92/100/120 | 80 / 87.5 / 100/120 / 137.5 | 84 / 112.5 / 120 / 137.5 | 120 |

Plant service

Nordex not only manufactures wind turbines, but also offers maintenance and service for existing systems. A total of four tiered service packages are available; They range from a basic contract that only includes regular maintenance and 24-hour remote monitoring to a full maintenance contract marketed as a premium package. In the 2013 BWE Service survey, Nordex Service achieved an overall rating of 2.87, placing Nordex third among German wind turbine manufacturers behind Enercon and GE Wind Energy . In 2014, the service business made up 9.6% of total group sales with sales of EUR 166.4 million. According to the annual report, the average system availability in 2018 was 97.7%, which is a typical value for modern wind turbines. The technical literature states that the technical availability of modern onshore wind turbines is between 97 and 99%.

Others

Nordex publishes a customer magazine every six months in which news from the company is reported. In addition, products are presented and developments in individual sales markets are described. Until 2012, the customer magazine was called Windpower Update , of which a total of 35 issues appeared. At the beginning of 2013, it was redesigned and renamed Nordex 360 ° ; the first edition appeared in February 2013.

See also

Web links

Individual evidence

- ↑ a b Annual Report 2019 . Nordex website, accessed on April 1, 2020.

- ↑ Factsheet website from Nordex, accessed on July 19, 2018.

- ↑ Largest companies in MV continue to grow . In: Nordkurier , November 27, 2018, accessed on January 15, 2019.

- ↑ Mario Neukirch: The international pioneering phase of wind energy use . Dissertation. Göttingen 2010, p. 288.

- ↑ a b Benjamin K. Sovacool: Energy policy making in Denmark: Implications for global energy security and sustainability . In: Energy Policy 61, (2013), 829-839, p. 830, doi: 10.1016 / j.enpol.2013.06.106 .

- ↑ Erich Hau: Wind power plants: Basics, technology, use, economy . Berlin / Heidelberg 2014, p. 57.

- ↑ Erich Hau: Wind power plants: Basics, technology, use, economy . Berlin / Heidelberg 2014, p. 60.

- ↑ See Mario Neukirch: The international pioneering phase of wind energy use . Dissertation. Göttingen 2010, p. 130.

- ↑ Mario Neukirch: The international pioneering phase of wind energy use . Dissertation. Göttingen 2010, p. 130.

- ↑ Annual report 2000/2001 . Nordex website, accessed on June 1, 2014.

- ↑ aktiencheck de AG: Nordex. Retrieved February 15, 2019 .

- ↑ Mario Neukirch: The international pioneering phase of wind energy use . Dissertation. Göttingen 2010, p. 185.

- ↑ Goldman Sachs sells Nordex shares to hedge funds . In: Die Welt , December 18, 2009, accessed July 1, 2013.

- ^ German turbine manufacturer Nordex to quadruple production . In: Windpower Monthly , December 1, 2007, accessed July 10, 2013.

- ↑ Wind turbine manufacturer Nordex inaugurates plant in Arkansas . In: Die Welt , October 30, 2010, accessed July 10, 2013.

- ↑ Nordex SE: Nordex now operates as a European stock corporation (SE). March 8, 2010, accessed April 20, 2010 .

- ↑ Nordex moves into new headquarters in Hamburg . Nordex website, accessed on June 1, 2014.

- ↑ Nordex achieves record orders in 2012 . In: Handelsblatt , January 15, 2013, accessed on January 15, 2013.

- ^ Lowering the CoE, a must in the wind industry ( Memento of October 29, 2012 in the Internet Archive ). In: notonlywindenergy.com , June 12, 2012, accessed July 3, 2012.

- ↑ Nordex ceases production in the USA . In: Manager Magazin , June 28, 2013, accessed July 10, 2013.

- ↑ Nordex hires 130 new employees for rotor blade production . In: Focus , November 2, 2012, accessed January 15, 2013.

- ↑ Nordex signs blade deal with TPI Composites . In: Windpower Monthly , August 13, 2013, accessed August 13, 2013.

- ↑ Wind power builders break the sound barrier . In: klimaretter.info , March 11, 2014, accessed on March 11, 2014.

- ↑ Nordex gets a major Spanish shareholder . In: Frankfurter Allgemeine Zeitung , October 5, 2015, accessed on October 5, 2015.

- ^ Acciona takeover. “A very big thing for Nordex” . In: Handelsblatt , April 4, 2016, accessed on April 4, 2016.

- ↑ Nordex acquires blade firm SSP Technology . In: Windpower Monthly , February 1, 2017. Retrieved February 1, 2017.

- ↑ Nordex buys rotor blade specialist SSP ( Memento of the original dated February 2, 2017 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice. . In: Renewable Energies. Das Magazin , February 1, 2017. Accessed February 1, 2017.

- ↑ DGAP-Adhoc: Nordex SE: Nordex resolves capital increase; Takeover offer from Acciona SA expected. Retrieved October 8, 2019 .

- ↑ a b Announcement pursuant to Section 23 Paragraph 1 Sentence 1 No. 3 of the Securities Acquisition and Takeover Act (WpÜG) , January 9, 2020, accessed on August 24, 2020 (pdf)

- ↑ Hamburg becomes the new wind capital . In: Hamburger Abendblatt , January 20, 2011, accessed on May 4, 2013.

- ↑ Resource protection at the Nordex Forum . Hochtief website , accessed May 4, 2013.

- ↑ Master data of the share. In: ir.nordex-online.com. Nordex, October 21, 2019, accessed on October 21, 2019 .

- ↑ Nordex Manager and Wind Energy Experts website, accessed on May 4, 2017

- ↑ As of May 2014, unless otherwise stated: Annual reports for the respective years of Nordex SE

- ↑ a b c 25 years of Nordex . The history of Nordex on the company website, accessed on May 7, 2013.

- ↑ a b Annual Report 2015 . Nordex website, accessed on March 23, 2016.

- ↑ Export quota in the wind industry in Germany from 2009 to 2012 . Statista , accessed March 23, 2015.

- ↑ Use of wind energy in Germany - as of December 31, 2012 (PDF; 6.4 MB). DEWI-Magazin 42, accessed on May 8, 2013.

- ↑ Status of onshore wind energy expansion in Germany ( Memento from April 2, 2015 in the Internet Archive ). Internet site of Deutsche Windguard, accessed on March 23, 2015.

- ↑ Cf. Robert Gasch , Jochen Twele: Windkraftanlagen. Basics, design, planning and operation , Wiesbaden 2005, p. 459.

- ↑ Danish concept - with passive or active house control . Internet site of the German Wind Energy Association, accessed on July 18, 2013.

- ↑ Products & Sales (PDF; 1.4 MB) Nordex SE, accessed on November 1, 2011.

- ↑ See Erich Hau: Wind power plants: Basics, technology, use, economy . Berlin / Heidelberg 2008, pp. 381–383.

- ↑ Erich Hau: Wind power plants: Basics, technology, use, economy . Berlin / Heidelberg 2008, p. 368.

- ↑ The following technical information on the platform and the individual turbine types comes largely from the platform brochure (PDF; 2.2 MB) and from the company magazine Windpower Update 30 (PDF; 2.1 MB).

- ↑ Nordex: Unit certificate guarantees smooth grid connection . Nordex press release from March 5, 2014.

- ↑ Nordex platform brochure Gamma Generation (PDF; 2.2 MB)

- ↑ for IEC 3a locations

- ↑ Windpower Update 15 (PDF; 2.4 MB), Nordex customer magazine, accessed on July 18, 2013.

- ↑ Nordex supplies exclusive 2.65MW turbine to UK project . In: Windpower Monthly , October 1, 2015, accessed October 1, 2015.

- ↑ Largest wind farm with Nordex N100 turbines on the grid . http://www.nachhaltige-produktion.de/ , accessed on July 27, 2013.

- ↑ Hybrid tower system Max Bögl ( Memento from April 11, 2014 in the Internet Archive ) (PDF; 2.2 MB). Max Bögl website , accessed July 18, 2013.

- ↑ WTs for low winds keep the onshore market going . In: Energie und Technik , December 3, 2012, accessed on July 18, 2013.

- ↑ Intense wind harvest in the pampas . In: Renewable Energies. Das Magazin , March 18, 2015, accessed on March 18, 2015.

- ↑ This information comes from an information board in the wind farm Hohenahr .

- ↑ Windpower Update 34 . (PDF; 1.9 MB) Nordex customer magazine, accessed on May 22, 2011.

- ↑ Nordex N117 / 2400 system: a positive result . In: oekonews.at , January 1, 2013, accessed January 15, 2013.

- ↑ Philip Tafarte et al .: Small adaptations, big impacts: Options for an optimized mix of variable renewable energy sources . In: Energy . tape 72 , 2014, p. 80-92 , doi : 10.1016 / j.energy.2014.04.094 .

- ↑ Record orders for 2016 . In: Renewable Energies. Das Magazin , June 12, 2015, accessed on June 12, 2015.

- ↑ Low wind focus opens up new markets . In: Windpower Monthly , July 1, 2013, accessed July 4, 2013.

- ↑ Nordex N117 / 2400 IEC 3a ( memento from March 24, 2015 in the archive.today web archive ). Internet site of the BWE, accessed on March 23, 2015.

- ↑ Turbines of the year - Turbines 2.1 - 3.5MW . In: Windpower Monthly , December 24, 2014, accessed October 2, 2014.

- ↑ First Nordex Generation Delta turbines erected and certificates received as planned. In: www.nordex-online.com. August 12, 2013. Retrieved August 12, 2016 .

- ↑ Nordex receives Delta approval . In: Windpower Monthly , August 12, 2013, accessed August 13, 2013.

- ↑ a b Nordex Delta Generation platform brochure (PDF; 2.2 MB)

- ↑ a b Close up - Nordex launches Delta turbine series at EWEA . In: Windpower Monthly , February 4, 2013, accessed January 5, 2013.

- ↑ a b N117 / 3600 and N131 / 3600 bring out up to twelve percent additional yield in medium and weak wind locations. In: www.nordex-online.com. August 3, 2016. Retrieved August 12, 2016 .

- ↑ Nordex readies first N117 / 3600 . In: Windpower Monthly , November 16, 2016. Retrieved November 16, 2016.

- ↑ Inland facility N131: Building by Numbers . In: Renewable Energies. The magazine , November 25, 2013, accessed November 26, 2013.

- ↑ Nordex: quiet 131-meter rotor . In: Renewable Energies. The magazine , November 25, 2013, accessed November 26, 2013.

- ↑ Nordex presents a new inland turbine for the German market . In: Renewable Energies. Das Magazin , September 16, 2015, accessed on September 16, 2015.

- ↑ Close up - Nordex launches new low-wind machine . In: Windpower Monthly , November 25, 2013, accessed November 26, 2013.

- ↑ Nordex interim report Q1 / 2015 . Nordex website, accessed on December 29, 2015.

- ↑ First order for Nordex N131 / 3000 . In: Windpower Monthly , September 23, 2014, accessed October 2, 2014.

- ^ Turbines of the year - The best wind turbine products of 2014 . In: Windpower Monthly , December 31, 2014, accessed January 2, 2015.

- ↑ Nordex unveils new 3.3MW model . In: Windpower Monthly , September 14, 2015, accessed September 14, 2015.

- ↑ Nordex installs the first new low-wind turbine . In: IWR , December 28, 2015, accessed December 29, 2015.

- ↑ The world's tallest wind turbine . In: Renewable Energies. Das Magazin , June 28, 2016. Retrieved June 28, 2016.

- ↑ Tallest turbine produces 9GWh in first year . In: Windpower Monthly , July 31, 2017. Accessed July 31, 2017.

- ↑ Nordex draws interim results for particularly high inland wind turbines . In: IWR , July 31, 2017. Retrieved July 31, 2017.

- ↑ Nordex unveils 3.6MW turbine . In: Windpower Monthly , August 3, 2016. Retrieved November 16, 2016.

- ↑ a b c 4 MW systems for low wind locations . In: Renewable Energies. Das Magazin , April 6, 2017. Retrieved April 6, 2017.

- ↑ Nordex erects the first new inland turbine . In: IWR , December 1, 2016. Retrieved December 1, 2016.

- ↑ Reference projects. WIND-projekt Ingenieur- und Projektentwicklungsgesellschaft, accessed on September 8, 2018 .

- ↑ a b Nordex Generation Delta grows up to exceed 4MW . In: Windpower Monthly , September 1, 2017. Retrieved September 1, 2017.

- ↑ a b Delta4000 . Nordex product brochure. Retrieved September 1, 2017.

- ↑ Nordex presents turbines of the 4 MW class for the first time at Husum Wind. In: iwr.de. September 1, 2017, accessed September 1, 2017 .

- ↑ Nordex Delta4000 production line begins rolling . In: Windpower Monthly , March 18, 2019. Retrieved March 18, 2019.

- ↑ Nordex's largest wind turbine, the N149, has been erected. In: iwrpressedienst.de. August 22, 2018. Retrieved September 9, 2018 .

- ↑ N149. Next generation inland prototypes. In: Renewable Energies. The magazine . July 4, 2018, accessed July 4, 2018 .

- ↑ Turbines of the year 2018: Onshore turbines 3MW-plus . In: Windpower Monthly , December 19, 2018. Retrieved January 2, 2019.

- ^ Felix Losada: Entering the 5 MW class: Nordex Group announces new N149 / 5.X turbine. In: Nordex Online. Nordex SE, March 26, 2019, accessed on April 1, 2019 .

- ↑ New Nordex turbine for strong wind locations . In: Sonne Wind & Wärme , April 26, 2018. Accessed April 26, 2018.

- ↑ SiGeKo wind energy systems . In: B2-Architekten.de . Retrieved December 2, 2019.

- ↑ Nordex launches new 155-meter rotor diameter turbine . In: Windpower Monthly , May 20, 2019. Retrieved May 29, 2019.

- ↑ Nordex adds 163-meter rotor to 5MW platform . In: Windpower Monthly , August 14, 2019. Retrieved August 14, 2019.

- ↑ Close-up: Acciona's AW3000 platform . In: Windpower Monthly , February 24, 2014, accessed April 5, 2016.

- ↑ Nordex launches larger rotor for AW 3MW class . In: Windpower Monthly , October 13, 2017. Retrieved October 13, 2017.

- ↑ Nordex spread its wings with N149 prototype . In: Windpower Monthly , August 23, 2018. Retrieved August 29, 2018.

- ↑ AW3000 platform brochure. In: nordex-online.com. October 2017, accessed April 23, 2014 .

- ↑ Nordex expands its service offering for wind farms - manufacturer takes on full maintenance for up to 12 years (PDF; 456 kB). Nordex website, accessed on July 11, 2013.

- ↑ Yearbook Wind Energy 2014 ( Memento from April 2, 2015 in the Internet Archive ). BWE website , accessed on March 23, 2015.

- ↑ Annual Report 2018 . Nordex website, accessed on April 1, 2020.

- ^ Robert Gasch , Jochen Twele: Wind turbines. Basics, design, planning and operation , Wiesbaden 2013, p. 564.

- ↑ Nordex 360 °, 1/2013 (PDF; 5.4 MB). Nordex website, accessed on May 24, 2013.

Coordinates: 54 ° 4 ′ 25.8 ″ N , 12 ° 7 ′ 52.5 ″ E