Electric car

An electric car (also e-car, electric car ) is a multi-lane motor vehicle for the transport of people and goods with an electric drive.

At the beginning of the development of the automobile around 1900 and in the following decade, electrically powered vehicles played an important role in city traffic. However, advances in internal combustion engine vehicle construction and the filling station network have displaced them. It was not until the 1990s that the production of electric vehicles rose again. In the 2000s, powerful lithium-based batteries were adapted for vehicles.

At the end of 2019, the global stock of passenger cars and light commercial vehicles with exclusively battery-electric drives, range extenders or plug-in hybrids was 7.89 million. Compared to the level of 1.40 million at the end of 2015, this is almost a six-fold increase and an average growth of 54.1% per year.

Definitions

Different definitions and delimitations are used for the term “electric car”. With regard to the vehicle type and class , these correspond to the lemma " automobile ". The electricity for the drive can be obtained from accumulators , capacitors , fuel cells or overhead lines ( e.g. in trolley buses and trucks ) or generated with the help of internal combustion engines or flywheel storage devices. However, the German Federal Motor Transport Authority only understands electric vehicles to be those “with an exclusively electrical energy source”. Vehicles “with at least two different energy converters and two different energy storage systems” count as hybrid vehicles .

General properties

Electric motors start by themselves and deliver high torque over a very wide speed range . Unlike vehicles with combustion engines , electric cars therefore generally do not need a (manual or automatic) gearbox and achieve high acceleration values. Electric motors are quieter than gasoline or diesel engines, almost vibration-free and do not emit any harmful exhaust gases. They typically consist of fewer parts and are smaller for the same performance, their efficiency is significantly higher. Due to the lower energy density of accumulators compared to fossil fuels in tanks, the mass of electric cars tends to be higher than that of conventional automobiles and their range is lower. The charging times are longer than corresponding refueling processes. Today's electric cars can recover braking energy through recuperation .

Vehicle concepts

Electric cars can be differentiated according to their construction principle:

- Newly developed electric cars (so-called purpose design), in which no constructive compromises have to be made in the implementation. This technical advantage is offset by the economic disadvantage of the high one-time expenditure for the new development, which is why this concept requires high production numbers. Examples include a. BMW i3 , Nissan Leaf , Tesla Model S , Tesla Model X , Tesla Model 3 , Renault ZOE , BYD e6 , Chevrolet Bolt , Streetscooter .

- Electric cars as an adaptation of conventional cars (so-called conversion): Here, components of the internal combustion engine drive are replaced by those of the electric drive in a conventional vehicle. This requires constructive compromises, since the electric motor and battery are fitted into the existing installation space. The low development effort is offset by high part costs for the custom-made drive components, which is why this is suitable for low production quantities. Both the Toyota RAV4 EV , the approximately ten thousand French electric cars since 1990 by PSA Peugeot Citroën and Renault of the "electric series" (Saxo, Berlingo, 106, Partner, Clio, Kangoo) and the Mitsubishi Electric Vehicle , which was launched in Europe in 2010 The world's first mass-produced electric car (around 17,000 vehicles per year) (in a slightly modified form also marketed by PSA as Citroën C-Zero or Peugeot Ion) and the Elektro-Smart are based on this cost-effective development method. These vehicles require around 12-20 kWh of electrical energy for 100 km in everyday life. Since the end of 2013, the VW e-up! offered, since 2014 the VW e-Golf . Further examples are the MINI E and BMW ActiveE used in the run-up to the development of the BMW i3 .

- Electric cars as retrofitting of series vehicles such as Stromos and Citysax enable small manufacturers to manufacture electric cars. A series-produced new drive train is installed, or the electric motor is flanged to the standard manual transmission. Driving performance, range and consumption are similar to those from adaptations to conventional production cars from major manufacturers. Higher production costs due to small series production are offset by flexible adaptation options to customer requirements and the use of used vehicles that are not available as an electric version or as a basis.

history

In 1821 Michael Faraday showed how a continuous rotation could be generated with electromagnetism , thus creating the basis of the electric drive . From the 1830s onwards, a wide variety of electric motor and battery variants were used to create various electric vehicles and table models, for example by Sibrandus Stratingh and Thomas Davenport . Davenport tested his electric motor on a model locomotive, which he let turn its rounds on a circle of rails about one meter in diameter. Around 1832 Robert Anderson is said to have built an electric cart in Aberdeen .

In November 1881, Gustave Trouvé presented an electric car at the International Power Fair in Paris .

The first known German electric car was built by the Coburg machine factory A. Flocken in 1888 with the Flocken electric car . The car is also considered to be the world's first four-wheeled electrically powered passenger car .

First heyday and early records (approx. 1896–1912)

“As motor vehicles, which carry their energy with them for locomotion, three categories are currently noteworthy, namely: vehicles moved by steam, vehicles moved by oil engines and vehicles moved by electricity. The first type is likely to come into consideration in the future mainly for wagons on rails and heavy road vehicles, while the large area of the vast country is rushed through by oil motor vehicles and the smooth asphalt surface of the big cities as well as the road rails are animated by wagons driven by collector electricity becomes."

The range of the historic vehicles was around 100 kilometers. By 1900, 40% of cars in the US were steam powered, 38% electric, and only 22% were gasoline. Almost 34,000 electric vehicles were registered in the USA, the highest number in the world at the time. In 1912, most electric vehicles were sold to date. After that, the market share fell. From 1896 to 1939, 565 brands of electric cars were registered worldwide.

The first documented speed record for a land vehicle was set by the French racing driver Gaston de Chasseloup-Laubat on December 18, 1898 with the electric car Jeantaud Duc by Charles Jeantaud in Achères , near Paris, at 62.78 km / h. In the following months he outbid each other in Achères with the Belgian Camille Jenatzy , until he finally set the first record beyond the 100 km / h mark with the La Jamais Contente electric car with 105.88 km / h.

In 1919 it was established in Germany that trucks with rubber tires with internal combustion engines should not exceed a maximum speed of 15 to 16 km / h. For trucks as towing vehicles , 12 to 14 km / h were to be aimed for. For rubber-tyred trucks with electric drive , practice in the same year had shown that a top speed of 18 km / h was realistic.

Niche vehicle (approx. 1910–1990)

The decline of electric cars began around 1910. The much greater range and the availability of cheap oil for carburetor fuels were (among other things) factors in the decline in demand for smooth-running electric means of transport with "highly sensitive batteries". Starting petrol engines using the starter instead of cranking has also become much more convenient. Under the influence of Standard Oil, gasoline became the main fuel in the USA and in all countries influenced by Standard Oil. At the same time, even the automobile manufacturer Henry Ford converted its Ford Model T , which was built from 1908 to 1927 and was developed for " ethanol ", to gasoline .

However, the electric drive is widespread in vehicles that draw the driving energy from overhead lines ( electric locomotive , trolleybus , tram ) or generate it themselves ( diesel-electric drive ).

The Dutch technical historian Gijs Mom takes the position that the decades of stagnation in the development of (individual) electromobility cannot be explained from a scientific and technological point of view, and that cultural factors in particular prevent the spread of electrically powered cars. As early as 1897, the then President of the Central European Motor Vehicle Association Klose said that the strengths of battery-powered electric vehicles lie in local urban transport , where they can even be superior to vehicles with internal combustion engines - in 1958 , the trade journal Automotive Technology made it clear that “all branches of the economy are in the interests of Economics should be interested in using electric vehicles where the operational requirements exist. ”In the early 1920s, the Leipzig company Bleichert manufactured electric carts and electric delivery vehicles (trucks) that were used all over Germany. In the GDR, electric carts intended for internal transport were widespread, and they were also roadworthy.

A niche in which motor vehicles with electric motors kept themselves was also the local transport with small delivery vans for the daily delivery of milk bottles in Great Britain and parts of the United States , the milk floats . Tens of thousands of these cars were in service in the UK. Milk float manufacturers in the UK in the 20th century were Smith's, Wales & Edwards , Morrison Electriccars, M&M Electric Vehicles, Osborne, Harbilt, Brush , Bedford and Leyland . With the drop in home deliveries, only Bluebird Automotive , Smith Electric Vehicles and Electricar Limited were left. Smith Electric Vehicles was the largest manufacturer of electric delivery trucks and trucks in 2008.

In some tourist regions, such as Zermatt in Switzerland , electric cars have dominated motorized traffic since 1931.

Renaissance (1990-2003)

Efforts to power cars with electric motors were increasingly considered after the oil crisis triggered by the Gulf War in the 1990s. The regulation drawn up by CARB and passed as a law in California in 1990, stating that vehicles must be gradually offered emission-free vehicles , forced the automotive industry to develop products.

This led to new types of accumulators ( nickel-metal hydride accumulators and later to lithium-ion accumulators ), which replaced the lead accumulators as drive batteries and to the development of a large number of electric cars. Examples are the Volkswagen Golf CitySTROMer , BMW E1 or the Mercedes A-Class .

From 1996 to 1999 General Motors built the General Motors Electric Vehicle 1, GM EV1, a series electric vehicle in an edition of around 1100. Toyota built around 1,500 of the fully electric RAV4 EV , Nissan around 220 of the Nissan Hypermini , and Honda the Honda EV Plus . The production of most electric cars was discontinued after the relaxation of the CARB legislation and deliveries stopped (see also Who Killed the Electric Car? ).

Various light vehicles have been produced in Europe since the 1990s , such as the CityEL , the Twike or the Sam electric vehicle . PSA Peugeot Citroën produced around 10,000 electrically powered cars from 1995 to 2005 (Saxo, Berlingo, 106, partner), which were only offered in France, the Benelux countries and Great Britain.

Developments since 2003

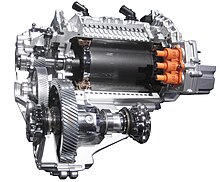

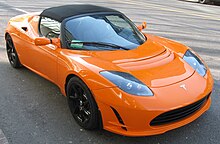

From 2003 onwards, smaller, more independent companies in particular developed electric cars or converted series vehicles, such as the Citysax or Stromos compact cars . In 2006 the sports car Tesla Roadster was presented, which showed the current technical possibilities with a range of approx. 350 km and its driving performance. As of 2007, many established manufacturers announced new developments (see also list of electric car prototypes ). In 2009 the Mitsubishi i-MiEV started as the first large-scale electric car.

In 2009, General Motors, like other automakers, ran into financial problems and announced that it would start producing plug-in hybrid cars from 2010 . As a result of this development, the Chevrolet Volt hybrid car became available on the US market from December 2010; its Germany variant, the Opel Ampera , received considerable media coverage. Also in 2010, the Nissan Leaf came on the market, which was the world's best-selling electric car by 2020.

In mid-2012, the Tesla Model S was the first full- size electric car to hit the market. Depending on the model, the range is up to 600 km ( NEDC ) and is by far a new record for electric series vehicles. It is in the range of cars with combustion engines. The Tesla Model S is the safest car tested by the National Highway Traffic Safety Administration through 2013 . The batteries can be charged to 80% within 30 minutes. From autumn 2012, the Smart Fortwo , which had been known for years, was also sold in the Smart ED electric version . Hayek's original smart concept already included an electric drive. In 2014, it was registered in Germany in second place for e-cars. Nevertheless, its production was stopped in 2015 with the end of the Smart 451 series.

At the end of 2012, the Renault ZOE came onto the market as the first small series production vehicle with lithium batteries from a major European manufacturer. A year earlier, Renault had introduced a rental battery system with the Twizy , which is also used by the ZOE.

With the Kia Soul EV (2013) and the Ford Focus Electric (2013) two other large automobile manufacturers offered electric vehicles. Since November 2013, the VW e-up! and the BMW i3 on sale, with which these two companies entered the market. In the same year, Google announced that it would develop electrically powered driverless vehicles ( Google Driverless Car ) and presented a prototype. The VW e-Golf has been available since 2014 . The Mercedes-Benz B-Class had been available as an electric version since November 2014 and, after the production of the Smart ED was discontinued, it was the only electric car produced by the group in large numbers.

The Tesla Model 3 has been in production since July 2017 and has been delivered in Europe since February 2019.

An electric bus named Olli from the manufacturer Local-Motors has been on the road near Washington DC (USA) since June 2016; the autonomous electric vehicle comes from the 3-D printer. Also since June 2016, an electric, series-produced, autonomous shuttle bus from the Navya company has been in regular experimental operation in Swiss Sion and Lyon in France . In 2015, more than 100,000 e-buses were already in use in the People's Republic of China, which corresponds to a share of over 20% of the bus fleet. Complete electrification of the entire bus fleet is conceivable. In 2016, 115,700 electric buses were newly registered in China. In 2017 there were 89,000 pieces.

Smaller manufacturers such as Goupil, Tropos or ARI Motors have also brought purely electrically powered commercial vehicles onto the market in the area of so-called light electric vehicles ( EC vehicle classes L6e and L7e ) .

Environmental balance

In addition to the most frequently discussed CO 2 balance , fine dust, nitrogen oxide and noise pollution also play a role. A distinction is made between the direct load during vehicle use and the indirect load during the manufacture of the vehicle, as well as the provision of resources during consumption over the entire life cycle (e.g. electricity). In addition to the absolute figures, the comparison with vehicles with combustion engines plays a particularly important role in politics.

CO 2 balance

In the case of an electric car, CO 2 emissions do not occur in the car itself, but rather during the generation of electricity and the manufacture of the vehicle and especially the battery. The environmental balance of automobiles is often only related to the direct energy or fuel consumption ( tank-to-wheel = from tank to wheel) and emissions of pollutants or climate-damaging gases. A well-to-wheel analysis (from the source to the wheel), which also includes the efficiency and emissions for the provision of energy, is also used. More comprehensive comparisons put on a life cycle analysis (life cycle assessment, "LCA"). Part of this balance sheet are a. also the manufacturing and disposal costs for the vehicle, the provision of the drive energy and noise emissions.

When considering the entire product life cycle, electric cars including batteries perform better than vehicles with internal combustion engines in terms of both energy consumption and greenhouse gas emissions . Only if electricity from coal-fired power plants is used to operate the electric vehicle and the batteries are manufactured in a technologically less advanced factory, the greenhouse gas balance of electric cars is higher than that of cars with combustion engines. When using the average European electricity mix , battery electric vehicles emit 44 to 56% or 31 to 46% less CO 2 than vehicles with internal combustion engines, depending on the approach used (simplified well-to-wheel analysis or full product life cycle analysis) . It should be noted here that the share of renewable sources in the electricity mix has increased in recent years, which means that these CO 2 emissions have now further decreased. The production of an electric car is more energy-intensive than that of a car with a combustion engine. According to a study from 2010, about 15% of the total environmental impact of electric cars is due to the manufacture of the accumulators .

2020 was published in the journal Nature Sustainability a study that the CO 2 footprint of electric cars over the entire life cycle (d. H. Manufacturing, operation and recycling) for both 2015 and analyzed the future. The authors first studied the global average and then divided the world into 59 regions, which they then analyzed individually in order to identify regional differences. They came to the conclusion that as early as 2015 the use of an average e-car would have produced significantly less carbon dioxide compared to an average fossil-fueled car. According to this, e-cars were always more climate-friendly than combustion engines when they were charged with electricity that produced less than 1100 g CO 2 / kWh. More than 90% of the world's electricity generation is below this emission level. Overall, the authors came to the conclusion that e-cars were already more climate-friendly than combustion engines in 2015 in 53 of the 59 regions worldwide, accounting for 95% of road traffic. On average, the emissions from e-cars were 31% lower than those from combustion engines. A few exceptions are countries such as Poland or Estonia , where electricity generation is primarily based on the combustion of emission-intensive fossil fuels such as oil shale or coal . In addition, the climate advantage of e-cars will improve even further in the future with the expected decrease in emissions from power generation, so that in future even the most inefficient e-cars will have a better climate balance than the most efficient combustion engines. Overall, the switch to e-cars would almost certainly reduce greenhouse gas emissions in most regions around the world, even assuming that this electrification of transport would not be accompanied by a decarbonization of electricity generation.

In its "Life cycle" environmental certificate documentation published in 2014, Mercedes-Benz extensively compares the B-Class in electric and combustion engine versions over the entire life cycle. Accordingly, the B-Class with electric drive causes 27% less CO 2 than the gasoline variant (assumption: EU electricity mix at the time). The German Institute for Energy and Environmental Research Heidelberg (IFEU) also examined the carbon footprint of electric vehicles in the UMBReLA project (environmental balances for electric mobility).

In a study, Volkswagen compares the CO 2 balance of the Golf with gasoline, diesel, natural gas and electric drives, taking into account the entire life cycle (including 200,000 km, primary energy factors, German electricity mix, manufacture of cars and batteries). The E-Golf achieves 120 g / km, the diesel 140 g / km (natural gas drive: 151 g / km; petrol: 173 g / km). Due to the advancing energy transition in Germany, the study extrapolates a CO 2 balance of 95 g / km for the electric vehicle and 114 g / km for the diesel, which means that the Golf Diesel causes 20% more CO 2 than the comparable E-Golf. However, due to the lack of reliable data, the study does not take into account a possible “second life” of the battery or, if applicable, recycling of the battery.

Depending on the primary energy used, electric vehicles shift emissions for their operation away from the vehicle to the places where the electricity for their operation is produced. These can be reduced if emission-free primary energies, for example from the regenerative sector, are used. According to a Shell study, 15–20% of the CO 2 emissions of internal combustion engines occur in the production and supply of fuels.

Battery recycling

Carbon dioxide is produced during the manufacture of the accumulators . Studies in the peer-reviewed literature come to values of around 70 kg to 75 kg of CO 2 per kWh of battery capacity. A study for the Swedish Ministry of the Environment from 2017, on the other hand, named values of 150 to 200 kg of carbon dioxide per kWh of battery capacity. Electrify-BW criticizes the presentation of the Swedish study due to a lack of basic assumptions. The study and its results were taken up many times, even though their database was already out of date when published. Among other things, some media wrote a very large CO 2 backpack for e-cars , whereupon the authors stated in a press release issued especially for this purpose that the media misquoted the study many times. The study only gives an indication of 150 to 200 kg CO 2 per kWh battery capacity, which is a current average value. This can easily be reduced, e.g. B. through the increased use of renewable energies in battery production. The study does not contain comparisons with cars with internal combustion engines. In 2019 an update of the so-called "Sweden Study" appeared, in which the authors corrected the values given in 2017 on the basis of more recent literature to around half of the original values. Accordingly, the CO 2 emissions in the production of the most frequently used NMC type are around 61 to 106 kg CO 2 equivalents .

According to a study by the Institute for Energy and Environmental Technology, just under a third of the material required for the batteries is reflected in the ecological balance of the electric vehicle.

The recycling of disused lithium-ion batteries still requires a lot of energy, which has so far been economically unprofitable. Even dismantling cannot be automated due to the many different battery systems. Used accumulators from electric vehicles that are still functional, but no longer have their full capacity, can be used as power storage for industry or single-family houses with photovoltaic systems. The production processes of the automobile manufacturers with their cost reduction potential can also influence other areas of the energy industry.

In a study for the European Environment Agency from 2016, the Öko-Institut and the research company Transport & Mobility Leuven stated that 70 percent more energy is used to manufacture an electric car than to manufacture a conventional vehicle, while the amount of energy required in operation is high is less.

There are different approaches to recycling car batteries, such as melting down or mechanical processing. With the latter process, a material recycling rate of over 90% is currently possible, whereby the CO 2 footprint of production can be reduced by up to 40%. Researchers at the Fraunhofer Institute have been working with industrial partners since 2016 on a new material- and energy-efficient recycling process, which focuses on electrohydraulic shredding using shock waves.

The recycling of lithium-ion batteries (LIB) from end-of-life vehicles is regulated within the European Union by Directives 2000/53 / EC and 2006/66 / EC. The former deals with the recycling of vehicles at the end of their life cycle. For parts with an increased risk potential, such as the battery of an electric vehicle, removal and separate handling is required. This is regulated in the Battery Directive 2006/66 / EC, which provides for extended manufacturer liability for battery producers. They have to cover all costs of the collection, processing and recycling system. Vehicle batteries are listed as industrial batteries. With regard to the recycling process, LIBs fall under the category "other batteries", for which only 50% of the average weight is recycled. The largest recycling facility is currently the Umicores LIB recycling facility and treats 7000 tons per year.

For the recycling of damaged electric car batteries, for example caused by traffic accidents, there are still no clear technical and legal requirements.

In a study by the Fraunhofer Institute for Systems and Innovation Research (ISI) from 2020, the expected yield from dismantling is estimated at € 210… 240 per ton of batteries. Half of the income is accounted for by aluminum, a quarter by steel and another quarter by copper. The actual cell recycling is, however, much more complex and no exact figures are available yet. In addition, the problem is made more difficult by the different designs of the batteries. The environmental assessment of the recycling process is just as uncertain, only laboratory data speak for a greenhouse gas reduction.

Direct vehicle emissions

All-electric cars are emission-free vehicles . They do not emit any exhaust gases and are therefore classified in the highest CO 2 efficiency class. This evaluation only compares the vehicles depending on their weight and emissions during operation. They are allowed to travel unrestrictedly in German environmental zones and, for example, also meet the “ zero emission ” regulations that have been in force in California since 1990 for air pollution control.

When road traffic noise is significant let noise reductions achieved. Electric motors are quiet because they don't make any loud intake or exhaust noises. Less engine noise is particularly noticeable in buses , trucks and motorized two - wheelers . The tire-road noises that dominate at higher speeds correspond to those of conventional drives. Around 50% of the population is so affected by traffic noise that health risks are to be feared. 15% are at risk of suffering from cardiovascular problems. Since electric cars are drowned out by the noise of other vehicles up to around 40 km / h and are therefore more difficult to perceive acoustically by road users such as children, cyclists and visually impaired pedestrians, vehicle manufacturers began in 2012 to standardize devices for the speed-dependent emission of warning noises, so-called Acoustic Vehicle Alerting Systems ( AVAS). After Japan and the USA, the installation of acoustic warning systems is also legally envisaged for new vehicle types in the EU from July 1, 2019 (and from July 1, 2021 for all types). Behind this demand are associations that represent visually impaired people.

In March 2016, AVAS was prescribed for 50 countries; At a meeting of the UN working group in Geneva in September 2016, negotiating partners agreed that a pause switch for the warning sound that could be activated by the driver should be prohibited.

Fine dust emissions are only produced to a small extent in electric cars by tire wear and braking processes ( brake dust ). The latter are also reduced by energy recovery systems . The greatest potential for avoidance, however, is due to the lack of exhaust gases from internal combustion engines, which can lead to serious respiratory diseases.

Energy consumption source-wheel (well-to-wheel)

(A consideration only related to the vehicle technology (tank-to-wheel) takes place in the section Consumption and efficiency .)

As with energy consumption, the observation limits must be carefully observed and the primary energy factors must be included. These can fluctuate depending on the year under review, the investigation procedure, electricity provider, country and other factors and change in some cases very dynamically due to changes in the electricity market. Different standards and institutions use different factors and use different calculation methods. The renovation of the infrastructure also results in CO 2 emissions, but the use of electric cars can reduce the greenhouse effect.

Recent external studies come to the conclusion that the origin of the electricity used to charge the batteries is reflected in more than two thirds of the ecological bill.

The energy requirement in kWh / 100 km, which is determined in a standardized driving cycle (in Europe, the NEDC ) is used as the basic information . It maps the energy consumption between the socket and the bike ( tank-to-wheel ). In order to determine the efficiency of the overall “car” system ( well-to-wheel ), the upstream losses during power generation, conversion and transmission must also be considered. The degrees of efficiency of traditional power plants differ greatly in relation to the use of primary energy . Depending on the type of power plant, they are between 35% (lignite power plant) and 60% ( combined cycle power plant ). Transformation and line losses in the power grid must also be taken into account. Therefore, the primary energy consumption of an electric car when charging on the public power grid (power mix) is higher than the power consumption “from the socket”. This overall consideration is expressed in a primary energy factor, which is multiplied by the pure vehicle consumption . The determination of this factor can turn out very differently due to different observation limits, time periods, calculation bases and dynamic developments in the energy market, which becomes relevant when comparing different systems.

Since 2016, a primary energy factor of 1.8 has been set for electricity generation in Germany in accordance with the Energy Saving Ordinance (EnEV) . Before that, the factor 2.6 had been in effect since 2009, which had already been reduced to 2.4 on May 1, 2014. Due to the conversion of the power supply in the course of the energy transition, the use of primary energy continues to change. For local considerations, special electricity tariffs and in other countries, different values apply depending on the electricity mix used. In Austria, for example, subsidies for electric cars are tied to proof of the primary use of electricity from 100% renewable energy sources.

Comparison of gasoline and diesel vehicles

If one takes into account the losses in the extraction, refining, exploration, drilling and transport / provision of fossil fuels ( well-to-tank ), a Swiss study from 2008 shows the efficiency for the provision of gasoline 77.5%, diesel 82 %, Natural gas 85% (primary energy factors of 1.29 / 1.22 / 1.17). According to estimates, the German Energy Saving Ordinance gives the value at 1.1. According to estimates from 2001, construction-related losses in the car (tank-to-wheel) are added to these supply losses. With combustion engine drives, these are much higher than with electric drives due to the low efficiency (with ideal operation of the Otto engine, the engine efficiency is 36%), the inefficient cold start phase , and the partial load operation. If you convert the direct fuel consumption into kWh / 100 km, the values are much higher than with electric vehicles.

If one takes the ideal engine efficiency for internal combustion engines as a basis, one comes to a primary energy factor of 3.58 for gasoline engines when considering well-to-wheel . With a primary energy factor of 2.97 (passenger car) or 2.71 (commercial vehicle), diesel engines do a little better but still worse than electric vehicles.

Comparison of fuel cell vehicles

Also, fuel cell vehicles have a lower overall efficiency than pure electric vehicles. These also require a hydrogen storage tank , for example . The production of the hydrogen and the storage (compression up to 700 bar or liquefaction up to approx. −253 ° C) is very energy-intensive. If the hydrogen is generated from renewable energies by electrolysis , the added losses from electrolysis and compression to 700 bar are 35%. Together with the power generation efficiency of the fuel cell of around 60%, there are losses of around 61% on the way from the power generator to the drive motor in the vehicle. For the same way, the charging and discharging losses of a lithium-ion battery are only 10 to 20%. The energy losses of a fuel cell vehicle are therefore higher than that of a purely battery-powered electric car. Therefore, the energy costs of pure battery electric vehicles are significantly lower than those of fuel cell vehicles that generate hydrogen using electricity (electrolysis).

Studies

According to a study by the BDEW , electric cars with a German electricity mix had 60 percent less CO 2 emissions in 2018 than comparable cars with gasoline or diesel engines.

In August 2017, the Öko-Institut published a study according to which electromobility was already superior to conventional cars in terms of the carbon footprint of the electricity mix at that time with around 30% renewable energies . Investigations of the entire life cycle assessment carried out in Switzerland confirm the statement that only when operated with pure coal-fired electricity can the environmental balance of electric cars be worse than that of vehicles with combustion engines. The comparative calculation for modern lithium-ion batteries was not considered conclusively. Improved production processes reduce the manufacturing costs and further improve the ecological balance of electric cars.

According to a study by the Alternative Fuels Data Center of the US Department of Energy, the annual CO 2 emissions of an average electric vehicle in the US amounted to around 2.2 tons in 2015 (total energy consideration, well-to-wheel , with 19,000 km of driving distance). The emissions varied depending on the emission intensity of the power generation between barely 0.5 kg in Vermont to 4.3 tons in West Virginia for power generation from coal. In contrast, an average combustion vehicle emitted 5.2 tons of CO 2 while driving the same distance .

From 2020, car manufacturers in the EU will only be allowed an average of 95 grams of CO 2 emissions per car driven per kilometer - fines will be payable if they are violated. This corresponds to a consumption of four liters per 100 kilometers. Since customers also buy SUVs and sedans, car makers have to sell electric cars, even if that would be a losing business. From 2020, the sale of an electric car has an additional value of € 12,400 for Mercedes due to avoided fines, € 11,900 for BMW and € 11,400 for VW. With electric cars, the penalties will be minimal if the share of total production is nine percent from 2020, i.e. just under 1.5 million units.

The Fraunhofer Institute for Systems and Innovation Research (ISI) published a study in January 2020, according to which an electric vehicle has 15 to 30% lower greenhouse gas emissions than a comparable modern conventional car in the overall balance of production, use and recycling phases over its service life This would improve further with the advancement of the energy transition and the exclusive use of renewable energies in the production of e-cars, which currently cause 70 - 130% higher greenhouse gas emissions than a conventional car. Thus, the environmental balance of an e-car therefore being better than a conventional one it therefore requires regular use. A vehicle with a large battery but with low kilometers driven, which charges the German electricity mix, is hardly better than a conventional car. In addition to greenhouse gas emissions, the study also looks at the environmental impacts over the entire cycle of an e-car. Compared to a conventional car, the e-car has disadvantages in terms of fine dust emissions, water abstraction, acidification and human toxicity, which mainly arise during battery production. On the other hand, there are advantages in this regard with summer smog , overfertilization , space requirements and greenhouse gas emissions. However, some of the disadvantages such as acidification can no longer make a difference in comparison to an electric car in 10 years.

resources

The electric cars with a range of more than 150 km, which have been built since the 2010s, use batteries with lithium technology (see #Lithium or lead or nickel ). In addition to the CO 2 balance, the extraction of the raw materials lithium and cobalt is also discussed in their environmental balance .

Is the environmental compatibility of lithium technology in the ARD documentary Will the e-car save the environment? Already controversial, the ZDF documentary “The true price of electric cars” goes a big step further and sheds light on the other side of the scale : the problematic extraction of raw materials. In the production of the raw material lithium, for example, entire areas of southern Argentina are driven into desertification through overexploitation of the groundwater and tens of thousands of indigenous people are robbed of their basic livelihood. However, these reports are based on outdated or unproven numbers; a new study comes to a significantly more environmentally friendly result. In the north of Portugal, where the production of lithium is being prepared, there is strong resistance from environmentalists.

In the case of cobalt, the main mining area is 60% in the Democratic Republic of the Congo. In addition to the difficult human rights conditions, up to 20% of the cobalt mined is mined in small-scale mining . ASM promotes child labor, works with little or no safety precautions and results, among other things, in direct contact with heavy metals (especially uranium) in the rock.

Market development and political framework

Worldwide

As of December 31, 2019, 7.9 million cars and light commercial vehicles with exclusively battery-electric drives, range extenders or plug-in hybrids were in use worldwide, of which 3.8 million were in China and almost 1.5 million in the USA.

The Tesla Model 3 , introduced in 2017, is the world's best-selling electric car with over 450,000 units (as of March 2020).

The Nissan Leaf , introduced in 2010, follows in second place with around 450,000 units (as of March 2020).

The luxury sedan Tesla Model S , in third place with 260,819 units (as of January 2019, Tesla Model S ).

- Distribution of sales figures by market

| region | percent | |||

| 1. China | 56% | |||

| 2. Europe | 23% | |||

| 3. USA-Canada | 17% | |||

| 4. Others | 4% | |||

| Status: July 2019, source: www.jato.com | ||||

The electric car market is developing most strongly in China by far. Mainly Chinese products are sold there, in the rest of the world it is mainly Tesla. In China, the rapid switch to battery buses is also remarkable. By comparison, 40% of all electric cars worldwide were on US roads in 2013, with Japan accounting for a quarter of the market. Germany and German car manufacturers do not play a significant role in the electric car market (as of 2019).

- The world's most successful electric cars by manufacturer / model

| Manufacturer | Model name | piece | ||

| 1. Tesla Model 3 | 134,000 | |||

| 2. BYD E5 | 55,000 | |||

| 3. BAIC EU | 41,000 | |||

| 4. Nissan Leaf | 35,000 | |||

| 5. BYD yuan | 28,000 | |||

| Status: 1st half of 2019 | ||||

- The development of the sales figures over the last decade , worldwide

| year | piece | |||

| 2019 | 765,000 | |||

| 2018 | 397,000 | |||

| 2017 | 201,000 | |||

| 2016 | 137,000 | |||

| 2015 | 107,000 | |||

| 2014 | 67,000 | |||

| 2013 | 46,000 | |||

| 2012 | 22,000 | |||

| 2011 | 16,000 | |||

| 2010 | 2,000 | |||

| Status: 1st half of 2019 | ||||

The year 2019 is only taken into account with the first half of the year. The increase will therefore be greater at the end of the year.

- Worldwide registration figures for e-cars, the 5 largest manufacturers

| Manufacturer | units |

|---|---|

| Tesla (USA) | 233.760 |

| BYD (China) | 215,800 |

| BAIC (China) | 160,790 |

| SAIC (China) | 107,950 |

| Nissan (Japan) | 87,560 |

| Status: 2018, source: www.nau.ch | |

Electric vehicles currently available on the market can be found under List of electric cars in series production .

The best-selling electric car in the world was the Tesla Model S in 2015, 2016 and 2017 . In 2018 it was replaced by the Tesla Model 3 .

Various studies predict a development similar to that of digital cameras, which replaced analog cameras, etc., a so-called tipping point . The electric car is considered a disruptive technology . In a 2011 study, the consulting firm McKinsey showed which vehicle type is most economical at which gasoline price or battery price. Accordingly, with a fuel price of over USD 1 per liter and a battery price below USD 300 per kWh, the battery-electric car would be the most economical. In fact, as of November 2013, the fuel price in many countries was over USD 1 per liter and the battery price was below USD 200 per kWh.

According to an interview published in 2017 with the German physicist Richard Randoll, the number of battery-powered electric cars sold worldwide doubles every 15 months. This exponential growth will lead to the “final end for the internal combustion engine” as early as 2026.

The auto trade also plays a major role in the spread of electric cars. According to the New York Times, car dealers often advise against buying an electric car if they are not familiar with the new technology, as the retailers earn more from servicing cars with internal combustion engines. According to the National Automobile Dealers Association, car dealers earn about three times as much from service as from car sales. Electric cars require less service. The trade is a bottleneck in the spread of electric mobility.

The European Union tightened the laws for CO 2 emissions from motor vehicles with the target of 95 g / km for 2020. The calculation is based on the fleet consumption of the automobile manufacturers. So-called super credits, a form of climate compensation , have been negotiated for electric cars . The sale of an emission-free electric car reduces the total fleet consumption disproportionately. Similar effects also occur in US climate policy, see Corporate Average Fuel Economy . Proponents, including the German government and the German automotive industry, see this as a market stimulus for electromobility; opponents refer to it as a subsidy for the automotive industry, whose statutory pressure to develop low-emission vehicles is relaxed and otherwise due fines for exceeding the Limit values are avoided.

In 2017, the Tesla Model S was the best-selling luxury vehicle in Europe for the first time with 16,132 units - an increase of 30 percent over the previous year. It was ahead of the S-Class from Mercedes (13,359 vehicles) and the 7 Series from BMW (11,735 vehicles). In the USA, the Model S has been the best-selling luxury car since 2014.

Europe

advancement

The European Union promotes electric cars, among other things, by limiting the average carbon dioxide emissions of the car fleets sold by the car companies (95 g carbon dioxide emissions per kilometer). A study from April 2020 found that car manufacturers would even pay off price dumping for electric cars, because the zero emissions of e-cars sold in 2020 could be counted twice for reasons of funding policy (1.67-fold in 2021). The companies could avoid fines to the EU by selling enough electric cars or could sell more profitable, conventional cars, whereby heavy types would be further favored. The authors continue to criticize that 5% of the fleet produced can be excluded from the outset.

Market development

- New registrations for cars, pure electric drive (BEV), EU, 2019

Germany

Duration

The number of purely electric cars (excluding hybrids, on January 1) increased almost a hundredfold between 2008 and 2020. The average growth was 46.2% per year.

| year | Stock on

January 1st |

development |

|---|---|---|

| 2008 | 1,436 | |

| 2009 | 1,452 | +1.1% |

| 2010 | 1,588 | + 9.4% |

| 2011 | 2,307 | + 45.3% |

| 2012 | 4,541 | +96.8% |

| 2013 | 7.114 | +56.7% |

| 2014 | 12,156 | + 70.9% |

| 2015 | 18,948 | + 55.9% |

| 2016 | 25.502 | + 34.6% |

| 2017 | 34,022 | + 33.4% |

| 2018 | 53,861 | +58.3% |

| 2019 | 83.175 | + 54.4% |

| 2020 | 136,617 | + 64.3% |

- Graphic representation of the inventory development

New registrations

The Federal Motor Transport Authority maintains extensive statistics on the vehicle population in Germany. Light vehicles and vehicles assigned to motorcycles in terms of registration, such as the Renault Twizy , are not included in the group of electric cars.

| quarter | piece | |||

| 2018 Q1 | 9,044 | |||

| 2018 Q2 | 8,047 | |||

| 2018 Q3 | 7.199 | |||

| 2018 Q4 | 11,334 | |||

| 2019 Q1 | 15,804 | |||

| 2019 Q2 | 15,028 | |||

| 2019 Q3 | 16,541 | |||

| 2019 Q4 | 14,911 | |||

| 2020 Q1 | 25,516 | |||

| 2020 Q2 | 18,061 | |||

| New electric car registrations in Germany, source: Federal Motor Transport Authority | ||||

For plug-in hybrid numbers, see plug-in hybrid .

State funding

The German Federal Government In 2009, a National Development Plan for Electric Mobility and founded a national platform for electric mobility with various support measures to support the development efforts intensify to electric vehicles. It set the goal “that by 2020 no fewer than one million and by 2030 even six million electric vehicles should be on the German roads”. This goal is clearly missed.

Since the market launch was sluggish, politicians created the Electromobility Act in 2015 , which allows municipalities to promote electromobility through privileged parking and charging areas and opening up bus lanes , among other things . The proportion of German motorists who can benefit from approved bus lanes is likely to be rather low, however. In addition, the purpose of the bus lanes is thwarted and this suggestion is criticized as unsustainable political activism. To distinguish it from other vehicles, an E-license plate can be applied for since October 2015 . Electric vehicles that were first registered before January 1, 2016 were exempt from vehicle tax for 10 years . Since the beginning of 2016, this period has been reduced to five years, after which a reduced tax rate applies. In September 2016 the Bundestag decided that this regulation should be 10 years retrospective from January 1, 2016. In contrast to larger automobiles, light electric vehicles (including class L7e) are currently exempt from the environmental bonus despite their greater environmental friendliness , which has been criticized by members of the Greens .

The lobby organizations of the car manufacturers, such as the Association of the Automotive Industry and the BDI , campaigned aggressively among German federal politicians in 2015/2016 for state subsidization of electric cars and the establishment of a network of charging stations. In May 2016, the federal government introduced a purchase premium of € 4,000 for all-electric cars and € 3,000 for plug-in vehicles. The total funding amount is 1.2 billion euros, including 600 million euros from the federal government and 600 million from industry. The federal government planned 100 million euros for charging stations and a further 200 million euros for fast charging stations. 20% of the federal vehicle fleet should be electric in 2017. Of the funds made available for this purpose, only 2.4% had been called up in mid-June 2018. At the same time, the target of one million electric cars in 2020 has been cut in half.

The Federal Council demanded in a resolution of 23 September 2016 from the year 2030 should no cars with internal combustion engines shall be allowed. The decision was also addressed to the EU Commission to only allow emission-free cars in the entire European Union by 2030 at the latest. The basis is the Paris Agreement , which stipulates that the world should be CO 2 -neutral from 2050 . In order to achieve this, new registrations of cars with combustion engines must be stopped as early as 2030.

Austria

- New registrations for cars, electric drives, Austria, 2019

|

|

vehicle | piece |

|---|---|---|

| 1 | Tesla Model 3 | 2342 |

| 2 | BMW i3 | 1191 |

| 3 | Renault ZOE | 944 |

| 4th | Hyundai Kona | 897 |

| 5 | VW e-Golf | 805 |

| 6th | Nissan Leaf | 557 |

| 7th | Kia Niro | 421 |

| 8th | Tesla Model S | 389 |

| 9 | Audi e-tron | 364 |

| 10 | Hyundai Ioniq | 361 |

| Source: kleinezeitung.at | ||

Tesla remains the market leader with two models in the top ten. The VW e-Golf lost one place in the last 3 months of last year.

- Motor vehicle population with electric drive, excluding hybrids, Austria, 2011 to 2019

|

|

piece | |||

| 2015 | 5,032 | |||

| 2016 | 9,073 | |||

| 2017 | 14,618 | |||

| 2018 | 20,813 | |||

| 2019 | 29,523 | |||

In 2010, the Austrian federal government also set the goal of increasing the number of electric cars on Austria's roads to 200,000 by 2020.

In 2016, representatives of the Ministry of Transport and Environment announced subsidies for the purchase and distribution of electric cars amounting to € 72 million. € 48 million of this is intended to support purchases and sales. Private individuals can receive € 4,000, clubs, institutions and companies € 3,000 when buying a purely electric car; all groups can receive € 1,500 for a hybrid electric car. The regulation applied to purchases between January 1, 2017 and the end of 2018. There should be license plates with green lettering for these vehicles. They wanted to combine privileges, for example when parking or using bus lanes. € 24 million each come from the Ministry of the Environment, the Ministry of Transport and the automobile importers. At least 12,000 grants can be financed with € 48 million. ÖAMTC and VCÖ criticized the funding as wrong incentives.

In spring 2018 it became known that the Federal Ministry for Sustainability and Tourism, headed by Federal Minister Elisabeth Köstinger, is planning to exempt electric cars from the " Immissionsschutzgesetz - Luft " - speed restrictions ("IG-L") that apply in places on Austrian motorways and motorways . This would follow the principle that only those road users - namely drivers of vehicles with internal combustion engines - who, in contrast to emission-free electric vehicles, are actually responsible for the excessively high air pollutant values that lead to the activation of these restrictions imposed by traffic control systems, are responsible for the subject to appropriate restrictions.

Switzerland

According to the Federal Statistical Office, the share of purely electric cars in the total number of passenger cars rose in 2019 from 0.4% in the previous year to 0.6%. In the same year, over 28,716 fully electric vehicles were registered and 13,165 new battery electric vehicles and 4,271 new plug-in hybrids were registered; that was 4.2% and 1.6% of the new vehicles and thus a total of 5.6%.

There are various funding measures for electric cars in Switzerland. For example, electric cars have been exempted from automobile tax at 4% of the vehicle value.

- New registrations for all vehicles, electric and combustion engines, Switzerland and Liechtenstein, 2019

|

|

vehicle | piece |

|---|---|---|

| 1 | Škoda Octavia | 9280 |

| 2 | VW Tiguan | 7018 |

| 3 | VW Golf | 6596 |

| 4th | Tesla Model 3 | 5028 |

| 5 | Mercedes GLC class | 4743 |

| 6th | Mercedes A-Class | 4672 |

| 7th | Škoda Kodiaq | 4594 |

| 8th | Škoda Karoq | 4344 |

| 9 | Mercedes C-Class | 4277 |

| 10 | VW Polo | 3933 |

| Source: www.auto.swiss | ||

This list includes electric and combustion vehicles together. The Model 3 takes fourth place, although, unlike other vehicles sold, it was only available in Europe from February 2019.

China

In China , the government launched a campaign in 2008 under the motto “Ten Cities, One Thousand Vehicles”.

In mid-2014, the Chinese government decided to waive VAT on the purchase of an electric car from September 2014 to 2017 and to grant a purchase premium of up to $ 10,000.

There is a registration restriction for cars in major Chinese cities. In 2016, only 150,000 cars were allowed to be registered in Beijing. Of these, 60,000 were reserved for electric cars. The admissions are awarded through a lottery. Only every 665th applicant can get approval for a gasoline car.

In October 2016, it was announced that China was working on a plan to introduce an electric car quota from January 1, 2018. According to the draft law at the time, every automaker would have to sell at least eight percent of its vehicles in China as electric cars. If a manufacturer does not meet this quota, the manufacturer has to buy credits from other manufacturers who exceed this quota or reduce their own production. The quota should then be increased every year. China imposes import duties of 25 percent on foreign vehicles. If you want to avoid this, you have to set up a joint venture with a Chinese manufacturer as a manufacturer. BMW works with the Chinese automaker Brilliance, VW with FAW and SAIC.

In China, a total of 718,000 vehicles with electric motors were sold in the first three quarters (January to September) of 2018, an increase of 80 percent over the same period of the previous year. Of these, 540,000 were purely electric cars, the rest were hybrid vehicles. The market share for new registrations is 4.5 percent. 90 percent of the electric vehicles came from Chinese manufacturers such as B. BYD , BAIC and Roewe . Only Tesla with a 3 percent share and BMW with a 2 percent share were the strongest of the foreign manufacturers. The luxury market is dominated by Tesla and NIO and no longer by German manufacturers as in the past.

France

France is the only country in Europe where Tesla does not hold first place. It grants a kind of scrapping bonus for exchanging an old car with a combustion engine for a new vehicle with an electric motor of up to 10,000 euros. A plug-in hybrid still receives 6,500 euros.

All three large French automobile manufacturers Citroën, Renault and Peugeot have electric cars in their current sales program and can look back on a longer history of electric cars on offer, even if on a small scale.

At the beginning of July 2017, the French environment minister announced that France would like to say goodbye to the registration of cars with internal combustion engines by 2040. The aim is to be CO 2 -neutral by 2050 .

In March 2017, more than 100,000 electric cars were registered in France.

About 80 percent of the electricity consumed in France is generated from nuclear energy (see Nuclear energy in France ).

Great Britain

Electric car sales in the UK have been growing rapidly since 2014 .

At the end of April 2019, more than 210,000 electric cars and vans were registered. This corresponds to a share of 2.7% of all new car registrations.

The purchase of electric vehicles is government subsidized in the UK. On January 1, 2011, the “Plug-in Car Grant” funding program was introduced. Initially, the purchase of an electric car was subsidized with 25% of the acquisition costs up to a maximum of 5,000 pounds (5,700 euros). However, since March 2016 the maximum funding amount has been only 4,500 or 2,500 pounds (5,100 or 2,850 euros), depending on the level of emissions and the purely electric range of the car. As of May 2018, 148,465 eligible electric cars were registered. Since February 2012, there has also been the “Plug-in Van Grant” program, which grants a subsidy of 20% up to 8,000 pounds (9,100 euros) for the purchase of an electric van. By March 2018, this grant had been used 4,490 times.

The UK wants to ban the sale of new diesel and gasoline vehicles - including hybrids - from 2035. Cars with internal combustion engines should disappear from the streets by 2050; in Scotland this will even apply from 2045. Diesel vehicles will be charged fees on busy roads from 2020. There are discussions about entry bans in city centers. The aim is to reduce air pollutants, especially in cities.

India

Electric cars in India are mainly manufactured by two domestic auto companies, namely Mahindra Electric and Tata Motors . The government is trying to promote indigenous manufacturing with its Make in India initiative and wants companies to source 30 percent of their raw materials from India.

In January 2013, then Indian Prime Minister Manmohan Singh announced the National Electric Mobility Mission Plan, which aims to put more than 15 million electric vehicles on the roads by 2020 through financial and monetary policy measures. Among other things, the project is said to pay subsidies of up to 150,000 rupees for electric cars. The government aims to achieve annual sales of 7 million electric vehicles by 2020. The subsidy scheme is called FAME and is to be supported with measures for infrastructure building. The abbreviation FAME (Faster Adoption and Manufacturing of [Hybrid] Electric Vehicles) means the faster introduction and production of (hybrid) electric vehicles in India.

The reasons for the introduction of electric vehicles in India are mainly the increasing air pollution and the rising gasoline price. However, the Indian government also wants to keep its promises in the Paris climate agreement , which is why it announced in 2016 that it would only allow electrically powered cars from 2030.

A survey by the SMEV interest group showed that sales of electric vehicles increased by 37 percent in 2016 compared to the previous year. However, only 8 percent of the approximately 25,000 vehicles were electric cars, most against electric scooters. According to SMEV, the lack of a basic infrastructure is the biggest problem.

Netherlands

In 2015, 43,000 electric vehicles (including plug-in hybrids) were registered in the Netherlands . The share of new registrations in 2019 is currently 9.0 percent. In 2016, the parliament in the Netherlands decided to develop a strategy to only allow all-electric new cars from 2025.

Norway

- Total stock of all registered electric cars, Norway

200,000 electric vehicles are registered in Norway (as of 01.2019). Only one single model, the Nissan Leaf, makes up a quarter of all electric vehicles. The Norwegian government has created a number of state perks and financial incentives (around 20,000 euros per vehicle) so that electric cars are sometimes cheaper than combustion engine vehicles. All-electric cars are exempt from VAT (25%), vehicle tax and new car levy. Electric cars can be driven past traffic jams on many bus lanes. Parking is free, as is the use of the fjord ferries and the use of toll routes. Up until the beginning of 2019, refueling at public charging stations was also free of charge, but the rotation did not work, so it was decided to introduce fees at the beginning of March 2019.

In 2013, nine percent of all new cars in Norway were electric cars. In February 2015, 21 percent of all new cars were electric cars. In 2016 this share rose to 29 percent, and in 2017 further to 39.3 percent.

In June 2017, for the first time, more cars with an electric motor (52 percent) were registered in Norway than those with a pure combustion engine. In their national transport plan 2018–2029, the Norwegian transport authorities set out to ban the sale of new vehicles with internal combustion engines from 2025. Only heavy vehicles can then be powered by gasoline or diesel engines. The plan was drawn up by the state authorities for roads, railways, coasts and airfields and should be submitted to the Norwegian parliament in spring 2017 for approval and implementation.

In September 2018, the market share in Norway for new registrations of passenger cars with gasoline engines fell to 16 percent and with diesel engines to 12 percent. Observers saw the internal combustion engine on the way to becoming a niche product.

United States

In August 2016, 500,000 electrically chargeable vehicles (including plug-ins) were sold. Battery buses are being tested in various cities.

Tesla Motors is based in Palo Alto, California, and is the only manufacturer that exclusively produces large-scale electric cars. This has three different models among the top 10 and a current market share of 78% (as of 10/2019). In the United States, there is financial assistance / purchase rewards for electric cars depending on the state.

In the third quarter of 2018, Tesla achieved a profit of $ 311 million. This is the third quarter with a profit for Tesla since it went public in 2010. For a long time, critics considered Tesla to be never profitable and therefore not viable. In September 2018, the Tesla Model 3 was the best-selling car model in the US by sales and the fourth best-selling car model in the US by number of units.

Vehicle technology

Electric cars are fundamentally different from conventional vehicles in terms of drive units and energy storage. However, the differences also affect other components to a large extent. In contrast to the internal combustion engine , the auxiliary units are independently operated electrically and not via a mechanical output from the main engine. This only runs when the vehicle is being moved and is used exclusively for propulsion or recuperation .

The arrangement of the components, the so-called space utilization concept, has also changed. In a vehicle body with a combustion engine, many components are arranged around the main drive, while in an electric car the components can be mounted much more decentrally. Essential components differ in their space requirements and their shape: The engine and radiator, for example, are smaller, and the battery system can be placed in different areas of the body depending on the vehicle concept. This also has advantages:

- A more aerodynamic front section is possible thanks to smaller air inlets for coolers

- Space for a crash- friendly design of the front end (space for struts and contact plates)

- lower center of gravity due to the heavy battery under the floor

- the electrification of the servo systems for brakes and steering makes it easier to implement automatic operation or assistance systems.

- Electric drives do not require any maintenance.

Most street-legal electric vehicles have, in addition to the large drive battery, another small accumulator, usually a 12-volt lead-acid battery. It is charged via the drive battery and supplies part of the on-board electronics, but above all the vehicle lighting, especially the hazard warning lights - even if the drive battery has been deactivated (e.g. due to discharge or an accident).

Drive and control

In contrast to combustion engines, electric motors start up automatically under load with very high torques. The speed controller, a power electronics assembly, controls the drive. The electric motors can be mechanically coupled to the wheels in various ways, mostly via reduction gears and drive shafts , integrated in the wheel as a wheel hub motor or z. B. in the case of conversions via the existing manual transmission .

Due to the large usable speed range of electric motors, electric vehicles do not need gearboxes or releasable clutches , but reduction gears are usually installed. Electric motors can run in both directions and therefore do not require a separate reverse gear. However, two-speed transmissions that can be shifted under load are available, especially for vehicles of medium and heavy weight. It should be able to get up to five percent of the range. Such two-speed transmissions are, for example, scalable in certain increments and grades when manufacturers offer different engine outputs as alternatives for a vehicle model. If there are several drive motors (for example one each for the front and rear axles), the electric motors can also be optimized for different speed ranges.

Electric motors are simpler and have significantly fewer moving parts than internal combustion engines. They are mostly air -cooled , and occasionally water-cooled .

Various motors can be used to drive electric cars.

Permanent magnet synchronous motor

The permanent magnet three-phase synchronous machine has a high efficiency of over 90%, a high specific torque (5 Nm / kg) and a high specific power (1 kW / kg). They are therefore the most widely used drives for e-mobiles.

Permanently excited synchronous machines do not have carbon brushes , collectors or slip rings for commutation and excitation and are therefore wear and maintenance-free.

The essential three-phase inverter is usually capable of four-quadrant operation, so it can be used in both directions of travel for motor operation and in generator operation for recuperation . The same circuit can also be used to charge the drive battery from the three-phase network. The integration of an alternating current normal charging or three-phase fast charging system in an electric car is therefore possible without significant additional effort.

DC motor

DC motors have only had historical significance in electric cars. The series machine, which is predestined for this due to its characteristic curve (high starting torque, variable speed without control), is easy to control, recuperative by reversing the polarity of the field winding and can be temporarily heavily overloaded. However, it has the disadvantage that it is not maintenance-free due to the commutation (brush wear). Upstream resistors and later a pulse width modulation were used for control.

Asynchronous motor

The asynchronous machine with squirrel-cage rotor, designed as a double rod rotor, can only be used for electric cars if a frequency- and amplitude-controlled three-phase inverter is connected upstream. This is the only way to achieve a high starting torque, a wide speed range and a high level of efficiency.

Asynchronous motors are cheaper to manufacture than permanent magnet synchronous motors and, in contrast to these, have no braking torque when they are switched off. However, they are less efficient. Asynchronous motors can also recuperate using four-quadrant inverters. Many electric cars have a mixed set of asynchronous and synchronous motors.

Further engine concepts

Synchronous machines with external instead of permanent magnet excitation are discussed. Associated with this is the saving of rare earth magnets. The separately excited synchronous machine is proposed as an axle drive and offers a further degree of freedom because it can be switched off in the field. With this concept, higher speeds are used than with the permanent magnet synchronous drive and a reduction gear is connected downstream. Losses in the electrical-mechanical efficiency compared to the permanent magnet excited synchronous drive are accepted.

A high-speed asynchronous machine drive with a downstream planetary gear is discussed as a further alternative . With the latter concept, the system is lighter than a synchronous drive. On the other hand, the electrical-mechanical efficiency is somewhat worse.

The use of reluctance motors is also proposed, which also manage without rare earths. A moderate efficiency in the lower speed range could possibly be mitigated by a reduction gear, but here, too, compromises in the electrical-mechanical efficiency are inevitable.

Wheel hub motor design

One design for the drive is the wheel hub motor . The motor is housed directly in the wheel, usually inside the rim. With this type of drive, the drive trains and the transfer case to the wheels are omitted , which simplifies the structure and creates freedom for the design of the floor pan. However, the installation space usually has to be shared with the brake and a higher unsprung mass is accepted. The engines are also more exposed to environmental influences. Wheel hub motors are often found in vehicles with low demands on driving dynamics . They can be found on electric bicycles, electric scooters and commercial vehicles. So far, they have not been able to establish themselves in production cars, but are the subject of research and development work.

Regenerative braking (recuperation)

In generator mode, electric motors are suitable for converting kinetic energy (kinetic energy) back into electrical energy ( recuperation ). When braking and driving downhill, energy is returned to the accumulator, which would otherwise be converted into heat loss via mechanical brakes or the engine brake. In long-distance traffic, the saving effect is lower than in city and short-distance traffic, since there are fewer braking operations.

When braking hard, the energy is generated very suddenly, i.e. with high output. Since the generator power is limited according to the engine power, only part of the braking power can be converted into electrical power. Further losses arise as a result of the significant resistance losses in the generator, charging electronics and accumulator at high currents. Up to 0.3g braking delay can be braked electrically.

With recuperation, urban energy consumption can be reduced by up to 30%. This value is also achieved with trolleybuses .

Hybrid electric vehicles also use double-layer capacitors as energy storage in order to be able to process higher outputs despite smaller batteries. This means that recovery rates of over 40% can be achieved in city traffic.

Consumption and efficiency

Consumption and efficiency consider the energy turnover within the vehicle (for example from the petrol station or socket - tank-to-wheel ). Further considerations about power generation and the primary energy used ( well-to-wheel ) take place under the umbrella term environmental balance (see paragraph environmental balance ).

The consumption to compare all types of passenger car was given in Europe according to the NEDC up to August 2017 . A BMW i3, for example, then uses 12.9 or 13.5 kWh / 100 km, depending on the equipment. In the same sales brochure, BMW itself specifies “customer-oriented” consumption of 14-18 kWh / 100 km. Renault specifies a standard consumption of 14.6 kWh / 100 km for the ZOE. The range with the 22 kWh battery is between 240 km in good conditions and 115 km in cold outside conditions. The consumption is accordingly between 9.2 and 19.1 kWh / 100 km. An e-Golf consumes 12.7 kWh / 100 km. In its own test, the ADAC determined an average consumption of 18.2 kWh / 100 km for the e-Golf. Tesla specifies an average consumption for its Model S according to the ECE standard R-101 standard for hybrid vehicles of 18.1 kWh / 100 km. The standard values are subject to the same deviations from real consumption as in internal combustion vehicles.

In Europe, the new WLTC / WLTP test procedure for type testing of new models and new engine variants was introduced on September 1, 2017, and became mandatory for newly registered vehicles from September 1, 2018. There is an overview of the electric cars with information according to WLTP .

The efficiency of the energy conversions carried out in the vehicle is decisive for the overall efficiency of an automobile. Electric motors typically have efficiencies of 90 to 98% , the associated electronics for charging and driving efficiencies around 95%. Accumulators achieve charging / discharging efficiencies of around 90 to 98%. This results in a much higher degree of efficiency from the socket for electric drives than for drives with combustion engines.

The efficiency of gasoline engines is a maximum of 35%, that of passenger car diesel engines a maximum of 45%. In practical operation, however, this best efficiency is only rarely achieved and further losses arise due to multi-stage gearboxes in the drive train. Therefore, in an internal combustion vehicle, less than 25% of the fuel's energy is converted into kinetic energy on average. This property is particularly effective in partial load operation, where the efficiency of internal combustion engines drops sharply. Here, the difference in efficiency is particularly high compared to the electric motor. Since automobiles almost always run at partial load in city traffic, the electric drive is even more efficient here. In contrast to an internal combustion engine, an electric motor does not consume any energy when idling or when it is at a short standstill.

According to Valentin Crastan , a gasoline vehicle has an average tank-to-wheel efficiency of 20%, which means that 52.6 kWh of energy have to be used with a consumption of 6 liters per 100 km; the mechanical useful energy is 10.5 kWh. An electric vehicle, on the other hand, has an efficiency of approx. 65%, which results in an electricity consumption of 16 kWh / 100 km. Other sources give about 70 to 80%.

Energy storage

The central point in the development of electric cars is energy storage . Since an automobile, with the exception of overhead line vehicles such as trolleybuses, is normally not connected to the power grid while driving, energy storage devices with high power and energy density are required. Electric cars can achieve ranges that are on a par with cars powered by internal combustion engines (e.g. Renault ZOE , Chevrolet Bolt , Tesla Model 3 , Tesla Model X , Tesla Model S ). There are electric cars with a range of up to about 600 km on one battery charge (as of 2016, for example Tesla Model S); their drive battery weighs several hundred kilograms. Small electric cars with a range of 150 km have drive batteries with a mass of approx. 200 kg (example: VW e-up!, 230 kg; as of 2017). Electric car batteries usually weigh between 300 and 750 kilograms, depending on the specific model. As an approximate rule of thumb, electric cars need around 15 kilowatt hours of electrical energy per 100 kilometers. The battery required for this weighs approx. 150 kg. Many electric cars can charge their batteries to 80 percent within 30 minutes at quick charging stations. According to the manufacturer BYD , the lithium iron phosphate battery of the e6 electric car is charged to 80% within 15 minutes at a fast charging station and 100% after 40 minutes. Research is being carried out to further shorten it to 5 to 10 minutes.

The price of batteries are the main factor for the vehicle costs. The development of battery technology that has taken place in recent years has also brought steadily falling prices and, together with other disruptions in the market, leads to a dynamization of the electric car development on the part of the manufacturers.

Lithium or lead or nickel

In the past, most electric cars used battery types, such as lead or nickel-cadmium batteries , which only lasted about an hour at top speed or which could cover 40 to 130 kilometers with one charge. Lead accumulators, especially if they are designed for high cycle stability, have a low energy density - they are very heavy for the energy content offered. The often lower cycle stability and service life also limit their use, so that they are practically no longer used in newer developments. They are still used in smaller electric vehicles and in industry, such as in floor conveyors ( forklifts ).

Ranges of 300 km to 500 km and more are possible with lithium- based batteries (for example lithium-ion , lithium iron phosphate and lithium polymer batteries ) and are also implemented (for example with Tesla Model S , Tesla Model X , Chevrolet Bolt , Renault ZOE ). These types of accumulators have a comparatively high weight-related energy density. Also, high-temperature batteries are used, for example the Zebra battery . In some vehicles that previously drove lead or nickel-cadmium batteries, these have been replaced by lithium-ion batteries. This enabled a multiple of the original range to be achieved.

With NiCd, NiMH and lead-acid battery sets, only partial blocks of several cells need to be monitored. Lithium accumulators need complex electronic battery management systems (BMS), protective circuits and balancers because they fail quickly when overcharged or deeply discharged. So that the entire battery system does not have to be replaced in the event of a defect in a single cell, it can be designed for individual cell replacement.

Battery capacity

The accumulator capacity is one of the most important determinants of the usability and economy of electric cars. Two opposing strategies for battery size can be identified.

- Increase in battery size: This enables a very large range without intermediate charging and extends the service life of the battery. The battery is loaded less in terms of its capacity as well as in terms of power consumption and can achieve cycle numbers that correspond to the service life of the entire vehicle. On the other hand, vehicle weight and investment costs rise sharply. The latter in particular can be partially offset by savings effects from series production and further technical development. Large batteries for electric cars currently (2018) store energy around 100 kWh, which is sufficient for a range of over 600 km with a vehicle consumption of 15 kWh to 25 kWh per 100 km. Examples are Tesla Model S , Tesla Model X , NIO ES8 , Jaguar I-Pace , Audi e-tron . On the other hand, battery buses also have capacities of more than 600 kWh in order to achieve ranges of around 600 km.