Measuring device

Measuring devices (also called measuring instruments ) are used to determine geometric or physical quantities . In the context of a measurement , they usually lead to a quantitative statement about the variable to be measured by means of a scale or numerical display . This statement, the measured value , is given as the product of the numerical value and the unit . The measurement methods on which it is based are given under measurement technology . General characteristics of the measuring devices according to DIN 1319-1 are listed under measuring equipment . Instead of a readable display, a measuring device can also output a signal, preferably an electrical signal ; or it can store data , electronically or on paper (e.g. as a measuring recorder or recording device ).

A measuring device is defined in the "Basics of measuring technology" in DIN 1319 as the "totality of all measuring devices and additional devices for achieving a measurement result" and in the simplest case consists of a single measuring device.

Measuring devices for performing measurements generally belong to the group of measuring devices. If these are used for testing , they are also referred to as test equipment in accordance with DIN 1319-2 .

The measuring device may work incorrectly or the measured value may contain measurement errors ; these are to be subtracted or their size estimated. Particularly precise measuring devices can be used for calibration , adjustment or verification of other measuring devices (see also measuring equipment monitoring ). A measurement uncertainty can be specified for determined values .

See also list of measuring devices and list of physical quantities including their units

Measurement of non-electrical quantities

Basic measuring equipment

Without the basic gauges for determining time, measuring lengths and simply counting , no other gauges can be made or used. Other quantities, including basic quantities, are derived or the measuring devices are determined by using these quantities.

Timing

Time is measured with different clocks :

- Sundials are historical, used today only as decoration or for teaching purposes

- Hourglasses are historical, only used in individual areas

- Water clocks are historical (for time measurement - not flow!)

- Flower clocks are very imprecise devices for measuring time, but they are very pretty to look at. Use as show pieces, for teaching purposes.

- Fire watches were ritual timepieces that burned an aromatic mass.

- Candle clocks and oil lamp clocks are historical, only used in individual areas

- Pendulum clock measures the time over the period of oscillation of a pendulum.

- Wheel clocks use the movement or vibration of mechanical parts

- Passage instrument measures the passage time of stars (combined with chronograph).

- Chronometer measures the time (mechanical short oscillator or quartz watch)

- Chronograph measures time (mechanical or quartz) and records or prints the course of time (often together with another variable, e.g. star passages ).

- Radio clock receives the exact time signal of an atomic clock via radio signal.

- Mechanical or electrical / electronic stopwatch

- Short-term alarm clock mechanical or electrical with acoustic, optical alarm signal and / or switch option

- Quartz watch measures the time with a quartz- controlled oscillator .

- Interval counter measures frequencies and time intervals based on an oscillator.

- Atomic clock measures time due to the high constancy of atomic oscillations. With hydrogen grains the most accurate clocks currently available.

Length measurement

In principle, we differentiate between two simple forms of measuring equipment for length measurement : the line measure , which embodies the measure through the distance between two lines , and the final measure (the original meter, for example), in which this occurs through the distance between two surfaces.

- Micrometer (obsolete colloquially "microns"), resolution to 0.01 mm

- Dial indicator , with pointer or with numbers indicating up to 0.001 mm

- Vernier caliper (colloquially also " slide " or " slide gauge "), resolution up to 0.02 mm

- The button measure , small, simple caliper, example of the development of length measurement: historically an important step, today only with low accuracy requirements, as there is no vernier

- Thread counter measures line widths and line spacing during printing.

- Kluppe , used in forestry to determine trunk diameters

- Ruler , metal rule, measuring ruler; Resolution ½ to ¼ mm

- Folding rule (colloquially "folding rule " or "yardstick"); Resolution up to 1.0 mm

- Measuring wheel for quickly traversing a measuring section (relative measuring deviation depending on the structure up to 1 ‰)

-

Tape measure for measurements up to 50 m, maximum 100 m (measurement deviation 1 to 3 cm)

- see also odometer and cyclometer (measurement technology)

- Optical distance measurement with a leveling staff (3 to 5 m long) and a thread net: at dm / cm graduation (aiming with theodolite ) approx. 5 cm resolution

- Basic measurement with temperature- resistant invar wire and triangulation: the basis of national surveying until around 1970, measurement deviation a few 0.1 mm per kilometer

- Electronic distance meter (EDM, distancer ): highly accurate distance measurement from a few decimetres up to many kilometers , with laser light, infrared or microwave . Measurement deviation terrestrial up to approx. 10 −7 (1 mm over 10 km)

- Satellite Laser Ranging (SLR): Laser runtime measurement from ground stations to satellites, measurement deviation up to 10 −9 .

Distance sensors such as:

- Laser rangefinder , laser interferometer

- Ultrasonic range finder

- Cable length encoder (resolution up to 0.01 mm possible depending on the structure)

- Glass scale

- Capacitive sensor

- Laser surface velocimeters are used to measure the length of continuously produced goods and rail goods.

counting

Counting is the most elementary measuring principle : Even when measuring time or length, people often simply count. With the penetration of measurement technology by digital methods, the measurement principle has gained enormous importance.

Counting in the metrological sense is determining the number (see also quantity ). Counters measure the number of objects or events, with limited counting they determine their frequency :

- Hand counter for individual events, decimal with transfers to several number rolls or number wheels

- Revolution counter with additional mechanical or optical detection of an axis marking

- Gear trains in many mechanical measuring devices for evaluating the number of revolutions for other measurement data, for example in the integrating (totaling) energy meters , water meters , odometers . Even the earliest calculating machines were pure counting devices

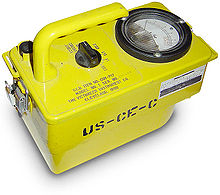

- Geiger counter for determining radioactive decay events

- For electronic counters, see the Counters section in the Digital Metrology article

- Counting scales for replacing the activity of counting with weighing when the same objects with a known unit weight are present at the same time

Further measuring devices of elementary sizes

Area measurement

Measuring devices for area measurement (planimization)

- Planimeter , a mechanical device for determining flat surfaces in maps or drawings

- Pantograph , a scale converter that can be used to measure the area by transferring it to a grid .

Volume measurement

The determination of both the hollow volume and the volume of solid bodies , liquids or gases has historically been realized using hollow bodies or scaled measuring vessels , but mostly by means of volume calculation .

- Measuring cylinder , for measurement based on the displacement , made of glass or plastic or other, with or without a scale

- Volumeter, for bodies that should not come into contact with liquids

- Capillary , by weighing or reading a scale (indirectly, for example with a thermometer to determine the temperature from the volume)

- Scheffel , an example of a historical volume-measure overview in ( history of measures and weights )

- Pipette to dispense quantities from one vessel into another

- Measuring cups , teaspoons and tablespoons , as measurements in the kitchen

- Measuring siphon, a measuring device usually made of glass to take a lot of liquid from a vessel ( sampling )

- Cubizing apparatus (measuring bells) for the determination of gases and liquids

- Flow meter , dynamic volume measurement see below

Location determination, angle and direction measurement

Geodesy : All devices for angle measurement in the field are also (to varying degrees) suitable for determining the location. For this purpose, maps or coordinate needed. By angle measurement and radiation rate can be height or height difference to calculate objects.

- Astrolabe historical, astronavigation. As a Ni2 astrolabe for modern astrometry

- Autocollimator for precise measurement of small angles

- Chorobates leveling device (historical, example: construction of aqueducts )

- Dioptra for bearings (historical)

- GPS - satellite navigation , direct display of the 3D position

- Gnomon , shadow staff, historically, to determine the geographical latitude of a place

- Groma , bearings (historical). Axis on rod, a plumb line at each end of the axis.

- Heliotrope historically a sun mirror for survey points

- Heliometer up to the 19th century, precise diameter u. Angle measurement in astronomy

- Measure coordinate measuring machine 3D, using probing, optics. Manual like CNC

- Jacob's staff historical, astronavigation and for determining the height of an object

- Compass for determining magnetic north ( navigation )

- Gyro compass to determine geographic north (or south) ( ship navigation )

- Laser gyro measures rotational movements without wear.

- Measuring plumb bob for determining the vertical

- Measuring arm for the geometry of components

- Measurement cameras - precision cameras for photogrammetry

- Leveling devices for geometric height measurement

- Planimeter for measuring areas (on drawings, plans, etc.)

- Radio telescope for measuring astronomical radio sources ( quasars and VLBI ).

- Hose level - physical leveling device (principle of communicating vessels)

- Bevel , mainly for transferring angles to workpieces

- Level , historical forerunner of the spirit level (application where, reading on a dragonfly)

- Sextant for angle measurement between two landmarks. Terrestrial and astro navigation .

- Stripe projection sensors - for non-contact shape detection

- Theodolites for measuring angles and geometric relationships in space

- Total station for angle and distance measurement

- Spirit level for horizontal and / or vertical alignment

- Protractor as a tool (see also set square )

- Zenith telescope and zenith camera : for measuring star points and plumb line

Mass, weight, density, etc.

The weight measurement is a field of mass metrology . Whereas in the past, scales were primarily determined by the clever construction of mechanical elements such as levers , weights and / or springs , weighing technology today is shaped by electronics .

- Scales are used to determine the mass of bodies

- Beam scales compare the mass of a test specimen with calibrated weights

- Inclination scale (historical letter scales )

- Spring balances determine the mass of a test specimen from its weight

- Pycnometers measure specific gravity or density

- Refractometers measure the refractive index of liquids in particular , and also parameters such as must weight , salinity, and general substance concentrations

- Lactodensimeters measure the density of milk .

- Turbidity meters determine the proportion of solids in liquids

- Gas collecting tubes or dasimeters allow the mass and volume of a gas sample to be determined.

temperature

The temperature measurement is discussed in more detail in a separate article, this list is only an overview.

Thermometry is the science of temperature measurement - measurement using different types of thermometers .

Early thermometer

- Alchemist's assessment : boiling water or wax melts

- Galileo thermometer : gravity / density (named after Galileo Galilei )

- Expansion thermometers (liquid or metal rod, direct reading on the scale): indoor and outdoor thermometers , centrifugal thermometers , stick thermometers

- Bimetal thermometer : utilization of the different expansion coefficients of two metals

- Thermochromatic colors : color change at a certain temperature

- Seger cones : Shaped bodies that change their strength and contour at a certain temperature. Melting point determination can also be used in the opposite direction

Modern thermometer

- Resistance thermometer (change in electrical resistance, e.g. with a platinum measuring resistor or silicon transistor)

- Thermocouples (see also: thermoelectricity )

- Radiation thermometer ( pyrometer )

- Bolometers measure the effect of (thermal) radiation on a test specimen

- Raman thermometer based on Raman spectroscopy

- Thermography : non-contact surface temperature measurement with infrared radiation . "Thermal image" in light-dark representation or in colors (see picture)

Measurement of electromagnetic quantities

Electrical quantities

-

Voltage measuring device , commonly known as voltmeter , for the electrical voltage or potential difference between two points

- Oscilloscope , for displaying the course of an electrical voltage over time as a graph

- Electric field meter for the electric field strength

-

Ammeter , commonly known as ammeter , for measuring the electrical current

- Galvanometers , special measuring devices for the smallest direct currents

- Power meter for the electrical power that a device consumes or outputs , see Active power measurement , reactive power measurement

- Energy meter , colloquially electricity meter, for electrical work

-

Resistance measuring device, commonly known as ohmmeter, for electrical resistance

- Wheatstone measuring bridge for ohmic resistance using a comparison method , alternatively for a small change in resistance using a deflection method

- AC voltage bridge for the AC resistance

- Conductivity meter for the electrical conductivity of a liquid medium (e.g. for the concentration of salts)

- Frequency meter for the frequency of an alternating voltage

- Cable fault location measuring device for the distance between the measuring point and the fault location

- Multimeter for several measured quantities

Magnetic field

- The compass points to the magnetic poles of the earth and measures the direction of the compass .

- Hall probes measure magnetic fields or currents.

- Proton magnetometers only measure the absolute magnetic field strength .

- Förster probes are used for the vectorial determination of the magnetic field .

- Flux meters measure the magnetic flux . Often used in conjunction with a Helmholtz coil.

- SQUID Superconducting Quantum Interference Device . For measuring very small magnetic fields. Use in magnetoencephalography (MEG). This is a measurement of the brain's magnetic activity.

- Magnetometers , commonly known as Teslameters or Gauss meters, measure the magnetic field strength in Tesla or Gauss .

- Faraday balances measure the effect of a defined magnetic field on a test specimen.

Radioactivity and radiation

- Spectrometers determine the absorption of a certain wavelength of radiation , but also emission , reflection and photoconductivity spectra

- Dosimeters measure the radiation dose as a time integral of the dose rate

- Geiger-Müller counter tubes measure the incidence of ionizing radiation

- Scintillation counters measure alpha , beta , gamma or neutron radiation depending on the structure

- X-ray devices measure the passage of radiation through an object

Derived measuring devices

Derived gauges have emerged from the original gauges.

speed

The speed is the quotient of distance and time .

- The speedometer shows the driving speed in the vehicle.

- The tachograph also records the speed.

- The log measures the speed of watercraft.

- The airspeed indicator measures the speed of aircraft.

- The variometer indicates the rate of climb or descent in aircraft .

- Radar device measures the speed via the Doppler effect of the radar waves generated by a radar transmitter and reflected by the vehicle.

- Lidar : Lidar stands for light detection and ranging and is a method related to radar (radiowave detection and ranging) for remote measurement of atmospheric parameters.

- A laser surface velocimeter measures the feed speed of a product strand in industry.

rotational speed

- Tachometer : mechanical or electronic measuring device, most common application in the automotive and aircraft sectors, provides information about the revolutions of a unit (engine, ...). If the gear ratio is known, it can also be used to determine the speed and distance.

- Gyrometer : (historical) mechanical structure for speed determination

- Hall sensor : for determining the speed using the Hall effect

acceleration

The acceleration is the change in speed over a period of time.

- Acceleration sensors usually measure the force acting on a test specimen in the accelerated system (K = mb).

Distance traveled

-

Rangefinder based on a variety of measurement principles, for example

- Testers ,

- Odometer ,

- Chiaroscuro geolocator for following the flight paths of very small birds.

power

- Power meters measure according to mechanical or electrical principles.

Measurements on liquids and gases

-

Flow meters measure the mass flow or the volume flow .

- An electromagnetic flow meter (MID) works without moving parts. It calculates the flow of an electrically conductive medium based on the electrical voltage resulting from induction by an externally applied magnetic field .

- Coriolis mass flow meters use the Coriolis force to determine the flow.

- Hot wire anemometers measure the cooling of a heated wire and use it to calculate the flow rate.

- There are water meters in different designs as impeller , Woltmann or compound water meters . They are used for counting and are therefore only calibrated to a quantity such as liters, but can also be used for flow measurement by differentiating a scanning signal.

- Laser Doppler - anemometer for the contactless measurement of the flow rate of gases or liquids.

- Pressure gauges , commonly known as manometers , measure the pressure of gases and liquids.

- Vacuum gauges are measuring devices for determining the gas pressure in a vacuum .

- Hydrometers measure the density of a liquid (see also: must scale wine, lactodensimeter milk, beer spindle, beer, ...).

- Rheometers measure the flow and deformation behavior of matter.

- Viscometers measure the viscosity of liquids.

- Level meter measures the thickness of a liquid in a container or a body of water, including level measurement .

- Common methods: radar sensor , ultrasonic sensor , capacitive sensor , conductometry , float switch only one or two switching points and thermography .

- Echosounder to determine the water depth or to find sound-active objects in the water (less often in aviation) see. a. Barcheck method for calibrating an echo sounder.

- Tensiometers measure the surface tension of a liquid.

- Potetometers measure the water consumption of a plant.

- pH meter measuring the pH ( acid , brine ) of a liquid.

- Transmissometer in environmental technology Determination of the dust content / amount of a gas in exhaust air.

- Turbidity meters (nephelometers) determine the proportion of particulate solids in a liquid.

- Explosimeters measure a gaseous atmosphere in order to detect an explosion hazard (ignitable gas mixture).

Measurements on solids

All measuring devices for determining length and density, weight and hardness measuring devices as well as X-ray devices can also be used for solids .

- Grindometers measure grain sizes .

- Lysimeters measure soil biological and physical data.

- Tensiometers continuously measure the soil moisture.

- Absolute moisture meters measure the material moisture in solids

- SRT pendulums measure the grip of road surfaces.

- Farinographs are used for the rheological investigation of wheat flours .

Meteorological instruments

The following measuring devices are used in meteorology and of course in other technical areas as well.

- Barometers measure the pressure of air and also the altitude ( altimeter ). Also used to forecast the weather via the barometric pressure display.

- Thermometers measure the temperature .

- Hygrometers measure the air humidity (see also coulometric humidity sensor ).

- Anemometers measure the wind speed .

- Lysimeters measure the infiltration-evaporation ratio → evapotranspiration .

- Netradiometer (also known as net radiometer) for measuring global radiation ( meteorology total radiation balance ).

- Pyranometer global radiation sensor ( meteorology ).

- Albedometer radiation balance sensor ( meteorology ).

- Windsock shows the wind direction and an approximation for the wind strength.

- Wind direction transmitter The weathercock also shows the wind direction.

- Cyanometer indicates the color intensity of the blue sky color, as a measure for the amount of water which is in the atmosphere.

- Transmissometer measures the visibility.

- Pyrheliometer measures the energy of the sun's rays.

- Evaporimeter measures the evaporation ( evaporation ).

- Ceilometer measures cloud cover and altitude.

- Ombrometer measures the amount of precipitation .

- Sunshine autograph (heliograph) measures the duration of sunshine .

Measurement of photometric parameters and color properties

- Photometry is the umbrella term for the measurement of photometric parameters as well as measurement methods derived from them (e.g. measurement of light absorption in biology, chemistry, medicine)

- Lux meters measure the illuminance to which the measuring cell is exposed.

- Densitometers are color measuring devices that measure the color tone values of surfaces.

- PV measuring devices are multi -measuring devices for solar systems. The light intensity and temperature are usually measured and the expected energy yield is calculated.

Sound and sound level measurement

In most cases, sound level meters measure the sound pressure level . For this purpose, they contain a precise microphone , a high-precision amplifier circuit and a logarithmic display. The sound pressure level is received equally well from all directions, which is why the position and orientation of the device are irrelevant. The measuring devices are used in most cases to determine noise exposure at work and in traffic. Another purpose is the determination of vibrations and running noises on technical devices and the investigation of countermeasures for their effectiveness.

Sound level meters have to be calibrated regularly by the user in order to check their function and to compensate for changed atmospheric conditions such as temperature, humidity and air pressure.

- Peak meters indicate the peak value of a sound recording and are used to control the sound recording - sound pressure and voltage .

- Speckle pattern interferometry ( ESPI ) vibration analysis and shape detection.

- Laser microphone

Combined devices

- Thermohygrograph at museums, for example

- Multifunctional environmental measuring device - measurement of parameters from environmental technology, for example temperature , humidity , illuminance and sound level . These devices are now available for little money. However, their measurement accuracy cannot be compared with high-quality devices. Often used in schools or for home applications.

Universal measuring devices for various electrical quantities

These devices are not designed for a specific application:

-

Multimeter : Universal measuring devices for voltage (~ / =, with the corresponding test tip also for high-voltage measurement), current (~ / =), resistance (partly also insulation resistance and continuity test), diode test, gain factor of PNP / NPN transistors, display of the temporal course of an electrical Size (multis with graphic display), min / max / mean value display, capacitor capacity, temperature (with appropriate encoder), logic tester (level adjustable), specification of a voltage / level / current (sink) (also the temporal progression of one of the variables can be specified). Whereby digital technology combined all measurements and tests in one device. Industrial multimeters are subject to verification within a certain period of time.

- Analog multimeter : voltage, current and resistance measurement with a pointer measuring device.

- Digital multimeter : often with an interface to PC data acquisition

- PC measurement cards are used to display and digitally record physical quantities.

- AC voltage bridges for determining capacitance or inductance

- SMUs combine multimeters with a laboratory power supply to supply and stimulate the test object

- SMMUs combine SMU with a multiplexer which both the voltages / currents of the power supply in the device under test feeds, as well as the connection between the test object and measuring system is prepared.

- Measuring recorders are recording measuring devices for voltage or values that can be represented by voltage, which immediately generate a paper record of their results.

Quality of the measurements

Measuring device manufacturers should provide information on the error limits (maximum amounts of the measuring device deviation of the displayed value from the correct value).

In the case of electrical measuring devices with a scale display (e.g. analog multimeters), these limits are preferably specified in% of full scale (percent of the final value), often using a class symbol . This means the maximum absolute measurement deviation ; it is calculated using the full scale value. A measuring device with a measuring range end value of z. B. 100 V and a class 1.5 can deviate from the correct value even in the best case by up to 1.5% ∙ 100 V = 1.5 V in its display. This information applies to the entire measuring range regardless of the measured value.

For measuring devices with numeric display, see measuring device deviation , also digital multimeter .

The relative error limit of a measured value is defined as the absolute error limit divided by the correct value; the smaller the measured value, the greater it is. With switchable measuring devices, the measuring range should therefore always be selected with which the greatest possible deflection is obtained.

- Example: With a measured value of 19 V with the named measuring device, one obtains (if the specified conditions such as temperature or position are observed)

- Result = 19 V ± 1.5 V = 19 V ∙ (1 ± 8%)

- i.e. relative error limit = 8% in the 100 V measuring range; in a measuring range of 30 V the result would be 2.4%.

Further measurement deviations, for example caused by own consumption or by non-sinusoidal progression in the case of alternating variables, cannot be recorded with the information given and must be determined separately.

Analytical measuring devices

- Chromatographs separate mixtures of substances or determine relative migration speeds of substances in the selected media. The exact designation describes the structure:

- Refractometer for determining the refractive index of a medium

- Ultracentrifuge (analytical) measure the density composition.

- Calorimeters are used to determine the calorific value

- Mass spectrometers determine the molar masses present in a substance mixture (see also Molar mass ).

- Electron beam microanalysis are various measurement techniques in connection with scanning electron microscopes , which analyze solid surfaces for their elementary or chemical composition.

- Polarimeters determine the rotation of the light plane at opt. active substances.

- Spectrometers generally refer to measuring devices that examine continuous values. Usually this is reduced to the measurement of electromagnetic radiation. In general, the intensity distribution of different wavelengths of electromagnetic radiation is measured. Special case: determine z. B. the absorption in a solid at certain wavelengths of radiation .

- Interferometers (general) are used to investigate the diffraction of light (various measurement applications).

- Dilatometers determine the change in length of a sample as a function of temperature.

Industrial metrology, production metrology and commercial metrology

These devices are used or in most cases to produce a product used for example in the materials testing the quality of the products or the billing of services.

- Coordinate measuring machine universal length measuring device in industrial quality inspection

- Typometer are linear scales are the scales for typesetting

- Layer thickness gauges determine the thickness of a layer on a carrier

- Acoustic microscopy offers a non-destructive imaging technique that uses high-frequency ultrasound to generate images of the inside of an object.

- Perthometer also a stylus device for characterizing the roughness of surfaces

- Grindometer for measuring the graininess of a paste or varnish

- Nephelometer or turbidimeter for measuring the suspension of small particles in a liquid or a gas colloid

- Tribometer for determining the friction in bearing materials and the like a.

- Ductilometer tensile strength tests

- Universal testing machine for examining mechanical properties such as modulus of elasticity , yield point , tensile strength , elongation at break or maximum compressive force

- A vulcameter rubber compounds-to measure the vulcanization of rubber /

Measurement of material properties

Hardness test

During the hardness measurement , a defined action of force leads to permanent deformation of the test body or penetration of a test geometry into the test body. The measuring devices are named according to the method used. Example: Brinell measuring device.

- The Poldihammer is used to measure the hardness of hard materials by means of an impact hardness test

- Hardness test according to Johan August Brinell : A ball is pressed into the sample. The diameter of the ball indentation is the measure for the Brinell hardness value HB.

- Rockwell hardness test : A ball or a diamond cone is pressed into the sample. The remaining penetration depth is measured and the Rockwell hardness HRx is derived from this value (x stands for C (cone) if tested with a diamond cone and for B (ball = ball) if tested with a diamond ball).

- Vickers hardness test : The tip of a four-sided pyramid is pressed into the sample. The diagonals of the permanent indentation are measured and the Vickers hardness value HV can be calculated from their length .

The various methods are well suited to varying degrees depending on the type and hardness of the material to be tested.

Standard measuring devices

Standard measuring devices - are measuring devices that carry out a series of measurements specified in a standard . These are usually also recorded in order to enable evidence to be provided for expert opinions.

The designation of the measuring devices is based on the standard.

Example: VDE113 (EN60204) with 10 A protective conductor test, high voltage test, resistance measurement and limit range detection, insulation test

Important standard measuring devices:

- VDE100 general test for electrical devices

- VDE113 ( EN60204 ) test for the electrical equipment of machines

- Earthing test device functionality of the foundation earthing

- Socket tester Standard-compliant connection (small part of VDE100)

- Overtravel travel measuring device For hydraulic presses to determine the travel covered after an emergency stop.

Data and communication technology

These standard measuring devices examine the correct execution of the cable connections (connection between plug and cable ) and / or the physics of data technology, i.e. the level of the signal and interference . In the industrial sector, these devices are mainly used for field buses or Ethernet . In addition to the testers, i.e. devices that examine the physics, there are also protocol analysis devices that examine the data content. The list only shows some typical devices as examples.

Local buses

- IEC-625 bus (IEEE-488)

Field buses

- Profibus tester: level height, data throughput, cycle time, termination, slave list

- CAN bus tester: error frames, data throughput,

- AS-Interface bus tester: level height, slave list, slave no. to assign

Ethernet

Because of its widespread use, it is the system for which there is the greatest number of analysis programs. Here is a small selection without rating ...

- Ethernet cable check tester: Thin Ethernet (RG98U), Thick Ethernet (yellow cable), RJ45

- MRTG Analysis: Multi Router Traffic Grapher depicting network traffic among others

- Ethereal or WireShark analysis: used data channels of a network, data, protocols

- nmap analysis: network scanner with many functions

Normal

Standards are material measures, measuring devices, reference materials or measuring devices that have the purpose of defining, embodying, preserving or reproducing a unit or one or more size values in order to pass them on to other measuring devices through comparison. Normal routinely used hot working standards . Reference standards , on the other hand, are only used for the occasional calibration of the working standards, possibly also via other intermediate standards, which are then called higher (second, third) order standards . This minimizes the burden on the higher-quality standards. The reference standards are also traced back to a primary standard that meets the highest metrological requirementsvia a further calibration hierarchy . This is usually a national standard maintained by a national metrological institute or an international standard. Within the calibration hierarchy, the accuracy of the standards increases steadily upwards.

Test stands are used for error control for quality assurance or calibration of measuring devices (e.g. for water meters ).

Legal for trade measuring devices

Measuring devices whose measurement results are used to calculate commercial services ( e.g. retail scales, water meters) must meet legal calibration requirements. This means that their design must be approved by the Physikalisch-Technische Bundesanstalt (PTB) and the devices must be calibrated, whereby a calibration must be refreshed after a certain time by state-approved test centers with a standard approved by the calibration authority . The calibration law defines calibration error limits which may not be exceeded for different load ranges.

Examples: scales , water meters , gas meters , electricity meters , heat meters , fuel meters , flow meters

Example of an exceptionally permitted measuring device that does not require verification: heat cost allocator

The European Measuring Instruments Directive (MID) was published in April 2004 and must be implemented in national law by October 20, 2006.

Intrinsically safe measuring devices

The measuring principle of intrinsically safe or explosion-proof measuring devices is the above. the same, but these devices must meet special requirements for their application, which they z. B. found in underground mining or the (chemical) industry. Directives such as 94/9 / EC or ATEX determine the requirements that are checked with regard to electrical, mechanical and material specifications. Approved test centers issue a certificate upon successful approval, which is a basic requirement for the commissioning of measuring devices in the special potentially explosive areas.

Medical measuring devices

Special rules apply to measuring devices in medicine . You must comply with the regulations of the MedGV , the medical device regulation. However, this only applies to measuring devices that a) are classified as medical devices and b) are used in recognized medicine. The field of alternative medicine remains unaffected. The Teslameter, a biofield measuring device or the body fat scale are not covered by the regulations.

- Actometer for recording movement activity

- Ergometer measures physical work or performance

- The sphygmomanometer developed by Riva-Rocci , with which the systolic blood pressure could be determined manually with a cuff , was historically often associated with this. Nowadays, however, measurements are usually no longer carried out manually with a mercury column, but instead using an oscillometric method with a digital display. In addition to these bloodless measurement methods, there are also clinical methods in which the blood pressure in a blood vessel is measured directly via a pressure transducer. See blood pressure measurement .

- Blood glucose meter - is an important device for people with diabetes . It is used to determine the current value of the * glucose level in the blood . In addition to the classic method in which a drop of blood is required, there are also newer approaches to measuring devices that enable bloodless measurements.

- EKG devices are medical devices that display and record the sum of the electrical activities of all heart muscle fibers.

- EEG devices are medical devices for displaying and recording the externally measurable electrical activities of the brain

- Clinical thermometer for measuring (human) body temperature

- Capnometer, capnograph to measure and monitor the carbon dioxide content of the exhaled air of a patient.

- Body fat scales indicate not only the body weight but also the percentage of body fat .

- Scoliometers measure the angle of inclination of the back surface to the horizontal.

- Spirometer to check lung function .

Technical aids for measurements in medicine

Technical aids for measurements in medicine are not actually measuring devices, but are used for measurements:

- Microscope , especially light microscopes z. B. for counting / detection of bacteria ...

- medical cameras (some with infrared or UV light)

- Ultrasound devices for diagnostics (pregnancy, ...)

- X-ray devices for diagnostics (internal organs, broken bones, osteoporosis ...)

- Parallelometer for measuring disparallelism in the manufacture of dentures

Remarks

- The classification according to the technical principle according to which the measuring device displays is dealt with in the article Display (technology) ; here it is only stated which size is measured.

- In individual cases, the term sensor or encoder (the part performing the measurement) is equated with the measuring device. When selecting a device or a method, you may also need to search under this reference.

- Out of Specification (OOS) means that a measured value is outside the calibrated range of the measuring device.

See also

literature

- HR Tränkler: Pocket book of measuring technology . Oldenbourg, Munich 1992.

- Jörg Hoffmann: Pocket book of measurement technology . Fachbuchverlag, Leipzig 2004.

- Wolfgang Schmusch: Electronic measurement technology . Vogel Buchverlag, Würzburg 1991.

- Jörg Hoffman: Handbook of measurement technology . Hanser, Munich 2005.