Unimog 406

| Mercedes Benz | |

|---|---|

Unimog 406.121 (1976) |

|

| Unimog 406 | |

| Manufacturer: | Daimler-Benz AG |

| Sales designation: |

U 65 U 70 U 80 U 84 (U 900) |

| Production period: | 1963-1989 |

| Engines: | OM 312 (diesel 48 kW) OM 352 (diesel 48–53 kW) OM 353 (diesel 59–62 kW) |

| Previous model: | |

| Successor: | Unimog 417 |

The Unimog 406 is a vehicle from the Unimog series built by Daimler-Benz AG . It was produced a total of 37,069 times at the Mercedes-Benz plant in Gaggenau between 1963 and 1989 . 406 is the first series of medium-weight Unimogs.

Compared to the Unimog 401 and Unimog 411 series , the vehicles have a wheelbase longer to 2,380 mm and more than twice the engine output. In contrast to the original Unimog, a large-volume commercial vehicle engine was installed instead of a car. As the first representative of the medium-weight Unimog model family, it had a completely new appearance. Later Unimog series are based partly technically and optically on the 406. There were a total of eleven different models of the 406, which were offered in four different model variants (U 65 to U 84) and could be supplied with a two- or four-door cab or as a convertible. In addition, there was the 406 for third-party manufacturers as a power unit , a variant in which only a “half” Unimog is supplied, which lacks the rear.

During its long production phase, the Unimog 406 was technically revised several times. The first revision was there in 1964, when the pre-chamber - diesel engine OM 312 by the direct injection engine OM 352 was replaced. From 1973 the 406 had disc brakes . For many Unimog enthusiasts, the 406, with its application in agriculture and forestry, is the classic Unimog. "The car was a winner and embodied the name Uni salinization Mo gate G et up instrument from all previous Unimogs best."

history

Conception and development

The original Unimog concept was both customers as well as cultivation equipment manufacturers estimated. In the early 1960s, however, there was demand for a heavy Unimog series that followed the trend towards more powerful tractors and had been triggered by a change in German agriculture from a labor-intensive to a mechanized way of working. This led to the end of the tractor boom in the mid-1960s, a demand for small, inefficient tugs. The most powerful Unimog type 411 offered at the beginning of the 1960s had a 34 hp (25 kW) diesel engine, which was considered too inefficient for some purposes. Analysts at Daimler-Benz warned that the annual production rate of the Unimog 411 would drop below 3000 vehicles per year after 1960. That point was reached in 1964. It was also foreseeable that the production of the military Unimog 404 would decline, as the Bundeswehr had equipped most of its regiments and battalions with a sufficient number of vehicles of this type. That is why Daimler-Benz decided to develop a more powerful Unimog: the 406.

The specifications were completed in 1960. The 406 was still intended to be an agricultural and forestry vehicle, but with a larger wheelbase , a higher top speed, the cranked frame of the Unimog 404 and a more powerful engine. Three body variants were planned: a convertible, a closed cabin and a closed double cabin . The original concept envisaged the four-cylinder OM 314 diesel engine with direct injection and an output of 54 hp (40 kW). Since the chief developer Heinrich Rößler rejected this engine, it was decided to use the six-cylinder OM engine instead 352 to be installed. From Dunlop and Continental specifically for the new 406 had tires are developed. A new hydraulic system was also required to power new attachments. In addition, the drive train and transmission were redesigned for the increased engine output. The new cabs required the construction of new 1000-megapond sheet steel presses with a force of 9,807 kN in the Unimog plant in Gaggenau.

The first prototypes were tested in 1961, prototype 1 was a camouflaged vehicle without a Unimog emblem and Mercedes star. It already had a cab and the bumper of the Unimog 404 similar to the production model. Prototype No. 2 received the cab of the production model and also the bumper of the 404. The public presentation of the Unimog 406 took place at the DLG exhibition in Munich in 1962 and was managed by the Daimler-Benz board of directors. In the run-up to the presentation on May 20, 1962, many small details on the Unimog were changed at short notice and there was a lot of improvisation. The Daimler-Benz AG announced the commercial vehicle production at the Gaggenau plant in 1963: while truck production in the new plant in Wörth moved, the Unimog production remained in Gaggenau. This enabled more production capacity to be used for the Unimog 406. In the first year of production, 1963, 800 Unimog 406 were produced, of which the first 100 were classified as pre-production models. The first model in the 406 series was the U 65.

During the late 1960s, the Unimog 406 developed into a popular model series, although the less powerful and less expensive Unimog 403 with a smaller industrial engine of 54 hp (40 kW) and the Unimog 421 with a passenger car engine of 40 hp (29.5 kW) were available from 1966 as an extension of the Unimog family. Annual model changes improved the quality of the Unimog; the highest production figures were achieved in the first half of the 1970s. With the start of series production of the heavy series with the types 425 in 1974 and 435 in 1975, the demand for the 406 fell sharply. The annual changes were minimized, and from 1979 the 406 was no longer significantly developed. The now only medium-weight 406 soon became very unpopular and the annual production figures fell to an average of only 380 vehicles throughout the 1980s. In 1989 the production was stopped after 27 years of production.

Annual series change

1964

The indentation in the bumper for the front PTO was added in 1964, but the right Unimog does not have it.

Due to a lack of engines of the type OM 352, the first 1766 series vehicles and the prototypes were equipped with the pre-chamber engine OM 312 , which was throttled to 65 HP (48 kW). From 1964 engines of the type OM 352 were available in sufficient numbers and were installed instead, also throttled to 65 hp. This performance turned out to be insufficient for some areas of application of the Unimog 406, so that Daimler-Benz later decided to offer more powerful models. Further changes in 1964 were a Rockinger - trailer hitch , a bulge for the front PTO in the front bumper, a new compressed air tank is now 27 instead of 20 liters, reinforced springs, new portal axles and new rims without the 90 ° angle to each other four slots .

1965 In 1965, production of the Unimog 416 and the powered end models 406.130 and 406.131 began. The 406 was equipped with new fenders, a new clutch and now rectangular taillights. In order to be able to attach the rear power take-off shaft below the trailer coupling in accordance with the provisions of the DIN and ISO standards, Daimler-Benz offered a power take-off transfer gear.

1966

The year 1966 was significant for the Unimog production. A tilt mechanism for the cab was introduced so that the cab could now be folded forward for maintenance work. The detachable bonnet and a new windshield were also new . The ventilation slots for heating and ventilation next to the headlights have been removed and replaced by ventilation slots on the indicators . The production of the U 65 model was discontinued, instead the U 70 was added to the range, whose engine developed 70 hp (51 kW). The double cab was also offered for the first time with the U 70. The drive train has been revised; Reinforced impeller back gears and new portal axles were installed and the welding process for the thrust tubes improved. Changes to the electrical system included an electrical thermostat and a new alternator with an external regulator. The master brake cylinder has also been revised and parts of the interior have been replaced.

1967 The year 1967 brought only minor changes. The seats have been made more ergonomic and the rearview mirror revised. The portal axes have also been modified.

1968 In 1968 the so-called F-gear was replaced by the G-gear (more information on this in the gearbox section .) In addition, the 406 received a new regulator for the pneumatic system, a reservoir for the oil circuit of the power steering and new exterior mirrors.

1969 With the model changes in 1969, Daimler-Benz introduced the foldable windshield in the convertible and equipped the models with a closed driver's cab with larger ventilation grilles. The U 80 model was added to the model range, and the doors of all models were reinforced.

1970

The previously installed power steering system was replaced by a hydraulically assisted ball nut system; a mechanical steering system was still offered as an option. New safety regulations required the overturning bar , which was initially offered as a special accessory, to be part of the standard equipment on the convertible. In addition, the models with a closed cab were given two additional rear windows. The master cylinder was reinforced again.

1971 In March 1971 the U 80 was replaced by the U 84. It has larger and rectangular indicators, new three-chamber taillights, reinforced portal axles and a new aluminum loading platform.

1972 From 1972 the ventilation slots above the windshield were removed and the coolant tank made of plastic.

1973 The last major change came on July 2, 1973 when the drum brakes were replaced by disc brakes. The introduction of disc brakes also brought a dual circuit braking system and the standard color of the wheels was changed from red to black. The steering system has been strengthened and the diameter of the exhaust pipe has been increased from 55 mm to 70 mm.

1974 to 1989 The most important series changes were made in 1974. In 1974 the muffler of the exhaust system was modified, followed by a new step on the driver's cab in 1975 and a switch from push-wheel to sleeve shifting of the gearbox in 1976. The four-wheel drive got a pneumatically operated shifting mechanism in 1977, the last major change in 1979 was to remove the chrome strips on the radiator grille . From 1979 to 1989 there were no more major changes to the Unimog 406.

Model of the Unimog 406

Eleven different models of the Unimog 406 were offered. The convertible (model 406.120) and the Unimog with closed cab (406.121) were the most important, accounting for 96% of all Unimog 406s ever built. The power car variants of the Unimog 406 had no independent model numbers until 1965, when they were given the numbers 406.130, 406.131 and 406.133. They were assigned to the 416 series as early as 1968. Each Unimog model was offered in different model variants; there are the four models U 65, U 70, U 80 and U 84 (later referred to as U 900). The two-digit number stands for the engine performance in hp DIN , optionally appended T stands for power car . The U 100 model with 100 hp was only built in very small numbers as a tractor in factory traffic with a top speed of 40 km / h. A detailed overview of which models were offered for which type is given below:

Model overview

| Model | Model name | Cab | wheelbase | Motor power (kW) | Production numbers | Remarks |

|---|---|---|---|---|---|---|

| 406.120 | U 65, U 70, U 80, U 84 | Convertible | 2380 mm | 48, 51, 59, 62 | 12,753 | |

| 406.121 | U 65, U 70, U 80, U 84 | closed cab | 2380 mm | 48, 51, 59, 62 | 22,936 | |

| 406.130 | U 65 T, U 70 T | Convertible | - | 48, 51 | 10 | 1968 assigned to the 416 series |

| 406.131 | U 65 T, U 70 T | closed cab | - | 48, 51 | 29 | 1968 assigned to the 416 series |

| 406.133 | U 80 T | Convertible | - | 59 | 523 | 1968 assigned to the 416 series |

| 406.142 | U 900, U 84, U 100 | Convertible | 2380 mm | 62, 73.5, 81 | 19th | Truck for works traffic, V max : 40 km / h |

| 406.143 | U 900, U 84, U 100 | closed cab | 2380 mm | 62, 73.5, 81 | 16 | Truck for works traffic, V max : 40 km / h |

| 406.145 | U 900, U 84 | closed double cab | 2380 mm | 62 | 302 | Bundeswehr aircraft tug |

| 406.170 | Convertible | CKD kit for export | ||||

| 406.171 | closed cab | CKD kit for export | ||||

| 406,200 A | was never sold | Convertible / closed cab | 2900 mm | 73.5 | 1 | Prototype, production model assigned to the 416 series |

| Unimog 406 | 37,069 |

The double cabin

It was originally planned that the Unimog 406 would also be offered with a double cab as a supplement to the convertible and the normal cab. The closed double cabin was manufactured by Wackenhut in Nagold. The type 406.145, an aircraft tractor, was mainly equipped with this cab. Only 353 Unimog 406s were built with a double cab, 302 of which are 406,145. However, the double cab was also offered for other Unimog models. The Unimog, which is far more frequently equipped with a double cab, is the 416, which was often used as a chassis for mobile homes due to its longer wheelbase.

Other vehicles from the 406 series

Originally the Unimog 406 was only offered with a 65 HP (48 kW) engine, later the output increased to 84 HP (62 kW); the performance of the production vehicles has never been greater. However, some prototypes and custom-made products were offered with more powerful engines. The first prototype of a road tractor for local freight and works traffic was the 406.200 A model in September 1969. This vehicle had the long wheelbase of the Unimog 416 and an OM 352 engine with 100 hp (73.5 kW). The later production model of this prototype was available as a convertible (416.140) and with a closed cab (416.141). The latter was built 3496 times.

There were two types 406.142 and 406.143 for factory traffic. Daimler-Benz decided to offer the normal engine with 84 hp (62 kW) for this model, but also had versions with 100 and 110 hp (73.5 and 81 kW) on offer. Neither of the two types were built more than 20 units, which makes the Unimog 406 with more than 84 hp (62 kW) engine output extremely rare.

The Unimog 406 was used as a chassis for road- rail vehicles. The maximum permissible trailer load was up to 300 t. The Unitrac tracked vehicle was built by Tractortecnic from parts of the Unimog 406, among other things.

Model family of the Unimog 406

With the introduction of the 406 series, Daimler-Benz laid the foundation for a medium-duty model family, which included a total of 94,215 vehicles from eight series that were produced between 1962 and 1994. The model family includes similar models with different wheelbases and engines, all of which are based either technically or optically on the Unimog 406. In 1965 a model with a long wheelbase was offered for the first time, the Unimog 416 . At 2900 mm, it has the same wheelbase as the long version of the Unimog 404 . The 416 was also available with a 3400 mm wheelbase. The power car versions of the Unimog 406 were later assigned to the 416 series. Engines with 80–125 hp (59–92 kW) were offered for the 416. From the Unimog 406 family, the 416 is the most built model with 45,544 units that were built between 1965 and 1994. In March 1966 the Unimog 421 was added to the model range, whose chassis technology is based on the Unimog 411; however, the cab is derived from the 406. It is a less powerful model with 40 HP (29 kW), which is counted among the light series.

In August 1966, the 406 series was supplemented by the Unimog 403 . The Unimog 403 has the OM 314 diesel engine originally intended for the 406 series with 54 hp (40 kW) and was placed in the model range as a lower-priced model. With the increasing demand for powerful towing vehicles, Daimler-Benz offered the 403 series from 1969 with 66 hp (48 kW) and from 1972 with 72 hp (53 kW). With the exception of the engine, there is no visual or technical difference between the Unimog 406 and the 403. Since Daimler-Benz also wanted to offer a cheaper variant with a long wheelbase, the Unimog 413 was offered analogously to the 416 from 1969 . With the under-dimensioned engine, this model was cheaper than the Unimog 416, but not popular. Only 633 copies were made.

Most of the military Unimogs belong to the 404 series; but some vehicles from the Unimog 406 family were also used for military purposes. This applies in particular to the 426 and 419 series. The Unimog 426 was created from CKD kits that were pre-produced in Gaggenau and shipped to Argentina for final assembly . The Unimog 426 is a license production of the Unimog 416 and was mainly manufactured for the Argentine , Chilean , Peruvian and Bolivian armed forces , producing 2,643 vehicles. From 1986, Daimler-Benz built the Unimog 419 for the US military . A total of 2416 vehicles were produced. The Unimog 419 has the same wheelbase as the Unimog 406, but is equipped with a more powerful version of the OM 352 engine that develops 110 hp (81 kW). He was branded Freightliner sold and promoted as Small Pitch Excavator (SEE) (German to roughly Kleinbagger classified), which was mainly used as a pioneering vehicle. The type 406.145 was mainly used as an aircraft tractor in the German armed forces.

technical description

The Unimog 406 is an all-terrain multi-purpose vehicle with four equally sized wheels. Like the Unimog 404, it has a cranked ladder frame. The front and rear axles are rigid . A standard PTO shaft is installed at the front and rear to drive additional equipment, the speed of which can be set to either 540 min −1 or 1000 min −1 . They can be switched on independently of each other. The 406 is a rear-wheel drive vehicle with selectable front-wheel drive with differential locks on both axles. A hydraulically tiltable platform is built on the rear of the ladder frame. Unlike the first Unimogs, the Unimog 406 does not have a 12-volt but a 24-volt electrical system with two 12-volt lead-acid batteries that are housed in a box on the left-hand side of the lead frame.

Cab

Daimler-Benz manufactured the Unimog 406 with a fabric top ("convertible"), closed driver's cab or closed double cab; the double cabin was supplied by Wackenhut. All cabs including the convertible version have a three-point linkage. Both the convertible and the closed cab have two seats, the double cab version has three additional seats. The dashboard, steering wheel, levers, adjustable seats and other parts such as heating and ventilation are similar to the corresponding equipment in the Daimler-Benz trucks of the 1960s. The cabs were considered to be ergonomically designed and comfortable. Convertible models from 1969 onwards have a folding windshield, from 1970 a roll bar was installed as standard, which was previously available as an optional extra. The engine air intake is on the left side of the Unimog 406, a snorkel with a built-in cyclone was available on request. This significantly extends the maintenance intervals for the air filter.

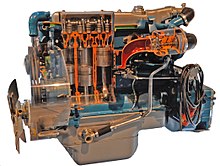

engine

The first vehicles were equipped with the OM 312. The OM 312 is a standing, water-cooled in-line six-cylinder naturally aspirated diesel engine with indirect injection and a displacement of 4580 cc, it is 65 hp (48 kW) at 2550 min -1 throttled. As early as 1964, this engine was replaced by the OM 352 , a further development of the OM 322 prechamber engine. The OM 352 was used for the Unimog 406 until 1989. Like the OM 312, the OM 352 is an upright six-cylinder naturally aspirated diesel engine with water cooling, but has direct injection . The displacement is 5675 cm³, the output was also here at the beginning 65 HP (48 kW), was then gradually increased over the production period to 70, 80 and 84 HP (51.5, 59 and 62 kW). Only a few series vehicles designed as machine tools were fitted ex works with enhanced versions of the OM 352 with 100 or 110 hp (73.5 or 81 kW) upon special request; however, they are extremely rare.

Chassis and drive train

front and rear areas of the frame allow a certain amount of torsion, while the cranked point in the middle is extremely rigid.

The ladder frame, which is cranked down in the middle, is supported by rigid portal axles at the front and rear. The front and rear of the frame allow a certain amount of twisting, the center is more rigid. This is achieved through the position of the cross members and weld seams: The cross members are drawn inwards and the weld seams are located in places where the material is less stressed. Two cross members are welded close together in the rear part, on the crank and on the front part of the frame; There is ample free space between the cross member pairs. Thanks to the portal axles with front wheels, the Unimog has a lot of ground clearance even with small wheels. The axes are guided on push tubes and panhard rods. The thrust tubes are mounted on the gearbox in ball joints and rigidly connected to the differential gears of the axles. The drive shafts, which transmit the torque from the gearbox to the axles, run in the push tubes. The axles of the Unimog are cushioned with two coil springs and hydraulic telescopic shock absorbers. The wheel suspension allows particularly long spring travel and therefore a large amount of axle articulation , which gives the Unimog good off-road mobility. The U 406 supplied with 10.5–20 ″ tires. Tires in the dimensions 12.5–20 ″, 14.5–20 ″ and 22–20 ″ were available as special equipment.

transmission

The 406 has the fully synchronized four-speed sliding gear group transmission UG-2/27 , which is designed for an input torque of 264.8 N · m (27 kp · m). It was offered in four different versions.

The standard design of the gear unit (F gear unit) was used for the U 65 and U 70 models. It has two groups of four gears each, but the first group can only be used in first and second gear, so that ultimately six forward gears are available. The gearshift lever accordingly has a six-speed H shift pattern. When shifting from second to third gear, the transmission automatically changes from first to second group, so it is downshifted to first gear while shifting to the higher group. The gearbox lacks a reverse gear, instead a reversing gear with a separate gear lever is flanged on. Due to the design of the gearbox, the reversing gear can only be shifted into the reverse direction when the main gearbox is in the first group. Since only the first two gears are to be used in the first group, there are two reverse gears.

The standard gear was available for the U 80 and U 84 models with a primary gear (G gear). The reduction gear doubles the number of all gears, so that 2 × 6 forward and 2 × 2 reverse gears can be used. The gearshift lever of the primary gearbox has three positions: "main gearbox", "primary gearbox" and "idle". In addition to the primary gearbox, a creeper gearbox was available. It can be used with the first two gears of each group and has two crawler gears, "creeper" and "super creeper", a neutral and a main gear position. When shifting to the main transmission position, the main transmission can be shifted to all six gears as normal. Overall, this results in 2 × 6 + 2 × 4 forward and 2 × 2 + 2 × 2 reverse gears.

In 1976 the sliding gear was replaced by a sleeve gear. The first group of the transmission was fully usable so that eight forward and four reverse gears were now to be used. The eight-speed transmission has a four-speed H shift gate and an additional lever for switching the transmission groups.

Depending on the gearbox version, either a single-plate dry clutch (usually type G 280 KR ) or a double clutch are installed.

Hydraulic system

Daimler-Benz installed a hydraulic system from WABCO from Hanover. It is more robust and powerful than the hydraulic system that was installed in the Unimog 411 from the early 1960s and consists of six main components: a gear oil pump, an oil tank, two hydraulic cylinders and two control units. The original hydraulic pump is of type 5 P 41-13 and has a delivery rate of 32 l / min at 150 bar working pressure. This pump was soon replaced by a more powerful version with 40 l / min at 180 bar. The oil tank is located in the front area of the Unimog, and the entire oil circuit has a capacity of 18 liters. The two control units are located behind the engine, they each have an operating lever; the control levers are mounted on a rod under the steering wheel. With the first lever, the driver can either operate the telescopic cylinder for tipping the flatbed or the hydraulic cylinder of the rear linkage. The second lever is used to control the attachments.

Originally the power steering was connected to the main hydraulics. A separate pump for the power steering and ultimately a separate oil circuit was installed later. The standard power steering system is a ZF 19/74 type spindle steering system . A recirculating ball nut steering was offered as an option and was part of the standard equipment from 1973. The Unimog 406 is equipped with a pneumatically controlled hydraulic brake (brake servo), initially with drum brakes, from 1973 disc brakes were installed as standard, for which the brake system had to be extensively modified. Vehicles for export were also optionally equipped with drum brakes until 1989.

Neither the prototypes nor the model presented at the DLG exhibition in 1962 had control hydraulics ; this meant that the hydraulic lever could not be operated in fine steps, but either full pressure or no pressure at all. This made the operation of some attachments considerably more difficult, so that control hydraulics were soon installed.

Pneumatics

Like other Unimog models, the Unimog 406 has a pneumatic system ; however, it is not used for the rear linkage, but mainly for the brake system. In addition, the compensation lock is activated with the support of the pneumatics. The pneumatic system consists of several parts: a compressor that is driven by the engine, a control valve in front of the rear axle, a compressed air tank in front of the left rear wheel, the valve for the differential lock, the brake booster and the master brake cylinder, which provides the pressure for the brake system for both the Unimog as well as for a trailer braking system. The pneumatic brake system of a trailer is connected to the Unimog with two quick-release fasteners, one line is for the brake pressure, one for the pneumatic activation of the brake itself. The Unimog's compressed air tank initially had a volume of 20 liters; it was increased to 27 liters in 1966. An additional compressor was available as an option, which reduces the time it takes to fill up the trailer's compressed air tank.

Painting

Originally the Unimog was painted truck green (DB 6277), around 70% of all Unimogs ever built have this color. There were a total of six different colors as standard for the Unimog in the 1970s. Other colors were available upon request.

Standard colors

| Truck green (DB 6277) |

Sap green (DB 6821) |

Truck gray (DB 7187) |

Deep orange (DB 2603) (RAL 2011) |

Ambra Yellow (DB 1624) |

Curry yellow (DB 1600) (RAL 1027) |

Custom colors

| Brown beige (DB 1448) (RAL 1011) |

Yellow orange (DB 2550) (RAL 2000) |

Fire red (DB 3534) (RAL 3000) |

Red-orange (DB 2553) (RAL 2001) |

Gentian blue (DB 5361) (RAL 5010) |

Moss green (DB 6294) (RAL 6005) |

Pebble gray (DB 7701) (RAL 7032) |

Gray white (DB 9136) (RAL 9002) |

Technical specifications

This vehicle already has the removable bonnet introduced in 1966, but still has the old ventilation grilles for ventilation and heating next to the headlights. The curved and non-folding windshield, which was retained in the 406.120 model until 1969, is striking. There is also no roll bar installed here.

| Parameters | U 65 | U 70 | U 80 | U 84 | |

|---|---|---|---|---|---|

| Years of construction | 1963-1964 | 1964-1966 | 1966-1968 | 1969-1971 | 1971-1989 |

| Dimensions | 2650 kg | 3100 kg | 3600 kg | ||

| length | 4000 mm | 4100 mm | 4160 mm | ||

| width | 2000 mm | 2030 mm | 2130 mm | ||

| height | 2250 mm | 2330 mm | 2325 mm | ||

| wheelbase | 2380 mm | ||||

| Gauge | 1536 mm | 1555 mm | |||

| Loading area length | 1950 mm | ||||

| Loading area width | 1890 mm | ||||

| Platform height | 400 mm | ||||

| tires | 10-20 "( 12.5-20" ) | 10.5-20 "( 12.5-20" ) | |||

| Engine model | OM 312.954 | OM 352.919 | OM 352.902 | OM 353.902 | |

| Engine type | Free - suction in- line six-cylinder diesel engine with liquid cooling | ||||

| Mixture preparation | Pre-chamber injection | Direct injection | |||

| Displacement | 4580 cc | 5675 cc | |||

| Bore × stroke | 90 mm × 120 mm | 97 mm × 128 mm | |||

| Nominal power (DIN 70020) | 48 kW (65 hp) at 2550 min -1 | 51.5 kW (70 hp) at 2550 min -1 | 59 kW (80 hp) at 2550 min -1 | 62 kW (84 hp) at 2550 min -1 | |

| Max. Torque (DIN 70020) | 210 Nm at? | 232 Nm at? | 240 Nm at? | 254 Nm at? | 270 Nm at? |

| Top speed | 65 km / h | 71 km / h | 79 km / h | ||

| source | |||||

Quantities

37,069 series vehicles, including 100 pre-series vehicles, an exhibition piece, at least two roadworthy prototypes in 1961 and 1962 and another roadworthy prototype in September 1969, were built by the Unimog 406.

| year | number |

|---|---|

| 1962 | At least 2 ready-to-drive prototypes + 1 exhibit |

| 1963 | 801 incl. 100 pre-series models |

| 1964 | 2044 |

| 1965 | 1977 |

| 1966 | 2022 |

| 1967 | 1078 |

| 1968 | 1825 |

| 1969 | 2321 + 1 prototype |

| 1970 | 3044 |

| 1971 | 2737 |

| 1972 | 1963 |

| 1973 | 2643 |

| 1974 | 2603 |

| 1975 | 2466 |

| 1976 | 1690 |

| 1977 | 1304 |

| 1978 | 1421 |

| 1979 | 1334 |

| 1980 | 941 |

| 1981 | 608 |

| 1982 | 505 |

| 1983 | 471 |

| 1984 | 331 |

| 1985 | 326 |

| 1986 | 298 |

| 1987 | 233 |

| 1988 | 81 |

| 1989 | 3 |

Performance improvements

The original version of the OM 352 diesel engine from 1963 produced an output of 93 kW and delivered a maximum torque of 353 Nm, later the output was increased slightly to 96 kW and the torque increased to 363 Nm. The Unimog, however, received a reduced-power variant of this engine. The unthrottled and performance-enhanced versions of this engine were never offered for the Unimog 406 because the transmission is only designed for an input torque of 264.8 N · m (27 kp · m). In order to be able to increase the output of the Unimog engine to 96 kW, the clutch and transmission must be modified beforehand to avoid damage. The engine requires a paper air filter instead of the oil bath air filter, a new oil filter and a different injection pump, as the standard injection pump cannot be adjusted to the increased engine output.

literature

- Carl-Heinz Vogler: UNIMOG 406 - Type history and technology. Geramond, Munich 2016, ISBN 978-3-86245-576-8 .

- Daimler-Benz: workshop manual Unimog 403, 406, 413, 416 and 417, No. 30 400 21 01 .

Remarks

- ↑ Since so many different types of OM 352 were built, some types had to be redrawn to the OM 353 series in order to maintain the logistics, catalog and spare parts system that made the introduction of the type principle necessary. This is the reason why some engines of the OM 352 series are referred to as OM 35 3 .

Individual evidence

- ↑ a b c Unimog Club Gaggenau: Unimog History 1957–1975 . Retrieved May 18, 2017.

- ^ A b c Gerhard Siem: Schlepperjahrbuch 2009. TIM-Verlag. ISBN 978-3-933451-08-8 . Page 30.

- ↑ Daimler-Benz: Additional model ranges. 1963 . Retrieved May 19, 2017.

- ↑ a b c d e Vogler, p. 57.

- ↑ a b c Vogler, p. 66.

- ↑ Vogler, pp. 12, 14, 16.

- ↑ Vogler, p. 16 and 17th

- ↑ a b Vogler, p. 60.

- ↑ a b Vogler, p. 34.

- ↑ Vogler, p. 15.

- ↑ a b c d e f g h i j Vogler, p. 14.

- ↑ Vogler, p. 56.

- ↑ a b Vogler, p. 16.

- ↑ Vogler, p. 55.

- ↑ Vogler, p. 65.

- ↑ a b c d e f g h i j k l m n o Vogler, p. 85.

- ↑ a b Vogler, p. 11.

- ↑ Vogler, p. 90.

- ↑ Vogler, p. 67.

- ↑ Vogler, p. 86.

- ↑ Vogler, p. 70.

- ↑ a b Vogler, p. 71.

- ↑ Vogler, p. 72.

- ↑ Vogler, p. 73.

- ↑ Vogler, p. 77.

- ↑ a b c d Vogler, p. 78.

- ↑ Vogler, p. 81.

- ↑ a b c d Vogler, p. 82.

- ↑ Mercedes-Benz Public Archive: Model 406.130

- ↑ Mercedes-Benz Public Archive: Model 406.131

- ↑ Mercedes-Benz Public Archive: Model 406.142

- ↑ Mercedes-Benz Public Archive: Model 406.143

- ↑ Vogler, p. 89.

- ↑ Vogler, p. 102.

- ↑ a b Peter Kautz: Mercedes-Benz Unimog 406 . Retrieved May 19, 2017.

- ↑ Vogler, p. 124 and 125

- ↑ Vogler, p. 104.

- ↑ Unimog Community: Unimog U 421 [1966 to 1989]

- ↑ Vogler, p. 107 and 108.

- ↑ Vogler, p. 122.

- ↑ Vogler, p. 116 and 117.

- ↑ Vogler, p. 32.

- ↑ Vogler, p. 48.

- ↑ Vogler, pp. 42-46.

- ↑ Vogler, p. 36.

- ↑ Vogler, p. 40.

- ↑ Vogler, p. 13.

- ↑ a b c Helmut Schmitz: Gear variants U 406 / U 421 . August 20, 2012. Retrieved May 19, 2017.

- ↑ a b c Vogler, p. 28.

- ↑ a b c Vogler, p. 27.

- ↑ Vogler, p. 135.

- ↑ a b Vogler, p. 61.

- ↑ Vogler, p. 76.

- ↑ Vogler, p. 80.

- ↑ a b Vogler, p. 79.

- ^ Franz Murr: Increase in output of the OM352 engine in the Unimog 406/416/417 to 96kW . September 24, 2008. Retrieved May 21, 2017.

Web links

| Vehicle class | 1920s | 1930s | 1940s | ||||||||||||||||

| 6th | 7th | 8th | 9 | 0 | 1 | 2 | 3 | 4th | 5 | 6th | 7th | 8th | 9 | 0 | 1 | 2 | 3 | 4th | |

| Compact class | W 15 (type 170) | ||||||||||||||||||

| W 23 (type 130) | |||||||||||||||||||

| W 30 (type 150) | |||||||||||||||||||

| W 28 (type 170 H) | |||||||||||||||||||

| Middle class | W 02 (type Stuttgart 200) | W 136 / W 149 (types 170 V / 200 V) | |||||||||||||||||

| W 11 (type Stuttgart 260) | W 143 (type 230 n) | ||||||||||||||||||

| W 21 (type 200/230) | W 153 (type 230) | ||||||||||||||||||

| W 138 (type 260 D) | |||||||||||||||||||

| upper middle class | W 03 / W 04 / W 05 (types 300/320/350) | W 18 (type 290) | |||||||||||||||||

| W 10 / W 19 (types 350/370/380) | W 142 (type 320) | ||||||||||||||||||

| W 22 | |||||||||||||||||||

| Upper class | Type 400 & Type 630 | W 24 / W 29 / W 129 (types 500 K / 540 K / 580 K) | |||||||||||||||||

| W 08 (type Nürburg 460/460 K / 500 / type 500 N) | |||||||||||||||||||

| W 07 / W 150 (types 770/770 K) | |||||||||||||||||||

| Sports car | Model K | ||||||||||||||||||

| W 06 (type S / SS / SSK / SSKL) | W 24 / W 29 / W 129 | ||||||||||||||||||

| Off-road vehicle | W 103 (type G1) | W 31 (type G4) | |||||||||||||||||

| W 133 III (type 170 VG) / W 139 (type 170 VL) / W 152 (type G5) | |||||||||||||||||||

| Vans | L 3/4 | L 1000 Express | L 301 | ||||||||||||||||

| L 300 | |||||||||||||||||||