Leopard 2

| Leopard 2 | |

|---|---|

Leopard 2A5 of the Bundeswehr |

|

| General properties | |

| crew | 4 (commander, gunner, loader, driver) |

| length | Tower 12 o'clock 9.67 m (A4, A5) 10.97 m (from A6) |

| width | 3.70 m (A4) 3.76 m (from A5) |

| height | 3.03 m (upper edge PERI) |

| Dimensions | 62 t (A6) |

| Armament | |

| Main armament |

120 mm smoothbore gun, 42 rounds |

| Secondary armament | 2 × 7.62 mm MG 3 4750 rounds |

| Protection systems | |

| Armor | 3rd generation composite armor, additional armor in bulkhead construction |

| Mine protection strength | A6M: STANAG 4569 Level IV, 10 kg anti-tank mine and EFP mine |

| agility | |

| drive |

12-cylinder - diesel engine MTU MB 873 1,500 hp (1,103 kW) |

| suspension | Torsion bar suspension |

| Top speed | 68-72 km / h |

| Power / weight | approx. 17.8 kW / t (24.2 PS / t) (depending on the variant) |

| Range | approx. 500 km terrain: approx. 161 km |

The Leopard 2 is a battle tank made in Germany . It has been in series production since 1979 and is the successor to the Leopard 1 . In the long production period, various optional retrofitting options and specifications for foreign customers arose. That is why there are a large number of variants of the Leopard 2. It is manufactured in whole or in part under license abroad . For the manufacturer Krauss-Maffei Wegmann - 1979 Krauss-Maffei - it is a commercial success with around 3,600 units built. By 2008, the Bundeswehr had reduced its number of active Leopard 2s from 2,125 in 1990 to 350. As part of the realignment of the Bundeswehr , this number was to be reduced further to 225, but was increased again to 328 in April 2015 due to the changed security situation. The A6 version with a longer cannon has been in service since 2001. The Leopard 2 tank was originally intended as the backbone of armored forces and to defend against enemy tank units. It was used for the first time at KFOR in the aftermath of the Kosovo war . The NATO countries Denmark and Canada deployed the Leopard 2 in the ISAF mission in Afghanistan and Turkey from 2016 to 2019 in northern Syria.

history

The Leopard 2 main battle tank has its roots in a bilateral armaments project between the USA and the Federal Republic of Germany . Both states strove to replace the M48 Patton II models in Germany and the M60 in the USA. Therefore, in August 1963, it was decided to develop a uniform main battle tank for the respective armed forces as part of a government agreement. The project with the name Kampfpanzer 70 ( KPz 70 or English MBT 70 ) failed due to the very high demands placed on this vehicle: fire fighting from moving towards a moving target, weapon tracking, automatic loader, 20 mm secondary weapon system and the The arrangement of the driver's cab in the tower were just some of the requirements that were far ahead of their time. After seven prototypes and 830 million DM development costs, the program was discontinued in 1969; However, both partners let the development results of the KPz 70 flow into their national tank projects. The M1 Abrams was built on the US side , while the Leopard 2 was built in Germany.

The actual beginning of the development of the Leopard 2 can be traced back to the year 1970 - after the discontinuation of the MBT 70 project, the decision was made to build a new, own battle tank; an increase in the combat value of the Leopard 1 was rejected (project designation Gilded Leopard ). The then Defense Minister Helmut Schmidt stipulated that the new building should be based on the experimental development Keiler (Leopard 2K) by Krauss-Maffei, Porsche and Wegmann, which began in 1968, as well as the assemblies of the failed Kpz-70 project. The Eber (Leopard 2FK) study with the 152 mm M81 “ Shillelagh ” combination weapon, initiated by the Ministerial Director Eberhardt, Armaments Department at the Federal Ministry of Defense , was not pursued.

The first prototypes of the "Leopard 2K" (cannon) were built between 1972 and 1974 for testing purposes. The 16 chassis were given the designation PT (PT 1 to 17, the 12 was not assigned) and used the advanced engine of the battle tank 70. The 17 towers of the first generation were designated T1 to T17 . The similarity of the turret shape to the Leopard 1A3 and 1A4 was intentional, as the EMES 12 rangefinder had to be retrofittable in the Leopard 1. The armouring of the hull and turret was made of mild steel, PT / T 6 to 10 and PT / T 13 to 17 were made of armored steel. Smooth-barreled cannons in caliber 105 mm and 120 mm served as the main armament . The turret 11 received the apex mounted 20-mm automatic cannon as secondary armament. In addition to the torsion bar suspension, the hydropneumatic spring system of the KPz 70 was also being tested .

In 1973 the first troop attempt at combat force school 2 in Munster followed with two prototypes; further tests with four additional prototypes followed in the summer of 1974. The climate tests in 1975 at the military training area Shilo / Canada and in Yuma (Arizona) served to determine the resilience. Another five prototypes were used at the Trier , Meppen and Greding test sites for system and component analysis. The prototype PT 7 was sold to the USA.

The second generation of the prototypes, which should at least outwardly come close to the later production version, were the Leopard 2 AV. Based on the findings from the Yom Kippur War in 1973, the armor protection was significantly improved, which led to a redesign of the hull and turret, but also raised the combat weight of the tank well above the targeted MLC 50 and therefore established the MLC 60 as the new upper limit. The bilateral study of a double-barreled casemate tank , in which the MLC-50 limit was complied with, was an alternative to the Leopard-2 development for a short time, but was not successful.

Due to the new protection concept and the elimination of retrofitting the Leopard 1, the first generation tower 14 was converted to the T14 mod. Due to reservations about laser rangefinders, Leitz built the EMES 13, a passive rangefinder that was based on the correlation principle and had a basic width of 350 mm. This allowed Wegmann to construct the shrew tower . Ultimately, the US demand for a better protection concept and the available composite armor led to the angular shape of the series tower. An auxiliary power unit from the first prototypes designed for the electrical supply of the vehicle when the engine was at a standstill and for preheating was omitted in favor of a larger tank volume. It was only 30 years later that the additional power supply was implemented based on the experience gained during operations in crisis areas. In addition, the fire control system (FLA) has been simplified; the optics were primarily stabilized, the bottom of the tank made mine-proof and the electronics, including hydraulics and ammunition, embedded in the turret rear. The previously used night vision devices were replaced by a thermal imaging device, which, however, was not yet available. The main armament was on-board cannons in caliber 105 mm and 120 mm. The armor was made of normal steel, the firing vehicle was made of armored steel.

Another important step was marked in 1976 by comparative testing of the Leopard 2 AV (PT19 / T19) with a 105 mm drawbar cannon and the XM1 (prototype of today's M1 battle tank) in the Aberdeen Proving Grounds , Maryland / USA. Here, the advantages and disadvantages of the two weapon systems were determined for the first time, although a commitment by the two states to a common battle tank was rejected from the outset by both sides. Of the 117 criteria established, of which 77 were evaluated, the Leopard 2 fulfilled AV 61 and the XM1 48. In 17 evaluation groups, however, only six were fulfilled by the Leopard 2 and 16 by the XM1. Evaluated according to the German system, in which each criterion was assessed and evaluated individually, the Leopard 2 was clearly superior to the XM1. The XM1 lacked the NBC protection system, an independent periscope for the commander and the ability to go underwater. However, according to the instructions of the then Defense Minister Georg Leber , any kind of protest had to be avoided. The signed letter of intent (MoU - Memorandum of Understanding ), in which the test conditions had been accepted, prohibited any contradiction. Instead, as many assemblies of the two tanks as possible should be identical. However, due to the advanced development phase of the German system and a different view of the performance of the respective in-house production, this only came to the fore. Significant changes on the way to the production vehicle were the installation of the 120 mm smoothbore cannon and the decision to install the license-produced laser rangefinder from the US company Hughes , which was cheaper and ready for series production compared to the EMES 13. Instead of the WBG-X thermal imaging device from Zeiss, the WBG basic device (US Common Modules) from Texas Instruments was selected. After the tests were completed, the 120 mm weapon system that had been brought along was installed in the AV on site to demonstrate its feasibility.

The Americans initially rejected the German smoothbore cannon and stuck with the 105 mm M68 cannon (variant of the British Royal Ordnance L7 ), but took over the German chains and ammunition holders. In 1985, the 120 mm smoothbore cannon was built into the M1 under license from the US - then designated as the M1A1. Plans to install the American gas turbine in the Leopard were examined by the company Maschinenbau Kiel (MaK) on a prototype in 1977 and 1978, but discarded due to the advanced stage of development because the tank would have had to be changed again.

In 1977 the then Krauss-Maffei company - today's Krauss-Maffei Wegmann - was designated as the general contractor for the delivery of 1,800 Leopard 2 battle tanks, 810 tanks (45%) were owned by the MaK company (since 2000 Rheinmetall Landsysteme ). The production should take place in five construction lots. At the end of the project, however, there were eight lots with an additional 325 Leopard 2. In the variants A0 to A4, 2125 copies were produced for the German armed forces. A total of 1500 companies took part in the production.

In September 1977, the Leopard 2 AV was presented to the public for the first time at an army show in Cologne-Wahn. After three Vorserienfahrgestellen to troops experimental purposes, the first was in mass-produced battle tank type Leopard 2 on October 25, 1979 in Munich the panzerlehrbrigade 9 passed in Munster.

According to the procurement instructions, the development costs for the Leopard 2 program amounted to 359.4 million German marks , but without taking into account the further development of the engine from the Kampfpanzer 70 program and the development of the 120 mm smoothbore gun including ammunition. The real costs rose to DM 600 million, which includes all items from experimental development to series production (1967 to 1984). The system price for a Leopard 2 in the 21st century is quoted from three to seven million euros, which fluctuate due to inflation and exchange rates and also depend on the number of items ordered. In addition to the vehicle, the price includes technical support and spare parts over a certain period of time. The Leopard 2 is to remain in service with the German Armed Forces until 2030 and will then be replaced by a successor, the development of which is to have started in 2015 as a Franco-German project under the name Main Ground Combat System (MGCS).

Function description

The Leopard 2 is a post-war third generation main battle tank with a crew of four. In a conventional design with a rear engine, it was designed for the concept of combined arms combat for anti-tank combat in conjunction with the Marder armored personnel carrier . It is the main weapon system of the armored forces of the Bundeswehr as well as foreign user states.

It consists of a tank with a self-supporting turret on top with a 120 mm smooth -barreled cannon as the main armament, a smoke-throwing system and two machine guns of different types, depending on the user state, as secondary armament. The fire control system in the tower enables the gunner to conduct fire fighting with stationary or moving targets, both while standing and while driving.

The tank was subjected to combat value increases several times. In the A5 version, additional armor was attached to the tower front ; a separate thermal imaging device for the commander made him independent of the gunner. With the residual light amplifier for the driver, the tank is fully capable of night-time and limited all-weather combat. With the A6 version, the firepower has been increased. Compared to the standard L / 44 cannon, the L / 55 is 1.30 meters longer and enables the powder energy to be converted better into projectile speed. This in turn increases the range, shot precision and penetration performance of APFSDS projectiles.

To protect the four-man crew, like all tanks of the Cold War, it has an NBC protection and ventilation system with an output of 300 m³ / h, which is intended to ensure endurance in areas contaminated with NBC weapons . The maximum duration of use is specified as 48 hours.

Like other main battle tanks, the Leopard 2 can cross bodies of water without the aid of pioneering technology . To 1.20 meter of water it is no superstructure or preparations for fording . With the foldable 50 centimeter deep wading shaft that is carried along, his deep wading ability increases to 2.25 meters; Thanks to a three-part rigid underwater drive shaft that is not carried, it can be driven underwater up to a water depth of 4 meters. That means it disappears completely under water. When wading deep, the diving hydraulics are switched on and a rubber diving cap is attached to the cannon muzzle. Up to the 2A4, the loader had to inflate the turret ring seal using a hand pump, but this measure was not required for the A5 with lower manufacturing tolerances. The hydraulic system closes the ventilation on the engine and opens a combustion air flap on the engine bulkhead inside the tank. During deep wading and underwater driving, the engine draws in the combustion air through the commander's hatch with the deep wading or underwater shaft attached. The commander stands in this shaft when driving through and supports the driver. Since water ingress cannot be completely avoided, the vehicle has two bilge pumps and the crew is equipped with diving rescues and swimming collars.

The tanks of the Bundeswehr each have two VHF radios SEM (transmitter / receiver, mobile) 80/80 or 80/90 for communication . As with the secondary armament, the equipment can also vary here. To reduce the heat signature and to support the passive armor protection, the Leopard 2 is provided with an infrared-reducing coating.

technical description

Armament

The armament consists of the weapon system with the main weapon and the fire control and aiming equipment and the secondary armament.

The main weapon of the Leopard 2 is the 120 mm smooth barrel cannon Rh 120 with smoke extractor from Rheinmetall for wing-stabilized KE sub-caliber balancing or full-caliber multi-purpose projectiles. It is journal-mounted and has a height adjustment range of −9 ° to + 20 ° and a swivel range of 360 °. When turning over the rear of the tank, the on-board cannon is automatically raised by the rear deflector function and prevents the on-board cannon from touching the rear of the vehicle between the turret positions 5 a.m. and 7 a.m. In this area, the on-board cannon cannot be aimed below −3 °.

Secondary armament is a tube-parallel ( coaxial ) machine gun ("masking machine gun"), a machine gun for anti-aircraft guns next to the loading gun's hatch ("anti-aircraft machine gun") and a multiple throwing system (MWA) with 2 × 8 throwing cups on the side of the turret for shooting Fog throwers for self-protection. Since May 2005, the armed forces have largely had a new multi-purpose throwing system (MZWA) with the arrangement 6/2 (six cups in the upper row, two cups in the lower row) on each side. The new system is able to fire explosive or non-lethal ammunition.

For maneuvers and the representation of the fire fight with and without training device duel simulator, the leopard has recordings for the KADAG (cannon-launching device), often also known under the abbreviation DARKAS (representation-cannon-shooting). The arrangement is up to the Leopard 2A4 above the on-board cannon and from A5 on the front left on the wedge armor of the turret.

In addition to the on-board armament, the crew has handguns for self-defense. In the Bundeswehr there are two MP7s , two P8s , an HK P2A1 signal pistol , four hand grenades and the two MG3s of the tank with a total of 4750 rounds, belted with soft-core tracer at a ratio of three to two.

Weapon stabilization

The turret or the main weapon on the Leopard 2A4 has a hydraulic weapon tracking system (WNA-H22); Main battle tanks from version A5 are equipped with an electric weapon tracking system (EWNA). In combination with the central logic / main distribution, the aiming devices, the fire control computer, the operating devices and the internal tank testing device RPP 1-8, the assemblies form the fire control system of the battle tank.

In the automatically stabilized STAB ON operating mode, uneven ground and driving speed are automatically compensated, so the weapon system remains aimed at the target under all external conditions. The cannon and the turret are stabilized by measuring the movement with gyroscopes and by the motorized directional drives in height and side by the weapon tracking system. The weapon is thus tracked to the target values of the leading aiming device (EMES or PERI). Because of the very small errors in the stabilization of the mirrors of the outlook assemblies, the intended target always remains in the picture even when driving. The gunner or the commander only has to aim at the target with the leading optics and follow moving targets if necessary. By pressing the button for the dynamic lead, the travel movement of a target is automatically taken into account.

Another operating mode is TURM OFF - in which the power supply of the tower is switched off, only the radio system, the lighting and the MG fan are supplied. Aiming and firing are done manually, the weapon is not stabilized. In the OBSERVING operating mode, there is a full power supply in restricted operation. Rough straightening is possible for the gunner, the optics are adjusted to the on-board cannon, which means that the line pattern changes with changed values. All aiming devices can be used, but in this operating mode it is not possible to shoot while moving. A manual lead is necessary against moving targets . The technology takes about 25 seconds to raise the tower in STAB EIN .

Target devices

The main aiming device is the EMES 15 with a CE628 laser from Zeiss-Eltro Optronic as an electro-optical rangefinder . The Nd: YAG laser measures distances of up to 9990 meters with an accuracy of 10 meters, with only shooting distances between 200 and 4000 meters being taken into account. For measurements below 200 meters, the fire control computer uses the add-on value for 1000 meters, values over 4000 meters must be entered manually. If the laser has multiple echoes, the first echo can be selected in addition to the last echo from the Leopard 2A5. Coupled with the twelve-fold magnifying main rifle scope (HZF), it is the primary target optics for the gunner. In the STAB EIN operating mode , the EMES 15 is the leading optics for the turret and on-board cannon. The gunner has the tower rifle scope (TZF) FERO Z18 at his disposal as a second target device. If the fire control system fails, it serves as an emergency optics. A scale in the line image supports setting the estimated shooting distance.

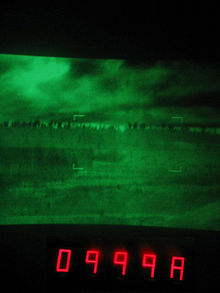

The thermal imaging device WBG-X from Zeiss has also been integrated into the EMES 15 from 1983 ; it replaces the PZB 200 as a night target device . A four- and twelve-fold magnification allows observation and combat both during the day and at night. With a detector made of mercury - cadmium - telluride , which has to be cooled to around −190 ° C, the WBG requires a pre-cooling time of around 15 minutes. The display is green-monochrome with a selectable polarity of black or white, so that heat sources appear particularly bright or dark. If there is a sufficient temperature difference between individual objects, these can be seen very well in an observed section of the terrain. Heavy rain, snow and thick fog with a high water content reduce the range of the thermal imaging device.

With the periscope R17 (PERI R17), the commander has his own observation and aiming device, but without a range-finding function. The stabilized optics with two and eight times magnification allow you to work independently from the gunner. In this way, the commander can independently observe targets, assign targets to the gunner and monitor him. The PERI has the following setting options for this purpose: By pressing the KH button (commander carries main weapon), the turret swings into the line of sight of the PERI, the target can be fought by the gunner or the commander. With the selection ZÜ (target monitoring), on the other hand, the PERI swings into the line of sight of the EMES, the commander sees the target of the gunner. By switching to the direct view adapter - an optical connection between EMES and PERI - the image of the EMES used by the gunner can be transmitted.

With the PERI R17A2 and the integrated thermal imaging device TIM ( Thermal Imaging Module), from the Leopard 2A5 onwards, maneuverability at night is made easier. For better all-round visibility, it was moved to the commander's left hatch. The PERI lookout head is raised. The OPHELIOS-P was installed as a thermal imaging module, the image of which is displayed on a monitor directly below the corner mirror . It is also possible to display the picture of the EMES. The WBG has four times, twelve times and 24 times magnification. Two fixed index positions at 6 o'clock and 12 o'clock make it possible to align the line of sight of the PERI with the longitudinal axis of the armored hull, regardless of the turret position.

With the retrofitting of the Attica thermal imaging module, which can be found in the Canadian, Danish and some German tanks, the commander and gunner are able to achieve significantly better target acquisition, as the higher thermal resolution means that lower temperature differences between the object and its surroundings can be seen more clearly. The third generation thermal imaging device is also used by KMW in the A7 + and is also found in the Puma (armored personnel carrier ) and in the Luna reconnaissance drone .

A field adjustment mirror near the muzzle of the cannon enables the gunner to correct the adjustment of the target equipment to the main weapon when the field adjustment system is switched on, in order to compensate for deviations in the core axis of the barrel caused by thermal and mechanical loads. When the alignment system is switched on, the main telescopic sight and cannon are at a structurally fixed angle, whereupon a reference beam is reflected by the mirror , with which deviations from the alignment mark can be detected.

ammunition

The ammunition for the cannon is located in the rear of the turret as well as in the tank hull. The ready-to-use ammunition behind a pressure-tight bulkhead door in the turret contains 15 cartridges (which can be of different types) and is accessible to the loader at any time. The 27 cartridges (from A6M reduced to 22 cartridges) in the tub (on the left of the driver in the direction of travel) are only accessible when the tower is in a certain position (3 o'clock - then lashed for safety reasons).

The Leopard 2 initially had two types of ammunition. The projectile used against enemy armored vehicle has the KE-ammunition (BW designation for K inetische E nergy, NATO designation APFSDS (-T) Armor Piercing Fin Stabilized Discarding Sabot tracer ), an armor piercing kinetic energy projectile with a sabot and tracer . Against hardened and soft targets, including infantry, the MZ-munitions (BW name for M honest Z wake ammunition, NATO designation HEAT -MP T High Explosive Anti Tank Multi Purpose - Tracer ), a shaped charge multipurpose projectile with tracer , used. Both types of bullets are wing stabilized. All types of ammunition consist of partially combustible cases, made of cellulose, nitrocellulose, resin and stabilizing additives and only leave the case base made of steel when fired.

With KE ammunition, a wing-stabilized arrow projectile with a caliber of about 38 millimeters made of sintered tungsten carbide is fired from the 120 mm smooth-barreled cannon with the aid of a sabot . The projectile has, depending on the type of ammunition and on-board cannon (DM 33 + L / 44), a muzzle velocity of 1640 m / s (i.e. about five times the speed of sound). The effect of the KE projectile is based on kinetic energy; it does not contain explosives; its effect is solely dependent on the energy it hits. After hitting the target and while penetrating the armor, the arrow displaces armor material due to its high kinetic energy. If it penetrates into the fighting compartment, it causes a rain of splinters on the inside. As the distance increases, the air resistance reduces the penetrator's speed and thus its kinetic energy and penetration performance.

The MZ bullet has a muzzle velocity of 1140 m / s. The speed has no noteworthy effect on the penetration power. This is due to the design of the projectile as a hollow charge projectile. As a result, the shooting distance also has no influence on the target effect. As a result of the extreme heat caused by the breakthrough, secondary explosions usually occur in the tank. Pressure and splinters of molten material act against the occupants. The penetration performance against homogeneous armor plates is around 600 millimeters for the MZ bullet and over 800 millimeters for the KE bullet.

Due to the improvements in the protection technology against shaped charge projectiles, Rheinmetall developed a HE projectile (high explosive grenade). It replaces the old and no longer produced MZ ammunition in the Bundeswehr and improves the effectiveness of the Leopard 2 against area targets, against positions behind cover, in shelters and buildings, against infantry, armored personnel carriers and lightly armored transport vehicles. The muzzle velocity of the 19 kilogram bullet is around 1100 m / s with the L / 55 and enables combat distances of up to 5000 meters. In addition to a time fuse, the ammunition also has an impact fuse with and without delay. The igniter is set either manually via a separate igniter setting device or automatically via a connection to the fire control computer. With the help of the time fuse it is possible to detonate the ammunition in the air at a predetermined distance from the target. The ammunition was introduced as DM11 in 2014. The unit price is around 9,000 euros.

In addition to this ammunition, the armed forces also have practice ammunition for the live shot. The Bundeswehr uses them for the KE and MZ transfer projectiles. Both are marked light blue. Due to the safety area of 90 kilometers for KE combat ammunition, the armored troops almost exclusively use the KE ammunition practice variant for live shots in Germany. The penetrator of the KE-Ub is made of a lighter material and has a perforated cone tail. Over the first 2,000 meters, the external ballistic properties largely correspond to those of combat ammunition; only at greater distances do there are rapidly increasing deviations. The safety area is 22 kilometers, with improved KE-OU ( APFSDS-T-TP, TP stands for Target Practice ) it is 7.5 kilometers. The MZ-Ub ( HEAT-T-TP ) is the same as the DM 12 A2 combat cartridge except for the warhead. This has a concrete head to reduce the damage in the target area and thus the costs.

In addition to the usual types of ammunition for the Leopard 2, Rheinmetall also advertised a retrofit kit called LAHAT , with which a further increase in performance is achieved. LAHAT is a laser-guided missile from Israel Aerospace Industries with an effective range of more than 6000 meters, which is fired from the on-board cannon or from a position-independent launcher. The improvement also includes a laser-based fire control system for weapon control. The rocket is insensitive to all known attempts to interfere and can be used against tanks, helicopters and targets out of sight of the crew.

In addition, PELE and canister ammunition are available depending on the user state .

| Surname | Type | Mass - cartridge in kg |

Mass - penetrator / bullet in kg |

Muzzle velocity in m / s |

Combat distance in m |

Introduction / note |

|---|---|---|---|---|---|---|

| DM12 | MZ | 23.2 | 13.5 | circa 1140 | approx. 2600 | 1979 |

| DM12A1 | MZ | 23.2 | 14.1 | circa 1140 | approx. 2600 | Successor to the DM12 |

| DM13 | KE | - | circa 1650 | approx. 3200 | 1979 | |

| DM23 | KE | - | circa 1650 | approx. 3500 | 1983 | |

| DM33 | KE | 19th | 4.6 | circa 1650 | approx. 3500 | 1987 |

| DM43 / DM43A1 (LKE I) |

KE | 20th | 7.2 with sabot | 1740 | - | International use |

| DM53 (LKE II) |

KE | 21.4 | approx. 5 | 1670 (L / 44) 1750 (L / 55) |

4000 | 1999 |

|

DM53A1 / DM63 (LKE II) |

KE | ? | approx 8.45 | 1750 (L / 55) | - | 2005 improved LKE II, stronger propellant charge; Increased effective shooting distance, shooting only from L / 55. |

| DM11 | HE | approx. 19 | - | approx. 950 (L / 44) approx. 1100 (L / 55) |

5000 | 2014 Can with a programming kit consisting of an "Ammunition Communication Module (ACM)" for programming the detonators, an interface (interface box) between the ACM and the fire control computer that generates all relevant data for the ACM and an additional switch box for the loader control unit (Add -on Control-Box / ACB) can be fired from every Leopard 2. |

Note: Ammunition used by the Bundeswehr

Armor

The Leopard 2 is protected by composite armor (also known as multilayer or composite armor ) of the third generation (C technology). The exact structure and the strength are subject to confidentiality and are based on the current development of weapon technology. The armor consists of a multiple bulkhead arrangement in which the spaces are filled with elastic rubber. Different types of steel with different degrees of hardness and composite materials such as ceramic, plastic or Kevlar can be used as materials. The structure follows the Chobham principle , but is not Chobham armor . Special emphasis was placed on strong front armor.

The hull and the tower are manufactured as a housing with integrated armor ; that is, the outer and inner armor plates also take on body functions in addition to protection. Within this load-bearing structure, the actual armor in the form of blocks is inserted into the intended cavities, which gives the armor its angular shape.

The wedge armor attached to the turret front since the Leopard 2A5 , on the other hand, was designed as spaced armor and has the task of increasing the depth of the armor, breaking KE penetrators and detonating shaped charge projectiles (HL) in front of the basic armor. For this purpose, the structure is usually divided into the destabilization stage (disturber), crushing stage (disrupter) and erosion stage (absorber). The often assumed ricochet of the projectiles does not occur, however, since KE ammunition of the 21st century is still effective at impact angles of 10 ° to 15 °.

The ammunition bunker in the rear of the tower has blow-out panels on the upper side in order to dissipate the energy of an explosion of the ammunition stored there to the outside. The interior of the armor is lined with fabric mats (spall liner) made of high-strength fibers such as aramid (Kevlar) in order to reduce or completely prevent the splinter cone when penetrating the armor.

In addition to these protective functions, the Leopard 2 has, depending on the operating country, other armor elements such as bomblet protection for the top, slat armor (a cage against HL bullets), extended mine protection (see A6M) or additional armor in the form of the composite armor from Mexico or AMAP from IBD Deisenroth Engineering (Deisenroth engineering office).

The various versions of the Leopard 2 have the following armor protection ( RHA equivalent) against HEAT and KE projectiles :

| Component | Leopard 2A1-A3 | Leopard 2A4 | Leopard 2A5 | Stridsvagn 122 |

|---|---|---|---|---|

| Tub front KE floors: |

350-550 mm | 600 mm | 620 mm | 620-780 mm |

| Tub front HEAT grenades: |

520 mm | 620-710 mm | 620-750 mm | 750-920 mm |

| Tower front KE storeys: |

500-550 mm | 590-690 mm | 850-930 mm | 920-940 mm |

| Tower front HEAT grenades: |

810 mm | 810-1290 mm | 980-1730 mm | 1290-1960 mm |

Drive and drive

The tank has a torsion bar sprung support roller running gear with lamellar dampers and hydraulic and mechanical end stops over the swing arms of the running wheel pairs. Its torsion bars are preloaded with 50 kN each. It has a "living" end connector crawler track with exchangeable chain pads from Diehl of the type 570 F (later FT). When driving in snow, on ice or to increase the grip of the chain, 18 chain cushions per side can be exchanged for cast iron snow grippers in a short time.

The Leopard 2 is of a liquid-cooled four-stroke V12 prechamber - multi-fuel engine of the type MTU driven MB 873-Ka five hundred and first With intercooling and two turbochargers fitted it makes 1100 kW (1500 hp) at an engine speed of 2600 rpm -1 and accelerate the tank to a top speed of officially 68 km / h. The real final speed to be achieved varies and can be up to 30 km / h higher depending on the surface. Overspeed from 2850 min −1 are prevented by the electronic engine control system (MKA). It is automatically switched off in the event of a critical coolant condition or oil level. For emergencies in combat situations, the MKA has a sealed bridging circuit. The maximum torque of 4700 Nm at 1600 min -1 achieved.

The unit comes from the Ka 500 engine program of the Kampfpanzer 70 development. In comparison, the Ka 501 has a larger displacement to 47.6 liters, which is reflected in a higher torque and load acceptance capability across the entire speed range and improved acceleration capability. The degree of separation of the combination air filter and the efficiency of the cooling system have been improved and increased stability. The pure multi-fuel capability was not pursued further during the further development by MTU Friedrichshafen, so that at least a fuel mixture of 60% diesel and 40% of another approved flammable liquid is necessary. A dry sump pressure circulation lubrication ensures an oil supply to all lubrication points even with an inclined position of 35 ° in the direction of the crankshaft and 25 ° across it. The supply lines to the vehicle are equipped with self-sealing quick release couplings. An oil-cooled 20 kW generator attached to the diesel engine via an intermediate transmission supplies the 24 V on-board network with electricity.

The combustion air required for operation is supplied through two combination air filters attached to the side of the engine. In them, the air sucked in through two circular intake ducts on the engine cover plate is cleaned and 95% of the coarse dust is freed via cyclone filters. This is then removed from the engine room by a coarse vacuum fan. Two further round fine filter inserts bind the remaining dust particles. The waste heat is dissipated via two temperature-controlled ring coolers with an integrated fan arrangement on the gear unit. These are separated from the motor by a rubber lip so that they can be rinsed with water when the immersion hydraulics are switched on. The fans are switched off during this time. In normal operation, the heated exhaust air is blown down through the large rear grating and used there to cool the hot exhaust gases; which are also ejected slightly diagonally downwards through two circular gratings. The exhaust system is equipped with non-return valves for underwater travel.

The hydromechanical shift, reversing and steering gear of the type Renk-HSWL-354 is used to transmit power to the chain. It combines the drive, steering and auxiliary drive as well as the brake system in one housing and is flanged together with the motor via quick-release devices to form the engine block. The drive is equipped with a hydrodynamic-mechanical 4-speed powershift transmission with a reversing stage. A mechanically bypassable torque converter is used as a low-wear power transmission in the lower speed range; the tank drives in converter mode. Above 1300 min −1 , an automatically closing lock-up clutch creates a fixed connection with which the engine power is transmitted like a rigid shaft. The service brake integrated in the transmission works in two stages. The tank is braked above 35 km / h by a wear-free hydraulic flow brake (hydrodynamic retarder ). Below this speed, the brake discs are activated with a pressure of> 98 bar. This enables a Leopard 2A4 to brake a distance of only 20.6 meters when the brakes are fully applied from 70 km / h.

As with its predecessors, the drive system is designed as a complete engine block, which enables the complete drive train to be changed with the support of an armored recovery vehicle within 15 minutes as part of a dynamic weapons show. However, many activities such as disconnecting the side gear or releasing the rear plate are already carried out in advance. A change according to the specifications of the technical service regulation is specified with four hours.

The relatively low fuel consumption of the Leopard 2 is also worth mentioning. Compared to the US M1 Abrams tank, which is often used as a comparison, with its Avco Lycoming AGT-1500 gas turbine, the consumption is around half. The diesel drive has the greatest advantage in idling and partial load operation .

A is for operating the electrical systems without running the main engine in the rear right hull rear auxiliary power unit (engl. Auxiliary power unit APU) installed. Depending on the user country, the diesel unit has an output of 7.5 kW to 17 kW. The batteries are charged and monitored in the Auto and Load operating modes . In the Continuous stage , the unit is in continuous operation; it takes over the complete supply and relieves the batteries.

crew

The Leopard 2 has a crew of four (commander, gunner, loader and driver). This is followed by a description of the job and the distribution of tasks for a German tank crew.

commander

The commander is responsible for the battle tank and its crew. In battle, he has to deal with a variety of tasks:

- Conducting radio communications with the platoon leader or company commander

- Reconnaissance of the battlefield and target assignment for the gunner

- Leading the battle tank in a platoon by giving instructions to the driver

- Conducting the fire fight by overriding the gunner (in emergency or duel situations)

- Determination of the type of ammunition to be used: (KE, MZ or MG)

This is only a selection of the most important functions; In addition, there are obligations to fulfill the deadline booklet (i.e. maintenance) and the checklist and thus to maintain the operational readiness of the tank. A multiple burden arises when the commander of the tank is platoon commander, company commander or battalion commander at the same time. He is then not only responsible for the elementary tasks in his own tank, but also has to take over the tactical coordination, i.e. movement, target assignment and fire clearance for the formation under him.

Gunner

The gunner is the deputy commander and, if he fails, must take over the relevant functions as far as possible. However, he is primarily responsible for leading the fire fight and observing the battlefield in his observation area. In addition, he must avoid damage to the tower by terrain or vegetation by moving the tower and the on-board cannon accordingly. Up to version A4, the gunner led the fire fight largely independently according to certain specifications, whereby first offensive units, for example battle tanks (then the use of ammunition was also directed), the commander could override the gunner in dangerous situations (aiming at a target, fought by gunner). As of version A5, the commander usually assigns the target to be fought to the gunner, as he has an observation facility (PERI R17) that is independent of the tower and enables him to have a 360-degree view without having to move the tower. However, if a duel situation occurs, i.e. if the gunner detects a target (for example an enemy main battle tank) that is about to fight his own tank, he is instructed to fight this target with the ammunition currently loaded without any further inquiry to the commander. As a secondary weapon, it uses the machine gun mounted axially parallel to the on-board cannon.

In addition to his duties in combat, he is responsible for fulfilling his points in the deadline booklet or in the checklist, i.e. he takes care of maintenance and care for the tower together with the commander.

Loader

The loader has the most physically demanding job in a battle: He has to remove the 120 mm cartridges from the ammunition bunker in the tower and use them to reload the on-board cannon. The often specified rate of fire of nine rounds per minute (realistically four to six rounds / minute) represents a very good performance by the loader, since even light terrain presents the loader with a physical challenge when conducting a fire fight while moving. In addition to reloading the on-board cannon, he is also responsible for the axially parallel MG3 and 7.62 mm FlaMG (anti-aircraft machine gun). Even if it is seldom or never used for the purpose originally intended, the loader also has the option of intervening in the fighting with the MG attached to his hatch. Like the commander and gunner, the loader is responsible for maintenance work on the tank. In addition, the loader is usually responsible as a guide for the tank and clears the tank for action, i.e. he removes the rotating beacon, covers the headlights, folds up the rear chain covers and removes the mud flaps.

driver

In contrast to the rest of the crew, the driver is accommodated in the front right of the tub and is practically isolated from the rest of his crew. He is the only member of the crew who can directly influence the movements of the tank and therefore has a special responsibility. In combat, he must guide the vehicle in such a way that it never occupies an exposed position, i.e. exposed to enemy fire. He has to have “an eye” for the terrain, spot the most favorable positions and position the tank there. The commander gives the driver basic marching orders or goals, the specific execution is left to the driver. Choosing the best driving movements is made more difficult by the severely restricted field of vision under the hatch (i.e. with the driver hatch closed). In certain emergency situations, the driver is instructed to evade independently, for example when artillery fire begins. For night combat, the driver can exchange the middle of his three corner mirrors for a night vision device . In addition, he is responsible for the maintenance of the entire hull including the engine and running gear, etc., whereby the other crew members, for example, help with adjusting the chain tension.

In civil road traffic, the driver is supported by the commander and loader; These help to assess the traffic situation, warn of overtaking vehicles or indicate following vehicles to keep more distance. In Germany, the driver has to drive over the hatch while driving on the road , i.e. the driver's hatch is open and he can see out above. The height of the driver's seat can be adjusted accordingly.

Operational experience

KFOR

On June 12, 1999, 28 Leopard 2A5s were deployed by the German Armed Forces when the KFOR troops marched into Kosovo . The vehicles of tank battalions 33 and 214 were sent from Macedonia to Prizren . They served as object protection and patrol vehicles and at the control and observation points as part of the Show of Force as security vehicles . The main battle tank appeared in the news in an incident on June 13, 1999 in which two Serb paramilitaries shot at one of these checkpoints in Prizren from a Lada . Since the crew was only partially on board, no shot was fired from the on-board weapons, but rather from dismounted forces from other vehicles. On the other hand, the on-board cannon was used on June 26, 1999, when the crew of a 2A5 fired four warning shots over the town of Orahovac . The problem with the use of the Leopard 2 was the insufficient load-bearing capacity of the bridges in the operational area.

Due to the decreasing threat level, the 2A5 were exchanged for a Leopard 2A4 at the turn of the year 2000/2001. Some A4 were also used during the 2001 riots in Macedonia . The battle tanks served as object protection vehicles for the Bundeswehr logistics warehouse there. Until the withdrawal at the end of 2004, the tanks were stationed in the Austrian-Swiss camp "Casablanca".

ISAF

Canada has been using 20 Leopard 2A6M-CANs in Afghanistan for ISAF operations since August 2007 . The entire crew survived a large booby trap attack on a Canadian leopard on November 2, 2007: “My crew came across an IED and went down in history as the first crew to test the ' M ' package. It worked as it should, ”wrote a Canadian officer to the German Defense Ministry, saying that there were probably no survivors in another vehicle. Only the driver of the tank suffered a hip fracture, the rest of the crew got away with bruises.

The chief of the Canadian General Staff, General Rick Hillier , responded to press reports and denied that the Leopard 2, damaged by the explosion, had been destroyed. Instead, the tank was repaired and is now back in action. "The Taliban attacked the new Leopard-2 tanks in several ambushes," and as a result the Taliban "learned some very hard lessons" and "lost the fight very quickly and very violently".

Denmark has also relocated a Leopard 2A5DK train to Afghanistan, where it is deployed in the Helmand province . On January 5, 2008, the tanks proved their worth in a first firefight in support of British troops against Taliban fighters . On February 26, 2008, a Danish Leopard 2 was hit by an explosive charge. A chain of the vehicle was destroyed, the crew was unharmed. Despite the destroyed chain, the tank was able to return to the camp on its own and be repaired there. On July 25, 2008, another Danish leopard was hit by an explosive charge in Afghanistan and the driver was killed. The 2A5DK did not have any additional anti-mine protection equipment at the time.

Euphrates shield

With the progress of the Turkish military offensive in northern Syria ("Euphrates shield") against Daesh (see Islamic State ) and after the M60 main battle tank and its further development, the Sabra, proved inadequate, the armed forces were reinforced by 50 Leopard 2A4s. They were used by the 5th Tank Brigade and the 172nd Tank Brigade of the Turkish 2nd Army . The use restrictions in Germany, which provide for the use of the Leopard 2 only for national defense, but not in Germany or against the PKK and therefore speak against a use in Syria, was lifted according to Turkish information in 2009 with mutual understanding.

The Daesh terrorist militia claims to have met at least ten Leopard 2A4s during the fighting over al-Bab and incapacitated them. An unverified list posted on the Internet shows ten tanks with failures. According to media reports, a tank is said to have been captured at the end of December 2016. Photos later appeared on the Internet that are supposed to prove that the tank had been destroyed - by an F-16 fighter aircraft of the Turkish Air Force . An official confirmation from the military leadership has not yet been received.

Olive branch

Leopard 2A4 tanks were used by the Turkish military in the fight against the YPG in the Afrin region of Syria in 2018 . The mission was confirmed to the German government . According to unconfirmed reports, a Leopard 2A4 was said to have been destroyed during the fighting by an anti-tank guided missile of the YPG on February 3, 2018 , killing five Turkish soldiers.

losses

Since the beginning of their invasion of Syria in 2018 ( Turkish military offensive on Afrin ), the Turkish armed forces have had to record an unknown number of their Leopard 2 A4s as total losses. It is speculated that at least ten Leopard 2A4s were either incapacitated or completely destroyed. Experts cited the reasons for this that certain weak points of the tanks were exploited by the enemy, for example by hits in the weaker side or rear armor and the lack of reactive armor or active distance protective measures .

LeoBen community

The further development of the weapon system to make Leopard and its family of vehicles on a common basis, was the Leoben-Community (1969 by Germany, Belgium, the Netherlands and Norway Leo pard- ben utzende States) was founded. Divided into several working groups and controlled by a steering committee, the objectives are to simplify supply, jointly develop the weapon system, simplify repairs, adapt the Leopard family to future threats and reduce costs.

variants

Variants of the Bundeswehr

The Bundeswehr has (as of August 2017) a total of 225 Leopard 2s in the versions A6 (155), A6M (50) and A7 (20). The 20 main battle tanks of this expansion stage that remained after the sale of 105 Leopard 2 A5s to Poland were taken out of service in order to avoid mixed equipment with different armaments.

The Leopard 2A4 disbanded units of the Bundeswehr were sold. Long-term storage that was common during the Cold War has been abandoned. Ten Leopard 2A4s have been demilitarized and are intended for exhibitions. The armaments companies Krauss-Maffei Wegmann and Rheinmetall Landsysteme also took over a few copies for internal tests and as base vehicles for possible conversions.

In April 2015, the federal government decided to increase the number to 328 vehicles. This will be achieved by buying back 100 tanks that are stored in the armaments industry. In a further step, a total of 104 Leopard 2 will be upgraded from 2019 and upgraded to the A7V level. This modernization measure includes all 20 Leopard A7s of the Bundeswehr, the 16 A6NLs made available by the Netherlands for the 414 tank battalion and 68 of the 100 Leopard A4s that were bought back. Eight vehicles are made available to the Federal Office for Equipment, Information Technology and Use by the Bundeswehr.

On March 20, 2019, the budget committee of the German Bundestag approved the retrofitting of another 101 Leopard A6 and A6Ms to a level comparable to the design of the A7V in order to adapt to the Leopard 2 A7V in terms of operation and logistics. Among other things, the Leopard 2 will receive a new target system, new radios and modified fire control computers. The renovation work should be completed by 2026. The number of Leopard 2 A7Vs (or comparable) then used in the Bundeswehr will then increase to 205 of a total of 328 planned Leopard 2s.

In the army, the tanks have been looked after in a dynamic availability management by the army repair logistics since mid-2014 and assigned to the troops if necessary. The A6 variants are used in the tank troops training center , in the Army Combat Training Center (GÜZ) and by the stabilization and intervention forces . The A7 is only available to the 203 tank battalion and the training center. The use of the Leopard 2A4 in the GÜZ as an enemy display vehicle and at the training center was discontinued in 2008. Occasionally, they were still used at the defense technology offices for technical testing.

| Construction lot | Construction year | variant | number of pieces |

|---|---|---|---|

| 1 | 1979-1982 | 2A0 | 380 |

| 2 | 1982-1983 | 2A1 | 450 |

| 3 | 1983-1984 | 2A1 | 300 |

| 4th | 1984-1985 | 2A3 | 300 |

| 5 | 1985-1987 | 2A4 | 370 |

| 6th | 1988-1989 | 2A4 | 150 |

| 7th | 1989 - 1990 | 2A4 | 100 |

| 8th | 1991-1992 | 2A4 | 75 |

Leopard 2AV

Prototype of the Leopard 2, also known as the austere version . In total, there were two chassis (PT 19, 20), three towers (T19, 20, 21) and a firing vehicle with the designation AV . The unit price in 1973 was around 2.3 million DM.

Leopard 2A0

First production version. Manufactured from October 1979 to March 1982 as the first construction lot with a total of 380 vehicles, 209 of them by Krauss-Maffei and 171 by MaK. The basic equipment consisted of the main EMES 15 rifle scope, a laser range finder, the PERI R17 panoramic periscope, the FERO Z18 tower rifle scope, an electro-hydraulic WNA-H22, a fire control computer, a cross wind sensor on the tower roof and a computer-controlled RPP 1-8 tank tester. Instead of a thermal imaging device possessed 200 vehicles of the batch over a residual light amplifier (PZB 200 = P assives Z IEL u. B eobachtungsgerät). Two chassis 10001 (KMW) and 20010 (MaK) served as training vehicles.

Leopard 2A1

Two construction lots with a total of 750 vehicles. The production of the construction lot 2 extended from March 1982 to November 1983 with 450 Leopard 2A1s, which was seamlessly followed by the third construction lot with the remaining 300 tanks. The final production was completed in November 1984. The main changes mainly comprised construction lot 2 and were: elimination of the cross wind sensor, standard thermal imaging device , uniform NATO standard for the ammunition holder of the main weapon, improved vehicle electrics, foot plates on the engine block, commander's periscope 5 centimeters higher, modified exhaust gas gratings , field cable connection point on the left rear of the tower, relocation of the tank filler neck on the side of the niche containers, enlargement of the cover of the intake hood for the protective ventilation system and rearrangement and crossing of the tow ropes at the rear of the vehicle. In construction lot 3, the main battle tank received detailed improvements in the interior.

Leopard 2A2

Retrofitting all 2A0s with a thermal imaging device . The PZB 200 is not applicable. The name changes to 2A2.

Leopard 2A3

Lot 4 with detail improvements. Installation of a new radio system SEM 80/90 (VHF) with shorter antennas, shortened pitot tube for the gunner's auxiliary rifle scope and now three-color camouflage. A total of 300 vehicles were manufactured between December 1984 and December 1985.

Leopard 2A4

The production of the Leopard 2A4 extended to four construction lots with 695 vehicles. The 5th construction lot began in December 1985 and ended in March 1987. The 370 Leopard had a digital ballistic computer for additional types of ammunition such as those used by the American armed forces, the ammunition hatch on the left side of the tower was omitted and an improved fire suppression system was installed. From the 97th vehicle, lot 6 of the series had improved armor protection for the turret and tub front, a new heavy chain apron, new chains from Diehl, low-maintenance batteries and maintenance-friendly idler covers. To protect the soldiers, the camouflage was changed to zinc chromate-free paint. The production of the 150 vehicles extended from January 1988 to May 1989. The construction lot 7 with 100 vehicles followed seamlessly and ended without changes in April 1990. From January 1991 the last construction lot 8 followed with 75 vehicles. The changes included an improved light and heavy chain apron in D technology - with a straight lower edge and only one stepping aid on the first segments - and a field adjustment mirror on the muzzle of the on-board cannon. The mirror was retrofitted on all vehicles. The construction lot ended on March 19, 1992 with the ceremonial handover of the last Leopard 2A4 produced by the Bundeswehr to the 8th Mountain Tank Battalion .

To standardize the design of the Leopard 2 fleet from 1995 on the level of the A4. The majority of the vehicles are mixed lots, consisting of tubs from the first construction lot and towers from the sixth to eighth construction lots. Two vehicles - chassis 11156 / tower 41164 (troop test model maximum); Chassis 11157 / tower 41265 (troop test sample minimum) - the eighth construction lot was used to test the Krauss-Maffei combat value enhancement program.

Troop test sample

In order to determine the extent of the planned increase in combat value, several test vehicles were commissioned by the Federal Office for Defense Technology and Procurement . The requirements of the BWB formulated in 1984 were implemented in the component test vehicle (KVT) in 1989. A series vehicle from the 5th construction lot served as the basis. The package, which was primarily designed for protection, comprised armoring of the hull and tower front as well as the tower roof with multi-layer armor of the 4th generation. The interior was lined with a splinter protection (Spall-Liner). An electric weapon tracking system replaced the hydraulic one and improved the passive protection for the crew by eliminating the hydraulic fluid. In order to eliminate ballistic holes in the armor, the driver was given a sliding hatch, the view of the EMES 15 was set higher. Other necessary changes, which primarily served the purpose of adaptation, were the relocation of the PERI R17 behind the commander's hatch, a new commander's corner mirror and an increase in the pretensioning of the torsion bars. The total weight increased by seven tons and reduced the specific power to 17.7 kW / t. The instrument test vehicle (IVT) created from the KVT - after successful testing - was used to test the Integrated Command and Information System (IFIS) in order to transmit situational information and the position of the battle tank.

The experience gained with the KVT was applied to two further series vehicles of the 8th construction batch in Troop Test Pattern 1 (TVM). The TVM-max (maximum requirement) and TVM-min (minimum requirement) were created between winter 1990 and autumn 1991. The two test models had the attachment modules on the tower and chassis, a bomblet protection on the tower roof, sliding hatches for the commander, driver and loaders, splinter protection in the fighting compartment, modified hydraulic end stops and the increased torsion bar pretension.

In some areas, however, different equipment was made and components from different manufacturers were installed. With the PERI-R17A2, the commander of the TVM-max had the Israeli thermal imaging device TIM 8-12 (El OP, since 2000 Elbit Systems), whose images were displayed on a monitor, the navigation was supported by an inertial navigation system. The directional drives of the tower were electric. With the PERI R17 TW, the TVM-min received a TV-based night vision solution with a large field magnifier and a GPS-supported navigation aid. The use of tip sights for the commander - with which the commander's panoramic periscope could be automatically swiveled to the corresponding area - was dispensed with. The armored hub caps of the drive and the laser first echo evaluation were also not implemented. The turret and weapon drive was carried out by means of enhanced electro-hydraulic directional drives.

From the winter of 1991 to the spring of 1992, both tanks were tested by the tank troop school in active service. The superiority of the electric directional drive quickly became apparent, the monitor viewing of the image output by the thermal imaging device was favored. The tip visors and the sliding hatches for the commander and loader turned out to be unsuitable for troops at the time.

The findings were discussed on March 30, 1992 to April 3, 1992 at the Federal Academy for Defense Administration and Technology in Mannheim by the three user states Germany, the Netherlands and Switzerland. The scope of the conversion corresponded to the following criteria: compliance with the financial upper limit of 1.18 million DM per vehicle, elimination of components with a high development risk and compliance with the loading weight of the heavy-duty transporter SLT-56 . The additional armor on the turret roof, the nose protection of the chassis, the splinter protection in the chassis and the tip visor were therefore not implemented. On the other hand, there was also the rear video camera for the driver. The configuration determined in this way was used with the Troop Test Pattern 2 - in some publications also as TVM 2 mod. - Tried in 1993, followed in 1994 by logistics trials at the Landsysteme Technical School and the Army Technical School for Technology . The design status during these follow-up examinations corresponded to that of the Leopard 2A5.

Leopard 2A5 KWS II

The Leopard 2A5 is the implementation of the combat value enhancement known as the Mannheim configuration (KWS) of level 2. Due to financing problems in the retrofitting in the Bundeswehr, the process was carried out in two lots; in 1995 to 1998 for lot 1 (225 vehicles) and 1999 to 2002 for lot 2 (125 vehicles). The changes to the 2A4 included additional armor on the turret front, light chain panels of the second and third generation (design in D-technology with straight lower edge), new commander's periscope PERI R17A2 with its own thermal imaging device (TIM, Thermal Imaging Module ), a digital computer, an electrical one Weapon tracking system, reversing camera and electropneumatic sliding hatch for the driver, Kevlar splinter protection (Spall-Liner) on the inside of the turret, armored hub covers for the rollers, installation of GPS and an inertial navigation system as well as preparation for the smooth-barreled L / 55 cannon. The tanks are exclusively conversions, consisting of the oldest towers (partly from the 1st lot) and the newest hulls from lots 6, 7 and 8. These are easy to see from the combination of the welded ammunition hatch on the tower and mostly six-part heavy chain covers on the Recognize tub. The reason for this was that not much had to be changed on the tub, only the driver's hatch was changed and the reversing camera was installed. The towers, on the other hand, were completely redesigned, so the oldest could be used here. The total costs were DM 347 million for lot 1 and DM 272 million for lot 2.

Leopard 2A6

The Leopard 2A6 is based on the KWS-I program from Krauss-Maffei, with which an increase in firepower should be achieved. The conversion of the tank therefore mainly concerned the weapon system. In detail, the barrel return brake and the trunnion bearing for the new 120 mm smooth-barreled L / 55 cannon were reinforced, and the fire control and weapon tracking system was adapted. The weighing pipe, smoke extractor, base piece and locking wedge were adopted from the old series gun. In contrast, the field adjustment system, the protective pipe cover and the case bag were completely renewed . 160 Leopard 2A5 and 65 Leopard 2A4, which were upgraded from the second KWS-II lot to the A6, served as the basis. On March 7, 2001, the first 2A6 was handed over from the manufacturer to the user and used in the 403 tank battalion.

In addition to these changes, a new KE ammunition was also introduced. The ammunition, known as LKE-II, penetrates up to 1000 millimeters of RHA , depending on the distance, and meets the requirements of the German armed forces for penetrating composite armor. The soiling of the field adjustment system when reversing, which has been known since the 2A4 version, turned out to be a problem. The armored troop school then tested front aprons (see Strv 121) with a modified tank (2A6 mod), which should prevent this. The new arrangement of the smoke thrower system was officially introduced with the 2A6M and installed with effect from May 2005 on all variants still in use during depot repairs.

Leopard 2A6M

The 2A6M corresponds to the 2A6 with additional mine protection. The conversion included the installation of a decoupled commander's and loader seat, a modified emergency exit hatch, an adaptable mine protection, torsion bar covers (to prevent them from flying around in a mine explosion), a cover for the slip ring assembly and a modified stowage of attached objects on the floor. A total of 70 of the 225 2A6s were modernized to the 2A6M stand.

The changes to the driver's position are particularly extensive and unusual. The conventional seat was removed and replaced by a Suspended Dynamic Seat . Developed by the company Autoflug , this seat with integrated harness is suspended from the vehicle ceiling via four straps, which decouples the seat and thus the driver from the rigid vehicle structure of the tank. Since these belts are attached to the vehicle ceiling via retractors (belt retractors), the driver can adjust his individual seat height (eye point) above and below the hatch almost continuously. The seat is then tensioned by further belts in such a way that the driver remains fixed in his position even in the event of a collision with another tank or when rolling over. With the help of a spacer cushion that is stowed away while driving, the driver can determine the necessary minimum distance to the ground. This is absolutely necessary, since the vehicle floor deforms both plastically and elastically during a stress acting under the tub, which has serious consequences if it is touched. Germany, the Netherlands, Norway, Sweden and Switzerland were involved in the development.

Combat value increase - level III

A KWS that had not been implemented was level 3. From 2008, the combat power of the Leopard 2 was to be increased by a 140 mm smooth-barreled cannon and an automatic loading system in the rear of the turret. The tower crew should be reduced to two men. At the same time, the installation of a computer system (Combat Forces Command and Control System IFIS) - in the parlance of the Bundeswehr as the command and weapon deployment system (FüWES) IFIS - and high-performance radio data transmission equipment should improve manageability. In 1995, the Federal Ministry of Defense discontinued KWS III at a planning meeting in Waldbröl . The funds were allocated to the New Armored Platform project .

Leopard 2 UrbOp

This variant of the Leopard 2 was a planned implementation of the PSO concept by Krauss-Maffei Wegmann for the German armed forces. The designation UrbOp stood for urban operations and at the same time denoted the required adjustments to the weapon system. The hulls of 150 Leopard 2A6M were intended as a chassis and were to be equipped with or prepared for PSO components. These included the clearing blade, improved front and side armor, the external intercom, the 360-degree camera system and the auxiliary power unit. Their A6 towers should be replaced by UrbOp modules when deployed. 50 A4 towers were planned, which would be reinforced with additional armor and upgraded with a remote-controlled weapon station, a guidance system (IFIS), the white light floodlight, a new PERI with an improved thermal imaging device and the air conditioning in the rear of the tower. The 120 mm smoothbore cannon L / 44 was still intended as a weapon system in the initial phase. The Leopard 2 UrbOp would therefore not be a new one, but a conversion and not always available. From July 2009 the experimental vehicle Leopard 2 PSO-VT was tested in this configuration. In contrast to the previous plans, he was armed with the L / 55 smoothbore cannon.

The original schedule was for the Leopard 2 to be upgraded accordingly from 2011 to 2018. KMW presented its final configuration under the name Leopard 2A7 + at the Eurosatory 2010 armaments fair . The Bundeswehr postponed the implementation of the PSO concept to 2019 and later discontinued it in favor of upgrading to the A7.

Leopard 2A7 / Leopard 2A7V

The Bundeswehr's Leopard 2A7 differs fundamentally from the KMW variant and is not optimized for combat in cities. So far, 20 Bundeswehr vehicles have been converted (as of February 2015). These are former Dutch vehicles that were returned to Germany from Canada. The original upgrade to the A6M was expanded in coordination with Canada and includes the tower-side unchanged combat compartment cooling system MKK6 from the Greek Leopard-2-A6M-HEL series, the completely newly developed energy generation system (EEA or APU) with a maximum electrical power output of up to 20 kW DC, based among other things on the 2-cylinder basic engine of the type "Steyr M12 TCA UI" (TCA UI = turbo charged, aftercooled , direct unit injection), the Barracuda camouflage system with heat transfer -System (SAAB BARRACUDA MCS with HTR CoolCam), the command and information system tried and tested in the troop test samples , on-board network optimization with UltraCaps in the chassis and tower area, a digital on-board communication system of the type SOTAS-IP as well as a renewal of the fire suppression system in the combat area and the retrofitting of the Attica -Thermal imaging module in the commander's optics. The weapon system is adapted for firing HE ammunition. In addition, the tank was prepared for the use of additional side armor. The first Leopard 2A7 was handed over to the German Armed Forces on December 10, 2014 in Munich. A total of 14 vehicles will be available to the tank battalion 203, four more are to go to the tank troops training center and one vehicle to the land systems technology training center . A reference vehicle is to remain at KMW. The combat weight reaches 62.52 tons.

In June 2016, KMW presented the next development stage of the Leopard 2A7V at the Eurosatory armaments fair. The demonstrator contains further improvements that were not ready for series production or could not be financed in the combat value enhancement program for the A7. Additional passive armor was added to the front of the hull, a third-generation thermal imaging device for the gunner, improved acceleration through modifications to the gearbox and side transmission, relocation of the NBC protection system to the rear of the turret to create space for a cooling device for the driver, the day and night vision system Spectus for the driver at the front and rear as well as an adaptation of the handgun holder and the stowage concept of the equipment. Overall, as part of the “Armored Combat Ability Development” initiative, the number of A7 vehicles in stock is to be increased from 20 to 104 vehicles.

When retrofitting the A7V and adapting the already built A7, the Federal Court of Auditors criticized that the terms of the contract were inadequate and would ultimately be at the expense of the taxpayer .

On May 5, 2017, a contract for the delivery of 104 Leopard 2s of the A7V variant was signed between the Federal Office for Equipment, Information Technology and Use of the Bundeswehr and Krauss-Maffei Wegmann as general contractor. The Bundeswehr's vehicle fleet is to increase to 328 A7Vs. The order volume is around 760 million euros, with Rheinmetall being the main subcontractors with 106.5 million euros and MTU Friedrichshafen with 21.2 million euros. In addition to the 104 A7V, the contract also includes a further 32 A4 chassis that are to be stored in order to form the basis for further vehicle variants. Delivery is planned between 2019 and 2023.

On March 20, 2019, the budget committee of the German Bundestag approved the retrofitting of another 101 Leopard A6 and A6Ms to a level comparable to the design of the A7V in order to adapt to the Leopard 2 A7V in terms of operation and logistics. Among other things, the Leopard 2 will receive a new target system, new radios and modified fire control computers. The renovation work should be completed by 2026. The number of Leopard 2 A7Vs (or comparable) then used in the Bundeswehr will then increase to 205 of a total of 328 planned Leopard 2s.

Variants Krauss-Maffei Wegmann

Leopard 2A6EX

The 2A6EX was a privately owned further development of the Leopard 2 from Krauss-Maffei Wegmann. A Leopard 2A4 from the eighth construction lot, which KMW converted in 1998/1999 as a presentation tank, served as the basis. The main battle tank, known in-house as Demo 1, was equipped with the Swedish Strv 122 with additional hull and turret armor, air conditioning, tip sights, hydraulic chain tensioners and an auxiliary unit. KMW presented its version of a combat enhancement program for the first time in 2002 at the Eurosatory military exhibition in Paris and Defendory in Athens. With Spanish markings, it also took part in the parade on October 12, 2002 on Spain's national holiday. The Spanish Leopard 2E and Greek Leopard 2HEL can be seen as a commercial counterpart.

Under the designation Demo 2, the battle tank was equipped with the smooth-barreled L / 55 cannon and the Euro-Powerpack as a drive. The Euro-Powerpack consists of the MT 883 diesel engine from MTU and the HSWL 295 TM gearbox from Renk. With the same power, it requires one meter less space in the engine compartment than the standard engine, but cannot be replaced without major changes to the pan. In addition, modifications have been made to the air duct to prevent incendiary devices from being drawn in; the heat radiation of the engine was reduced and a silencer was installed to reduce noise.

Leopard 2 PSO / 2A7 +

One of the most modern variants of the Leopard 2 is the Leopard 2 PSO ( Peace Support Operations ). Initially developed by KMW as a separate offer for deployments in local combat , so-called MOUT deployments (Military Operations in Urban Terrain), the PSO has been since the Tested and improved by the Bundeswehr in cooperation with the tank troops training center in Munster. As part of the Show of Force, it serves specifically for peacekeeping and peacekeeping measures. The complete equipment is modular and can be adapted as required. There is therefore no fixed configuration.

The hull of the Demo 2 presentation tank and a turret of the Leopard 2A5 served as the basis for the demonstrator. It was equipped with mine protection and additional passive all-round armor. As armament, he has the smooth barrel cannon L / 44 and a remote-controlled weapon station with an uncooled thermal imaging device on the rear tower roof. In 2002, KMW used the Autonomous Weapons and Observation Station (AWBS) from the WE program in Switzerland, which, however, was limited in terms of armament and was replaced by the unarmored FLW 200 with a Zeiss sensor box. Compared to the AWBS, the weapon station is lighter, more flexible in the weapon mount (for 5.56 mm to 12.7 mm machine guns or the 40 mm grenade machine weapon ) and has a larger elevation range.

The main battle tank was equipped with a clearing shield for obstacles and barricades. The shield, which comes from civilian production, has the same construction as a snow plow with floating position and is only used for clearing.

In order to be fully operational in all climatic zones, in all weather conditions and also at night, improved air conditioning systems ("combat room cooling system"), a stronger power supply and a 360-degree camera system (MiniSight from Cassidian Optronics (formerly Carl Zeiss Optronics, later Airbus DS Optronics)) integrated for all-round visibility - with thermal imaging device and day view for operations at night or in adverse weather conditions. Since the tank works closely with the infantry in local and urban combat and is intended to support them in their tasks, there is an externally accessible communication platform on the tank to enable the infantry to communicate with the tank crew as well as between the soldiers.

At the Eurosatory armaments fair 2010 KMW presented its final modification using a presentation vehicle under the name Leopard 2A7 + and with the advertising print; Developed by KMW - tested and approved by the German Federal Ministry of Defense ( developed by KMW - tested and qualified by German MoD ). In this presentation vehicle, only one side of the vehicle was equipped with the new armor, the left side of the vehicle from the driver's point of view was still on the Leopard 2A5 stand. The hull front was equipped with the additional armor known from the Strv 122, the underside of the hull had the mine protection of the Leopard 2A6M. The equipment of the 2A7 + was supplemented by a night driving system, combined with a residual light amplifier and thermal imaging device (SPECTUS from Cassidian Optronics) for the driver, as well as a new PERI RTWL commander's periscope derived from the Puma infantry fighting vehicle. The L / 55 was chosen as the on-board cannon in order to maintain the battle tank's ability to duel in symmetrical combat .

Variant IBD Deisenroth Engineering

In 2008, IBD Deisenroth Engineering presented its protection concept for main battle tanks under the name Leopard 2A4 Evolution . According to the company, it was developed for a foreign buyer, which was not specified at the time, that the AMAP armor was chosen and a demonstrator armored with it. The Leopard 2A4 variant was equipped with ballistic protection (AMAP-B) combined with AMAP-SC protection against shaped charge projectiles and extended mine protection (AMAP-M, AMAP-IED) as well as interior cladding, the liner (AMAP-L). The roof protection (AMAP-R) in the extension level 2 with a weight of 120 kg / m² protects against projectile-forming loads. The armored rear was provided with cage armor . AMAP-ADS was chosen as the distance-active protection system and integrated in 2009. The total weight of the demonstrator is 60 tons.

Rheinmetall Defense variant

In 2010, Rheinmetall's armaments division presented its application-oriented modular concept for the Leopard 2A4 at the Eurosatory armaments fair, which is marketed under the name MBT Revolution . The combat value increase, designed as a modular system, can be adapted to the respective requirements of the user. According to Rheinmetall, this applies to protection, active agents (ammunition), command and networking capabilities, and reconnaissance and vision systems.